The autumn period is the time when it is possible to find win-win ideas for your business. Any natural resources that are available in unlimited quantities can be used. We are talking about fallen leaves. In autumn, several tons of leaves fall and rot uselessly in the ground.

If you approach waste-free production wisely, then ready-made free raw materials can be found right on the street.

From leaves processed in production, you can make fuel that will cost much less than firewood or coal, but the energy output will be almost the same. Pressed fuel is a good way to start a profitable personal business and save the environment.

DIY juice presses

It is quite possible to make a juice press with your own hands, the main thing is to find operating diagrams and drawings of such homemade products, which will not be difficult. Many of those home craftsmen who already have experience in making such equipment are happy to share photos of their devices and even videos showing the process of their manufacture and the principle of operation in detail.

Homemade juice presses

Most often they try to make screw-type presses with their own hands. Meanwhile, it should be borne in mind that it will not be possible to make a powerful screw for such a device without the involvement of a qualified turner. You can make a homemade press without third-party specialists if you replace the screw mechanism with a conventional jack (mechanical or hydraulic), which is in the arsenal of every car enthusiast.

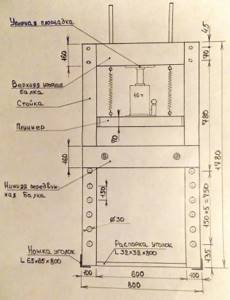

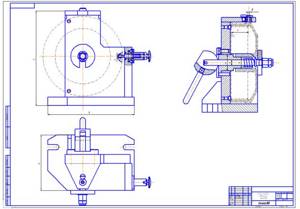

Drawing of a press based on a car jack

The main supporting element of a homemade juice press is the frame

Its strength should be given special attention. To make such a frame into which the jack will rest and create the required pressure, you can use a square metal pipe with a cross-section of 40x40 and a wall thickness of at least 3 mm

When calculating the height of the frame of your homemade press, you should take into account the total thickness of the drainage grids, pads and bags of raw materials, as well as the height of the jack. The width of the frame can be chosen arbitrarily - the main thing is that a storage tray for collecting the squeezed juice is placed in the opening created.

The jack can simply be placed on the piston or rigidly attached to the top crossbar

When creating a press for apples or grapes with your own hands, you should pay special attention to its stability. To effectively solve this problem, three pieces of square pipe can be welded to the bottom of the frame, which will act as legs and ensure the stability of the unit

A stand made of boards or wood boards is placed on the top of the legs, on which the pallet will be placed.

Drainage grates, complete with which your apple, grape or any other press will work, should be made only from hardwood (oak or beech). The thickness of the planks from which such gratings will be made must be at least 20 mm.

The bags in which apple pulp or other raw materials for squeezing juice will be placed can be made from various fabrics (the main thing is that such fabric is highly durable and the bags that are sewn from it do not rupture under the influence of high pressure created by the jack). As such fabrics, in particular, you can use ordinary burlap, jute, cotton and linen fabrics, chintz and synthetic materials.

A tank from an old washing machine is quite suitable as a frame holding wooden slats.

You can make an apple press with your own hands or a squeezing device for processing other raw materials using an even more complex design scheme, which involves the simultaneous use of both a jack and a screw mechanism. The latter in such a press is used to fix the fruit or berry mass, which is placed in a perforated casing made of stainless steel.

The mechanism that creates the required pressure is a jack, which is installed in the lower part of the frame structure of the press. With its upper foot, the jack rests on the lower part of the support platform, which can move along the side guides of the press frame. Thus, when the jack is raised, the support platform also rises, moving towards the piston, which is equipped with the lower part of the screw.

Screw press with jack

Thus, it is quite possible to independently manufacture an effective press for producing apple, grape and even pomegranate juice, and this does not require significant financial costs, special knowledge, skills or the ability to handle complex equipment.

Manufacturing and assembly instructions

The order of operations in the manufacture of the press looks like this:

- It is necessary to weld the base of the device from the channels.

- From the corner we make 4 racks 1.5 meters long. They are welded vertically and with the same pitch.

- Next, you need to make a drum from a pipe or sheet of tin in which the raw materials will be mixed. If you have a broken washing machine, the drum, as well as the bearings, can be removed from it.

- The drum must be attached to the stands. If possible, it should be equipped with an electric motor. If the motor is too high-speed and it is not possible to reduce the rotation speed of the drum to an acceptable value due to the difference in pulley diameters alone, a gearbox should be used.

- It is necessary to attach a tray under the drum through which the prepared material will be fed into the matrix.

- In the walls of the pipe used as a blank for the matrix, it is necessary to make several holes with a diameter of 3 - 5 mm. They must be distributed evenly so that air and water are squeezed out throughout the entire volume of the briquette.

- A flange must be welded to the bottom of the matrix, to which the removable bottom will be screwed. This bottom is cut from a steel sheet in the form of a disk with eyes.

- The matrix is welded or screwed to the base under the loading tray.

- We cut out a round punch from a steel sheet. This is simply a disk whose diameter allows it to freely enter the matrix.

The rod is made of a pipe: a diameter of 30 mm is sufficient. One side of it is welded to the punch, and the other is attached to the hydraulic unit.

We fix the receiving tray under the matrix

It is important to install it in such a position that it does not interfere with removing and installing the removable bottom of the matrix. To reduce the time spent on removing the finished briquette from the matrix, and thereby make the machine more productive, a spring with a disk of the same type can be welded to the bottom of the matrix diameter the same as the punch.

To reduce the time spent on removing the finished briquette from the matrix, and thereby make the machine more productive, a spring with a disk of the same diameter as the punch can be welded to the bottom of the matrix.

After turning off the hydraulic unit and removing the punch, the product will be pushed out automatically by the spring.

What are fuel pellets

Externally, fuel such as pellets are cylindrical granules, the diameter of which, depending on the equipment used for their production, can be 5–10 mm, and the length is in the range of 10–60 mm. The raw materials from which this fuel is produced are production waste from enterprises engaged in the following fields of activity:

- woodworking and production of wood products for various purposes (sawdust and shavings generated as a result of the activities of enterprises operating in these areas are used as raw materials for the production of wood pellets);

- growing and processing of agricultural products (in this case, pellets are made from straw, hay, wheat, rice or buckwheat husks, sunflower husks);

- processing of coal and peat, small fractions of which are also used for the production of fuel briquettes.

The color of fuel pellets depends on the feedstock and its preparation technology

In most cases, the production of fuel pellets is carried out by those enterprises whose main activities generate a large amount of waste suitable for the production of such fuel. Thus, such enterprises not only solve the problem of recycling their production waste, but also receive additional profit from it.

In terms of economical use, the more preferable type of fuel is still coal, but fuel pellets have one significant advantage over it: their use makes it possible to automate the process of supplying fuel to the boiler as much as possible. In addition, as mentioned above, wood pellets and straw pellets are characterized by low ash content: its value is 20 times lower than that of traditional types of solid fuel.

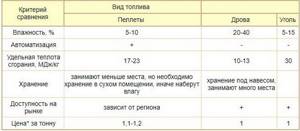

Comparison of different types of solid fuels

Do-it-yourself fuel for a biofireplace

The biofireplace is a container for biofuel and a decorative body. The basis for the heating material is alcohol, which is based on natural components with the addition of denatured alcohol or purified gasoline. Ethanol is extracted from root vegetables and starchy crops. For these purposes, corn, beets, cane, potatoes, sweet potatoes, and barley are used.

Rice and wheat straw, residues from sugar cane and wood production are often used.

In industrial settings, different methods are used to produce raw materials. Hydrolysis or fermentation is used. The second option is more popular and is widely used all over the world.

Stages of biofuel production:

- Cleaning and preparation of raw materials;

- Loading products into a special bunker and adding yeast;

- Cleaning the resulting liquid from foreign oils.

There are several significant advantages of ethanol. Among them, the safety of the product is highlighted, since no toxins are released during combustion. Only steam and carbon dioxide enter the air. When using a bio-fireplace, it is necessary to ensure a flow of fresh air into the room.

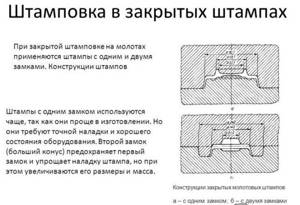

Features of open and closed dies

Stamping equipment can be equipped with open or closed dies. In an open die, excess metal flows into a burr or flash that performs a specific function. The main disadvantages of this technology are: loss of alloy due to flash, reduction in product quality due to cut fibers when removing burrs.

Closed dies are used to produce simple shaped products. This flash-free technology is characterized by metal savings, no costs for cutting burrs, and high product quality due to all-round compression. Metal fibers are not cut. The closed die processing method is used for low-plasticity alloys. The main disadvantages are: the need for precise dosage of the alloy, the complex design of the die.

In modern manufacturing, stamping is primarily a preparatory operation that allows the production of parts for both electronics and aircraft or watercraft. The resulting products are subsequently subjected to welding, cutting, riveting and other processing methods depending on the technological process.

Related video: Sheet stamping

Selection of questions

- Mikhail, Lipetsk — What discs should I use for cutting metal?

- Ivan, Moscow - What is the GOST for rolled sheet steel?

- Maxim, Tver - Which racks for storing rolled metal products are better?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals without the use of abrasives mean?

- Valery, Moscow - How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Mechanisms for metal processing

The hydraulic press is capable of developing significant force up to 2 thousand tons. It is used for bending or stamping operations of thick-walled products. The action of the mechanism is based on the movement of the pistons of two communicating hydraulic cylinders, which have different diameters. It is the difference in diameters that determines the amount of force that a metal stamping press can develop.

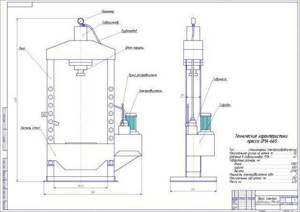

Drawing of a hydraulic press

The radial forging machine is designed to perform forming operations in order to obtain cylindrical products. The design of the mechanism includes an induction furnace for preheating the part. During the processing process, the workpiece rotates from an electric motor as it passes through the forging zone.

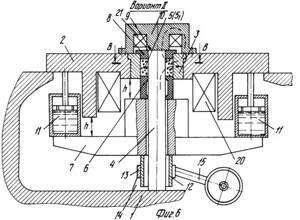

Drawing of a radial forging machine

Electromagnetic presses are new high-performance, economical equipment for stamping. The principle of operation is based on the movement of an electromagnetic core, which directs the actuator of the machine to the metal part.

Drawing of an electromagnetic press

Making fuel briquettes at home

Fuel briquettes, which have recently become increasingly popular as fuel for heating residential and industrial premises, can be made with your own hands. Naturally, it is advisable to make equipment for the production of pellets if there is access to a sufficient amount of inexpensive raw materials.

Press or extrusion type equipment can be used as home-made devices intended for the production of fuel pellets. Such a device can be made either on the basis of a ready-made power mechanism or from scratch. In the first case, a hydraulic jack or a small press, also equipped with a hydraulic drive mechanism, is used as the main working body. When manufacturing equipment for the production of pellets from scratch, a lever or screw mechanism can be used as a power element, which will provide the required pressure.

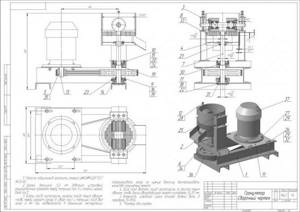

You can take the design of a factory granulator as the basis for a homemade machine for making pellets. Click on the drawing to enlarge

Regardless of the design diagram of home-made equipment for the production of pellets, when manufacturing such a device, it is necessary to solve the following technical problems:

- make a press support platform and install vertical posts on it, on which all structural elements will be fixed;

- using the appropriate diameter, make a machine matrix, in the cavity of which the pre-prepared mixture will be pressed;

- make a punch that will put pressure on the mixture when forming pellets;

- equip the punch with a rod and connect it to the power hydraulic mechanism;

- using a large diameter pipe or sheet metal, make a drum in which all components of the mixture will be mixed;

- Make chutes from sheet metal for loading raw materials and unloading finished products.

Assembling a homemade pelletizer

All elements of a homemade pellet press are fixed on its base and vertical posts. In this case, it is necessary to ensure their correct spatial position relative to each other.

Manufacturing technology

We must not forget that production is a complex and time-consuming process, so it must be treated with special attention.

Production sequence:

- Grinding and crushing of raw materials to the required size.

- Drying and preparing leaves for production.

- Pressing raw materials into briquettes. Before pressing, crushed dried leaves are mixed with clay in a ratio of 1 kg of clay: 10 kg of leaves. The mixture is diluted with water (temperature 30 degrees) until a homogeneous, non-liquid mass is obtained. Next, the resulting mixture is poured into a pressing machine. During pressing on factory equipment, excess moisture is removed. The briquettes take shape.

- Cooling and drying of the resulting products. Mandatory moment. During drying, excess moisture is removed from the briquettes, making the product whole.

During production, it is important to monitor the moisture content of the product. After the production of fuel briquettes, it should not be lower than 8% and exceed 14%.

Products can be dried in specialized dryers or in the open air. The main condition for drying outside: the products must be hermetically sealed from moisture and other foreign bodies.

Storage for goods must meet the following requirements: the room must have ventilation (or windows) and high ceilings. Briquettes are stored in vacuum packages up to 25-35 kg each.

Types of stamping technologies

The stamping process of processing blanks can be carried out using the hot or cold method. These technological varieties involve the use of special equipment and the use of certain metal processing conditions.

Cold stamping is one of the types of stamping

The hot stamping method processes workpieces that are preheated in special devices to a given temperature. Hot stamping is necessary when there is not enough equipment power to process a cold alloy. Heating devices can be electric or plasma ovens. This method requires accurate calculation of the parameters of the finished part, taking into account the shrinkage of the metal during the cooling process.

In cold stamping, parts are formed due to the mechanical pressure of the elements of the stamping press. Cold stamping is considered a more common method of metal processing. It does not require additional equipment, complex calculations or mechanical modification of parts. Thanks to this method, the strength properties of the material increase. The resulting products are distinguished by high surface quality and precision.

Production of fuel briquettes

fuel briquettes from leaves

To obtain raw materials in large quantities, it will be useful to negotiate with the heads of parks and forestry enterprises. After all, they are often interested in collecting and removing leaves from their territories. When creating unusual firewood, the leaves must be dried and compressed as much as possible. One log requires a large bag of collected leaves. The authors of the idea from Britain use wax in logs as a binding element and additional flammable material.

Logs made from fallen leaves have several advantages over conventional firewood or compressed sawdust briquettes:

- The heat of combustion of leaf logs is comparable to high-quality coal and is significantly higher than the thermal energy released during the combustion of wood fuel.

- The weight of firewood from deciduous biomass is half, and the volume is 10 times less than traditional firewood, taking into account the combustion efficiency. A deciduous log burns almost 3 times longer than a wooden log of the same weight.

- The compactness and low weight of pressed logs make them easy to transport.

- Such briquettes do not require kindling; they ignite quickly and easily.

- In the middle of the combustion process, eco-logs emit significantly less smoke and harmful combustion products.

The environmental aspect of business deserves special attention. After all, harvesting traditional firewood leads to deforestation

As for leaves left to rot over the winter, during the process of decay they release methane into the atmosphere, which has a pronounced greenhouse effect. Burning leaves is also not the best solution, because this releases significantly more harmful combustion products than when burning pressed logs. In addition, huge fires of fallen leaves cause death to plants and insects in the ground. So selling last year’s leaves can bring the entrepreneur not only benefits, but also the opportunity to contribute to improving the environment.

Types of technological operations

Technological operations with metal sheets are separating and forming.

Separation stamping operations are performed on equipment equipped with special tools. As a result, a certain part is separated from the workpiece along a straight line or a given contour. The separation of part of the sheet occurs in the following processes:

- Segment. To perform this action, the equipment is equipped with disk, vibration devices or guillotine shears.

- Trimming. This operation separates the extreme parts of the resulting product.

- Punching. Holes of various configurations are created in a metal sheet using a stamp.

- Felling. A shaped part with a closed contour is obtained from the workpiece.

Form-changing operations are intended to create a product with different parameters and dimensions without mechanical destruction. The following types of these operations are distinguished:

- Beading. The contour of the workpiece or the internal holes are exposed to the stamp to form beads of certain sizes.

- Hood. This operation is a type of volumetric stamping, in which a spatial element is obtained from a flat material.

- Crimping To narrow the ends of a hollow workpiece, a stamp with a conical-type matrix having a narrowing working area is used.

- Flexible. As a result of the operation, the curvature of the surface changes by bending the metal and deforming the workpiece.

- Molding is a change in the shape of individual sections by reducing the thickness of the part without disturbing the external contour of the product.

- Puklyovka. Connecting two plates with a stamp without using additional elements.

Pressing fuel lumps at home

Extrusion is more in demand on an industrial scale. And for home use, craftsmen are constructing another installation. It will not work to use a homemade press on a factory scale. At home, it is unprofitable to obtain high pressure, so water and binding materials are additionally used to seal the components:

- clay;

- wallpaper or any cheap type of glue;

- paper;

- corrugated cardboard.

To make briquettes, it is enough to have a press of the simplest type. Drying equipment is optional. Craftsmen came up with this method:

- Sawdust or other suitable raw materials are soaked in water.

- The wet mass is mixed with clay in a ratio of 10:1. An alternative is to mix it with damp cardboard, paper or wallpaper glue in the same proportion.

- The mixture is placed in a pre-prepared mold of the required size and compressed with a hand press.

- The brick is removed from the mold and left to dry naturally outside.

(no votes yet)