Device

Studying the design will allow you to understand what a deck oven is. It consists of 11 most important elements:

- No. 1 Convection chamber with louvers and valves on top.

- No. 2 The body is made of steel or fireclay.

- No. 3 “Direct stroke” valve (summer stroke type), directing smoke directly into the chimney.

- No. 4 – Main firebox (chamber).

- No. 5 Side fireboxes.

- No. 6 Fireclay brick of the side firebox (fire-resistant element).

- No. 7 – Under (lower horizontal surface of the stove)

- No. 8 Reinforced wall (made from SHA-94 brick).

- No. 9 Fireclay brick in the 4th combustion chamber.

- No. 10 – 4th combustion chamber.

- No. 11 – chimney outlet, the chimney pipe is attached here.

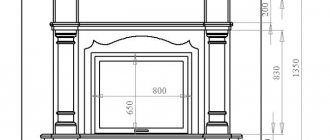

The listed stove parts are shown in the diagram:

Scheme

All models are equipped with doors (cast iron, steel). Sometimes a heat-resistant window is made in the center of the door, allowing you to observe the flame.

If the stove will be used for cooking, it is equipped with grates and burners that reduce the thermal stress in the stove, then dishes can be placed on it.

Principle of operation

A bottom combustion furnace allows you to achieve high efficiency with minimal fuel consumption. The device allows for “top” combustion, evenly distributed from the top layers of firewood to the bottom. The air supplied through the combustion door ensures good oxidation of the fuel, which improves the quality of its combustion and increases the intensity of heat release.

The body of the stove is made of a polished stainless steel alloy, and the firebox is lined with fireclay bricks or other refractory material. This allows you to achieve a heating temperature of up to 420 degrees. The bricks heat up to 700 degrees, which guarantees stable combustion of the fuel even in difficult conditions (for example, with high humidity in the room where the stove is located).

Additional furnace classification parameters

The main one, as mentioned earlier, is the functional purpose of the stove, which consists of three main ones (heating, cooking, combined) and an additional one (bathhouse).

In addition, the following criteria are distinguished:

heating temperature of the walls; combustion time of one load of firewood; heating time of the walls and creating a comfortable temperature inside the room; direction of movement of exhaust gases in the channels; design of the smoke exhaust channel; shape of the stove - square, rapezoidal, T-shaped, etc.; method of the external part stoves - tiles, tiles, panels, lack of finishing; manufacturing material - home-made refractory clay, ready-made industrial composition, bricks.

Types of furnaces

Top combustion products come in different types. According to their purpose, they are divided into kitchen and heating. According to the type of heat source used - gas, electric, wood. Based on the main material, hearth products are either metal or brick. Let's look at the features of different types.

Kitchen

As the name suggests, these ovens are designed for installation in the kitchen and subsequent cooking on them (baking bread, confectionery). It can be as simple and miniature as possible, suitable for private homes. For restaurants and bakeries, there are functional and production models on sale that allow you to prepare many dishes at the same time.

Gas

Inside the housing there is a burner and ring-shaped pipes (up to 19 pieces) through which gas passes. There are 2-5 tiers inside, for each the temperature is regulated separately. The maximum operating temperature in gas stoves is 300 degrees. You can work with her around the clock. The energy created by the burner passes through three circles: in the first, it directly heats the area near the burner; in the second and third circles, the pipes and bricks that form the bottom and walls of the furnace are heated with flammable gas. The heated parts begin to distribute uniform heat.

Design example

Electrical

Externally, gas and electric hearth ovens are no different. The differences lie in the “filling”. Inside, instead of a gas burner and pipes, there is a heating element (in the upper and lower tier it is possible to arrange the turns of the heating element in the center)

As in gas ovens, electric ovens can have from 2 to 5 independent chambers. The temperature inside each chamber may be different, allowing you to cook different dishes.

From a financial point of view, gas is a more economical fuel, but from the point of view of safety and ease of control, electric furnaces will be more profitable.

Wood burning

A wood-burning hearth oven was used by our ancestors. True connoisseurs believe that food made from it will be much tastier than that made on an electric or gas stove. The light aroma of wood adds a zest to the dishes. Cons: The wood stove is the most difficult to use. You have to manually add fuel and monitor its burning.

Heating

The difference between heating stoves and kitchen stoves is their single-chamber design - there is no need to create separate zones for kitchen baking sheets. In Europe, a hearth-type stove is the only permitted heating structure inside residential buildings. This is explained by the safety and environmental friendliness of the system - in the hearth stove the fuel burns out completely, and there is no exhaust of smoke polluting the atmosphere through the chimney.

Metal

For the manufacture of such stoves, cast iron or steel alloy is used. The advantage of the design is simple installation and maintenance. The downside is that the body gets very hot, so you can get burned if you touch it. The service life with proper operation is 30-50 years. Minus - metal stoves do not tolerate sudden changes in temperature, which can cause them to crack.

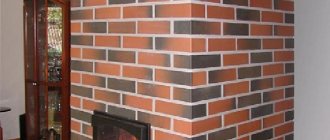

Brick

Such a stove accumulates (accumulates) heat better and releases it longer. It looks very impressive, so it will decorate any classic interior. It lasts twice as long as a cast iron or steel structure, but it costs an order of magnitude more. Installing a brick stove is difficult; it is better not to install it yourself without specialists.

Expert opinionPavel KruglovStove maker with 25 years of experienceThe disadvantage is the lack of portability - after installation it will not be possible to quickly move it to another place (you will have to completely disassemble the structure).

Beautiful brick hearth oven

We make a deck oven with our own hands

Place to install the stove - How to make the stove safe

The safe location of the stove in the room is the first thing you need to pay attention to. Consider a location option that will allow you to take into account all the necessary indents.

Distances from room surfaces to the stove:

- When installing a steel stove that runs on wood or coal, maintain a distance of 14 centimeters between the floor and the heater.

- A brick or iron stove is mounted on a separate foundation with a backing made of non-flammable materials. The size of the substrate should be 50 centimeters larger than the size of the heater on each side.

- The gap between the ceiling of flammable materials and the stove is 100 centimeters.

- Between a steel stove and a wooden wall without thermal insulation or brick lining - 100 centimeters. If a mirror metal ceiling is installed in advance - 38 centimeters.

- If there is a protective screen on the stove and the walls of the room in the form of bricks or ceramics are protected from the stove, a distance of 13 centimeters is maintained.

Place the stove in a corner of the house so it doesn't take up much space. At a short distance from it, you can install the unit and speed up the heating of the house.

It is possible to heat several rooms with one stove without any special expenses. When building a room, you must immediately decide on the location of the stove. Prepare niches in the walls and install the stove in the opening of the interior partition, treating the cut walls with a layer of high-quality thermal insulation. This design saves money and heats two or three rooms at once. If a stove is needed to heat a larger area, we recommend inviting an experienced stove maker to make a heating panel.

Hearth ovens and basic materials for their laying

Nowadays, furnace production has not been forgotten. Many owners of suburban areas at the stage of building a house come to the decision to install a brick hearth stove. It will give off its heat to the house longer than its metal counterparts. The brick heats up and then warms the room for up to 24 hours. A metal stove heats up quickly and releases heat sharply, which is why you have to add twice as much firewood, approximately every 7 hours.

Also, unlike metal stoves, a brick stove produces steam when heated, and when it cools, it absorbs it back. This is called "furnace breathing." Thanks to this process, the humidity in the room always remains at a comfortable level. If an electric heater or metal stove is running, the humidity decreases and the air becomes dry.

The brick from which the stove will be built must be of high quality. It is better if it contains up to 70 percent fireproof clay, the so-called fireclay. This material is used both for the internal laying of stoves or fireplaces themselves, and for chimneys. It is considered to be an excellent heat accumulator.

Brick with a high content of fireclay will be grainy, without pores in the structure. The shape can also be not only standard, but also wedge, which will help to create an arch and any bend. To lay refractory bricks, heat-resistant glue is used - this is a special mixture for such work on a cement base.

If there is no particular need to save on material, you can use ceramic clinker bricks to lay out the inner wall of the stove. This type of brick is made from a special type of clay. During the processing process, the product is fired at a temperature of about 1200 C, which gives the bricks different colors.

In order for the refractory brick to retain heat longer and heat the room for a long time, it is recommended to lay ceramics or brick on top of it in 0.5 layers.

When laying stoves, sand-lime bricks should not be used. This material is made by dry pressing, after which it is treated with water steam. The product does not undergo heat treatment, which means it is not suitable for laying stoves.

Laying the foundation of a deck furnace, furnace projects

The issue of the foundation of any furnace must be approached very seriously.

The foundation of the room and the foundation of the furnace itself have different settlements caused by the deformation of their base under the influence of the load from the structure. Therefore, the foundation for the stove must be its own and located at a distance of 5 centimeters from the main one.

Making a pit for the foundation of furnaces

The pit is prepared wider than the base of the furnace by 15-20 centimeters on each side, since the foundation must be wider than the base of your furnace by 7-10 centimeters on each side, and you also need space for an auxiliary structure - formwork.

The depth should be 14 - 19 centimeters below the level of winter soil freezing. Each soil has its own characteristics of behavior under certain conditions. This fact must be taken into account during the creation of any foundation project in any territory, in any region.

In soils containing sand, the depth can be 50 centimeters, and in clay soils - 75 centimeters.

Construction of the furnace foundation

- 15 centimeters of sand are poured into the bottom of the pit. It is laid gradually, filling with water between layers.

- We recommend buying sand here. A rubble layer is laid on the sand - stone masonry, the basis of which is made up of large uneven pieces of torn stone - rubble. Mainly dense rocks: shell rock, dolomite, granite, diorite, basalt, tuff. The thickness of this layer is 20 centimeters.

- Next, cover everything with sand, filling it with water until it settles.

- The next layer is laid out crushed stone, at least 10 centimeters.

- The pit formwork is installed. The height is 17 centimeters above your ground level.

- Prepare a pair of frame meshes that match the size of the formwork walls. Install one mesh on the crushed stone so that it rises 3-5 centimeters, and place the second one 15-20 centimeters using a stand.

- The fittings are selected with a diameter of 1.5 centimeters. The prepared concrete solution is already poured inside the formwork.

- The concrete is leveled and allowed to dry one hundred percent. Then the formwork is removed.

Key points of chimney outlet

There is no smoke without a stove, and a stove without a chimney. To remove the gases released during combustion, the stove needs a chimney. It is made from the same material as the firebox, not for beauty, but because the coefficient of thermal expansion differs between different materials. If you constantly heat the metal and the brick during heating, a gap will form between them. Therefore, the entire structure is laid with one brick.

A brick chimney will best conserve heat. It will remove gases outside the walls of the living space, and gradually release the accumulated heat inside.

The calculation should be carried out at the design stage of the entire stove. It is difficult to attach the outlet pipe to the finished base. Such a project must be prepared by a qualified stove maker. Then the firebox will work as a single organism, serving its home efficiently and for a long time.

Now that we know the operating principle of the stove, let’s think about the location of the stove chimney. The passage of the stove chimney through wooden ceilings must be reliable, since the hot walls of the pipe are located close to flammable fittings. Contact of the chimney and wood is unacceptable. It is also important that the chimney does not come into contact with wallpaper, electrical wiring or gas pipes.

For an insulated chimney, 15 centimeters are maintained between the sheathing or floor joists, for non-insulated chimneys - 30 centimeters.

How to properly light a deck oven

If the oven has not been used for more than a day and has cooled down to room temperature, heat it carefully. Be sure to remove excess ash.

Stack the wood or coal so that there is a space in the center. Place the bark or kindling in the middle and set it on fire.

Close the door tightly and open any existing blinds to allow air to enter. Thermal decomposition of compounds releases gas, which burns cleanly in the furnace.

If you light wood from below, the gas will not be released evenly and will not burn completely. When all the contents have burned a little, close only the top blinds on the door. After complete combustion of the fuel, you can close the chimney damper.

Advantages and disadvantages

Stoves of this type have advantages and disadvantages over other types of heating and kitchen devices. The main advantages are:

- It is possible to install several tiers to cook many dishes at the same time.

- Quickly warms up large rooms.

- It does not pollute the atmosphere with its smoke (unlike grate stoves).

- Easy to use.

- Durable (subject to operating rules).

It is also worth noting the high efficiency of the stove (79-82%), long burning period (in a wood-burning stove, 10 kilograms of briquettes burn out in 10-12 hours).

The downside is that the design requires only one heat source (wood, electric heating or gas). There are no hearth stoves that run on peat or coal.

Design Features

The deck oven can have 1, 2 or 3 loading tiers with independent control. The main feature is the presence of a hearth, that is, a stone baking bottom. Deck ovens can be used to bake pizza, rolls, bread or other products. Some models have a conveyor loading type for higher productivity. Models are distinguished by loading capacity, number of levels, type of power supply (electric, gas, wood). When working with the device, dough pieces can be placed directly under the oven or baked on baking sheets or gastronorm containers.

Among other features, the requirement for a large amount of free space should be taken into account. Such designs are not distinguished by their compact overall dimensions, but they are also purchased for large production workshops. As a rule, large ovens are designed to bake 10-12 pizzas at a time, which corresponds to large establishments with several dozen visitors per hour.

Advantages of deck ovens

The advantages of deck ovens include environmental friendliness, durability, and high productivity. The bottom is made of heat-resistant refractory stone and is not afraid of oxidation and does not react with food. Despite their design complexity, such devices are easy to control due to high-precision electromechanical thermostats. Bakery products prepared in a deck oven have an optimal consistency: softness, uniform baking, aromatic crust, etc.

It is also worth noting the high versatility of such devices. After all, in such an oven you can also bake desserts, biscuit bases for cakes, etc. Hearth furnaces have high productivity and wear resistance. Most models are capable of operating continuously for 10 hours or more, which covers several shifts of employees. At the same time, there is no need to turn the product over during the cooking process. The average baking time for one pizza is 4-5 minutes, which is much faster than in an oven or convection oven.

Electricity or wood?

Electric deck ovens are easy to set up and operate. However, you should not expect economical power consumption. As a rule, this is from 10 kW/h for small single-tier structures and more. Electric ovens have a high-precision thermostat with the possibility of various settings, power control, and setting a delayed start.

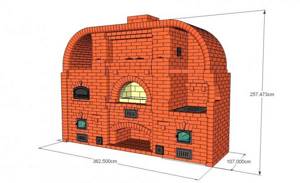

An alternative to such designs are wood-burning hearth ovens. In some establishments they are very widely used and are the calling card of a particular cafe, restaurant, or pizzeria. On the one hand, their design seems simple, because they are non-volatile and existed long before the advent of electric ones. Classic designs date back to the early 16th century.

This is evidenced by many drawings of massive hemispherical stoves made of fireclay fire-resistant bricks. No one will dispute their beauty and monumentality, the ability to maintain temperature for a long time and the ability to heat up to 1250 degrees. It’s just that the requirements for installing such structures are much greater than just having a three-phase connection to the electrical network. Due to its high massiveness, a special foundation and chimney will be required. It will be no less simple to acquire skills in working with a stove and study safety precautions when working with open fire.

If in an electric deck oven the temperature is maintained by a thermostat, then in a wood-burning oven everything must be done manually using firewood, charcoal or fuel briquettes, which requires knowledge, experience and skill.

How to choose?

It’s easy to get confused in specialized stores, as they offer a wide range of different deck ovens and fireplaces. Let us briefly examine the most important criteria for choosing heating devices for kitchens, heating residential and non-residential premises.

For kitchen

If you buy a stove for subsequent cooking, you need to choose a model that has the required number of tiers. The depth of the oven should allow you to place the number of baking sheets or cooking containers you need. It is better if the oven has more different programmable modes - this will allow you to cook more varied dishes.

Example of a deck oven for baking bread

Popular kitchen stoves are the following models:

- Steel deck ovens for BASSANINA bakeries – models FM 2T-4T, 3T-6T for 2-6 trays with dimensions 4060 // 4666 cm.

- Stainless steel ZOOM oven. It has a wide bottom where large containers can be placed. At the top there are 4 rows of independent compartments.

- Electric model PAVAILLER. Contains 4 tiers, with 2 separate doors. The area of the “culinary” zone is 9.5 sq.m.

For home heating

When choosing a stove, you need to evaluate the capabilities of the room where it will be installed. First of all, it is important to calculate the appropriate dimensions of the device. When installing a stove, you must ensure that the chimney pipe is at least 1 m long; this is the only way to ensure heating of living spaces. When buying, pay attention to the power - a strong model will warm up the house better, but will require more fuel.

Mini hearth stove for home heating

Among heating systems, it is worth paying attention to the following options:

- Heating fireplace stoves WGO. A high-quality German model, made from fireproof fireclay HBO+. Size from 52x54x11 cm.

- Hearth burning fireplace ECO+. Distinctive features are the simplest design and affordable price of a deck oven. Made from fireproof fireclay. Dimensions – 56x56x89 cm.

For bathhouse and garage

To heat non-residential premises, it is necessary to choose products with exactly the same requirements as for a residential building. The most important criteria are dimensions and power. Unlike models of hearth ovens for homes, devices for garages and baths may be less attractive. The absence of external decor will significantly reduce the price. Suitable models are:

- Stove in the form of a fireplace of the KIV series. The narrow rectangular shape allows you to place it even in a small room (up to 45 sq.m.).

- Round heating stove PKO-40 with a metal body. Thanks to the barrel shape

- The device warms up evenly. The oven body is made of steel, painted with powder enamel, and the inside of the oven is lined with wedge-shaped heat-resistant bricks.

Recommendations for selection

Hearth stoves for heating a home are selected taking into account their location. You need to calculate in advance what dimensions the device should have. You must also ensure that the chimney pipe is at least 1 meter in length. An equally important indicator is power. The higher it is, the better the oven heats. But a powerful device will require more fuel.

Popular models for residential premises:

- Fireplace stoves WGO. Manufactured in Germany and made from fireproof fireclay HBO+.

- ECO+ oven. It has a simple design and low cost. Made from fireproof materials.

To heat non-residential premises (bathhouse, garage), you also need to select a model based on power and size. Externally, such hearth sauna stoves look less attractive, but their cost is lower. It is recommended to take stoves of the KIV, PKO-40 series. They are able to heat a room to the desired level without significant fuel costs.

Features of operation and safety precautions

Using hearth-type ovens is not particularly difficult.

Here are instructions for heating the product:

- The wood-burning hearth oven is loaded with pallets. Gas and electric are connected to the network or gas pipeline.

- Electric models require preliminary drying of the heating element after a long period of inactivity. Other types of stoves do not require such an operation.

- The required program modes are installed.

- The chimney is heated to ensure stable draft (this is done by opening the damper for 6-7 minutes).

The temperature in the oven must be maintained automatically using temperature controllers, as evidenced by indicators on the housing panel. If there is no automation on the stove, you will have to independently monitor the thermostat indicators.

If a hearth-type stove is used for cooking, then after heating to the desired temperature, you need to open the lid and load sheets of kitchen utensils into the chambers. After finishing work, you must turn off the device; keeping it running unnecessarily for more than an hour is prohibited.

Expert opinionPavel KruglovStove maker with 25 years of experienceIt is worth remembering that steel structures become very hot. When loading and unloading baking sheets, be sure to use oven mitts, oven mitts, and a towel. Failure to comply will result in burns.

Types of wood stoves

A wood stove is a universal device that can heat a small house and be connected to the heating system and water supply. Before purchasing, you need to study the features of the classification of heaters.

According to case material

Metal wood stove for heating a house

Depending on the material of manufacture, a wood-burning stove can be:

- Cast iron. The thermal capacity of the housing and its ability to accumulate thermal energy ensure the operation of the device as auxiliary heating. A corrugated chimney or sleeve is designed to remove combustion products. The cast iron unit is equipped with a blower system to maintain temperature for a long time.

- Metal. Stainless metal reduces the time it takes to heat the air in the room. When purchasing, you should focus on the thickness of the walls - thin ones cool down very quickly. Structures with thick seams are less susceptible to cracking.

- Brick. It is built as the main source of heat and is equipped with a serpentine-shaped smoke pipe. Despite the long heating time, the brick can retain thermal energy for several hours.

Depending on the chimney design

External chimney for stove

The chimney pipe removes combustion products and, depending on the installation method, can be internal or external. In the first case, it is located outdoors and has good traction. External systems are not routed through the roof and are used for aesthetic purposes.

Based on the type of construction, several types of chimneys can be distinguished:

- Wall. The lower part is combined with the foundation of the wall. The chimney is made of brick.

- Root. It is installed on a separate base near the outer wall, equipped with a brick or ceramic liner.

- Sandwich. The single-layer pipe has the form of a nozzle and is quickly mounted on a fireplace or stove.

- Coaxial system Schindel. A two-pipe design that injects air in a counter-current manner and removes combustion products.

By type of design

Brick stove with stove bench

Reliable hearth stoves operate on wood and are designed to heat a home of any size. There are several types of devices based on their design.

A stove with a closed heater is suitable for installation in saunas or baths if it has a special compartment for laying stones. The heater is heated by convection or with an open flame. The water circuit is represented by a tank with pipes.

Russian stoves are made of brick and equipped with a sleeping place - a stove bench. The combustion chamber is located under the stove bench, the stove is next to the firebox. The heating intensity is adjusted through the blower. The Russian stove runs on a large amount of fuel and efficiently heats a room of more than 40 m2.

Depending on the location area in the room, you can select fireplaces:

- Angular. Models with a built-in or attached chimney are placed in the outer corner. Rectangular or square are distinguished by a wide fireplace podium with a niche for fuel.

- Wall-mounted. The back of the structure is located near the wall. The average size of the base is 75x125 cm, which is suitable for living rooms in a small house.

- Island. They are built on a separate foundation in large rooms. Perform zoning and heating functions.

Depending on the functional purpose, you can choose a fireplace stove for a wood-burning sauna or a design with a hob.

Swedish stove for home heating and cooking

Swedish stoves are distinguished by a rear chimney outlet and are classified according to the type of section into several types:

- Vertical. Smoke exhaust duct with 2-3 elbows and a cleaning door.

- Horizontal. It is laid out horizontally, has at least 2 bends and heats up evenly.

- Kolpakovy. Warm air masses are retained in 2-3 chambers, the shield heats up evenly.

Fuel combustion duration

A stove or fireplace with a long-burning system operates by burning pyrolysis gases, but wood-burning models are also divided into several types:

- With water circuit. They warm up large rooms efficiently, since the water type circuit is connected to heating radiators.

- No outline. Equipped with an afterburner chamber and a plate deflector. Primary air masses ignite the fuel, secondary air is supplied to the afterburner.

The long-burning system allows you to operate the stove with one load for 3-8 hours.

Related Posts

- Wood-burning stoves and their variety of designs

- How to choose a stove for an Ermak sauna: top 7 models with descriptions of technical characteristics and customer reviews

- Buleryan oven: do it yourself

- Fire-battery 7b (thermophor)

- A stove with a water circuit for heating a house: features of stove heating + choosing the optimal option

- How to fold a Swedish oven with a stove

- Homemade Russian stove on the street under a canopy

- Cast iron stove for bath Vesuvius

- Types of Kuznetsov furnaces and their order

- DIY metal rocket oven

- How to weld a metal sauna stove

- Fast and correct furnace repair

- How to install a stove in the house?

- How to make a Buleryan oven with your own hands: description and drawings

- Secrets of stove makers: brick stove for a bath

- Types and sizes of Russian stoves: types, sizes, 5 construction recommendations

- Do-it-yourself gas heater: options for the best homemade products

- Solid fuel stove Professor Butakov engineer

- Manufacturing and connecting a sauna stove with a water heat exchanger

- Do-it-yourself stove-fireplace

- Installing a stove in a steam room: location, fencing, protective screen

- Do-it-yourself Dutch oven: device, diagrams

- And let all the fuel burn out to the end! cast iron grate

- Induction furnace lining

- 9 types of heat-resistant tiles for fireplaces and stoves: choosing the best

Read with this

- Wood-burning stoves and their variety of designs

- How to choose a stove for an Ermak sauna: top 7 models with descriptions of technical characteristics and customer reviews

- Buleryan oven: do it yourself

- Fire-battery 7b (thermophor)

- A stove with a water circuit for heating a house: features of stove heating + choosing the optimal option

- How to fold a Swedish oven with a stove

- Homemade Russian stove on the street under a canopy

- Cast iron stove for bath Vesuvius

- Types of Kuznetsov furnaces and their order

- DIY metal rocket oven