Types of structures

To begin with, it is necessary to say that there are two types of similar structures that have a similar purpose and at the same time can perform different additional functions. Modern protective screens for sauna stoves quite often combine several different materials and are made in accordance with the design of the stove.

Taking into account these features, the craftsmen try to combine all the properties of similar products in order to achieve maximum results.

Brick walls and trim

- Very often when creating ovens with their own hands, craftsmen resort to creating brick screens.

- Usually this is a partition that separates the metal product from the walls. It prevents the spread of infrared radiation to wooden surfaces and protects them from high temperatures that can lead to fire.

- The installation instructions also advise installing such structures between metal sauna stoves and the place where people will be. So intense radiation will heat the partition, which will play the role of an additional heater. However, it is worth remembering that when using a simple wall, you should leave a small air space.

- Some craftsmen suggest immediately framing the entire sauna stove with a wall of brick or stone so that it can perform both tasks simultaneously. This way the structure will protect the walls of the room and prevent intense radiation from getting outside.

- It is worth noting that the screen for the sauna stove does not need to be used if the structure already has its own lining. This also applies to brick stoves, which actually themselves represent a firebox with thermal protection.

- For the manufacture of such structures, only red ceramic bricks or other materials with similar properties are suitable. The fact is that it tolerates moisture well and can withstand large temperature changes. Some craftsmen use special stones for this, which have low thermal conductivity and at the same time retain heat well.

Advice! When choosing a material for creating such structures, it is necessary to take into account that it must be able to withstand high humidity and even direct contact with water. It should also be remembered that the product will be exposed to high temperatures and it is desirable that it be able to maintain it for a long time.

Reflective surfaces

- Quite often, craftsmen recommend using a stainless steel screen for a bath. It should be noted that this metal must be perfectly polished and reflect infrared radiation.

- Such systems are usually used on back walls near stoves. They protect the surface from intense heating and at the same time redirect the heat inside the room. This allows you to reduce the cost of kindling and maintaining the regime.

- Such heat-resistant screens for sauna stoves work very effectively even with brick stoves or when combined with stone partitions.

- Some manufacturers, making structures for heating baths, actively use them to improve the technical characteristics of their products. At the same time, professional craftsmen prefer to additionally mount bath screens made of stone or brick so that they absorb all the radiation, converting it into normal heating.

- Special attention is due to the fact that the metal also gets very hot and, if it comes into contact with wooden surfaces, can lead to a fire. That is why it is best to protect such a screen for a bath on the reverse side with heat-resistant material or create a small air gap.

- Quite often on sale you can see screens made of metal with a matte surface. Their price may be several times less, but they are less effective, and professional bath attendants claim that such screens are generally useless and only take up extra space.

- It is worth noting that such structures require periodic maintenance, since plaque and stains appear on them over time. To do this, they can be wiped with a special detergent or lemon juice.

Advice! Recently, ready-made products with a reflective surface can be purchased in stores. They are immediately placed in a heat-resistant frame and do not require additional processing. That is why it is much easier to use them.

Additional aspects

It is worth understanding that not all situations require a protective screen at all. For example, for brick kilns with an initially protected firebox, fences are not required. If the screen needs to be installed, then red ceramic materials are selected for it, capable of withstanding severe temperature changes and exposure to moisture.

Often, a bathhouse screen made of stainless steel loses much of its visual quality over time. To ensure their normal decorative properties, it is necessary to periodically wipe the metal with special cleaning compounds.

Conclusion

A DIY sauna stove screen is an important sauna structure that can prevent accidental burns and balance the operation of the stove. By implementing one of the proposed schemes, you can achieve a combination of protection efficiency, good functionality of the stove and good visual qualities of the entire system.

Conclusion

In the proposed video in this article you will receive detailed information on this topic. Moreover, based on it, we can come to the conclusion that the screen is a necessary element of the bathhouse, especially if it uses metal stoves. The choice of a specific type of such design depends only on the personal preferences of the master, although experts say that it is the combined products that give the maximum result (see also the article “Camping sauna - how to steam in the field”).

9ban.ru

Why and when is a protective screen required?

Heat from the stove is transferred to people and surrounding objects in two ways:

- through air; when heated, the air transfers the generated heat;

- through infrared radiation.

Only the first option is suitable for people - it is safe and comfortable. When taking bath procedures, you can always easily and quickly increase the temperature in the steam room. It is enough to moisten the stones. But, unfortunately, we also have to deal with infrared radiation. The latter is characteristic of all heated objects.

The temperature of the sauna stove reaches 300-400 degrees and higher. At such a high temperature of the metal walls, a powerful stream of infrared radiation is formed, which can lead to burns. The problem is especially relevant for small home baths, where there is nowhere to hide from the negative flow.

Mid-price ovens are in many cases equipped with metal convection protection. Expensive models are shielded with ceramic or stone cladding, which also plays a decorative role. But inexpensive and “handicraft” models almost never have thermal insulation.

Brick (or, less preferably, metal) protection is required in such cases:

- when the body of a freestanding metal stove is not covered with anything;

- if the factory shielding is made poorly and does not protect well from thermal radiation;

- if the heat generator is equipped with casing, but is installed too close to a wall made of flammable materials; Since most often the walls in steam rooms are wooden, providing protection is necessary in most cases.

Situations where sauna stoves are made entirely of brick are rare. Such structures take up a lot of space and therefore require large premises. Much more often we deal with small-sized steam rooms, for which the described situations are true.

Important! Not only people need protection, but also walls, if the latter are made of flammable materials.

Situations in which wall protection becomes vital

The use of protective screens around the stove is not always necessary. In situations where, during the installation of the furnace, a safe distance was maintained between the described object and the flammable surface, there is no need to construct additional protection. And that's why. The occurrence of a fire becomes possible if the IR radiation of the wood sheathing stove reaches. If the stoves are moved the required distance from the walls, the IR rays are scattered while they reach them.

Determining a safe distance is not difficult. It is different for brick and metal stoves.

- If the brick oven is laid in a quarter of a brick, the safe distance to the walls is considered to be 32 cm.

- If a metal stove that is not lined inside is installed in a bathhouse, it should be at least a meter away from the walls.

- When a lined metal stove is installed in a bathhouse, the safe distance is reduced to 70 cm.

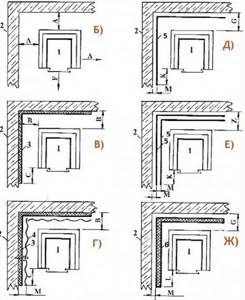

Possible options for safe installation of stoves and protective screens are shown in the photo.

- Number 1 – shielded metal oven.

- Number 2 is a wall made of flammable material (wood).

- Number 3 – protection made of metal sheet (asbestos-cement cardboard must be placed under it).

- Number 4 – galvanized steel roofing sheet installed up to the ceiling.

- Number 5 – steel sheet, the thickness of which is at least 1 mm.

- Number 6 is brickwork, the thickness of which is 55 mm (a quarter of a brick) or 120 mm (half a brick).

Advantages of a brick screen

Brick screens for sauna stoves are preferable to others for the following reasons:

- brick is complete protection against infrared radiation;

- brick finishing is characterized by heat resistance - wooden walls, screened with brick partitions, are reliably protected from fire and charring;

- brickwork is characterized by heat capacity and high heat transfer; brick accumulates heat, after which it releases it to the surrounding space for a long time and evenly;

- brick protection can be made independently - in many cases this does not require high qualifications;

- the method does not require large financial investments - masonry is accessible to anyone;

- brick can play the role of a decorative element; The design of the protection can be varied, so the artistic component of the screen can be adjusted to suit the bath interior and personal tastes.

Which brick is preferable?

Bricks are different. It is better to use those that have the most suitable properties.

Remember! Silicate (white) is not suitable as a screen. A material based on lime, under the influence of constant humidity and temperature fluctuations, will quickly lose strength, crack, or even collapse.

We recommend using solid ceramic (red) bricks to construct the protection. It is characterized by:

- heat resistance;

- thermal capacity and excellent heat transfer;

- aesthetic performance; By using facing materials, you can achieve a very attractive design.

Hollow “ceramics” with a similar structure are also quite suitable for the stated purposes. But it is distinguished by a shorter service life, due to its response to temperature fluctuations and less thermal accumulation.

Is it possible to lay fireclay bricks? Yes, it will also serve as good protection. But its use is inappropriate in most cases. The high cost of the material and not so high heat capacity make fireclay a less preferable option.

Note! Fireclay brick is suitable for constructing a screen in rooms designed for higher temperatures.

Types of brick partitions

One way or another, any brick heat shield acts as a barrier between the heat source and its surroundings. But the purpose of protection is somewhat variable. Depending on the specific task, barriers can be divided into 3 categories:

- fire screens; they are erected between the furnace and walls made of flammable materials; such structures protect walls from fire; the distance between elements is regulated by relevant standards;

- screening partitions; their goal is to protect people from heat flow and infrared radiation;

- decorative elements; in addition to their main purpose, such structures serve as independent interior elements; in such cases, they are not limited to primitive masonry - partitions are made in an aesthetic, and often exclusive, design.

Sometimes the distinction between categories is blurred. If the heat source is made using a homemade method, then most often even ordinary masonry will artistically enhance the interior. As for fire screening, it is necessary for any wooden (or wooden-clad) bathhouse. Yes, according to standards, flammable walls from a stove in a bathhouse can be protected with a metal sheet. But in decorative terms, the latter is very far from brick design.

Installation Requirements

In 1991, SNiP requirements were approved that determine the distances from heating elements. They indicate the following distances:

- from the wall surface to the heater there must be at least 38 cm for protected surfaces and from 50 cm for unprotected ones,

- to protected walls – 38 cm,

- all opposite walls - from 1.25 m.

According to Finnish standards, it is allowed to protect walls made of wood material with basalt material, metal, or galvanized corrugation. Screens must ensure that there are no gap areas to prevent contact of the flame with combustible materials, and that the outer surfaces are heated to a temperature not exceeding the melting or ignition point.

Recommendations regarding the installation of brick screens

A brick screen weighs a lot, so you need to take care of a solid foundation. If the protective contour is high, up to the ceiling, reinforcement of the foundation is required.

Remember! The base of the stove and screen must be common and reliable enough to support the mass of dozens of bricks.

A reinforced concrete foundation is recommended. If the stove is miniature and the protective “casing” is not high, there are few complaints about the base.

Recommendations regarding the construction of a brick screen:

- no need to place the brick close to the stove; there should be a gap of 5-10 cm between the elements; due to the distance, air circulation is possible - this ensures faster heating and heat transfer; the absence of an indentation leads to the fact that at first (and for a long time) the screen warms up, and only after that the brick gives off some of the heat to the steam room;

- a gap of at least 5 cm is also required between the masonry and the wall; This will protect the wooden wall from excessive heating; besides, heat transfer, again, occurs faster; but it is also necessary to leave a distance between the non-combustible wall and the screen - this will allow you to do without condensation in winter, which will arise due to temperature differences;

- in the lower rows of bricks it is necessary to make gaps; sometimes they are made over the entire screen area at certain intervals; the gaps provide air circulation and allow you to regulate the rate of heat transfer; openings can be closed with doors - thanks to them, thermoregulation becomes more convenient;

- the top of the screen should be higher than the firebox, but does not have to extend to the ceiling.

Important! Ventilation holes are required. Without them, full circulation of air flows is impossible. Only their number and placement vary.

The masonry mixture is prepared from sand, clay, cement and water. The usual ratio of components is:

- clay – 1 part;

- sand – 2 parts;

- cement – 10-20% of the total volume of the previous components; M400 cement is used;

- water - at your discretion; the solution should be such that it does not crumble or spread.

The amount of cement depends on the load received by certain structural elements. For vertical partitions, 10% is enough, but, for example, arched elements will require more binder.

Typically, half-brick masonry is used with a standard checkerboard pattern. The thickness of such a screen is enough for optimal, comfortable heat transfer. If faster heating of the room is required, the brick is placed on its edge. And vice versa - if the furnace is too powerful, and capacious accumulation with a long-lasting thermal effect is required, the partitions are thickened.

Masonry mortar

Durability depends on its quality.

Sand. It should be fine without impurities and poured through a sieve with a mesh of 1.5 mm.

Clay. Pour into a container and fill with good water (not musty), then stir. After kneading, the water should cover the clay. The mixture is left to “sour” for 2-3 days. Then filter through a sieve, rubbing out lumps. Add a new portion of fresh clay to the container and soak again. And so on until the required volume of paste-like consistency is formed.

Clays have different fat content. Particularly oily ones are “neutralized” by adding sand (otherwise they dry out and crack). The proportion of added sand ranges from 0.5 to 1.5 by volume. A good solution is to use fireclay clay. Some craftsmen add heat-resistant glue. However, I will not recommend it because the results may vary.