Heating systems are designed not only in residential buildings, industrial premises and commercial buildings intended for people to stay in them. Without heating, plants planted in the ground under the protection of polyethylene, glass or plastic structures cannot exist. Unlike classical climate systems, heating greenhouses has its own characteristics.

Read below about which installation scheme is optimal and which heating boilers are best to use in this case.

To achieve this result, you need to take care of high-quality heating

Industrial greenhouses with heating: review of thermal energy sources

Heated greenhouses are not uncommon in the rather harsh Russian climate. How can heating be implemented in an industrial environment?

The article provides the reader with a brief overview of heating methods used in our time.

An industrial greenhouse is a huge space. Which, of course, needs heating in winter.

General points

Regardless of the chosen heat source, there are a number of points to consider when building a heated greenhouse.

- As a rule, greenhouses are oriented to the cardinal points so that the transparent surface of the maximum area faces south. In this case, the structure captures maximum thermal radiation.

Please note: do not forget that plants need lighting for photosynthesis. The better the beds are lit, the faster the growth and the more abundant the harvest.

- Heat loss through glazing is much higher than through solid walls. Depending on the material, the thermal power requirement for greenhouses is estimated at 100 – 150 watts per cubic meter. For comparison, in modern houses, projects usually include no more than 30 watts/m3.

- Compared to single-strand glazing, cellular polycarbonate has noticeably lower thermal conductivity, which allows you to save on heating costs. However, when building a greenhouse with your own hands, it is worth considering one more feature: polycarbonate is less transparent and will provide worse illumination on cloudy days.

Polycarbonate transmits much less light than glass.

Heat sources

So, what can a heated greenhouse use as a heat source?

Central heating

If there is a heating main at a short distance from the greenhouse, the obvious solution is to connect to it. The classic water heating scheme with convectors or registers mounted parallel to a single-pipe filling system will be relatively inexpensive.

However, cheap central heating at the implementation stage will mean quite high operating costs. The price of thermal energy obtained from a thermal power plant necessarily includes the costs of repairing and laying heating mains, unnecessary heat losses during transportation, staff salaries, contributions to the state budget, and much more.

Boiler room

One way to significantly reduce overhead costs is to build your own boiler house. In this case, costs are reduced to the purchase of fuel and routine repairs of equipment.

What can burn in a boiler?

- Natural gas. The cheapest heating for a greenhouse is gas; however, this is only possible if there is a highway at a short distance from the greenhouse. Many regions of the country are still not gasified.

Modern block-modular gas boiler house.

- Fuel oil. Being a by-product of cracking oil, it is flammable and inexpensive compared to gasoline or diesel fuel.

- Coal. In modern boiler houses, the services of stokers are dispensed with to load it: fine-grained coal is dosed out from the bunker.

- Wood processing waste. Sawdust and wood chips are excellent fuel; Moreover, they are more than inexpensive.

However, with all its advantages, your own boiler room in a greenhouse is not the most economical heating method.

There are several reasons for this.

- Some heat is inevitably lost during transportation. Of course, the losses are less than on the way from a remote thermal power plant, but they exist.

- For the boiler room you need to build a separate room, which is not cheap.

- Finally, the very concept of water heating implies repeated transfer of thermal energy:

- from combustion products - to the heat exchanger;

- from the heat exchanger - water or other coolant;

- from it - to radiators or registers.

They, in turn, heat the air, which, when circulating, heats the soil and the plants themselves in the greenhouse. And at every stage, losses are again inevitable.

The traditional water heating scheme is associated with large non-target heat losses.

Electricity

Traditional heating of a greenhouse with electricity - using a heating element water heating boiler or air heaters - is quite an expensive undertaking. To estimate the scale of costs, it is enough to perform a simple calculation.

With a greenhouse size of 20x50 meters and an average height of 4 meters, its total volume is 20x50x4 = 4000 cubic meters. With a heat demand of 150 watts per cubic meter, 600 kilowatts of thermal power are needed to heat the room. Since the efficiency of any direct heating electric heating device is 100 percent, this will result in the same 600 kW of electrical power.

Now let's calculate the average monthly expenses at the cost of electricity at 3.5 rubles per kilowatt-hour.

- 24x600=14400 kilowatts of electricity are consumed per day.

- Per month – 14400x30=432000 kilowatt-hours.

- Expenses will amount to 432,000 x 3.5 = 1.512 million rubles.

It is unlikely that the harvest from the heated area will cover the costs, not to mention the profit.

An electric heater is a solution that is cheap only at the installation stage.

Let us clarify: the average actual electricity consumption is usually much less than the calculated one, so we are exaggerating the picture a little. On sunny days, the greenhouse will spend several times less electricity on heating.

However, there are two loopholes that can significantly reduce costs.

Heat pumps

This is a whole category of devices that consume electricity not to generate heat, but to move it from a colder object to a warmer one.

Different environments can serve as a source of low-grade heat.

- Air-to-air heat pumps are the most structurally simple devices. A typical example is a regular household air conditioner. The fan blows outside air through the heat exchanger, cooling it even more; the air in the room is heated in a similar way. The cost of such devices is relatively low, but the operating temperature range is quite limited. The best examples of air source heat pumps operate only at -30 degrees (in particular, this is the minimum operating temperature of the most popular Mitsubishi Zubadan pumps), while in many regions of Russia the thermometer drops to -40-50 degrees in winter.

Characteristics of an air source heat pump.

- Ground-air and ground-water are schemes that involve the use of geothermal heat. Heat exchanger probes are immersed in vertical wells up to hundreds of meters deep. An alternative solution - laying a horizontal collector in the ground - requires a large area, which is not always acceptable.

- Finally, water can also serve as a source of heat. The heat exchanger is placed in a non-freezing reservoir and pumps thermal energy from there.

The difference between the energy expended and the heat produced reaches five times in the best heat pumps.

Infrared radiation

Infrared heating of greenhouses also allows you to significantly save heat. Due to what? After all, infrared heaters for greenhouses are typical direct heating devices, aren’t they?

The point is a more rational distribution of heat. Emitters - reflectors with quartz high-temperature heaters or ceramic panels - are mounted on the ceiling. Thermal radiation directly heats the leaves, stems and soil.

As a result, at a room temperature no higher than +5 degrees, plants and the soil under them can be heated to the optimal +25 C.

An important point: the emitters are mounted at a height of at least three meters. The instructions are due to the fact that plants can receive serious burns at a short distance from the heating element.

The photo shows an infrared heating system in an industrial greenhouse.

Conclusion

We have considered only the most popular greenhouse heating systems in our time. The full list of possible solutions is, of course, much more extensive. In the video in this article you will find equally useful information on this topic. Good luck!

oteplicah.com

Heating of industrial greenhouses: air, do-it-yourself, main types and advantages

Industrial greenhouses made of polycarbonate are designed to promote crop growth in the warm season. As for the winter period, the issue of heating industrial greenhouses arises. In order for heating in such greenhouses to be organized correctly, it is necessary to equip the heating system with a fan, the main task of which is to distribute heated air around the perimeter of the entire room.

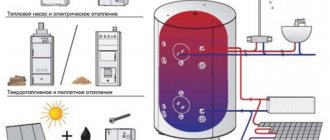

The main components of a hydronic heating system in a greenhouse.

According to the rules, heating of such structures should begin in mid-spring, which will make it possible to safely begin planting crops. The creation of heating systems during this period allows you to harvest up to three harvests. If tropical plants are grown in a greenhouse, heating must be maintained constantly.

Many people mistakenly think that heating of industrial greenhouses should be implemented only for winter greenhouses. This is not true, because even high-quality materials are not always able to protect plants from sudden cold.

Heating in a greenhouse should allow the greenhouse to function even in the most severe winter cold. The choice of the current heating system is determined by the area of the room that needs to be heated.

Heating system for large greenhouses.

As a rule, in industrial greenhouses, where certain plant crops are grown en masse, they do not skimp on choosing a modern system. Heating in a greenhouse should be done by a professional. This is due to the fact that many people make one common mistake when placing heating equipment in a specific location in the room. This will lead to the fact that the heated air will not circulate properly; there simply will not be enough of it for all the greenhouse plants. To solve this problem, you need to use a powerful fan. However, heated air rises very quickly, which causes it to cool. This problem is also easily solved: in the greenhouse you need to use a pipeline with warm water. These preemptive “blows” allow the heated air to reach the polycarbonate less quickly.

Gas and electric convectors are also used as the main unit for heating air in a greenhouse. The choice of convector may depend on the acceptable financial costs used to heat the greenhouse. This is due to the fact that electrical appliances for heating a room per hour will require less than 3 kW of energy, which can significantly hit the pocket of the owner of such industrial facilities.

An example of an industrial convector.

The most common is a special multi-circuit room heating system. The circuit has a specific purpose:

- The under-trough heating circuit is responsible for ensuring snow melting during heavy precipitation.

- The overhead heating circuit regulates the temperature in the upper part of the greenhouse, completely eliminating the penetration of cold air into the growing zone during sudden drops in temperature and brief openings of the curtain screen.

- The lower process heating circuit is needed to create a certain thermal regime.

Hot water is chosen as the coolant, the calculated temperature value of which is in the range from 50 to 95 degrees Celsius.

Components of the heating system

A modern heating system for industrial greenhouses consists of:

- control unit for supplying coolant to the main;

- main pipelines;

- pipelines of three heating system circuits;

- control cabinets for electric drives of pumps, mixing valves.

The temperature regime is set in accordance with the clear requirements of the agricultural technology for growing a particular crop. Using temperature control units, you can achieve distribution of warm water supply. All control falls on a modern automated indoor climate control system.

It is important to remember that proper heating of industrial greenhouses will significantly affect the crop and the speed of its ripening.

ultra-term.ru

Covering material

The following are used as covering materials:

- cellular polycarbonate;

- glass;

- polyethylene film.

Cellular polycarbonate

Currently, the most popular covering material is cellular polycarbonate . It is easy to install, is reliable during operation, and is not destroyed by accidental sharp impacts. This material will not be broken even by strong hail.

Foreign industry produces cellular polycarbonate of various thicknesses (from 3.2 to 25 mm) and structure. For small winter professional polycarbonate greenhouses, material with a thickness of 3.2 to 6 mm is used. Transparent polycarbonate is usually used for greenhouse buildings and greenhouses. The light transmission coefficient depends on the thickness of the sheet and ranges from 62% to 83% .

Glass

The light transmittance of glass is high ( 88-92% for glass of various thicknesses). Greenhouse structures can be glazed with both window and greenhouse glass, which is much stronger. Dutch industrial glass greenhouses are covered with a special type of float . This glass is cast into ready-made molds, which increases its strength.

Polyethylene film

Film industrial greenhouses have been used for a long time, but this material has a number of disadvantages. The film is difficult to secure without damaging it. Winds stretch the film, it begins to inflate and tear, which is why it has to be replaced. Arched farm greenhouses under film, which are located in areas of strong winds, have to be closed annually .

Film farm greenhouses - photo:

Heating of polycarbonate greenhouses, in winter, industrial systems, video

Greenhouses that are not equipped with a heating system are not very efficient, even those in which plants are grown in the spring. If you start heating the greenhouse in April, you can extend the harvest season by almost three months, and if you have industrial greenhouses with heating, this will be especially important. During this time, you can collect not one, but several harvests.

Greenhouse heating

If you intend to grow more southern crops, then the greenhouse must be heated throughout the cold period. Even if you build a greenhouse from the most insulating material, such greenhouses still need additional heating. Insulating materials in severe frosts will not even be able to maintain any positive temperature, so heating of greenhouses is necessary.

The choice of heating system, as well as what the layout will be, mainly depends on the size of the greenhouse.

Of course, a lot also depends on financial capabilities. The entire area of the greenhouse must be heated, otherwise some plants may not germinate. You can use not only gas, but also heating greenhouses with wood. In order for the heat to spread to all corners of the greenhouse, you will need a fan. To heat a greenhouse, you need to supply electricity to it by installing air heating for greenhouses.

Heating greenhouses with wood

Winter greenhouse heating assumes that the source of heat for heating the air in the greenhouse can also be pipes with hot water. Heat from such pipes is consumed quite economically and is released slowly. The diameter of the pipe determines how fast the water flows.

A more effective means than pipes with warm water are convectors. Such devices have a larger area for reflection and also reduce the water mass.

Heating a greenhouse using a convector

Quite often it happens that heating for a greenhouse for the winter is overestimated. The simplest and most convenient method to find out the heat requirement is to send a request to the manufacturer. This data can be quite helpful in choosing the most suitable heating system.

Industrial greenhouses with heating are common, where the approximate heating power can be determined using the following formula:

Total glass area * temperature difference * heat transfer coefficient = heating power.

If you make heating in a polycarbonate greenhouse and heat the greenhouse where the seedlings are located, then the period for cultivating crops can be extended by several weeks.

If there is gas heating in the greenhouse, then you need to carefully ensure that the required amount of oxygen is supplied to the open fire.

Heating a polycarbonate greenhouse

Electric heating

Quite a lot of houses have recently been heated using electricity. Electricity will be most effective for small greenhouses, or for those greenhouses where heat must be maintained occasionally. To set up such greenhouses and an electric greenhouse heating system in winter, you will not need to buy a blower; you can get by with a regular fan designed specifically for greenhouses. Such a fan will be able to distribute heat in the most efficient and safe way.

Special heating systems that involve heating greenhouses in winter can make it possible to regulate the dosage of heat entering the greenhouse.

To begin with, it is best to set the lowest mode, and if there is not enough heat, then you can already open the other valves. Ribbed radiators equipped with a thermostat are considered the most durable and reliable. The heat is distributed throughout their entire body. On sale you can find radiators of different sizes, from 1.5 to 2.5 m. Basically, such radiators have a power of 2 kW. In such greenhouses, where the maintained temperature is more than +10 degrees, it is possible to provide for a decrease in temperature at night.

With electric blowers

The greenhouse can also be heated with electric water heating. Water heating of greenhouses is one of the most beneficial for heating greenhouses or greenhouses. The greenhouse water heating device is equipped with a boiler in which water is heated, and after that the warm water is pumped into the pipes using a circulation pump. Such plastic pipes can be laid along the outer walls of the greenhouse or between plants.

Heating greenhouses with infrared heaters is also common - a fairly effective way to heat a greenhouse room.

Infrared heating of greenhouses has a number of advantages - it is an almost natural type of heating. Also, such a system does not dry the air, since it is not the air itself that is directly heated, but the objects in the greenhouse. Infrared heating of a polycarbonate greenhouse is an economical option. After all, soil heating occurs at a lower temperature, so the volume of heat resources decreases by 35%. Infrared heating of a polycarbonate greenhouse in winter provides an efficiency of about 95%. But you will not achieve such a result using the same steam heating in a greenhouse with heat loss.

Using infrared heaters

Connection to the heating system

The most profitable option, including from a financial point of view, would be to connect to an existing heating system. However, it is necessary to determine if the boiler can provide the necessary pressure in order to allow the implementation of greenhouse heating systems. The pipes leading to the greenhouse must be insulated, and this is not cheap.

Greenhouse heating scheme

Insulating pipes is also not always advisable. This can only be done if the greenhouse is located a short distance from the house. It is also necessary to take into account that the greenhouse must be heated at night. New, more innovative heating systems can help you regulate and lower your temperature at night.

Gas heating

Gas cylinders are an ideal solution if the greenhouse only needs to be heated for a couple of weeks a year. In order to heat the greenhouse constantly, you will need a gas tank or connection to a common gas network system.

Small greenhouses can be heated with catalyst burners with a thermostatic control system.

Since the efficiency factor is the highest, the option that carbon monoxide will be released is excluded. When installing gas heating for a greenhouse, you also need to make sure that the oxygen supply will be at the proper level. In this case, the best option would be to install an exhaust system.

Much of the success depends on good air circulation. Ventilation in the form of blinds is well regulated, but it is not suitable for winter greenhouses and greenhouses. Greenhouses like these need to be sealed before the cold sets in. For this you will need an additional layer of polyethylene film. A video about heating greenhouses can be viewed below.

otoplenie-doma.org

Electric greenhouse heating

Most often, when installing electric heating in a greenhouse, IR heaters are used. They quickly heat the soil and plants with little energy consumption. To calculate the number of such devices, a simple scheme is used - for 10 m² of room you need 1 kW of heating equipment power. Moreover, the thermal power should be evenly distributed throughout the room.

The greenhouse frame is used to attach the IR panels. The heaters are mounted on brackets and connected to the electrical network. If you additionally install temperature sensors, the heating can be automated. The sensors are mounted at a height of 0.8-1 m from the floor. Moreover, they should not be exposed to light from devices.

Industrial greenhouses: advantages in size

Industrial greenhouses allow you to grow various crops. Industrial greenhouses differ from standard ones in that they are much larger in size; they can be equipped with a heating system, thanks to which they can produce crops several times a year. Small greenhouses are not able to maintain crops all year round, unlike the industrial version. Greenhouses of this type, as a rule, occupy a large area not only in width and length, but also in height. They are very popular in agro-industrial complexes. In addition, such structures can have several tiers, and the walls are constructed from building materials. The useful area of an industrial greenhouse can be up to several thousand square kilometers.

Content:

Installing a heating device is an important step for a greenhouse. Heating most often occurs by circulating hot water through steel pipes. Circulation is a forced process and is carried out using pumps, the power of which is calculated based on the area of the greenhouse.

In large industrial greenhouses, a contour system is used.

So the upper circuit is used to regulate the temperature in the upper parts of the greenhouse and not allow cold air to pass through, creating an air “cushion”. The lower circuit plays a major role in heating the room and maintaining the desired temperature.

Large industrial greenhouses use a contour heating system

In addition to the two above-mentioned circuits, there are also the following types:

- Under tray heating;

- Zone heating;

- Substrate heating.

Temperature control is carried out by an automated system. Hot water is used as a coolant, and the design temperature is from 50 to 90 degrees. Temperature indicators

Each heating system has distributors (temperature control units) through which the heat supply is distributed.

The nodes also consist of:

- Circulation pump;

- Mixing valve;

- Pipelines;

- Instruments for control and measurement.

Frames for industrial greenhouses: 3 varieties

For industrial greenhouses, a durable frame is used, most often it is an arched installation or a gable structure.

There are 3 main types of frames:

- Hat;

- From a profile pipe;

- From the corner.

The hat frame is installed simply and quickly, but this design is not designed for the heavy weight of snow. Frames made from profile pipes are more durable; they are used to build farm greenhouses. Such a frame is usually welded, and the pipe has a round or square cross-section. Metal structures are becoming more popular. Although the design is stronger than a hat frame, it will also not be able to withstand heavy loads. An alternative is a frame made from a corner. This design does not require welding and is assembled using bolts. The entire profile is galvanized, so it can be used by more than one generation.

For industrial greenhouses, you can use one of three types of frames

The corner frame can withstand up to 100 kg of weight, which means that the pressure of snow in winter will not break it.

If there is a need to create additional reinforcement of the structure, you can use anchor bolts or fixed studs. It is not recommended to use aluminum as a material, since under the influence of heat or snow, the structure will be prone to deformation.

Construction of industrial greenhouses: where to start

Building an industrial-type greenhouse is not an easy task; film coverings are not suitable here. This issue should be approached thoroughly and each point of preparation should be dealt with.

Where to start construction:

- From choosing a location;

- To make a plan;

- Select the necessary material from which the frame will be made, most often it is made of metal or wood;

- Organize heating and irrigation system;

- Decide on a curtain system.

In order for the yield to be maximum, it is necessary to properly position the greenhouse.

The best location for the greenhouse is the area south of the latitude of 60 degrees from north to south. As for the northern part of the country, it is better to place the greenhouse from the western to the eastern part.

Before building an industrial greenhouse, you need to choose a location for it

The greenhouse must be equipped with lighting; lamps or LED lamps will not be amiss. The construction of an industrial greenhouse should begin with the selection of a site. It should be as level as possible, without tilting. If there are strong gusts of wind in the area of construction, it is necessary to take care of additional fences or shields that will help reduce its speed. It also depends on the correctly selected area whether the foundation of the greenhouse will be flooded, since melt water from snow or rain will drain, and this is not desirable. Tackle the soil. As for the soil, it must be fertile and ready for various types of fertilizing, including anthracite.

Once all the points have been provided, you can start selecting and preparing the project. To do this, you need to decide what exactly will be grown in this greenhouse in summer and winter. With the right approach and compliance with all construction rules, you can build a greenhouse that will serve for many years.

Specialized enterprises in Russia can provide dozens of schemes according to which you can construct a greenhouse; in addition, you can purchase all the components and organize independent installation. You can also use the services of the manufacturer, who offer their mounting and installation services. Israel and Holland can offer excellent greenhouse options; the sale of their venlo-type products is very popular. And Dutch hydroponic greenhouses can satisfy any farmer, because they can produce large yields. The greenhouses from this manufacturer are of the highest quality, and their production does not take much time.

Projects and drawings of industrial greenhouses: where to look for them

The work on the project cannot be called typical; it all depends on what technology will be chosen. At the moment, there are a lot of special photos, magazines, books or tips that can be downloaded on the Internet in dwg format completely free of charge; they can offer ready-made diagrams of industrial greenhouses. They are always accompanied by a diagram of upcoming expenses, income, as well as instructions for construction. All that remains is to make a choice, the use of materials and coating, the use of film or glass.

In this case, you need to know that choosing a project from the above resources is not ideal. Such options always need improvement. The book is only part of the work on the project.

In addition to the literature, there is a special program that, taking into account all the parameters, will help calculate and create the necessary drawing. You just need to enter all the necessary dimensions, you will also need the height and expected shape of the roof, possible loads, and the result is a finished building that takes into account all your wishes and features.

Projects and drawings for industrial greenhouses can be found on the Internet

A question appears. If there are all kinds of programs, books and magazines, why do we need specialists? The thing is that it is almost impossible to construct an industrial greenhouse on your own, since it is a complex cycle that is equipped with many systems, such as heating, ventilation, watering and lighting. Since this is a largely automated process, greenhouse construction requires human presence for constant monitoring.

In order for all the shortcomings to be taken into account during the design, engineering, constructive and agrotechnical solutions are required. Only in this case will the greenhouse be able to generate the necessary income.

To ensure that the drawing meets your expectations, pay attention to the following points:

- Decide what will be grown in the greenhouse. Will it be one specific type of crop for sale or only seasonal seedlings for personal consumption;

- The size of a future industrial greenhouse should be determined based on the area used;

- Correct selection of building materials. An important detail to remember is that the thinner the polycarbonate sheet, the more often it is necessary to use the lathing;

- It is best to use metal pipes as a frame. Sometimes wooden materials are created, but they are not designed to last long.

Once a clear image of the future greenhouse has been created, you can begin design and construction. Farm greenhouses require maximum responsibility, because it is in them that all the necessary crops are grown.

Industrial greenhouse: winter design, its differences and requirements

If there is a winter industrial greenhouse on the site, this indicates that an experienced person is taking care of the farm. Despite the harsh Russian climate, such greenhouses make it possible to grow roses; the Krasnodar region is famous for its special harvests.

Greenhouses that are used all year round have their differences from summer options.

These include:

- Complexity of design, glazing;

- Increased structural strength;

- Availability of foundation;

- In such greenhouses, plants feel comfortable in any season.

A winter-type greenhouse must be equipped with a ventilation system

Every winter-type greenhouse must be equipped with ventilation. It must be provided for when creating the project.

The most important requirement for an industrial greenhouse is the organization of the heating system and the creation of tightness. If all the necessary details are taken into account, the crop can be harvested even in winter. Winter greenhouses made of polycarbonate are very often used in agriculture, as well as in the production of crops on a large scale. But it should be remembered that the organization of such greenhouses is not always capable of growing crops by a private individual; most often, a factory can do this.

DIY industrial greenhouse: projects and construction (video)

What conclusion can be drawn and what can be said about industrial greenhouses? It is quite difficult to create a structure with your own hands, but after watching the training video, you can get to work and get a greenhouse that fulfills its intended purpose. This option helps to increase production and obtain year-round vegetable harvests while using small areas. Greenhouse conditions allow even flower seeds to germinate. The quality of the resulting harvest does not depend on external weather conditions, which makes agricultural technologies for soil more in demand. It is this quality that makes the design more popular among users.

Details: industrial greenhouses (photo examples)

Attention, TODAY only!

oteplicah.ru

Stove greenhouse heating

Industrial greenhouses are often heated using stoves. In this case, brick or metal stoves are used. The first option is preferable because the brick accumulates heat better and cools down longer, maintaining a constant temperature in the greenhouse. With this heating, normal air humidity is maintained.

Although metal stoves heat up quickly, they do not retain heat well, so they need to be constantly loaded with firewood. Due to the strong heating of the walls of the device, the air in the room dries out greatly.

Important! To maintain normal humidity, metal furnaces are supplemented with water circuits with radiators and registers, which ensure slow cooling of the coolant and eliminate sudden temperature changes.

Metal furnaces

Metal stoves are more suitable for greenhouses that are used in spring and summer.

This is due to the following advantages of such heating devices:

- Thanks to the mobility of the device, it is easy to install it for temporary heating of a room and remove it if the temperature outside rises.

- Metal furnaces do not require the construction of a foundation and are compact in size.

- If you choose a specific model of such a furnace, it can be supplemented with a water circuit.

- The units are reasonably priced.

- Easy installation and connection. If you decide to make heating in the greenhouse yourself, then you can make a metal stove yourself.

- Another advantage of such a stove is its rapid heating.

- When using this unit, it is impossible to get carbon monoxide poisoning.

Disadvantages of metal appliances:

- the heating process cannot be automated, so the device needs constant monitoring;

- The unit greatly dries out the air in the room, so additional humidifiers are installed there.

To install a metal stove, you can use the greenhouse itself, a vestibule, or any utility room. In the last two cases, a water or air circuit is brought into the greenhouse. Additional heating of the room can be provided by a chimney from the stove, which is installed at an angle of 15°C. An uninsulated metal pipe is used as a chimney. In the place where it passes through the roof or wall, thermally insulated boxes are installed.

Do-it-yourself heating options for a summer cottage

Popular models of metal stoves:

- The Vesuvius potbelly stove is inexpensive and has compact dimensions. A unit with a thermal power of 4 kW is suitable for heating a greenhouse with an area of 25-30 square meters (with a volume of no more than 80 cubic meters). The steel appliance runs on wood.

- The Cinderella stove has side convectors to distribute heated air. With a power of 6 kW, the device is suitable for heating a room up to 60 square meters. On top there is a burner for heating water. Garbage and firewood are used as fuel.

- The Teplodar stove with a power of 5 kW is used to heat greenhouses no more than 50 m². For uniform heat transfer, the unit has a casing with holes. There is a burner on top. Powered by wood.

- The Normal heating device has a power of 6 kW and is suitable for greenhouses with an area of no more than 80 m². The sides of the stove are protected by casings with convection holes. The ash is collected in a separate box and used for fertilizer.

- The Aquaten furnace has a water circuit and a power of 6 kW. It is used for heating greenhouses up to 60 square meters. There is a water jacket around the firebox. The device is connected to the water circuit.

Installation of a metal stove

If you decide to use a metal stove, a heated greenhouse with your own hands is made in the following sequence:

- A base is made of compacted earth or paving slabs for the stove. For uniform heating, the unit is installed in the central part of the room. But devices with a water or air circuit can be installed anywhere. The main thing is to observe the standardized distances.

- The stove is installed on a prepared base with the back wall facing the wall of the building.

- Using a heat-resistant sealant, connect the chimney pipe to the stove pipe.

- If required, the device is connected to an air or water circuit.

Brick kilns

Brick stoves are suitable for greenhouses that are used year-round. It is important to select a device based on thermal power taking into account the heated area.

For a stove measuring 77x51 cm you will need the following materials:

- solid ceramic bricks – approximately 220 pieces;

- fireclay bricks – up to 80 pieces;

- 80 liters of clay masonry mortar;

- a quarter cube of concrete for foundation construction;

- 30 liters of fireclay mortar;

- cast iron parts - smoke valve, doors for cleanout and ash holes, firebox and grate;

- a little glass insulation or roofing felt.

Sequence of making a brick kiln:

- To begin with, a foundation cushion with a height of 200-300 mm is made, which must be reinforced. To do this, soil is removed from an area measuring 0.7x1 m to a depth of 350-400 mm.

- The bottom is covered with sand in a layer of 200 mm and compacted. The walls are reinforced with formwork. A spatial reinforcement frame is made from a rod with a cross-section of 12 mm, which is installed in increments of 200 mm.

- The pit is filled with concrete and allowed to set for 21 days.

- They begin laying the furnace. The first 4 rows are laid out of red brick using clay mortar. The ash pan door is secured in the masonry.

- The next 11 rows are laid out of fireclay bricks using refractory mortar. During the work, the combustion and cleaning doors are installed, and the firebox arch is made.

- From the 16th row, the masonry is done with red brick according to the scheme.