Causes of deterioration in traction

First you need to determine the cause of the deterioration in traction. Therefore, first of all, the general condition of the chimney and all associated elements of the system is checked.

This is done very easily. First, the entire heating system is completely turned off, after which the amount of soot in the chimney is measured using a long probe. This value should not exceed 2 mm.

The reasons for insufficient draft in the chimney are conventionally divided into 2 groups: external factors and design features.

Among the design features:

- the use of tees, elbows along the smoke exhaust duct, bypassing obstacles that create aerodynamic resistance;

- incorrect installation and adjustment of the damper;

- incorrect height and diameter of the chimney, which does not meet the requirements of the manufacturers of heating or water heating boilers.

External factors mean:

- placement of the draft outlet below the roof ridge, which under certain conditions can lead to a draft “overturning”;

- the presence of large objects near the chimney, forming an area of high pressure or, conversely, vacuum;

- the predominance of strong winds in the region or, on the contrary, calm,

All this can have a significant impact on the traction force and create additional resistance, thereby reducing its level. To avoid this, it is imperative that you take certain steps to increase or stabilize the draft so that your furnace or boiler operates more efficiently.

Advantages and disadvantages of such a connection

Switching to stainless steel sandwich pipes provides the following advantages:

- simpler and faster installation of a new chimney;

- you can install it yourself;

- less expensive;

- the design is lighter in weight, smaller in size;

- soot and other combustion products do not accumulate on smooth walls;

- the device can be brought out either through the roof or through the wall;

- the presence of an insulating layer, which to a certain extent reduces the amount of condensation;

- Possibility of installation through the rafter system.

The disadvantages of sandwich chimneys are the same as those of all modular smoke removal devices:

- over time, some loss of tightness at the joints;

- significant price of the kit and its installation;

- restrictions on service life (15-30 years).

Methods and devices

For normal functioning of the chimney, the upward flow must have a pressure of about 10-20 Pa. To determine the level of thrust, anemometers are used, and based on their readings and the results of fuel combustion, a decision is made - to increase or decrease thrust.

There are various options for how to bring traction into compliance with standards:

- chimney extension;

- use of special devices;

- use of electric smoke exhausters;

- traction stabilizers.

Chimney extension

The easiest way to eliminate low draft is to lengthen the chimney pipe. Due to the increase in the difference between the levels of the chimney outlet and the boiler, the difference in pressure of the upward flow also increases. For a chimney, the most suitable height is 5-6 meters, subject to the minimum distance between the vertical section of the chimney and the stove or boiler, and the absence of all kinds of bends, narrowings and deviations of the shafts.

If you have a high roof or there are large objects nearby the house that significantly impair traction, this method makes it possible to achieve the best result. However, with a very high chimney, the draft level can greatly exceed the required value, as a result of which the bulk of the heat will be released into the environment rather than spent on heating the premises. To prevent such a situation, special dampers are used to reduce the volume of exhaust gas.

Deflectors

A deflector is a device that allows you to optimize air flows to enhance draft in a smoke exhaust or air duct pipe. The deflector is translated as a guiding device, reflector. The name, in principle, fully describes its purpose and functionality.

The simpler the design, the greater the efficiency, since the flows reflected from the roof and side winds increase the traction force and suck smoke from the chimney. The deflector, even in heavy winds, prevents the thrust from tipping over, but in calm conditions it is ineffective. The model of the chimney draft amplifier should be selected not only according to the size of the smoke exhaust duct, but also according to the expected wind load.

If you have the desire, a sheet of galvanized iron, a minimal set of tools, available materials and even minor skills in working with metal, you can make such a device yourself.

To make the device you will need:

- square;

- roulette;

- metal scissors or grinder;

- wooden hammer;

- riveter;

- hand electric drill;

- set of drills;

- drill bit self-tapping screws with a 15 mm press washer;

- tin or galvanized 0.3-0.5 mm;

- improvised material for fastenings.

After carrying out the calculations and drawing the contours of the parts onto the metal, we perform the following:

- cut out all the necessary parts;

- roll up the nozzle body and fasten the edges using self-tapping screws or rivets;

- assemble and connect both cones of the device;

- Before assembling the umbrella, you need to install pins in the lower cone to attach it to the common body, and if the installation will be carried out on legs, then they can be fixed from the outside with rivets.

Such chimney draft amplifiers not only tolerate flue gases and high temperatures well, but also have corrosion resistance and durability.

Vane

The weather vane is another draft amplifier with a fairly simple design without extending the smoke exhaust pipe, and also dependent on wind strength. However, this device, unlike the one described above, creates virtually no resistance in calm conditions. A small wing is installed on the head, which protects the edge of the chimney from the wind from only one edge.

Thanks to the auxiliary blade, and its placement opposite the place where the weather vane is fixed on the chimney, the device constantly closes the mouth from air flows, which, flowing around it, create a vacuum at the outlet, thereby significantly increasing draft. Manufacturers advise using such devices for the chimneys of wood-burning fireplaces when there is insufficient or unstable draft, in the case of strong winds or when air vortices form above the smoke exhaust channel due to the unfavorable location of the pipe.

Rotary turbines

Rotary turbines are a mechanical device that uses wind energy to increase draft in a chimney. The turbine nozzle, regardless of the direction of the wind, always rotates in one direction, creating a vacuum above the smoke channel, which helps to increase thrust.

The design of such a draft amplifier allows you to protect the chimney from debris, leaves, precipitation and other things getting into it. A special feature of the turbine is that in calm weather it does not work; in the non-heating season, air is removed from the smoke channel, and in the presence of wind, high rarefaction is created and an increase in thrust.

It is not recommended to install such draft amplifiers on the chimneys of coal-fired stoves and wood-burning fireplaces. It is worth considering that the temperature of the flue gases should be no more than 150-250˚C. This device is effective for natural ventilation systems and smoke exhaust pipes of heating boilers operating on gas fuel.

Electric smoke exhausters

In some cases, for example when using wood-burning stoves or fireplaces, it is permissible to install special electric smoke exhausters. These devices are designed for use in conditions of elevated temperatures, the presence of ash, condensate and other combustion products. However, it is strictly forbidden to install them on the flue pipes of solid fuel boilers, in which the gas temperature can reach 650-800˚C.

Such devices allow you to fully automate the operation of the chimney duct. Flow and temperature sensors regulate the intensity of rotation of the electric drive, thus constantly maintaining optimal traction in the system.

The choice of method to increase draft depends directly on the design features of the smoke exhaust duct. The use of all of the above devices to enhance draft in a chimney is relevant only under certain conditions, namely: the predominance of windless weather in the region or the impossibility of installing a chimney pipe of the required length.

Instructions on how to repair a brick chimney

During the operation of a brick chimney, sooner or later, the time comes for repair and restoration work aimed at giving the chimney its original performance characteristics. Read the instructions on how to assemble and install a stainless steel chimney.

The photo shows a brick chimney made by yourself.

It is worth paying special attention to the outer part of the chimney, located on the roof, since it is this part that is exposed to the destructive effects of the environment. To improve the appearance and increase the strength characteristics of a brick chimney, you can resort to lining it with various finishing materials. The building materials market offers a wide range of decorative and finishing materials suitable for finishing a chimney. You can find an overview of the types of caps for chimney pipes here.

In addition to finishing an old brick chimney with facing bricks, you can plaster the surface of the chimney walls and paint them with heat-resistant paint. Brick chimneys lined with flexible acrylic tiles imitating stonework look original. If the choice was tiles or corrugated sheets, then additional installation of a metal profile frame will be required. Fiber cement boards that imitate brick or stone can also be fixed to the frame base.

As an option, galvanized sheet metal can be used as a finishing material. The sheet of tin is cut into strips 40 cm wide, then the prepared tin strips are encircled around the chimney at a height of 25 cm. The outermost sheets are cut in steps, bent at an angle of ninety degrees, inserted into the seams between the bricks and secured with galvanized hooks. A thermal insulation layer must be laid under the sheets of tin. Read an overview of the characteristics of the Bavaria stove-fireplace.

Roofing slate can also be used as a finishing material. Installation of slate tiles is carried out on a frame base using copper nails. When laying tiles, it is necessary to maintain an inclination angle of at least twenty-two degrees.

The figure shows the installation of a brick chimney on the roof.

The process of plastering a brick chimney on the street can be divided into several main stages:

- the surface of the chimney is first cleaned of dust and dirt, then treated with a primer to improve adhesion;

- then a reinforcing mesh is fixed on the surface of the chimney walls (if the mesh is made of fiberglass, then the reinforcing mesh will be fixed to an adhesive base; if a metal mesh is used, then its fixation will be carried out using nails driven into the seams between the bricks;

- after the reinforcement of the chimney surface is completed, you can proceed directly to plastering (at least five layers of plaster are applied).

Keep in mind that before applying the next layer of plaster, you must allow the previous one to dry.

To plaster the surface of the external walls of the chimney, you can use any heat-resistant plaster mixtures.

You can add marble chips to the last layer of plaster.

The photo shows the process of chimney insulation.

How to insulate?

Regardless of the material used to make the chimney, the outer part of the chimney must be insulated. In the case of insulation of a brick chimney, a sheathing is mounted on the surface of the chimney structure. Thermal insulation material is placed in the space between the slats. Sheet foam or expanded polystyrene foam, as well as basalt wool, can be used as thermal insulation material. Decorative and finishing material can be fixed on top of the insulation on the sheathing, or the chimney can be lined with hollow bricks. Read the guide on how to install a sandwich chimney on this page.

Brick chimneys, due to the technical characteristics of the manufacturing material, are susceptible to the formation of large amounts of condensation, which has a destructive effect on the brickwork of the chimney.

Certain actions will help prevent or minimize the formation of condensation:

- in the case of operating heating equipment that runs on solid fuel, it is necessary to use only pre-chopped and thoroughly dried firewood;

- it is necessary to completely seal the chimney channel, carefully seal all the cracks, thereby preventing unnecessary air leaks;

- Insulating the chimney pipe will definitely reduce the level of condensation.

One of the modern and effective technologies aimed at repairing a brick chimney is lining the brick chimney with a polymer sleeve. The polymer pipe is characterized by the smoothness of the inner surface of the walls, high strength and ease of installation. The polymer liner is placed in a brick chimney, filled with compressed air, then steam, as a result of which the polymer sleeve expands, fills the chimney channel and hardens.

One of the reasons for poor draft in the chimney may be its insufficient height. In this case, to increase the draft level you will have to resort to building up a brick chimney. You can build up the chimney either through brickwork or by installing a sandwich pipe made of stainless steel. The transition from a brick chimney to a sandwich chimney can be accomplished using a special square nozzle. The nozzle is fixed to the brick chimney, and at the other end of the product the nozzle is equipped with a pipe into which a sandwich pipe is inserted. A guide on how to install a coaxial chimney and installation requirements here: https://mykaminz.ru/dymoxod/vidy/koaksialnyj/rukovodstvo-kak-ustanovit-koaksialnyj-dymoxod-i-trebovaniya-k-ustanovke.html.

The soot accumulated on the internal walls of the chimney during its operation causes a narrowing of the chimney cross-section and, accordingly, a significant decrease in the draft level. Chimney cleaning can be done either mechanically or chemically. The chemical method involves the use of special substances that, during the combustion process, react with soot and have a destructive effect on it. The mechanical method of cleaning a chimney involves using a rigid metal brush attached together with a load to a cable or rope. Cleaning the chimney of a brick stove should be carried out at least twice a year.

A stove damper is an integral element of a brick chimney, since with the help of a stove damper, air exchange is controlled; in addition, an installed and closed damper, after complete combustion of the fuel, avoids heat loss through the chimney duct. The valve is installed directly during the installation of the brick chimney.

I encountered a problem with extending the chimney

The situation is this: two asbestos pipes are coming out (outer diameter 180, inner 143), they need to be extended using galvanized ones. There are galvanized pipes of 135 diameter. How can they be combined with asbestos? Some kind of adapters? so that it all holds tightly, because... increase 220 cm

It is not clear what kind of pipes are, but in any case you should not narrow the pipes. I advise you to find a pipe of larger diameter and put it on top, securing it with a clamp

chimney pipes, on the roof they come out touching each other. Everything around is cemented, you can’t move them apart, i.e. putting it on top is a problem

What are the initial conditions? Maybe you can do without building up the chimney.

Initially, everything was fine, then a neighbor’s wall of the second floor appeared nearby (the house is divided in half - one half is one-story, the other was built into two floors). There are chimney pipes on the roof of the one-story half; they are about a meter away from the wall. There are turbulences from the wall and the boiler goes out. That's what the experts said. It needs to be built higher than the ridge of the neighbor's extension. this is 220 cm.

Well, no one will tell you

You have a flue made of two pipes! Put one large pipe on them. Bend it into an oval and put it on. Or order... Just remember, the pipe will start crying. I have an iron pipe, I heat it with gas, I wrapped it on top with polystyrene foam film and foil and secured it with tape with the foil facing outward - protection from the sun and it turned out beautifully. And seal the joint with the asbestos pipe with mortar, even clay will do. You can’t do anything else - it’s winter

It's winter though. Equip existing pipes with clamps to prevent them from flying into the chimney, prepare a clamp for attaching guy wires, make or buy caps, stock up on asbestos sheets and asbestos cord. Secure the clamps with prepared braces, wrap the steel pipes with asbestos and push them into the existing chimney. Secure with stretch marks. Wrap the pipes with Izover, Ursa, etc. Wrap with foil, foil-foil polyethylene foam, etc. Wash three times to complete the job successfully. It is not advisable to combine chimneys. I won’t get into theory, this is on the topic of heating and ventilation.

In your case, I would do this: I called companies involved in tin production and ordered from them an F180 pipe with flaring on one side up to F184, the length of the flaring is 15-20 centimeters. After which this pipe is put on the asbestos pipe and fixed with self-tapping screws. To reassure yourself that the fastening is secure, you can install guy wires. Use F135 pipes somewhere else, for example, in a bathhouse. Because It’s pointless to even make a sandwich with it (it’s not stainless steel, there’s a big difference with the internal diameter). I don’t recommend sticking them into asbestos pipes, wrapping them with asbestos fiber, because... similar operations are carried out on the ground. Otherwise you will end up with “snot”, and snot and carbon monoxide in the room are a RISK.

Why does reverse draft occur?

Weak thrust can become the basis for the formation of reverse thrust. How can you recognize that all is not well with cravings?

This is “spoken” by moments that can be seen with the naked eye: a lot of smoke in the stove, soot on the door, incoming smoke movement inside the house. In other words, smoke and fumes from the burning fuel do not go into the chimney through the chimney, but tend to enter the living space when the door is open and through cracks.

Causes of backdraft:

- Design flaws of the chimney. A low pipe means an increased risk of reverse draft. The higher the pipe, the better the process of extracting exhaust gases and smoke. The optimal pipe height is about five meters .

- Correspondence of the pipe diameter to the parameters of the furnace device. A powerful stove requires a chimney with a pipe of rather large cross-section. But the measure here is very important, because using a pipe that is too wide will make the combustion process unprofitable (all the warm air will literally fly into the pipe). It is unacceptable to use several pipes with different cross-sections in the chimney!

- Use of non-smooth pipes. Unevenness, chips, roughness, etc. are an obstacle to good traction. Over time, the chimney opening may narrow due to soot deposits and other combustion elements and complicate the process of lighting the stove and its normal functioning.

- Poor/lack of ventilation. Drafts and open windows in rooms located above the firebox do not help the fuel combustion process, but distort it, making it useless and unsafe.

Chimney channels made of metal are in many ways inferior to brick pipes. Rapid heating and equally rapid cooling are not good for the heating system in general and the chimney in particular.

Brick pipes are much more effective in terms of smoke extraction

Reverse thrust can also appear for objective reasons beyond a person’s control. Strong gusts of wind, rainy, cloudy weather with high humidity are unfavorable moments in terms of the formation of problems with traction.

There is such a term as temporary backdraft. What is this? In this case, it is worth talking about temporary traction disorders, lasting for several days. After a certain period, cravings return to normal.

Temporary reverse draft can occur due to a cold room that has been unheated for a long time. Very cold air accumulated in the chimney pipe prevents the fuel from burning quickly. Therefore, smoke can be “pushed” out of the chimney into a home, bathhouse or other room with a stove or fireplace.

Effective ways to increase chimney draft

Designing a chimney is complex and responsible, on the correct execution of which the efficiency and safety of using the heating device depends. No heat generator is capable of functioning normally without a pipe that removes smoke from the room. Smoke is a mixture of gases containing residual products of fuel combustion. The appearance of smoke inside a heated room is a sure sign of an incorrect design of the chimney system, which entails the risk of fire and carbon monoxide poisoning. This article will tell you what backdraft in a chimney is and how to prevent its occurrence.

Selection of devices for regulation

Let's consider some characteristic features and methods of using devices for monitoring and adjusting traction.

Deflectors

Such structures are installed on the chimney (at its very top) to create obstacles to air flow. The intensity of the wind force drops noticeably when encountering such devices placed on a pipe. The smoke escapes through the channel “to freedom” due to weak air currents entering the pipe. These flows “catch” the exhaust gases and “push” them out.

Deflectors eliminate the possibility of pipe clogging, and, if made with taste, they significantly improve the appearance of the entire building.

There are several types of deflectors:

- TsAGI;

- round Wolpert;

- Grigorovich;

- plate-shaped;

- in the form of the letter H;

- rotating;

- vane.

Almost all of these devices are made from stainless steel, in rare situations - from copper. Using brackets, clamps, bolts, sealing tape, the deflector is attached to the chimney pipe. Some devices are also equipped with additional functions: to extinguish sparks (to eliminate a possible fire in the roof), to control the temperature of the exhaust air (in this case, the sensor is triggered if hot air does not come out and there is a possibility of reverse draft).

The disadvantages of using deflectors are their minimal effectiveness in calm weather.

Photo gallery: types of deflectors

Rotary devices

Turbines installed at the head of the chimney use the energy capabilities of the wind. Air flows set the rotary nozzle in motion (it always moves in one direction), and thereby the air becomes rarefied near the chimney. The entry of any foreign objects and sediment into the chimney with a rotary pipe is completely excluded.

Rotary pipes have a big disadvantage, similar to the operation of a deflector. Their use on a windless day is ineffective.

If you do not have great abilities, buying such devices is not a problem.

Traction regulators

Such devices are a real find for residents of country houses, lovers of baths and fireplace gatherings. These devices are attached to the boiler chimney. They are equipped with a metal plate with a weight that balances it on one side. When the draft is good, the metal plate does not interfere with the free access of air into the chimney. With weak or reverse thrust, the metal plate serves as a kind of stupor.

Measurement methods

If you doubt that the chimney draft of a stove, fireplace or heating boiler is sufficient, you need to check it. The easiest way to dispel doubts is to check it yourself using an anemometer. If the device shows a draft of 10-20 Pa, then it is considered normal . The problem with this method is the low measurement accuracy of inexpensive anemometers; if the draft is less than 1 Pa, then they will show that there is no draft. More accurate professional instruments are expensive; they are used by stove makers.

If you don’t have an anemometer, use one of the popular methods for determining the draft force of a chimney:

- By the smoke. The most obvious sign that there is no draft is the presence of even slight smoke inside the room; a large amount of smoke indicates a high risk of fire and carbon monoxide poisoning.

Note! The draft inside the chimney duct is created due to the difference in pressure outside and inside the room. In a heated room, the temperature is higher than outside, so there is more pressure there. Heated air, supported from below by colder air, is squeezed into a zone with lower pressure, that is, into the atmosphere. If you take measurements in the summer, when the temperature difference between inside and outside is minimal, you will get a lower result than in winter.

Solving problems yourself

Let's try to make the heating process safe and efficient with our own hands. The most common way to combat soot accumulation in pipes is with a brush and a sinker.

Cleaning the pipe with a brush

First, let's prepare everything you need:

- A hard bristle brush. The diameter of this device is selected taking into account the cross-section of the pipe (from fifty to three hundred millimeters).

- A thin metal cable (can be replaced with a very strong rope or rope).

- Weight for hanging from a brush.

This is what a device for cleaning a chimney pipe looks like

Do not start work if there is strong wind or too much humidity outside. Try to think through and use reliable insurance to protect yourself from unforeseen events.

The ruff is weighted using a sinker, attaching it to the bottom of the device. The brush itself is hung on a cable. All fastenings must be especially reliable, otherwise the structure will fall apart and you will have to perform additional actions - to “fish” them out of the pipe.

First, all inspection holes in the chimney are cleaned, and then they begin to clean the pipe itself. By making a few up and down motions, you can get rid of any soot that will fall from the chimney into the furnace. It is best to have someone else around the stove to signal efficiency and when to stop working.

Cleaning the pipe should be completed when the soot stops falling out.

You can also clean the pipe using improvised means, about which many videos have been made.

Video: cleaning a pipe with improvised means

Causes of malfunctions

After making sure that there is not a sufficient level of draft inside the chimney system, you need to determine and eliminate the possible cause of this defect. Experienced craftsmen claim that the most common causes of failures in smoke exhaust ducts are:

- Design error. The choice of chimney pipe should be made based on the volume of the firebox. If the diameter is less than the calculated parameter, the weak one will not allow smoke to escape from the room.

- Insufficient pipe length. A pipe length of less than 5 m does not provide a significant difference between the pressure indoors and outdoors, which results in weak draft.

- Incorrect placement of the chimney pipe. I advise stove technicians to lay the chimney vertically, as narrow turns trap smoke inside the chimney, reducing draft.

- Long horizontal sections. If, when laying a chimney, you cannot avoid horizontal sections, then make sure that their length is no more than 100 cm. Otherwise, it will need an amplifier.

The first step when detecting problems in the chimney system is to dismiss the most obvious causes of insufficient draft. When inspecting, make sure that the connections of all pipe segments are tight and that there are no soot blockages. Check that no moisture has entered the smoke exhaust ducts and that the atmospheric pressure is normal.

Conclusions and useful video on the topic

The video will talk about how to make a ventilation deflector yourself:

So, for the full functioning of the ventilation system, it is recommended to extend the air duct above the roof level and check the vertical location of smooth, hard, wide ventilation pipes.

It is also necessary to check the operation of the supply ventilation or fix the nozzle on the head of the shaft - the simplest models of the deflector can be made independently; each master chooses the method that suits him to increase traction.

Have you ever encountered insufficient draft in the ventilation duct and how did you manage to cope with this problem? Please share your experience with other visitors to our site. The communication block is located below.

Ways to increase traction

If the draft force is in the chimney duct of the heating device, eliminating this defect is not always easy. Experienced stove makers use the following methods and methods to increase it:

- The first thing to do if you suspect insufficient draft in the chimney is to clean the pipe. To do this, call a chimney sweep or remove soot deposits from the inner surface of the chimney with your own hands using a metal stove brush.

- A significant increase in the power of the chimney can be achieved by increasing the height of the chimney above the roof surface by adding several additional segments. Using the same method, the chimney is removed from the zone of wind pressure from a ridge or higher building.

If you were unable to find a solution to the problem of lack of draft inside the smoke exhaust duct on your own, seek advice from an experienced stove maker who will tell you what to do and correct the defect in the most rational way.

Options for connecting a brick chimney to a sandwich pipe

According to fire safety regulations, the connection between a brick chimney and a sandwich duct must be sealed and well insulated. This transition can be mounted using several different devices.

With adapter

The easiest way to install a transition from a brick pipe to an iron pipe is to use a ready-made metal adapter. Its lower part is square, corresponding to the standard dimensions of a brick channel. The top one is round, the diameter of a sandwich. The finished adapter is already filled with a reliable heat insulator and complies with all fire safety rules and requirements.

The square part is installed on a brick section so that the masonry is inside the box. The remaining gaps are filled with building material for masonry

The sandwich pipe is mounted on top, also inserting it inside the adapter. The gap is sealed with sealant and further strengthened with a tightening clamp.

Without adapter

The transition without using a ready-made adapter is carried out by installing a metal platform on the brick part of the chimney. The dimensions of the platform are exactly along the outer edge of the brick channel section.

A hole is cut out in the center of the metal platform equal to the outer diameter of the sandwich pipe into which it is inserted.

The platform should be firmly fixed to the top of the brickwork. To do this, holes are prepared in the metal for self-tapping screws. Holes for dowels are drilled in the brick, symmetrically. Before fastening, the platform is coated with oven sealant and laid on the brick. Secure with self-tapping screws.

Installation of the external part of the pipe

The external one can be assembled from other materials.

The transition of the “sandwich” pipe to the outer part is assembled taking into account the parts used. The main rule that must be followed is that each joint must be completely sealed. Smoke tends to seep into any crack, which is fraught with negative consequences. If combustion products are not completely removed from the premises, this will negatively affect the health of all residents. Smoke will also negatively affect the condition of the house, having a destructive effect on all elements with which it interacts.

A “sandwich” on a brick pipe is one of the most common types of joint. This is not surprising, given that such an external chimney has the best durability and is simple to design and construct. The brick is well protected from damaging atmospheric influences and is adapted to work with high temperatures. Now we are talking specifically about heat-resistant bricks, which are used in the construction of fireplaces, stoves and chimneys.

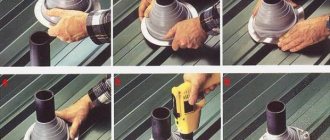

Step-by-step DIY connection technique

Video: installing the adapter and passing the ceiling:

Let's look at how to properly install a vertical sandwich pipe on an old brick channel.

- The unusable part of the brick chimney is dismantled.

- Prepare the adapter for installation: bend the bends, cut off the outer rim at the bottom.

- Using the lower pipe, insert the mounting pad into the channel of the old chimney onto the stove mortar and secure it to the bricks in the corners with dowels.

- Then the first segment and subsequently the entire pipe assembly are installed in the upper pipe.

Required tools and materials

- For dismantling you will need a hammer drill, a chisel, and a heavy hammer.

- To cut a hole in the masonry, use a circular saw.

- For installation and fastening - oven mortar, trowel, sealant, screwdriver, self-tapping screws.

Work progress

Often the portion of the old brick channel in the house remains in good condition. Therefore, the outlet in the attic and roof is dismantled.

In this case, dismantling begins before reaching the ceiling 20 cm, preparing a flat surface for the adapter.

The gaps between the nozzle and the brick are sealed with heat-resistant sealant.

A fire-resistant platform is made in places where there is a passage through the attic and the roof.

The assembly connections of the sandwich, if provided for by the manufacturer's instructions, are additionally secured with clamps.

On the roof, the pipe is fixed using a special roofing element, sealed with a silicone nozzle, and the external design of the chimney is made.

Installation features

If the brickwork has to be dismantled close to the brick kiln, then it is better to make a thick-walled single steel pipe made of stainless steel as the first link of the transition chimney. This area, especially in sauna stoves, is characterized by high temperatures during peak loads. The pipe with insulation will overheat and quickly burn out.

To protect the chimney from wind and rain, improve draft and remove smoke, a deflector is placed on top of the chimney, securing it with galvanized screws.