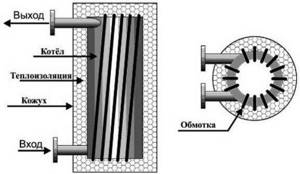

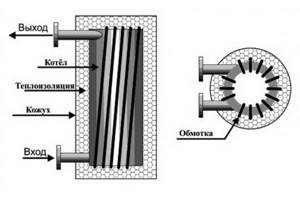

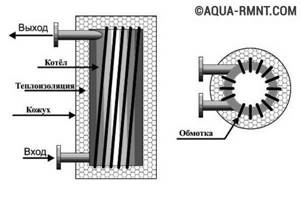

The internal one is a sealed cylindrical container in which the coolant is directly heated. There is nothing in this tank except water, 2 pipes through which cold and heated liquid passes.

The middle circuit includes a powerful induction coil, the turns of which are made of thick insulated wire. High frequency alternating current is passed through it. This circuit is wrapped around a water tank in the form of a torus or cylinder. The first version of the equipment has greater efficiency and less weight.

The outer contour also performs important functions of housing protection and thermal insulation. It prevents workers from accidentally touching dangerous wires. To increase energy efficiency, the external circuit is highly insulated and an electrical converter is used. Inverters produce current with a frequency of 20 kHz of increased power.

Operating principle and design features of inverter-type boilers

The ability of electromagnetic radiation to increase the temperature of materials placed in its field of action was discovered back in the century before last. The principle of operation of electromagnetic induction, which is used by an inverter electric boiler, was discovered by Faraday in the 19th century. The same principle is used in many household appliances (induction hobs) and in industry (heating metals in various technological processes).

What does a boiler of this type consist of and how does it actually work:

- The main element of the design is an inductive coil, which, when an electric current passes through it, creates a magnetic field around itself.

- Inside the inductor (solenoid) there is a pipeline through which the coolant circulates (in most cases, ordinary water).

- This entire structure is placed in a sealed housing, which in some cases can be additionally insulated.

These are, in principle, all the main structural elements. Of course, the boiler is equipped with means of monitoring operating modes, control systems and ensuring safe operation.

Now consider the operating principle itself, due to which water is actually heated in the heating system:

- As already mentioned, when a current of a certain (high) frequency passes through an electromagnetic coil, an electromagnetic current occurs.

- Under its influence, so-called eddy currents (Foucault currents) arise in the materials placed inside the coil (in this case, a pipe with a coolant).

- It is under the influence of Foucault currents that the pipeline and the water passing through it are heated.

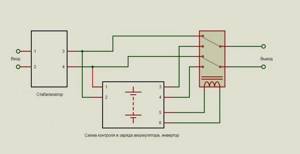

Diagram of the inverter heating boiler

What does the inverter have to do with it, you ask, and you will be absolutely right. The fact is that the inverter itself is an auxiliary equipment. Its main purpose is to increase the frequency of the current, because for the inductor to work, it is precisely high-frequency indicators of electricity that are needed. At its core, an inverter is a regular frequency converter. Therefore, it is more correct to call an inverter boiler induction (according to the principle that is used).

How does an induction heater work?

Very simple.

Apply operating voltage to the coil. An electromagnetic field is created in the coil. Then we read carefully - here is the essence of his work: The electromagnetic field induces Foucault currents or eddy currents in the heating pipe and the metal pipe begins to heat up.

If anyone doesn’t know, the transformer’s magnetic circuit is specially assembled from many thin plates of electrical steel, insulated from each other.

This is done precisely to avoid energy losses from heating by eddy currents.

The fact is that the more massive the conductor, the more it will heat up from Foucault currents; in turn, the force of influence of eddy currents can be increased by the rate of change in the magnetic flux.

Did you know that a power transformer with a voltage of 110 kV at idle, even without load, produces a thermal power of about 11 kilowatts?

This is mainly due to the influence of eddy currents, which heat the magnetic circuit on which the primary and secondary windings are mounted.

At the same time, it is magnetically conductive, but if it were solid, then the heat losses would increase many times over!

And the transformer would simply burn out from overheating.

An induction electric boiler works on the same principle and the steel pipe with water running inside the coil gets very hot, BUT! - due to the circulation of water, the heat has time to be removed from the pipe into the heating system and overheating does not occur.

But can it be more economical compared to electric boilers using heating elements? Due to what?

Let's first think about these two types of boilers without analyzing and comparing them:

There is a house

It doesn’t matter which one and it doesn’t matter where. Either underwater or on Everest

This house has a heat loss of 6 kilowatts.

Through walls, through windows, through the ceiling, etc., heat is lost and in order to maintain a constant temperature, it is necessary to compensate for these heat losses and for this, naturally, 6 kilowatts of heat are also needed.

And it doesn’t matter where and how this heat comes from, this thermal energy - 6 kilowatts - even if you burn a fire, even gas, even gasoline, the most important thing is that these necessary kilowatts of heat are released!

Now the most important thing:

To heat such a house you will need either an induction heater or an electric boiler with heating elements - still with a power of at least 6 kW.

In other words, the boiler simply converts electrical energy into thermal energy.

And how he does this is completely unimportant, because for us the most important thing is that the house be warm. Energy is simply converted from one type to another, from electrical to thermal

And if you allocated a 6 kW heat boiler, then you took at least the same amount of electricity from the network, and given that the efficiency of the boilers is not 100%, then even a little more energy is consumed from the network

Energy is simply converted from one type to another, from electrical to thermal. And if you allocated a 6 kW heat boiler, then you took at least the same amount of electricity from the network, and given that the efficiency of the boilers is not 100%, then even a little more energy is consumed from the network.

Then maybe the efficiency of an induction boiler is higher? According to manufacturers, this value reaches 98%.

The same is true for an electric boiler with heating elements. Their efficiency reaches 99%.

Well, think for yourself - where else can the energy in the heating element go except to be released into heat?

All energy consumed from the heating element network is converted into thermal energy. I took 5 kW and released 5 kW of heat.

I took 100 kW and released 100 kW of heat. Well, maybe a little less if you take into account the energy loss in the transition resistance at the heating element’s terminals, but again, this energy loss is released in the form of heat (the clamp gets hot) and in the supply cables.

But both the clamps and the cable cross-section are the same in parameters for both the vortex induction electric boiler and the heating element.

Pros and cons of inverter boilers

The assessment of any equipment is carried out on the basis of a comparison of advantages and disadvantages, so it is worth considering all the factors characterizing the operation of an inverter boiler.

Let's start with the advantages:

- Small overall dimensions. At its core, an inverter boiler is a closed cylinder of a relatively small diameter. Thanks to this, such a unit can be installed in an ordinary kitchen; it does not require large rooms, a chimney, and there are no requirements for ceiling heights or other conditions that must be observed when using gas equipment.

- The high thermal power and minimal inertia of the equipment allows the coolant to heat up very quickly, so there are no problems with creating a comfortable atmosphere in the room.

- The fire safety of equipment of this type is in many ways superior to that of gas and solid fuel equipment.

- Possibility to use various coolants. The unit is capable of working with both water and oil heating systems.

- Very high efficiency, for many models it reaches 97-98%.

- The cost-effectiveness of the equipment allows you to significantly reduce the cost of paying bills (compared to conventional electric boilers).

- The simple design guarantees the durability and reliability of the boiler.

Now let's look at the existing disadvantages:

- The most important thing is the high cost of this type of equipment; such boilers cannot be classified as budget models.

- Can only be used in closed heating systems.

- The use of an inductance coil leads to a significant increase in the mass of the unit; it can only be mounted on solid walls.

That's basically all the main disadvantages. That is why the use of inverter boilers is considered advisable if it is impossible to operate equipment on natural gas. In addition, you can assemble an inverter boiler yourself; it is enough to have certain skills in working with metals and electrical equipment.

Vortex Induction Heater

A vortex induction heater (VIN) is a type of induction cooker. It consists of a coil, a magnetic core and a heat exchanger. Alternating current flowing through the coil creates an alternating magnetic field. If a conductive material is placed in this field, it will heat up. The main advantage of VIN is that the inductor temperature does not exceed 140 degrees C. In addition, the alternating magnetic field counteracts the formation of scale. Unlike a vortex heat generator, the operating principle of a VIN fits into the laws of physics. The efficiency of a vortex induction heater is close to 100%, which gives it the right to use in heating systems and other liquid heating systems. However, what do the sellers of vortex induction heaters promise us? And this is where miracles begin. They promise savings of up to 50% compared to conventional heating elements. That is, either the efficiency of the heating element is 50%, or the efficiency of the VIN is 200%. Let's try to figure it out. Your humble servant was not lazy and called several companies selling vortex induction heaters. The most important question that was asked was: what advantage will I get by paying quite a lot of money for this device? Here are the answers I received:

- We have a lot of sales and everyone is happy

Fantastic reliability and durability

Savings up to 50% compared to heating elements

No noise

Well, you can argue with the first and second statements. Regarding noise, heating elements do not make noise either. But, with savings, this is interesting. It turns out (according to sellers), the formation of scale on the heating element reduces its efficiency. Accordingly, the efficiency of VIN is due to its constant efficiency compared to heating elements. But excuse me, how does scale reduce the efficiency of heating elements? Let's remember the law of conservation of energy. Let's say we supplied 1 kW of electrical power to the heating element. Accordingly, we should receive 1 kW of thermal energy. If we receive less heat, then the remaining energy must be released in some other form. I don’t remember that heating elements in water glowed or emitted, say, electromagnetic waves. Undoubtedly, scale reduces the heat transfer of the heating element, but this does not in any way affect its efficiency. With a decrease in heat transfer, the temperature of the heating element itself increases, and, consequently, its electrical resistance increases. As the electrical resistance increases, the power consumed by this heating element decreases. In fact, the change in temperature and power consumption is so small that the average user won't even notice it. Will the kettle boil in a minute or in a minute and 5 seconds - does it matter? At the same time, the amount of electricity required to heat a kettle of water will remain unchanged. However, VIN sellers are trying to turn the situation upside down and talk about a decrease in efficiency.

Thus, VIN can be an alternative to heating elements, but it will not provide any savings. There are no miracles. And as for “fantastic reliability”, for the money that VIN costs, you can buy several electric boilers and arrange a backup. Reliability will be several times higher.

Features of installation of inverter boilers

In order for the inverter boiler to provide efficient and safe heating of the room, you should remember some installation nuances:

- Like any electrical equipment, the inverter boiler must be reliably grounded.

- Do not install the device in close proximity to flammable objects and materials. The distance to other equipment should provide access to all components for repair and maintenance work.

- To ensure the operation of the heating system, it is mandatory to install an expansion tank. In addition, it is advisable to install a booster pump that can increase the productivity of the device and ensure heating efficiency.

- The boiler can only be connected using a separate wiring line, which must have a cross-section corresponding to the power.

- The use of an RCD is considered mandatory; only in this case is safe operation of the equipment possible.

How to calculate boiler power

A number of factors influence the final capacity of the installation. On average, ceilings up to 3 meters high are accepted. In this case, the calculation comes down to the ratio of 1 kW per 10 m2, in a climate typical for the middle zones. However, for an accurate calculation, consider the following number of factors:

- the condition of windows, doors and floors, the presence of cracks in them;

- what are the walls made of?

- the presence of additional insulation;

- how the house is illuminated by the sun;

- climatic conditions;

If you have blowing from all the cracks in your room, then 3 kW per 10 m2 may not be enough for you. The path to energy saving lies in the use of quality materials and compliance with all construction technologies.

You should not take a boiler with a large reserve, this will lead to high energy consumption and financial costs. The margin should be 10% or 20%.

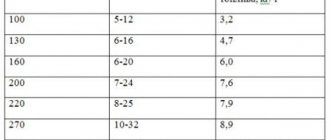

The operating principle also affects the final power. Take a look at the comparison table, it will certainly help you:

The most popular models of inverter boilers

Products from domestic manufacturers are quite widely represented in this segment. Experts recommend paying attention to the following series.

The VIN brand offers inverter boilers with a power from 3 to 45 kW, which can also be used in hot water supply systems.

Suitable for an apartment or small house:

Inverter boiler VIN-7

- Power 7 kW.

- Capable of heating a room up to 80 square meters.

- The cost of such a boiler is approximately 5-60 thousand rubles.

Miratron A boilers are no less famous. This series offers units with a power of up to 30 kW:

Model of inverter boiler Miratron A009

Boiler Miratron A009

- Enough to heat a house up to 120 square meters.

- Power consumption is 9 kW,

- The average cost of the device is 55,000 rubles.

If you are looking for modern, efficient equipment for electric heating systems, be sure to pay attention to inverter boilers. Investments in this type of technology are justified and advisable.

Vortex induction heater VIN Useful DIY

It turns out that this mysterious VIN heater is very simple and can be easily assembled right at home. Let's briefly consider the principle of operation.

The operation of such heaters is based on the heating of conductive materials by Foucault currents, which are induced by a high-frequency magnetic field. The resulting thermal energy is taken by the coolant (water, oil, etc.) and used, for example, to heat a room.

As you can see, nothing complicated. Now let's see how I managed to put all this into practice.

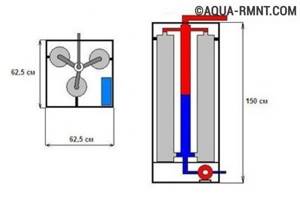

In order not to create unnecessary complications, I decided to use a ready-made high-frequency welding inverter with a welding current of 15A (I had a sample with the ability to continuously adjust the current). You can, of course, take something more powerful. It all depends on the required heater power. Since I was just conducting an experiment, I took the high-frequency inverter that was available.

As a material that will be heated in a high-frequency field, I decided to use pieces of thick steel wire. I was able to get a wire rod with a diameter of 7 mm and bit it into pieces of about 5 cm. If you do everything for centuries and for yourself, then you can get scraps of stainless steel, although if the heating circuit is always full, then this is not necessary. Even ordinary iron will not rust.

As the section of the pipeline where the water will be heated, I decided to use a thick plastic pipe. The internal diameter should be chosen slightly smaller than the length of our wire scraps. We attach an adapter to one side of the pipe to connect it to the rest of the heating system, lay a metal mesh on the bottom (so that the pieces of wire rod do not fall further) and pour our wire inside. Then we close the free end of the pipe with the second adapter in the same way. You need to pour in so many wire scraps so that they occupy all the free space there.

Now let's make the induction coil itself: to do this, we simply wrap the middle of our plastic pipe with scraps of wire rod with copper enameled wire turn to turn (PEV or similar). For my inverter, 80-90 turns of wire with a diameter of 1.5 mm will be enough.

That's basically all. All that remains is to connect our device to a break in the heating circuit, fill the whole thing with water, connect a welding inverter to the winding and turn on the pump (to ensure forced circulation of water in the system). Of course, it is highly not recommended to turn on the inverter without water, since in this case our plastic pipe is guaranteed to melt from the heated pieces of wire inside.

Thus, in a matter of hours, I was able to assemble a working vortex-induction heater from scrap materials. By the way, it is very economical - if you believe what they say, its efficiency reaches as much as 98-99%!

You can not stop there and, in order to further increase efficiency, organize cooling of our inverter with the same coolant from the heating circuit. True, this only makes sense if the inverter circuit itself is located outside the heated room.

You can also organize automatic temperature control. To do this, you just need to get a thermostat and connect it to the inverter power supply line, and place the thermostat sensor in the controlled area.

I did all this a long time ago, but I’m writing about it only now (at the urgent request of one friend), so there will be no photo report. I’ll be honest, I only assembled the heater itself, I didn’t turn it on anywhere, I didn’t try to heat anything with it. Yes, I didn’t even have a pump. I just poured water inside and turned on the device. The water quickly heated up to boiling point. So, as you can see, the described method for making VINs really works and there is nothing complicated about it.

Design and principle of operation

To explain how this boiler works and how it works, we must first recall how conventional electric boilers work. In them, the coolant is heated by special tubular heating elements (heating elements), which are in direct contact with the coolant. The temperature in the heating system also depends on the power of the heating element used.

Inverter (induction) boilers operate on a completely different principle, which is based on magnetic induction. Hence the completely different design of the device. Let's take a closer look at it.

The main element of the device is a transformer (inverter, inductor), hence the very name of the heating boiler. The transformer has two coils (windings), each of which is responsible for its own function.

- The primary, which is the boiler body itself, is short-circuited.

- The secondary is constantly energized. It is this that closes on the supply of electric current. This winding is called an inductor.

The boiler has two pipes for the coolant inlet and outlet. When an energy carrier is supplied to the secondary coil, a magnetic field is formed, which emits a fairly large amount of thermal energy. Water passing through a magnetic field heats up. This is a simple explanation of how an inverter heating boiler works.

Now about the device. Since the secondary winding can be located differently, the design of the inverter boiler can accordingly be different. It all depends on which direction (horizontal or vertical) the coil turns will be located. For example, the basis of the heat exchanger is an ordinary metal pipe, which is installed vertically in relation to the turns of the winding. That is, in order to heat this pipe through which the coolant will move, you just need to wrap it around the perimeter in the form of a coil from top to bottom or vice versa. In this case, the direction does not matter.

This design will be long but narrow in size. Essentially, you end up with a pipe within a pipe, because the heat exchanger must be well insulated by enclosing it in insulation and an outer casing (usually metal). But you can also propose a completely different design, although in terms of its purely design features it exactly repeats the previous one. A distinctive feature is the induction coil, which not only wraps the heat exchange pipe around the perimeter, but captures it along its length. Each turn completely covers the length of the device. This is a more complex system, but we will not claim that it is more effective. We simply propose several modifications for consideration.

Advantages and disadvantages

Let's start with the advantages, because from the very design of inverter boilers it becomes clear that they are, first of all, much more economical than traditional electric heating units. And this is probably their most important advantage. But there are other advantages:

- Complete absence of a heating element in the truest sense of the word. This means that the service life of the device increases significantly.

- Reduced requirements for the quality characteristics of the coolant. Since the secondary induction coil does not come into direct contact with the coolant, it does not receive any negative impact from it.

- Low heating inertia. This allows you to increase the efficiency even in heating systems where a circulation pump is installed.

- It is possible to make a homemade inverter (induction) boiler. More on this below.

And a few negative points.

- Whatever you say, inverter-type electric boilers are more expensive than conventional heating elements.

- If you decide to install an inverter-type heating boiler to heat a large country house, you will have to choose an induction boiler that is huge in size and weight. Because the number of turns in its secondary coil must be large. This is the only way to heat a large volume of coolant in the system.

- In addition, it is very difficult to regulate the power of the device and the temperature of the coolant in this model, so these boilers are equipped with a complex automation system.

A few words about homemade inverter (induction) heating boilers. There are a huge number of different designs that are publicly available on the Internet today. Craftsmen make them from different materials according to different drawings and advertise them as the cheapest and most reliable units. Let's just say that among them there are actually worthy ones, with guaranteed quality and high safety indicators. But the bulk of the designs are untested devices without guarantees that are scary to use in the heating system of a private home.

Do not forget that heating systems most often use water as a coolant. Incorrect assembly of the device can lead to a short circuit. It’s good if the coil just burns out without causing harm to people. Therefore, we recommend that if you are not experts, then you should not create another headache for yourself. It is better to buy a ready-made factory version. This is both high quality and guarantees of long-term operation and safety. published econet.ru

If you have any questions on this topic, ask them to the experts and readers of our project here.

Did you like the article? Write your opinion in the comments. Subscribe to our FB:

Solar collectors

The essence of solar collectors is to collect, store and transfer heat from the sun. Solar energy can be used freely and endlessly; it does not require extraction or transportation. There are two main types of collectors - flat and vacuum.

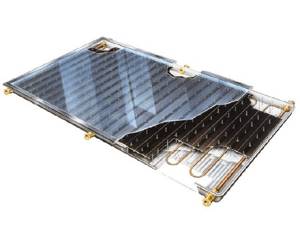

Flat-plate collectors

Flat solar collector

The design of flat-plate solar collectors is a heat-insulated panel located under glass, inside of which there is an absorbing plate. It is she who accumulates the energy of the sun. However, even taking into account the thermal insulation of the bottom and side walls, in winter the charge level is much lower due to heat loss. Flat-plate collectors are less suitable for temperature changes, but are more widespread due to their low cost.

Vacuum manifolds

The structure of vacuum solar collectors involves several vacuum tubes converting sunlight into thermal energy. The tubes themselves are similar to a regular thermos and consist of several glass tubes built into each other. The outside of the tubes is translucent, and inside there is a material that collects sunlight.

Vacuum manifolds

Collectors are located on the roof and/or walls of the house. Vacuum solar collectors are much better protected from temperature changes and absorb heat better, which is why they are suitable for operation in cold weather.

Voltage converter for heating boiler types and features

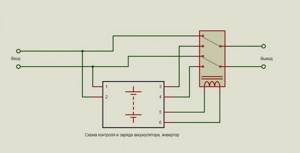

If an electric or gas boiler is used for a closed heating system in a personal home, then if there is an interruption in the supply of electrical energy, the heating of the premises will naturally be stopped. To avoid such an unpleasant phenomenon, a special device was invented - a voltage converter for a heating boiler, which converts the stable battery voltage into a sinusoidal voltage of 220 volts with a frequency of 50 Hz.

Specifications of voltage converters for gas and electric boilers

The voltage converter is part of an uninterruptible power supply (UPS) for volatile systems. IBNs duplicate electrical power, which significantly improves the reliability of heating equipment. These emergency power supply devices turn on quickly when the voltage level drops or when there is no voltage at all.

Why is it needed for a gas boiler?

If you do not focus on energy independence, then a fully functional modern gas boiler requires a connection to the electrical network to power a control board with a controller, a circulation pump and a group of control units that can be distributed throughout the house. Such a set of equipment allows you to completely and accurately control the heating of the house, raising the heating to a higher level, ensuring high comfort of life in the house. If this is the case, then when the power goes out, the heating, unfortunately, stops completely.

In order not to be left without heating, you should provide in advance a backup power source for the gas boiler and all auxiliary equipment. Options include: gas or diesel (gasoline) generator, uninterruptible power supply (UPS) or inverter.

Installing a generator requires large capital investments, which is why UPSs and inverters have become more widespread. In them, electricity is stored for future use in batteries and, if necessary, given to the load, the boiler. More often than not, if the electricity goes out, it’s not for long, so the energy stored in the batteries is quite enough to keep the boiler from stopping and the coolant from cooling down.

The main requirement for any backup power source for a gas boiler is a stable sinusoid and output voltage amplitude. The gas boiler does not have any converters or stabilizers of its own, so any surges or deviations will affect the quality of the controller and sensor readings. The shape of the sine wave is critical for the circulation pump. The more regular the sinusoid shape, the more stable the current frequency. The better the pump works.

Household and computer UPSs produce a signal only partially similar to a sine wave, more like alternating rectangular pulses. For the intended purposes, this is enough; computer and office equipment have their own power supplies that convert the input voltage.

Putting all of the above together, it becomes clear why uninterruptible power supply units and inverters for heating boilers are designed and manufactured separately and with increased requirements for the characteristics of the output signal.

Inverter home heating, what and how does not stop working

1. Design of inverter heating boiler

2. Pros and cons of inverter heating 3. Installing an inverter boiler with your own hands 4. Independent power sources

The heating system is considered one of the most important components of every home, since it is impossible to talk about comfort in an unheated house. Heat supply is considered very important in cold climates. The choice of heating system depends on most indicators, but the key ones are efficiency and economy. Very often, heat supply is used for six months, and in certain regions - all year.

Compared to most types of heating systems, inverter heating boilers stand out as a bright spot, which stand out with an unlimited number of indicators. Inverter heating belongs to the category of devices that use electrical energy to heat a house. Basically, the majority of electric heating structures consume a very large amount of energy, so manufacturers are putting every effort into increasing the efficiency of these systems. This publication will discuss the working principle and specifics of inverter heating. In an inverter boiler, the heating medium is heated by converting electricity into heat; in the end, the batteries are heated from the network. The boiler consists of two circuits: magnetic and heat exchange. The magnetic circuit is considered to be a coil of conductor attached to a dielectric. This circuit creates an electromagnetic field that acts on a metal core installed in the heat exchange circuit. The core itself transfers the resulting heat energy to the thermal carrier. Heating voltage converters are one of the most promising types of heating devices, which can be used both for heating personal homes and as a heater for industrial buildings.

Pros and cons of inverter heating

The list of differences is quite impressive:

- The design of inverter boilers has no moving parts or mechanisms, making such devices more resistant to wear. Likewise, the working life of inverter boilers is much longer than similar devices of a different type and in most cases is at least 10 years.

- Inverter boilers have a fairly conventional design, and if necessary, you can assemble it yourself.

- The coolant in inverter boilers heats up much faster than in any other heating system. The reason is very simple: inverter-type devices do not have an ordinary heat exchanger, so all the thermal energy is used to heat the coolant.

- Almost every inverter boiler is capable of working with any type of coolant, since the working parts of the boiler do not come into direct contact with the coolant. The coolant can only influence the characteristics and performance of the heating system, but the boiler will operate normally.

- Inverter boilers are expensive: in comparison with ordinary home appliances, an inverter boiler will cost at least several times more.

- Home inverter boilers are heavy, but the size of such devices makes up for this disadvantage. Moreover, the successful form allows such a structure to be placed virtually anywhere.

- Boiler adjustment is carried out using complex electronic systems that will ensure continuous operation and monitoring of boiler performance. Likewise, despite the ease of assembling the boiler itself, to create the control components yourself, you will have to learn electronics. Installation of electronic systems is considered mandatory, otherwise the equipment may be damaged and break down.

- Inverter radiators do not make noise and are fireproof devices: no fuel is used during operation, which could result in an ignition, and there are no moving parts.

- Such systems are environmentally friendly: since no fuel is used, there are no emissions into the environment that surrounds us, because there are no gaseous, liquid or solid substances.

Myths about induction boilers

One of the most popular myths is created by sales representatives selling induction electric boilers. The bottom line is that these boilers are supposedly 20-30% more efficient than other heating electrical installations, especially heating elements. This information is not true, since all heat generators that convert electricity into heat operate with an efficiency of at least 96% in accordance with the physical law of conservation of energy. The only undeniable fact is that heating elements heat up the coolant a little longer due to their multilayer structure. The tungsten spiral first heats the quartz sand, then the tube material, and then the water. In this case, energy is not lost anywhere, and the efficiency of the heating element unit is 98%, the same as the vortex unit.

Example of a heating system

Another myth is that an induction electric boiler requires no maintenance at all, since the alternating magnetic field prevents deposits from settling on the heating elements. This question depends on the quality of the water and scale appears on the coil core in the same way as in heating element heaters if the coolant is not desalted. Therefore, at least once every 2 years, the heat generator itself and the heating system must undergo a flushing procedure.

Contrary to the assurances of the sellers, the water heater cannot be installed in any room. There are two reasons: the danger of electric shock and the presence of an electromagnetic field around the device. It is better to place it in a technical room with limited access (boiler room).

Heating installations that use eddy currents for heating do have many advantages, especially the heating speed, compactness and durability. How much these advantages justify the high cost of the product - each homeowner will have to decide individually.

Electric inverter heating boiler for a private home

Easy to operate and practical to use, electric heating boilers remain in demand among residents of apartments and private houses, even despite rising tariffs. Such boilers are installed without obtaining a permit and can be of any power. To reduce maintenance costs, an inverter is installed for the heating boiler. In this case, the models are called inverter and differ from standard products in many advantages. Let's take a closer look at all the features of the units.

Types of UPS

According to their design, uninterruptible power supplies are divided into three types :

- Offline UPSs are the simplest class of devices, familiar to everyone from computer uninterruptible power supplies. A control circuit is connected to their input, charging the battery and switching the power relay at the output of the uninterruptible power supply from the external input to the built-in inverter when the external power is lost or its voltage differs significantly from the specified 220 V. Such an inverter is as simple and cheap as possible, but also the least efficient of All types consume the energy reserve in the battery.

- Online inverters for boilers, unlike offline ones, have a built-in stabilizer at the input and, thanks to this, switch to backing up power from the battery only when the network power is turned off. When its voltage deviates from 220 V, the stabilizer operates. This scheme is more expensive, but also more effective when used in a network with strong daily voltage fluctuations (for example, a low-power substation in the private sector). An offline inverter under such conditions will go into standby mode too often, requiring the installation of a separate voltage stabilizer in front of it.

- Line-interactive inverters are the most advanced class of devices. In them, the input voltage is immediately converted into direct current, supplied to the output inverter, and the battery is connected between the blocks. A conventional welding inverter is constructed in a similar way (if you do not take into account the battery). Thus, the supply voltage is always stabilized, and when it is turned off, there is no delay in switching the UPS output from the external network to the inverter.

What are inverter heating boilers?

A standard electric boiler operates from heating elements located inside the housing. The coolant receives heat, which it then transfers to network devices. The power of electric heaters determines the heating mode of the coolant. An inverter heating boiler operates on the principle of magnetic induction - water or other coolant does not come into contact with the heater, so the devices have an impressive service life.

An inductor is needed to convert direct current coming from the network into alternating current. The equipment is installed in gravity, pressure heating systems; the device increases the rate of heating of the coolant; therefore, installation of a liquid dosing unit is required to reduce the device’s need for a heated substance and increase the efficiency of the model.

On a note! Before purchasing an inverter boiler, you should check the endurance of the electrical wiring. Some types of models require a three-phase network, for which a separate cable is provided from the distribution box. An additional protection unit will help with power surges.

Design and principle of operation of an inverter boiler

The design of the equipment looks like a three-circuit diagram, in which all the circuits are nested within each other:

- The outer contour is a housing with thermal insulation material. The sheath is needed to prevent heat leakage and prevent user contact with the wires.

- The middle one is an induction coil wrapped around an internal circuit. Winding insulation limits the transmission of high-frequency current; all mass flows only to the wires. The coil can be made in a cylindrical or toroidal shape. The toroidal shape is two tubes made of a ferromagnetic steel alloy and wrapped with wires. The pipes are located at the bottom and top of each turn. The mass of a toroidal coil is lower than that of a cylindrical coil, but the efficiency is higher.

- The inner casing is a sealed cylinder, inside of which the coolant is heated. Two pipes extend from the cylinder - one for transporting water into the network circuit, the second for the return flow of liquid for heating.

The circuit includes an inverter (current converter), a temperature sensor and an automatic electronic control system. The principle of operation is not complicated - when mains current is supplied, the inverter converts direct energy into alternating energy, then an induction current is generated through a magnetic field, which is used to operate the boiler and heat water.

Important! Rapid heating of the coolant reduces energy costs, which is why inverter boilers are considered the most economical type of electric heaters. Low-power models consume little electricity and operate on mains power or batteries.

What is an inverter?

An inverter is a transformer that converts direct electric current (on average 12 V) from batteries into alternating current and changes the voltage depending on the situation. If electricity is supplied normally, it begins to charge the batteries. If the voltage drops or is turned off, the power from the home network goes to the battery, turning their 12 V DC voltage into an alternating voltage - 220 V/50 Hz.

Compact car inverter

To keep your inverter running properly, you need the best materials and parts. How well the inverter is installed determines how long other components, especially the battery, can operate. The quality of the inverter determines the life of the battery - it will last for 2 years or for as long as 12 years.

Better battery life can be achieved through the use of different components, for example, wind generators or solar panels.

Types of inverter boilers for heating systems

There are two types of equipment - industrial and household models.

- the industrial boiler has increased heat exchanger parameters, a complex system of current converters and high power;

- household inverter electric boiler is a compact device, equipped with a toroidal coil, powered by mains and batteries.

The performance of domestic boilers is lower than that of industrial boilers, but they are cheaper, more convenient and easier to operate. Inverters for gas boilers are available for sale, in which a circulation pump is installed. These are high-power, volatile devices in which installing an inverter will reduce maintenance costs.

Advice! When choosing an inverter for a gas boiler, it is important to calculate the power of the connected energy carrier to take into account the starting current for the pump. To do this, the pump power is multiplied by 3, then by a factor of 1.2-1.3.

Additional power in the form of DC generators will not hurt. They are required if an inverter gas boiler is installed in regions with interruptions in the electricity supply - batteries will not help here, a generator will be useful.

Effective ways to save energy

The most effective way to save money is to install a multi-tariff meter, however, it must be borne in mind that this method already incurs considerable costs for its purchase and installation.

Multi-tariff meter (right)

Power limiters also cope very well with this task. After all, during the day we load the network in surges. The most logical thing would be to heat the house at night from 22:00 to 6 o'clock. For efficient heating operation, use a circulation pump; it is installed in the return network.

Advantages and disadvantages of equipment

The main advantage of inverters is the reduction in maintenance costs for electrical appliances, but there are a number of other advantages:

- Long service life. There are no heating elements or other heaters that can damage the unit.

- Undemanding to the coolant. The induction coil does not interact with the filling; it is allowed to fill the network with antifreeze and tap water.

- Low heating inertia. This quality increases the efficiency of systems with forced and gravity circulation of coolant.

- There is no risk of corrosion since the water does not touch the steel elements. And the inner body of the cylinder filled with water is made of stainless material.

- The ability to switch the unit to batteries guarantees warmth in the house during a power outage for any period.

- The models are used in private houses, apartments, and are built into any heating systems without permits or inspections.

- Manufacturers offer a wide range of devices with different dimensions and power parameters.

Inverter electric boilers operate very quietly; they do not have to be taken outside the living space. A home craftsman can assemble the unit if he has experience and simple tools. In this case, the boiler is formed with any required power, supplemented with pipes for the water storage tank, and other types of necessary parts for modernization.

Advice! Powerful models with performance ratings from 60 kW are installed in a separate room, for example, in a basement or boiler room. A separate cable is provided for power supply; the circuit is equipped with a control and protective response unit.

Induction boilers are more expensive than standard types of electric heaters. When choosing a device, it is important to calculate the indicator, this is approximately 5-15%. If the house area is large, the size of the model will also be impressive, because the number of turns of the secondary coil increases. One-time investments pay off with further savings on maintenance, ease of use and long service life of the devices.

Advice! Each unit is equipped with sophisticated automatic monitoring and control. Making changes to the factory settings will result in equipment failure. If you need to make adjustments to the operating mode, you should entrust the matter to a specialist.

Induction water heater

Induction water heaters have a body and an original electric inductor (transformer) inside it, and its secondary winding is the metal pipe with water itself, in the form of a short-circuited turn.

As a result of the flow of significant electrical currents in it, from the inductively induced electrical voltage in it, this pipe intensively heats up and heats the water in it with its heat.

In a nutshell, how does an induction heater work?

this is a step-down transformer that is installed in a pipe

At first I decided that if the word “induction” is in the name, then heating occurs with high-frequency currents, like in a microwave oven, but it turned out not.

There is no trace of any high frequency, power supply is 220/380 volts, industrial frequency 50 Hertz.

The technology is actually very simple - there is an ordinary coil in a shielded pipe - this is like the primary winding of a transformer, if we draw an analogy with a transformer.

The role of the secondary winding, and at the same time the magnetic circuit, is performed by a metal heating pipe!

Choosing an inverter air conditioner

Although inverter models of air conditioners are significantly more expensive, they, as we have already seen, have many advantages over conventional air conditioners. In what cases is an inverter air conditioner preferable? Of course, they should be chosen when the most stringent requirements are imposed on climate control equipment in terms of comfort and noise level. Only an inverter air conditioner operating in constant mode is capable of maintaining a comfortable indoor microclimate. This air conditioner is best installed in a bedroom, children's room or any other room where comfort and uniform distribution of cooled air throughout the room are of great importance. An additional argument in favor of an inverter air conditioner is its low noise; it will not disturb your sleep with its annoying buzzing.

It is beneficial to install an air conditioner with an inverter when you plan to live indoors for a long time. Because even though the initial investment makes such an air conditioner look like the most expensive, thanks to its long service life and low power consumption, its purchase will more than pay off. An inverter air conditioner is also preferable if you are going to use it to heat the room in winter. An air conditioner without an inverter periodically turns off, resulting in a risk of freezing of the fan of the external unit.

For office, utility or industrial premises where there are no such increased requirements for comfort, it is quite possible to choose a cheaper air conditioner without an inverter. In addition, it is better not to purchase an inverter air conditioner if the stability of the voltage in the electrical networks of your home leaves much to be desired.

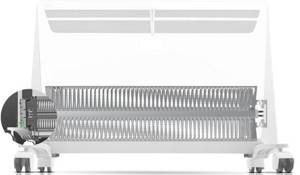

Manufacturers of inverter convectors

The world's first electric convectors with digital INVERTER technology were shown by Ballu, which specializes in the development and production of various climate equipment. Its inverter convectors are capable of achieving energy savings of up to 70% compared to conventional convectors with a mechanical thermostat.

In addition to better energy efficiency, Ballu convectors boast an increased service life (twice) and stability of temperature maintained with maximum accuracy. And this while reducing the load on the power grid.

Ballu convectors differ in power and heating area

These heating modules are combined into the EVOLUTION TRANSFORMER SYSTEM group - they are distinguished by a monolithic heating element HEDGEHOG, which has a service life of 25 years. Its surface is ribbed, due to which the metal heat transfer area is increased by 20%, which gives higher performance and faster heating.

This is what the heating element looks like

And the special trapezoidal shape of the body helps the air to be evenly distributed inside the convection chamber, warming up the room faster.

Selection and calculation of the inverter

When calculating the required output power of the inverter, it must be taken into account that the presence of circulation pump electric motors in the load circuit will cause an increase in both constant current consumption, which determines the so-called power factor of the electric motor (cosine phi), and a significant current load at the time the pumps start. The maximum power consumption should not be more than 75% of the maximum power of the inverter output stage, especially for line-interactive devices in which the inverter operates constantly.

For an example of calculation, let's take a system consisting of a Baxi Fourtech gas boiler and two Oasis 25/2 pumps. Since the boiler electronics itself does not have an inductive load component, we will take its rated electrical power of 130 W into account without correction. The pumps have a rated power of 35 W. If the manufacturer did not also indicate the power consumption (in this case, 60 W), it could be defined as two times the nominal. Consequently, the consumption of two pumps will be 120 W in steady state, setting a double margin for the starting current and summing it up with the consumption of the boiler itself, we get a figure of 370 watts. Taking into account the power reserve for the inverter output stage, we will need a converter with a power of at least 0.5 kW.

If the inverter manufacturer indicates its power in kilovolt-amperes (kVA), you can convert it to kilowatts by knowing the power factor (cos φ) of the inverter itself. So, an uninterruptible power supply with cos φ=0.8 and a power of 1 kVA has a real power of 800 W.

The second parameter when choosing an uninterruptible power supply is the time during which it can supply power to the intended load. When calculating it, it must be taken into account that, on average, the functionality of the UPS output converter is maintained when no more than 75% of the battery capacity is exhausted. For example, if we use a battery with a capacity of 60 Ah, it can actually deliver no more than 45. Then, taking into account the average inverter efficiency of 80%, we get the following:

- The load from the previous example in steady state is 250 W, taking into account the losses in the inverter, we obtain the power taken from the battery at 312 W.

- At a nominal voltage of 12 V, this power means a current consumption of 26 A - a fully charged battery can supply the load for approximately 1.7 hours.

The type of uninterruptible power supply you choose determines both the budget and the features of the electrical network used. If the voltage in the network is relatively stable, it is enough to purchase an “offline” class UPS, but if the voltage fluctuates greatly, it would be more reasonable to either supplement it with an external stabilizer, or immediately buy an “online” or line-interactive class inverter. Since inverters of the required power usually use external batteries, it is worth checking what maximum charging current they can provide.

Considering that the optimal current for charging a battery is 10% of its nominal capacity, a device with a stated charging current of 6 A will work with batteries with a capacity of up to 60 ampere-hours.

Examples of homemade designs

Option #1 - Plastic pipes + welding inverter

Having some knowledge in the field of physics and owning wire cutters, you can assemble a basic induction model yourself.

To do this, you need to purchase a ready-made welding inverter, high-frequency, with continuously adjustable current and a power of 15 amperes, although for heating it is better to choose a more powerful device. Stainless steel wire rod or simply pieces of steel wire are suitable as a heated element. The length of the segments is about 50 mm, with a diameter of 7 mm.

Copper wire can be purchased at the store. It is better not to use winding from old coils

The housing (the base of the induction coil) will also be part of the pipeline, so a plastic pipe is suitable for its manufacture, always with thick walls, the internal diameter of which is slightly less than 50 mm. Two pipes are attached to the body for the flow of cold coolant and the return of heated coolant.

The internal space is completely filled with pieces of wire, covered at both ends with a metal mesh so that they do not fall apart. The induction coil is made in the following way: an enameled copper wire is carefully wound around a ready-made plastic pipe - approximately 90 turns.

The homemade device must be connected to the network. A section of pipe is cut out from the installed pipeline, and a homemade induction boiler is installed in its place. It is connected to the inverter and the water is turned on.

The induction heating boiler is located together with the rest of the equipment - in the boiler room

It is important to note that induction heating boilers only work if there is coolant in the system; without it, the plastic body will melt

Option #2 - design with a transformer

To manufacture this unit, you will need a welding machine, as well as a transformer (three-phase) with the ability to be fixed.

It is necessary to weld two pipes so that they look like a donut in cross-section

This design performs both conductive and heating functions. Then the winding is wound directly onto the boiler body so that it works more efficiently, despite its low weight and size. The coolant heating circuit is standard: it receives thermal energy upon contact with the winding.

Like the simpler option, the complex model is equipped with two pipes - for the cold coolant inlet and the heated coolant outlet

The presence of a protective casing will help prevent loss of thermal energy. You can also make the casing yourself.

Types of devices

There are two types of inverter heaters - infrared and gas. The first type is used for heating residential and utility rooms, as well as cottages and verandas. Such equipment tolerates moisture and precipitation well.

The gas heater runs on natural and liquefied fuel. Its main advantage is its ability to maintain heat over large areas. This is a very productive device that operates with low fuel consumption. It is very easy to use and mobile.

Inverters differ, at a minimum, in heating power

New generation air conditioners

Usually this equipment is associated only with cooling the air in the apartment. But it is not so. Inverter air conditioners can not only cool, but also warm the living space.

Such air conditioners are used in apartments and offices. But if the temperature in the winter is -26 degrees, the device will not be able to cope with heating the room alone. This option will be inconvenient for use in a country house or garage. The air conditioner is environmentally friendly. During its operation, no fuel is burned, therefore there are no emissions of harmful substances into the atmosphere.

Inverter air conditioners have many advantages. The following advantages of the systems are highlighted:

- Adjustment of the desired temperature occurs quickly.

- The device operates almost silently. This is achieved through built-in fans operating at low speed.

- Compared to other models, an inverter air conditioner saves up to 65% of electricity.

- When using the system, the occurrence of drafts is excluded, since there are no sudden temperature changes.

However, each mechanism has its drawbacks. An inverter air conditioner has the following disadvantages:

- Higher price compared to other types of systems.

- Sensitive electronics that respond to voltage fluctuations.

- Inability to turn on the compressor at temperatures of -10 and +42 degrees.

- Difficulty in selecting spare parts.

Equipment Manufacturers

The leader in the production of inverter air conditioners is Japan. It was in this country that such systems were first developed. Daikin produces wall-mounted equipment for residential maintenance. Air conditioners have minimal noise levels and also purify the air. Some models are equipped with a special energy saving sensor. If there is no one in the room for more than 20 minutes, the system switches to this mode.

A large selection of inverter air conditioners is also presented by Toshiba. The models have an original and effective design, suitable for any modern interior. The equipment reaches the set temperature 25% faster than other heaters. The system does not require large amounts of electricity to operate; on the contrary, it is consumed 2 times more economically. The models are equipped with an air filter that allows you to destroy 99% of pathogenic bacteria in the room.

Heating electric boilers for 220 V

What to consider when choosing a heating boiler:

- type of structure;

- boiler price;

- stability of electrical networks and the ability to obtain the necessary power.

If paying for used kilowatts is not scary, and the electrical networks are stable and allow you to get the necessary power, and in the place where you live there is no central heating and gas, and there are also problems with installing a solid fuel device, then 220V electric boilers will help solve this problem.

Select a 220V electric boiler according to the required power for heating a room of a certain area. The calculation formula is as follows. For 10 m2 you need 1 kW of power from a 220V electric boiler with a ceiling height of up to three meters.

Popular models

Currently, there is a fairly large selection of inverters for heating boilers on the Russian market. They can be used in heating systems with any types of heaters.

The most popular models are:

- Energy PN-500 is a floor-standing inverter of a linear-interactive type with a power of 250 W. For uninterrupted operation, an additional battery is required. The unit is small in size and weighs 4.8 kg.

- Energy PN-700N is considered the best wall-mounted unit with a built-in voltage stabilizer. It allows you to ensure uninterrupted operation of the heating system with circulating pumps. This unit can operate at temperatures as low as minus 5°C.

- Energy Pro-1000 is an inverter with quite wide functionality. In addition to working in the heating system, it can be used to power other equipment. For example, for the operation of automatic gates and medical electrical equipment. Widely used in both the private sector and industrial production.

- CyberPower SMP 350EI - in addition to the heating system, this unit can provide electricity to any equipment during an emergency shutdown. You can connect low-power household appliances to it. The device has a fairly fast switching time of 4 milliseconds.

You can also note the following brands produced under the Energy brand: Pro-5000, Pro-3400, PN-1500S, etc.

Why should you buy an electric boiler?

There are many options for heating your home.

The choice depends on the availability of a particular resource and conditions of use. So the gas main may be located away from a private building. In this case, you will not be able to connect gas equipment. Heat generators operating on solid or liquid fuels require special conditions. To store raw materials you need to allocate a specific place. In addition, constant monitoring of the operation of the unit is required. In this regard, the 220 electric boiler is more practical and easier to maintain. Its installation is quite simple, the device works stably and does not take up much space. Of course, the cost of electricity is constantly rising. But this does not reduce the popularity of units of this type. Moreover, today there are energy-saving models.

Many owners of suburban areas prefer boilers powered by electricity.

Some models of these units can provide the room not only with heat, but also with hot water. In city apartments, electric boilers are sometimes also installed. It should be noted that an electric sauna boiler can also be successfully used. There are devices that can be controlled remotely. This way you can turn on the boiler while still on the road, so that upon arrival the bathhouse will already be sufficiently warmed up. Therefore, in many cases, electric heaters are an excellent alternative to other types of heat generators.

Profitable and safe

Finally, it is important to note the high reliability and unpretentiousness of the system. Unlike water heating, convectors do not require regular maintenance; a high class of dust and moisture protection allows the devices to be used in rooms with high humidity

Inverter convectors have passed all the necessary tests and have a fire safety certificate from the Ministry of Emergency Situations.

An analysis of the Electrolux inverter heating system clearly shows a clear benefit when using it. The equipment, as well as its installation, will be cheaper than in the case of using a water boiler. An important factor is flexibility - from individual modules it is easy to assemble a system suitable for a particular home, divide it into zones and control them, including using power limiting technology.