Standards and requirements for room ventilation

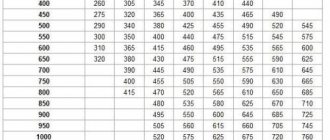

According to SNiP requirements, for residential buildings the required fan performance is calculated based on the air exchange rate. Each household premises has its own standards:

- combined bathroom - at least 50 m³/h;

- bathroom and toilet - from 25 m³/h;

- kitchen - 60-90 m³/h;

- other premises 3 m³/h.

Taking into account the calculated frequency of renewal of the air mixture and the cubic capacity of the room, the required overall performance of the ventilation system is determined.

Calculation of electric motor power for a pump

The choice of electric motor for a pumping installation depends on specific conditions, first of all, on the water supply scheme. In most cases, water is supplied using a water tank or a water boiler. Centrifugal pumps with asynchronous motors are used to drive the entire system.

The selection of the optimal pump power is carried out depending on the need for fluid supply and pressure. The QH pump flow is measured in liters delivered per hour and is designated as l/h. This parameter is determined by the following formula: Qn = Qmaxch = (kch x kday x Qav.day) / (24 η), where Qmaxch is the possible maximum hourly water flow rate, l/h, kch is the coefficient of unevenness of hourly flow, kday is the coefficient of unevenness daily flow rate (1.1 - 1.3), η - efficiency of the pumping unit, taking into account water losses), Qavg.day - value of the average daily water flow rate (l/day).

The optimal water pressure should ensure its supply to the specified location, subject to the required pressure. The required parameters of the pump pressure (Hntr) depend on the suction height (Hvs) and the discharge height (Nng), which together determine the indicators of static pressure (Hs), losses in pipelines (Hp) and the pressure difference between the upper (Pvu) and lower (Pnu) levels.

Based on the fact that the pressure value will be equal to H = P/ρg, where P is pressure (Pa), ρ is the density of the liquid (kg/m3), g = 9.8 m/s2 is the acceleration of free fall, g is the specific liquid weight (kg/m3), the following formula is obtained: Hntr = Hc + Hp + (1/ρ) x (Pvu – Rnu).

After calculating the water flow and pressure from the catalog, you can already select a pump with the most suitable parameters. In order not to be mistaken with the power of the electric motor, it must be determined by the formula: Pmod = (kз x ρ x Qн x Нн) / (ηн x ηп), where kз is a safety factor depending on the power of the pump motor and is 1.05 – 1, 7. This indicator takes into account possible water leaks from the pipeline due to loose connections, pipeline breaks and other factors, so electric motors for pumps must have some power reserve. The higher the power, the lower the safety factor can be assumed.

For example, with a pump electric motor power of 2 kW - kз = 1.5, 3.0 kW - kз = 1.33, 5 kW - kз = 1.2, with a power of more than 10 kW - kз = 1.05 - 1.1 . Other parameters mean: ηп – transmission efficiency (direct transmission – 1.0, V-belt – 0.98, gear – 0.97, flat belt – 0.95), ηн – efficiency of piston pumps 0.7 – 0.9, centrifugal 0 .4 – 0.8, vortex 0.25 – 0.5.

How to calculate fan performance

The calculation algorithm is as follows:

- Measure the exact dimensions of the room.

- Multiply the volume by the established air exchange rate.

- The result obtained is the required productivity of the ventilation unit.

Additionally, the cross-section of the air ducts, their geometric configuration, and the resistance of the filter elements are taken into account. The power calculation formula is as follows: L = n*V, where:

- L is the required system productivity;

- n - air exchange standards provided for by SNiP;

- V is the total cubic capacity of the room.

The throughput of the installation is also determined by the diameter of the air channels. Constantly running fans for ventilation must be at least 100 mm.

Calculation of exhaust fan performance in residential premises

Correct calculation of the required performance of the ventilation unit will ensure proper efficiency. To do this, you need to correctly calculate the volume of air, which should be constantly updated. An important requirement for the hood is to ensure a complete exchange of the atmospheric mixture every 15 minutes. According to current regulations, in the kitchen this figure should be at least 9 times per hour.

In the bathroom 5-8 times are enough. To accurately calculate the required productivity of a climate control device, you should know the size of the room being served, which is multiplied by the set air exchange rate. For a kitchen with a volume of 20 m³, the power calculation is carried out as follows: 20x9 = 180 m³/h. This is the minimum acceptable value.

Determining the volume of the room

The cubic capacity of a room is calculated by multiplying the length, width and height. The mathematical formula is as follows: V=a*b*c. The design power of a fan for a bathroom with a volume of 22.5 m³ should be at least 270 m³, which will ensure a complete renewal of the atmospheric mixture every 5 minutes. Additionally, in this room it is necessary to take into account the need to remove water vapor and polluted air. If you perform calculations without taking into account the increased density of the exhaust atmospheric mixture, then the exhaust system may not be able to cope with the load.

For the bathroom and kitchen, it is advisable to choose a fan with a performance reserve to ensure the proper quality of the air mixture in any conditions. The design of the ventilation system also has a significant impact on performance. The corrugated walls of the air duct take approximately 7-9% of the device's power. Losses of filters and noise-absorbing elements are indicated in the accompanying technical documentation. Each right angle of the air duct takes another 2-3% of the power.

Selecting a fan based on the minimum required performance

A certain reserve is included in the design capacity of the ventilation system. In practice, a less productive installation is sufficient. An exhaust fan for a kitchen or bathroom must cope with extreme loads, which include:

- cooking food;

- oven operation;

- taking a shower associated with intense steam formation.

Therefore, the calculation of fan performance is carried out with some margin. Modern models of ventilation systems necessarily have an enhanced operating mode. To ensure the minimum norm under standard conditions, a good air flow and draft in the channel are sufficient.

Intelligent VAV systems can reduce costs and ensure proper sanitation. They have sufficient ventilation and the ability to manually adjust by turning off or limiting air exchange in individual rooms. The required fan performance should not be determined based on a simple formula that does not take into account additional factors. These include:

- The principle of operation of the unit. Modern ventilation systems can operate in standard air exchange or recirculation mode, in which the installation's performance is lower, but it requires more power.

- Placement method. The location of the device in the room also affects the ability to update the atmospheric mixture. The kitchen hood is placed directly above the stove to increase the efficiency of suction of contaminated air.

- Energy consumption. The most economical option is an axial exhaust fan.

In residential premises, a market novelty is often installed - a centrifugal-type device.

Calculation of fan performance for special industrial conditions

When calculating the required performance of a ventilation unit for complex industrial facilities, a technical specification is first drawn up, which includes the expected operating conditions of the climate system. Among them:

- position of the object on the ground;

- the purpose of each room;

- layout and layout of the structure;

- properties of building materials;

- the approximate number of people permanently present inside the building;

- specifics of production and features of technological processes.

Ventilation systems

Elena Galtseva is a design engineer.

Basic formulas used:

1.Calculation of fan productivity: L=VxK

L – productivity that the fan must have in order to cope with the task assigned to it, m3/hour.

V is the volume of the room (the product of S is the area of the room and h is its height), m3.

K is the air exchange rate for various rooms (see Table 1 in the article “how to choose a fan”).

2. To calculate the number of diffusers, use the formula:

N=L/(2820xVxd2)

N – number of diffusers, pcs;

L – air flow, m3/hour;

V – air speed, m/sec,

(air speed for office premises is 2-3 m/sec, for residential premises 1.5-1.8 m/sec;

D – diffuser diameter, m;

3. To select the number of gratings, use the following formula: N= L/(3600xVxS)

N – number of gratings;

L – air flow, m3/hour;

V – air speed, m/sec,

(air speed for office premises is 2-3 m/sec, for residential premises 1.5-1.8 m/sec;

S – live cross-sectional area of the grating, m2.

After drawing up a complete equipment layout, the diameters of the air ducts are determined.

4. Knowing the amount of air that needs to be supplied to each room, you can select the cross-section of the air duct using the formula:

S=L/Vx3600

S – cross-sectional area, m2;

L – air flow, m3/hour;

V – air speed depending on the type of air duct, i.e. main or branches, m/sec.

5. Knowing S, we calculate the diameter of the air duct:

D= 2x √(S/ 3.14)

6.

The power of an electric duct heater is calculated by the formula:

P=Vx0.36x

∆T

P – heater power, W;

V – volume of air passing through the heater, m3/hour (= fan performance);

∆Т – increase in air temperature, 0С (i.e. the temperature difference – external and coming from the system into the room – which the heater must provide).

∆T is calculated based on the customer’s wishes and the availability of the necessary electrical power for this. It is most advisable to take ∆T within 10-20 ºС.

Basic principles:

All rooms in the building are divided into those into which supply air should be supplied (bedrooms, children's rooms, etc.), into those from which exhaust air should be produced (kitchens, bathrooms), and mixed (basements, attics, garages, etc.) etc.). To supply air to those rooms from which the exhaust is mainly produced, for example, shortened doors or special grilles are installed, which allows for sufficient air exchange by flowing air from other rooms of the apartment.

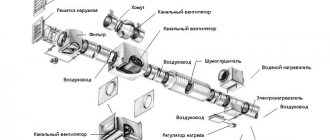

KIV Marta Kolibri Alfa

Today, in addition to simple air-handling units (see figure), units with heat recovery are offered. The heat recovery system consists of two separate circuits; one is where fresh air is supplied to the living space, the other is where exhaust air is removed. The required amount of outside air is supplied by a fan, then it is cleaned in filters. Another fan takes in the exhaust air and directs it to the heat exchanger to transfer the heat of the exhaust air to the external supply air. LMF units (Italy) with a capacity from 900 to 4200 m3/hour have proven themselves very well.

Aventis LMF

Design.

When designing ventilation units, first of all, it is necessary to determine: - the installation location of the ventilation unit - the location of the supply and exhaust openings - the location of the air ducts in the rooms - determine the rooms into which supply air should be supplied, exhaust, and mixed rooms To ensure that odors and residues are avoided in the room harmful substances, the exhaust air flow rate can exceed the supply air flow rate by 10% in systems with mechanical supply. In this case, a slight vacuum is formed, which prevents exhaust air from entering the room.

Air ducts.

In supply and exhaust systems, it is better to use galvanized steel air ducts, since smooth pipes have the least resistance.

The dimensions of the air ducts are determined by the flow of supply and exhaust air (see formula No. 5).

To reduce pressure losses, as well as to prevent aerodynamic noise due to too high air speed, when designing air ducts, the following should be ensured:

- simple and regular arrangement of supply and exhaust shafts;

- the shortest possible sections of air ducts;

- as few bends and branches as possible;

- hermetically sealed connections.

Supply and exhaust grilles.

Supply and exhaust grilles should be located at the top of the walls or on the ceiling. The number of grilles depends on their characteristics and air flow (see formulas No. 2 and 3). Air is distributed into the room through the supply grille, so its design must ensure good air distribution. For good air exchange, it is advisable to place the supply and exhaust grilles opposite each other.

An example of calculating fans for a ventilation system.

The resistance to the passage of air in a ventilation system is mainly determined by the speed of air movement in this system. As speed increases, resistance also increases. This phenomenon is called pressure loss. The static pressure created by the fan causes air movement in the ventilation system, which has a certain resistance. The higher the resistance of such a system, the lower the air flow moved by the fan. Calculation of friction losses for air in air ducts, as well as the resistance of network equipment (filter, silencer, heater, valve, etc.) can be made using the corresponding tables and diagrams indicated in the catalog. The total pressure drop can be calculated by summing the resistance values of all elements of the ventilation system.

Recommended air speed in air ducts:

| Type | Air speed, m/s |

| Main air ducts | 6,0-8,0 |

| Side branches | 4,0-5,0 |

| Distribution ducts | 1,5-2,0 |

| Supply grilles near the ceiling | 1,0-3,0 |

| Exhaust grilles | 1,5-3,0 |

Determination of air speed in air ducts:

V= L / 3600*F (m/sec)

where L

– air flow, m3/h;

F

– channel cross-sectional area, m2.

Recommendation 1.

Pressure loss in a duct system can be reduced by increasing the cross-section of the ducts to ensure relatively uniform air velocity throughout the system. In the image we see how it is possible to ensure relatively uniform air speeds in a duct network with minimal pressure loss.

Copyright 2006-2009 "Atmosphere" Website creation, website promotion - "Serenity"

- Construction market "VASILEOSTROVSKY", St. Petersburg, st. Uralskaya, 10 module 105 - at the entrance from the street. Uralskaya, tel. 448-69-34

- Construction market “Your Home” module No. 1, Vsevolozhsk, Doroga Zhizni, 9a, module 1, tel. (81370) 28763

PHYSICAL COMPONENTS OF CALCULATIONS

According to the method of operation, ventilation circuits are currently divided into:

- Exhaust. To remove used air.

- Inlet. To let in clean air.

- Recuperative. Supply and exhaust. Remove the used one and bring in a clean one.

In the modern world, ventilation schemes include various additional equipment:

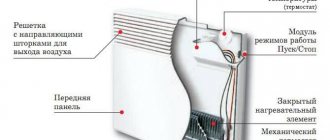

- Devices for heating or cooling supplied air.

- Filters for purifying odors and impurities.

- Devices for humidification and air distribution throughout rooms.

When calculating ventilation, the following values are taken into account:

- Air consumption in cubic meters/hour.

- Pressure in air channels in atmospheres.

- Heater power in kW.

- Cross-sectional area of air channels in sq. cm.

Calculation of engine power formula for compressor

When choosing an electric motor that is most suitable for the operation of a particular compressor, it is necessary to take into account the long-term operation of this mechanism and the constant load. The required power of the RDV engine is calculated in accordance with the power on the shaft of the main mechanism. In this case, the losses arising in the intermediate link of the mechanical transmission should be taken into account.

Additional factors are the capacity, purpose and nature of the production where the compressor equipment will be operated. They have an impact and the equipment may require minor but ongoing adjustments to maintain proper performance.

The engine power can be determined using the formula:

, wherein:

- Q – compressor performance or flow value (m 3 /s);

- A – work to perform compression (J/m 3 );

- ηк – indicator efficiency (0.6-0.8) to take into account power losses during real air compression;

- ηп – mechanical efficiency (0.9-0.95) taking into account the transmission between the engine and the compressor;

- kz – safety factor (1.05-1.15) to take into account factors that cannot be calculated.

Work A is calculated using a separate formula: A = (Au + Aa)/2, where Au and Aa represent isothermal and adiabatic compression, respectively.

The value of the work that must be done before the required pressure appears can be determined using the table:

Typical compressor operation is characterized by continuous operation. Reversible electric drives, as a rule, are absent; switching on and off is extremely rare. Therefore, the most optimal option to ensure normal operation of compressors would be a synchronous electric motor.

Calculation of exhaust ventilation example

Before starting the calculation of exhaust ventilation, it is necessary to study the SN and P (System of Norms and Rules) design of ventilation systems. According to SN and P, the amount of air required for one person depends on his activity.

Low activity – 20 cubic meters/hour. Average – 40 kb.m./hour. High – 60 kb.m./h. Next, we take into account the number of people and the volume of the room.

In addition, you need to know the frequency - a complete exchange of air within an hour. For a bedroom it is equal to one, for living rooms - 2, for kitchens, bathrooms and utility rooms - 3.

For example, calculate the exhaust ventilation of a room of 20 sq.m.

Let's say two people live in a house, then:

V (volume) of the room is equal to: SxH, where H is the height of the room (standard 2.5 meters).

V = S x H = 20 x 2.5 = 50 cubic meters.

Next V x 2 (multiplicity) = 100 kb.m./h. Otherwise – 40 kb.m./h. (average activity) x 2 (persons) = 80 cubic meters/hour. Choose a higher value – 100 kb.m./h.

In the same order, we calculate the exhaust ventilation performance of the entire house.

How to choose the right fan for forced ventilation of the bathroom and other rooms

Forced ventilation using fans is necessary where there is no good natural draft. The selected fan model must correspond in power to the volume of the room and its purpose. Most often, fans are installed in blind rooms without windows: toilets and bathrooms.

Why do you need an exhaust fan?

Exhaust fans are very neat and easy to use

In most apartment buildings, for various reasons, natural ventilation does not work.

The most affected areas are those with high humidity or the release of heat and odors: kitchens and bathrooms.

Here, condensation settles on the glass and tiles, mold appears in the corners, and unpleasant odors spread into the living rooms.

A fan for apartment ventilation will save the situation. It will draw out moist exhaust air and create the necessary air exchange.

In order for the appearance of a fan in the ventilation system to be truly useful, the device is selected for a specific room according to certain parameters.

Too powerful, it will cause drafts that are completely unacceptable for the bathroom. And a weak fan will not cope with its function, wasting the owner’s kilowatts in vain.

Types of fans

bathroom fans with built-in lamp

There are several types of fans on the market for ventilation of domestic premises for various purposes.

Structurally, they are all divided into three types:

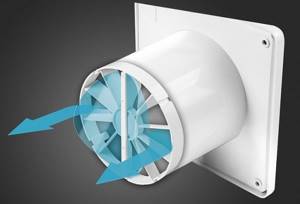

- Axial;

- Centrifugal;

- Duct.

Axial fans are exactly the type that are installed in apartments. Axial fans for exhaust ventilation work very efficiently, are easy to install, and are therefore suitable for premises of any purpose.

Centrifugal fans are commonly used in large industrial systems and for tunnel ventilation. Centrifugal fans are called “snails” because the body resembles a gastropod shell.

They are quite bulky, so installing them in an apartment is difficult. But some manufacturers create compact household models for bathrooms.

This type of equipment is 2.5 - 3 times more expensive than the previous one, but the performance of the ventilation fan is several times higher with the same power.

The intensity of fan operation in a ventilation system depends on the size and shape of the blades. Centrifugal fans create high pressure, reducing losses when air moves along winding networks and even during climbs.

Duct fans for forced ventilation are installed directly into the air duct. There are models for round and rectangular sections. In addition to the main function, duct fans are equipped with humidity and shutdown sensors.

Such devices start when a given level of humidity in the room is reached and stop automatically. Duct exhaust fans are often hidden in a moisture-proof casing.

Therefore, they can be installed in saunas, indoor swimming pools, winter gardens and other damp places.

Silent duct fan

Depending on the location of installation, household fans are divided into:

- for the bathroom;

- kitchen;

- for bathrooms;

- window;

- ceiling;

- high temperature.

Household fans with a check valve are designed specifically for ventilation of kitchens and bathrooms of apartment buildings. The valve prevents exhaust air from returning from the exhaust duct to the apartment.

Irresponsible residents of houses independently insert fans for ventilation of the bathroom or kitchen into the central exhaust duct, causing it to depressurize. Exhaust air from the kitchen or toilet spreads to neighboring apartments.

Therefore, it is advisable to install a fan with a check valve in the kitchen and bathroom.

Household fans with ventilation grilles have a power of no more than 3 thousand cubic meters of air per hour and are built into ducts no more than 400 mm in diameter.

In residential buildings, wall fans are usually used, since the outlets from the ventilation ducts are located in the walls.

Silent fans cannot be called a separate category, but it is precisely by this indicator that home appliances are often selected.

A silent fan for ventilation of rooms is ideal for small apartments. Quiet operation is ensured by the special shape of the blades and their slower movement.

Most often, silent axial fans are purchased for domestic exhaust ventilation.

High-temperature fans are installed in saunas, steam rooms, and fireplace rooms to eliminate steam and smoke from the room. Equipment of this class can withstand temperatures of 70 – 180 degrees Celsius. When purchasing a fan for forced ventilation of a sauna, it is advisable to select a model with additional protection against moisture getting on electrical parts (IP class protection).

In addition to those listed above, there are also corrosion-resistant, spark-proof, smoke removal, dust and jet fans for tunnel ventilation. These are powerful and large devices used in industrial systems. We dwell in detail only on household models.

Criteria for selecting a fan for forced ventilation

Performance is the main indicator that people pay attention to when choosing a fan for ventilation of an apartment. Fan performance is calculated using the following formula:

P = Kv * O,

where Kv is the exchange rate for a given room, O is the volume of the room.

The air exchange rate depends on the purpose of the room; this is a constant indicator indicated in SNiP.

Another 10–15% error is added to the resulting figure.

fan - the main element of exhaust ventilation

The noise level is very important when selecting a fan for ventilation of a small apartment. During operation, any type of fan produces two types of noise: aerodynamic and mechanical.

Mechanical noise occurs when the body vibrates, blades rub, or loose parts rattle. Aerodynamic noise occurs when air moves through air ducts and between fan blades.

The noise level of a fan operating in a residential area should not exceed 25 decibels. For the kitchen, they purchase appliances that produce up to 35 decibels.

Fans for ventilation of the bathroom and toilet may be a little louder, because they turn on for a short period of time. Noise characteristics are indicated in the documentation for the device.

To reduce noise, an insulating box and a silencer are installed. But this option is used in industrial fan systems for ventilation of tunnels.

The degree of moisture protection is an important point when choosing a fan for a bathroom, sauna and ventilation of other rooms with difficult climatic conditions.

Any fan is powered by electric traction, so it is necessary to protect the contacts from the penetration of moisture and steam. Otherwise, there is a risk of electrical short circuit and even fire.

Fans running on 24 V are less dangerous.

heat resistant sauna fan

The degree of heat resistance is taken into account when purchasing a fan for ventilation of rooms with fireplaces, steam rooms and baths. The fan housing must withstand high temperatures, so it is made of metal.

Ease of use is not the last parameter when choosing a fan with a ventilation grille.

You can purchase an electric fan to ventilate any room, which will turn on along with the light. This method leads to unnecessary expenses.

So, after bathing, the bathroom is always very humid. To expel the damp air, you will have to leave both the light and the fan on.

Fans equipped with humidity sensors or timers are more practical for apartment ventilation systems. The sensor starts the engine regardless of lighting and the presence of people in the room, and the timer turns it off after a specified period of time.

Value for money . A powerful and quiet fan for an apartment’s ventilation system can break down without even working for a year. Therefore, pay attention to products from large and well-known manufacturers. They are supplied with quality certificates, guarantees, and special markings that determine the protection of the product. Minimum protection class IP 34.

Don't rely on fan dimensions alone. A very powerful device can be hidden in a small case. And even the price does not always indicate high quality. A good domestically produced device will work for at least 5 years.

Selecting an exhaust fan depending on the purpose

compact centrifugal fan

Household overhead wall fans are perfect for bathrooms and toilets They cope with small areas while saving energy. This device is very easy to install. Part of its body is inserted into the ventilation duct, the other protrudes and is covered with a ventilation grille.

The built-in hydraulic sensor will increase efficiency. It will turn on the engine when the humidity in the room rises and turn it off on its own. It is desirable that the bathroom fan has increased moisture protection. The fan capacity for bathroom ventilation is 60 – 350 cubic meters per hour, depending on the size of the room.

Window fans are installed in a window or in a hole in the wall. Such fans are often installed in shops, hairdressing salons, warehouses, and cafes.

To install a window fan, you need to make a hole in the glass, so installing them in existing plastic windows is problematic. If desired, you can build a fan into the double-glazed window at the stage of its assembly.

The fan instructions indicate the maximum permissible glass thickness. There are supply and exhaust window fans with a round or square profile. Round ones are often equipped with a check valve; it prevents street dust from entering the room.

Most models fall into the silent category; regardless of power, the best models emit no more than 46 decibels. The performance of window fans for room ventilation reaches 1 thousand cubic meters per hour.

There are models with remote control. Window fans are economical and invisible in the interior.

Kitchen fans are installed directly into the hood. When choosing a fan for kitchen ventilation, it is necessary to clarify the degree of heat resistance.

To protect the fan blades from grease and soot, a protective mesh is installed on the side of the room. A container is provided to collect grease and dirt.

An axial fan for kitchen ventilation should be dismountable, this will simplify its cleaning. Most models have several power levels.

After watching the video, you can correctly install the purchased fan:

Source: https://StrojDvor.ru/ventilyaciya/ventilyaciya-v-nezhilyx-pomeshheniyax/kak-pravilno-vybrat-ventilyator-dlya-prinuditelnoj-ventilyacii-vannoj-i-drugix-pomeshhenij/

Calculation of exhaust ventilation for industrial premises

When calculating the exhaust ventilation of a production room, the multiplicity is 3.

Example: garage 6 x 4 x 2.5 = 60 cubic meters. 2 people work.

High activity – 60 cubic meters/hour x 2 = 120 cubic meters/hour.

V – 60 cubic meters x 3 (multiplicity) = 180 kb.m./h.

We choose a larger one - 180 cubic meters / hour.

As a rule, unified ventilation systems are divided into:

- 100 – 500 cubic meters/hour. - apartments.

- 1000 – 2000 cubic meters/hour. – for houses and estates.

- 1000 – 10000 cubic meters/hour. – for factory and industrial facilities.

Calculation of supply and exhaust ventilation

AIR HEATER

In the middle climate, the air entering the room must be heated. To do this, supply ventilation is installed with heating of the incoming air.

Heating of the coolant is carried out in various ways - with an electric heater, the intake of air masses near radiator or stove heating. According to SN and P, the temperature of the incoming air must be at least 18 degrees. Celsius.

Accordingly, the power of the air heater is calculated depending on the lowest (in a given region) street temperature. Formula for calculating the maximum heating temperature of a room with an air heater:

N/V x 2.98 where 2.98 is a constant.

Example: air flow – 180 cubic meters/hour. (garage). N = 2 kW.

Further 2000 W / 180 kb.m./h. x 2.98 = 33 deg.c.

Thus, the garage can be heated to 18 degrees. At outside temperature minus 15 degrees.

Electric motor power calculation

The conversion of electrical energy into kinetic energy is carried out using various types of electric motors. Most often, electric motors serve as electric drives for machines and mechanisms and are used to ensure the operation of pumping equipment, ventilation systems and many other units and devices. In connection with such a wide application, the calculation of electric motor power is of particular relevance. For these purposes, many different methods have been developed that allow calculations to be performed in relation to specific operating conditions.

- Main types of electric motors

- Calculation of electric motor power for a pump

- Calculation of engine power formula for compressor

- Calculation formula for fans

- Calculation of motor starting current

- Operating modes of electric motors

PRESSURE AND SECTION

The pressure and, accordingly, the speed of movement of air masses is affected by the cross-sectional area of the channels, as well as their configuration, the power of the electric fan and the number of transitions.

When calculating the diameter of the channels, the following values are empirically taken:

- For residential premises – 5.5 sq.cm. per 1 sq.m. area.

- For a garage and other industrial premises - 17.5 sq.cm. per 1 sq.m.

In this case, a flow speed of 2.4 – 4.2 m/sec is achieved.