A metal garage performs many useful functions. Caring car owners park their car inside it for the winter, other people simply store their summer harvest, and still others equip the box for a workshop. All these goals will be successfully realized if the garage is well insulated from the inside.

The minimum temperature for such a room is considered to be −5 degrees; Otherwise, the vegetables will rot, it will be cold to work there, and condensation will form on the car, causing rust. Therefore, it is advisable to insulate an iron garage from the inside in order to effectively retain heat.

Plastering walls

To perform the “wet facade” technology, it is necessary to apply a layer of glue to the surface of the walls on which the polystyrene foam boards are glued. At the next stage, a second layer of glue is applied, onto which the reinforcing mesh is attached, and plaster is applied to the surface.

The main advantages of this method are additional thermal insulation, strength and reliability of the walls, as well as the affordable cost of materials. The disadvantages include a rather complex execution process and the need to level the walls for a high-quality coating.

A special feature of plastering is the ability to create an original and unique coating, which is characterized by practicality and unique design.

Technologies for insulating walls of frame houses from the inside

Diagram of the construction of frame walls and their thermal insulation

Firstly, for this you need to stock up on the following materials:

- glassine (to create a waterproofing layer);

- beams or metal profiles (for assembling the frame);

- vapor barrier (for example, penofol);

- insulation (let's take mineral wool as an example);

- edged board with a section of 2.5x15 cm and a humidity of no more than 15%.

Features of siding application

Before sheathing the outside of the garage, you should familiarize yourself with the variety of siding, which includes the following types:

Vinyl siding is considered the most popular due to its reasonable cost and good performance characteristics. It is made from polyvinyl chloride, which is moisture resistant and has a simple installation method.

The main advantages include fire safety, resistance to temperature changes, a large selection of palettes, durability, and low weight of the panels.

Wooden siding is characterized by environmental friendliness, safety, and increased thermal insulation, but it has a high cost, so it is not advisable to use it for finishing a garage.

Metal siding differs from other types in its increased strength, resistance to temperature changes and mold, and in order to prevent corrosion, it is recommended to use self-tapping screws with a rubberized head.

Cement siding has significant weight, which creates an increased load on the garage foundation. Therefore, it is necessary to find out whether the walls and base of the garage can withstand such weight.

Traditional lining inside

The construction market is rich in finishing materials. Before choosing a material, you need to familiarize yourself with the basic requirements for finishing a garage space. Each surface of the garage must be able to withstand loads.

It is important that the floor does not deform under constant high loads.

The walls should not be damaged by mechanical influences. The ceiling must be finished with a material that is durable and resistant to moisture. Don't forget about the aesthetic side of the cladding. It is traditional today to cover the room with plasterboard.

Advantages of plasterboard sheathing:

- Lightness of the material;

- Easy to install;

- Affordable price category;

- Flexibility;

- Possibility of decorative finishing.

The disadvantages of drywall include its low impact resistance. The disadvantage can be eliminated by covering the surface with ceramic tiles. Interior finishing of walls and ceilings with plasterboard will be cheap, but will last for many years.

Using lining

In some cases, lining, which is made from coniferous and deciduous trees, is used to cover the outer walls of garages. It is a safe and natural material and has a special tongue-and-groove fastening, which makes it easy to connect the panels to each other.

There are several classes of lining, and the most ideal option is premium class material, which is characterized by excellent quality and a fairly high price, but it does not allow the presence of any defects or flaws on both surfaces. For a garage, you can use class A, which refers to the first grade and allows minor defects while maintaining the normal quality of the panels.

The most popular type recently is eurolining, as it is produced under strict control and meets all established European norms and standards.

Insulation of a garage cellar

If there is a cellar or inspection hole, they also need to be carefully insulated.

Cellar ceiling

Before insulating the cellar ceiling, install a layer of waterproofing on it. Then you can glue the foam to the ceiling. The ideal insulation option is liquid filler, although its use is much more expensive.

Cellar walls

The material for wall insulation must be mold-resistant and moisture-proof. The best option is polystyrene foam. Its slabs should be attached to the sheathing or directly to the walls. When performing insulation work, do not forget about the wiring. It must be laid in a metal sleeve or a box must be secured.

Cellar floor

Since the floor in a garage cellar is usually unpaved, it is better to fill it with bitumen. First you should pour crushed stone, then sand, compact everything and pour bitumen on top. If the floor is reinforced concrete, it is better to cover it with roofing felt on top of sawdust, and then fill it with a cement screed on top.

Finishing garage walls with stone

The most durable, durable and high-quality finishing material is stone. If you have unlimited financial possibilities, you can clad the garage façade with natural stone, which allows you to create a rich and unique appearance, as well as ensure the durability of such a coating.

In order to save money, you can select a certain artificial material that has an acceptable cost and an average level of quality. However, a wall lined with such stone also looks interesting and allows you to choose the material among a wide variety of its types.

Installation of natural and artificial stone requires a professional and responsible approach, which involves a sufficiently large amount of adhesive solution to properly glue the stone to the surface of the walls.

It must be remembered that the weight of natural stone significantly exceeds the weight of artificial material.

Blockhouse: features and characteristics

The blockhouse is made from high-quality trees, and the lined wall imitates a log covering. Depending on the price and quality, there is a division of the blockhouse into classes, which include the premium class, classes A, B and C. The highest quality is the premium class blockhouse, which does not allow any defects, but at the same time is quite expensive.

The best option for a garage is to use first-class material, which is characterized by an acceptable combination of quality characteristics and price.

The wooden panels of the blockhouse create comfortable conditions inside the garage, while simultaneously increasing thermal insulation, and they are also coated with special protective impregnations that extend their service life and prevent the formation of mold and mildew.

To install a blockhouse, it is necessary to install a frame, which allows additional insulation measures to be carried out by placing a certain thermal insulation material, which can be used as roll or tile insulation. Wooden beams are mainly used for the frame.

Watch the video:

Thus, before choosing what to cover the outside of the garage with, it is recommended to study in detail all the characteristics and properties of the materials offered, as well as the methods of performing the work.

Description of the insulation process

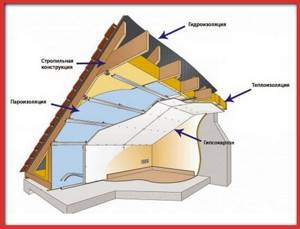

When insulating different types of enclosing surfaces of a frame house with mineral wool, their own insulation scheme is used. But just like for frame walls, one general rule applies - the vapor barrier of the insulation is carried out from the side of the heated room.

The vapor barrier is laid in a continuous layer without “gaps” between the insulated surfaces

Floor slab above basement

In the case when the frame house project includes a basement, a strip foundation is used as the foundation.

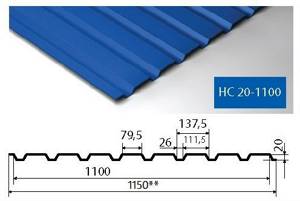

How to sheathe the outside of a garage with corrugated sheets

To sheathe the outside of the garage, you need to purchase a profiled sheet of grade C or NS (wall). The numbers in the marking indicate the height of the wave. The best option is NS-20 grade corrugated sheet with a sheet thickness of 0.5 mm.

With corrugated sheets you can sheathe not only the walls, but also the roof. This material is suitable for making gates. Sheathing with corrugated sheets allows the use of insulation for garages used year-round.

Let's consider the technology of cladding the outside of a garage made of bricks/concrete blocks.

- Markings are made on the walls for installation of guides. Using a hydraulic level, mark horizontal lines.

- Holes for embedded parts (metal corners) are drilled according to the markings and at equal distances. The corners are fixed with dowel nails.

- Guides are laid on the mortgages, the shelves of the metal profile and the mortgages are connected with self-tapping screws.

- If necessary, insulation (mineral wool or Penoplex) is placed between the guides. For the city of Moscow and the region, the insulation thickness is 50 mm (two-layer installation) or 100 mm (single-layer installation). If the garage is used only in the warm season, insulation may not be used.

- The insulation is fixed using dowels, 5 pieces per slab.

- If mineral wool is used for insulation, then a waterproofing membrane, for example, Eurotop L2, is stretched over it. The canvases are stretched with an overlap of 10-15 mm, fixed with self-tapping screws to the guides.

- A U-shaped guide profile is attached horizontally along the lower edge of the walls or along the base line, to which the base casting profile is fixed with self-tapping screws. Corner profiles are attached to the corners of the garage walls.

- Profiled sheets are installed on the casting of the base and fixed with self-tapping screws right through to the guides. Adjacent sheets are installed with an overlap in one wave.

- If necessary, platbands are installed around gates and windows.

If a metal garage frame is sheathed with corrugated sheets, then the sheets are attached directly to the racks. And insulation is done from inside the room.

Why do you need to insulate your garage?

The temperature regime that has a positive effect on the condition of the car differs significantly from the one in which a person is comfortable. If in residential premises the standard is to maintain the air temperature at +20-22 degrees Celsius, then for storing a car +5 degrees is considered the most optimal. At this temperature, almost no condensation forms on metal parts, causing destructive corrosion.

Therefore, to create a microclimate suitable for technology in the garage, other approaches to insulation are used. After all, the desire to recreate room conditions in the garage using insulation and heating devices will harm the vehicle. For example, in winter, when entering a heated room from the cold, the car will instantly fog up, the air humidity will increase, and the car will sit in such a warm-humid fog all night.

How to properly insulate a garage? Let's figure it out.

How to cover the outside of a garage with siding

Siding consists of separate panels that are fastened together with a lock. Siding panels are made from vinyl (the most budget option), aluminum, copper, cement, steel, ceramics, wood, etc. The length of the panels varies from 2 to 6 meters, it is easy to choose the best option in accordance with the dimensions of the garage. Siding panels usually imitate wood trim (ship plank, herringbone, blockhouse). You can even sheathe the outside of an iron garage with this lightweight material.

You can sheathe a garage with siding, as well as corrugated sheets, with or without insulation. The panels are installed on a metal (preferably) or wooden sheathing. The racks are fixed vertically (for horizontal siding) or horizontally (for vertical siding) to the walls through long dowel nails or by means of mortgages (when using insulation.

On a note! For Moscow, the Moscow region and other regions, it is recommended to pre-treat all wooden elements with an antiseptic to increase the service life of the finish.

The base flashing and the initial strip are attached along the lower edge of the wall, and special corner profiles are attached to the outer corners. Self-tapping screws are screwed into the holes along the edges of the profiles, and the self-tapping screw cannot be tightened too much; a gap is left between the head of the screw and the profile of up to 0.5-1 mm (the linear parameters of the profiles and the siding itself change at different air temperatures).

Siding panels are attached from bottom to top or from left to right (vertical).

The edge of the siding panel is inserted into the groove of the corner profile, after which it is fixed to the sheathing with self-tapping screws.

Important! When installing siding, it is important to check the horizontal position with a building level to prevent distortion. If the garage wall is long, a connecting profile is vertically attached in advance at the intended junction of the panels. Platbands are attached around the openings. And along the upper edge of the walls there are finishing profiles.

Cladding the garage with clapboard

Wooden lining is an environmentally friendly, very high-quality material that can profitably transform the outside of a garage, and covering the walls with this material is not at all difficult. The outside of the lining is treated with antiseptics and fire retardants to prevent the material from drying out and rotting, as well as possible fire. Wooden siding is attached to the sheathing with nails or self-tapping screws all the way through the top edge.

Clapboard finishing, including blockhouses, is often used by owners of wooden houses to decorate buildings on the site in the same style.

A metal garage is a strong, reliable structure with a high degree of burglary resistance. But it has one serious drawback - the high thermal conductivity of the steel sheets from which the structure is assembled. That is, the street temperature calmly migrates inside the garage through the fencing structures. It is cold in winter and hot in summer. Therefore, the owner of the building faces an important question: how to insulate a metal garage, from which a number of other questions arise:

- what thermal insulation material is best to use for this;

- What is the best way to insulate – from the outside or from the inside?

Garage insulated with foam plastic

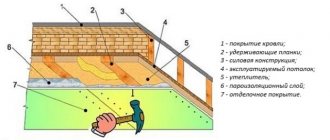

Garage roof structures

After making sure that the roof is completely closed and there are no flaws in it, you can proceed to choosing insulation that matches the existing structure of the building. They can be:

If for a single-pitched type of roof metal or wooden slats can be used, between which sheets of foam plastic or mineral wool are attached, then work on attic and gable options involves the creation of a stable frame. Professionals can best advise you on how to insulate a garage roof. Especially if the attic space is planned to be actively used, for example, for storing tools or seasonal tires.

Even before purchasing materials, it is worth calculating the permissible thickness of the insulation along with the structure itself. Separately, it is worth considering the functioning of the ventilation system, as well as ensuring absolute waterproofing of the roof.

External or internal insulation

The best option is external insulation. In this way, a shift in the dew point (formation of condensation at the border of contact between cold and warm air) is achieved closer to the outer surfaces of the insulating layer. And if you choose the right thermal insulation material with the lowest possible thermal conductivity, you can achieve a shift in the dew point to the finishing surface. The second positive factor is the low internal volume of the garage space in terms of overall dimensions.

How to heat a garage

High-quality thermal insulation is meaningless if there is nowhere for warm air in the room to come from during the winter. There are several heating options for the garage:

- Heating with electric heaters. Efficient, safe, compact, but the electricity consumption is considerable.

- Air heating is efficient and fast: the device increases the temperature of the air passing through it and blows it into the room. The advantage of the method is a high heating rate, the disadvantage is that the air flow raises dust from the floor, which will require frequent cleaning.

These compact devices take up little space in the garage, they can be turned on for a short period of time, and the effect lasts for a long time.

More massive and substantial installations include:

- Gas and solid fuel boilers;

- Buleryan stove;

- Water heating.

The choice of these settings is only advisable if the garage is constantly used and there is sufficient internal space.

- Exterior finishing

Materials for garage insulation

Let's move on to the question of what is the best way to insulate an iron garage. Let's consider what materials are used for thermal insulation from the outside and inside.

Materials for external insulation

It should be noted that the walls and roof of the garage are insulated in different ways using different materials. And most often, the roof is thermally insulated from the inside, because the steel sheet that forms it will in this case serve as a roofing covering.

When it comes to walls, there are several options. Brick cladding (half or whole) is considered traditional. In this case, the bricklaying is done under jointing, that is, with the precise installation of each stone horizontally and vertically, with a joint thickness of no more than 8 mm. At the end of the work, the seams are leveled with a special tool - a scraper, made by hand or purchased in a store.

There are several points that need to be taken into account when insulating with bricks:

- a small foundation is poured under the cladding: pouring depth is up to 15 cm, width is within 12-15 cm;

- the steel sheets forming the roof must create a cornice at least 15 cm long to cover the cladding from rain and water from melting snow.

Metal garage lined with brick outside

Today, manufacturers produce special paints that increase the thermal insulation qualities of metal structures. They contain thermal insulation fillers in the form of foam glass granules, ceramics, perlite or fiberglass fibers. In appearance, they resemble a thick paste, and are applied to metal surfaces with a thickness of 2-4 mm.

This is the best innovative option for insulating garages, easy to use, but expensive in terms of the cost of the material itself. Therefore, it never received its widespread use in everyday life.

Materials for internal insulation

Let's move on to the internal insulation of iron garages, as the most frequently used. All thermal insulation materials that are used to insulate buildings and structures can also be used when thermally insulating a garage from the inside. This means there is a fairly large list of materials offered.

But for many garage owners, the question arises with one additional question: how to insulate an iron garage from the inside yourself and inexpensively. That is, there are two positions in priority: with your own hands for little money (cheap).

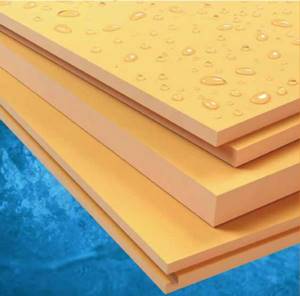

As for inexpensive materials, everything will depend on which element of the structure needs to be insulated. If these are walls and a roof, then optimally either mineral wool in mats 100 mm thick, or polystyrene foam (common name), also known as polystyrene foam boards with a thickness of 30-50 mm. But if you make a choice between mineral wool and polystyrene foam boards, then it is better to give preference to the second. There is only one reason - low hygroscopicity. That is, the material does not absorb moisture, so after its installation there is no need to cover the warm layer from the inside with a waterproofing membrane. In the case of mineral wool, this will have to be done.

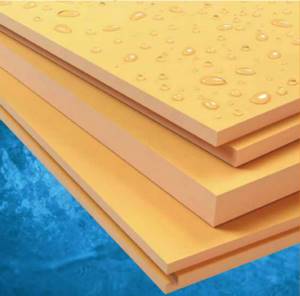

Expanded polystyrene boards

And one more reason. Installation of polystyrene foam boards can be carried out using a special adhesive composition. Mineral wool is laid using frame technology, which increases the cost and complexity of the work carried out due to the elements of the frame structure.

As for floor insulation, it is best to use expanded clay. It is added instead of crushed stone to the concrete solution used to fill the screed. And this solves the problem of thermal insulation of the garage floor base.

Expanded clay concrete for garage floors

Do I need to insulate the floor in the garage?

Whether to insulate the garage floor or not is up to everyone to decide for themselves. From the point of view of complete thermal insulation of the internal space, it is of course better to insulate. After all, through a floor laid directly on the ground, cold will always enter in late autumn and winter, disturbing the balance of the microclimate.

On the other hand, insulating the floor of an already built garage can be quite a difficult task. After all, after installing the insulation, the floor level will rise to a height of 10 to 20 cm. At a minimum, this will create problems when driving the car. And at the very least, it will make it impossible to park your car in the garage due to the fact that it will no longer fit through the gate.

Therefore, before you start insulating the floor, you need to carefully measure everything and find out whether there is enough headroom.

Among the options for do-it-yourself garage floor insulation, two main approaches can be distinguished:

- Quick modification of the floor to reduce heat loss.

- Installation of a full layer of insulation.

For the first option, when time, and most importantly finances, are limited, you can cover the garage floor with boards or OSB boards. Of course, this cannot be called serious insulation, but a noticeable effect will still appear. The floor will no longer be cold, and an additional air layer will appear under the flooring, holding back the cold from the base of the floor.

The second option is to fully insulate the floor by creating a multi-layer thermal insulation cake.

Taking into account the fact that the car puts a significant load on the garage floor, extruded polystyrene foam would be the best insulation option.

How to insulate with foam plastic

The process of insulating a metal garage with polystyrene foam consists of two stages: preparation and installation of the insulation. The preparatory process includes cleaning the surfaces of the metal sheets that form the roof and walls from dirt, rust and peeling paint. Any method that guarantees the quality of the final result will do. Most often, ordinary sandpaper is used for this. To increase the speed of the procedure, use a grinder with an attachment in the form of a metal brush.

Now about the adhesive composition. Since a metal structure is subject to insulation, it is better to use special glue in a can for polystyrene foam boards. This is a universal adhesive material in the form of foam, which guarantees the strength of the insulation to the metal. It is resistant to moisture and temperature changes. One can is enough to fasten 10 m² of slabs; it takes 30 minutes to harden.

Attention! Polystyrene foam does not expand in volume after its application, like mounting foam.

Please note that the walls and roof of the garage are steel sheets welded to the frame of the building. The latter is made from a metal profile, usually from a 50x50 mm corner. The frame is covered with sheets of iron from the outside, that is, it remains inside. Therefore, it is important to precisely cut the sheets of polystyrene foam to the dimensions of the frame structure so that the insulation lies between the frame elements, pressing tightly against them. Trimming is done with a sharp knife.

Now you need to apply glue to the slabs: along the perimeter and diagonally. Expanded polystyrene sheets are placed at the installation site and pressed with your hands, but not too much. Installation is best done from bottom to top. There are several points to pay attention to:

- Insulation boards have a low specific gravity, which makes it possible not to install supporting elements on the vertical planes of the walls. The foam itself is enough. But you will have to think about supports on the roof slopes. One option is regular tape, one end of which is glued to the insulation, the other to the steel frame element.

- If there is a small gap between the slabs of heat-insulating material and the garage frame, you just need to foam it with glue.

The main tasks of insulation

The insulation of metal structures significantly reduces the cost of operation (and increases comfort). Therefore, the insulation must have high thermal insulation properties, but in addition to them, a number of additional properties would be desirable:

- low thermal conductivity – effective in preventing heat loss in winter and protecting against heating in summer;

- plastic. The material must cover a structure of any shape in an even layer, since only a complete coating can provide insulation of the frame;

- no additional fastenings. Adhesion – the ability to stick to various surfaces;

- impermeability to gases and liquids. – protection of the coated surface from the negative effects of moisture and various gases;

- vapor permeability - the ability to allow steam to pass out of the room; the indicator should be lower than that of the wall material;

- durability. The service life of the insulation should be the same as the service life of the building;

- environmental friendliness. The release of harmful substances is unacceptable; for this you need to use natural ingredients.

Insulating the roof of a steel garage

The option using foam plastic, which is laid along the internal planes of the roof slopes, is the simplest. The garage structure includes lintels that hold the longitudinal walls of the building together. Sometimes these lintels are used to form a ceiling. They are hemmed with sheet materials: plywood, chipboard, OSB or iron sheets, which are laid on wooden slats. The latter are attached to the jumpers either with self-tapping screws, or bolts, or with binding wire.

It is the insulation of the ceiling that will solve the problem with the roof. To do this, you will have to lay sheet material from the above mentioned on top of the lintels, and these are the same steel corners 50x50 mm. The sheets are attached to the jumpers with ordinary knitting wire in increments of 50 cm. That is, you need to:

- drill holes in the flooring on each side of the lintels;

- insert the wire into them so that the ends hang down on different sides of the frame element;

- twist the wire along the bottom edge, pulling the sheets to the jumpers.

Now foam plastic is glued to the laid sheets, and then the entire ceiling structure is hemmed with sheets of plywood, OSB, fiberboard or chipboard. Although there are a huge number of finishing options here.

Ceiling insulation with foam plastic

How to make a metal frame yourself?

If you need to assemble factory parts into one design, this can be easily done with help. The difficulty lies in finding the required element and installing it according to the drawings.

If it is necessary to weld frames from a profile pipe, then this is a rather complicated matter. Although for the construction of a small country house, the frame is installed similarly to a wooden one. For a one-story building, pipes of 80*80 mm are suitable; for intermediate elements, a smaller diameter is suitable. But it also needs to be insulated.

ATTENTION! For reliability, it is best to purchase a disassembled house structure from the manufacturer.

Garage interior decoration

The difficulty of finishing the interior of a metal garage after thermal insulation work is that there is nothing to attach the finishing material to. If a frame method of insulation were used, that is, with the installation of a frame made of wooden slats, then the finishing would be attached to it. But since the simplest option was considered - frameless, it is necessary to tell how you can attach, for example, a plywood sheet to the garage wall.

To do this, you will have to carry out additional preparation, which consists of welding a certain number of M6 or M8 bolts from the inside to the steel sheets that form the surfaces of the garage structure. The caps must be welded to sheets of iron.

The length of the fastener is selected based on the thickness of the insulation and the thickness of the finish. For example, the thickness of the foam is 50 mm, the thickness of the plywood is 8 mm, which means that you will need bolts 70 mm long, where 12 mm will be spent on fastening with a nut and washer. The number of fasteners is determined by the distance between them. There is no exact data here, so approximately 40-50 cm.

The process of insulation on fasteners is carried out in the following sequence:

- An adhesive composition is applied to the foam sheet;

- it is placed in the required place and pressed tightly with your hands;

- insulation – the material is loose, so the bolts will pass through it easily;

- The finishing material is cut to the required size;

- the ends of the bolts are treated with chalk or paint;

- apply the finishing panel to the required place; traces of chalk or paint will remain on its surface;

- holes are made according to the marks using a drill and a drill bit, the diameter of which should be slightly larger than the diameter of the bolts;

- the finishing panel is put on fasteners and clamped with nuts, under which wide washers must be placed.

Attaching foam and fiberboard sheets to garage doors

Insulating a garage from the inside with bricks

There are no contraindications to using brick to insulate a garage from the inside. Just brick cladding will reduce the volume of the building. This is a more complex process in terms of work, and it is more expensive than using foam plastic. In addition, in terms of thermal conductivity, brick is much inferior to polystyrene foam boards:

- 0.81 W/m K – thermal conductivity of solid brick;

- 0.032 – 0.044 W/m K – range of thermal conductivity of foam depending on its density.

It turns out that polystyrene foam laid 30 mm thick replaces a masonry of three bricks laid lengthwise.

How to insulate garage doors

Not everyone knows how to properly insulate a garage from the inside. Effective and reliable thermal insulation of walls will not be enough, because a significant amount of heat escapes through the gate. The lack of insulation in this design will not allow the garage to warm up to the required temperature levels. At the initial stage of work, a hole is made in one of the doors and the doors are inserted. To reduce heat loss, a curtain made of thick fabric is fixed in this place.

A transparent polyethylene film with a minimum thickness of 0.8 millimeters will help to insulate the entire plane of the gate. This material is cut into strips 20-30 centimeters wide and fixed above the opening, so that the lower edge does not reach the floor surface by 1-2 centimeters. The strips are secured to a wooden beam using staplers. This insulation is very effective - when entering the garage, the driver will see the surrounding space. In addition, narrow strips of polyethylene will smoothly flow around the car and return to their original position.

Some car enthusiasts insulate the inside of their garage doors with polystyrene foam. To do this, a sheathing of wooden blocks is installed on the inside of the structure and the voids are filled with polystyrene foam slabs. To prevent cold air from penetrating through the gaps, the joints of the thermal insulation are taped with tape.

To eliminate drafts entering through the gates, it is necessary to replace the rubber seals. Condensation forms where the thermal insulation comes into contact with the metal surface. To prevent destruction, the steel is treated with paint or other anti-corrosion compound. Waterproofing substances are also applied to other surfaces.

The wooden guide elements of the frame are coated with a primer or heated drying oil, which will protect the material from rotting and exposure to fungus. After laying the foam, the surface is cleaned. Garage doors are finished with OSB boards or thin boards. It is not advisable to use moisture-resistant products for this, for example, gypsum board.

Polyurethane foam for garage insulation

And a few words about polyurethane foam, the thermal conductivity of which is 0.019 W/m K. That is, it is better than polystyrene foam. But it is more expensive and requires special equipment to apply it. Until recently, such equipment consisted of huge containers and a compressor. Today, manufacturers offer compact devices whose weight does not exceed 30 kg.

These are two cylinders and a mini-compressor with hoses and nozzles. The cylinders have two components that are connected and supplied through hoses under pressure. The applied layer is thin (15-20 mm), please note - it is continuous, without seams or joints, and is more effective than many modern thermal insulation materials used for insulating garages. But if we compare it in terms of cost, it is inferior to the same polystyrene foam. Although good insulation cannot be cheap.

Insulation of a metal garage with polyurethane foam

There are several effective and inexpensive technologies for insulating iron garages. But, as practice shows, polystyrene foam is most often used if the conversation turns to DIY processes. There are no restrictions or contraindications in the use of this material. At the same time, the insulation has a number of good technical characteristics, plus the low price of the product itself.

Types of insulation

Expanded polystyrene is one of the best insulation materials on the modern thermal insulation market: a high degree of thermal insulation, does not rot, and does not allow moisture to pass through.

Penoizol is a well-known and inexpensive material since the last century. It has a porous fine-cell structure. Pleasantly pleased with the cheapness. Can be used both in sheet form and by pouring.

Fiberglass or glass wool - consists of long and wide fibers, between which there are a large number of voids, and the voids are filled with air. This provides good thermal insulation as well as noise protection. The material is strong and elastic, withstands vibration well, and is durable. Fiberglass does not absorb water, yet allows steam to pass through, is resistant to chemical and biological influences, and does not burn. Used for insulating metal structures of wooden houses and roofs.

Basalt mineral wool is produced from basalt melts, therefore it is characterized by a very long service life. Does not change its properties under the influence of an aggressive chemical environment or high temperature, while being safe for humans, since it does not emit toxic substances.