Arguments in favor of a ventilation device

Is a specially organized air exchange system needed in a wooden building as such?

The opinion that wooden houses “breathe” does not provide grounds for completely abandoning systems that remove excess moisture and exhaust air from premises. Just as in the construction of buildings made of concrete and brick, the construction of houses made of lumber uses technologies that reduce heat loss. It’s just that instead of synthetic materials, natural seals made of jute, flax, and felt are used in the inter-crown joints. Mineral wool is placed in the ceilings.

Houses built from timber or logs require the installation of ventilation systems, since they operate heat-generating equipment that burns oxygen from the air mass

Insulated wooden building structures do not allow air masses to circulate naturally. In addition, builders and owners began to actively replace the usual window and door frames with sealed plastic analogues.

As a result, fresh air does not enter inside, and exhaust air does not exit outside. The inhabitants are not supplied with the required amount of oxygen for breathing. Mold fungus settles on undried wooden structures, destroying buildings with amazing speed.

Air exchange provided by ventilation is especially urgently needed in wooden buildings with sealed window and door structures

In addition, wood perfectly absorbs moisture! If you do not deal with humidity, heat loss will at least double. After all, water is an ideal conductor for heat waves.

The tree does “breathe,” but not so much that air exchange occurs in full without a specially organized ventilation system. Walls made of wood will not be able to fully remove household fumes. They will not provide the opportunity to remove dust suspended in the air with microorganisms.

The choice of the optimal ventilation scheme should be made at the project development stage, although in wooden structures it can be organized or strengthened after construction

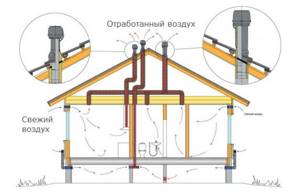

Organizing ventilation in a house made of timber or logs will eliminate the influence of the listed negative circumstances on the organisms of residents and building structures. It is simply necessary to create a natural scheme, but you can also build an artificial one. And if the supply and exhaust system is also equipped with a recuperator, then the exhaust air can be used to heat a fresh portion from the street.

Ventilated floor installation

An important component of organizing air exchange in a log house is the ventilation of the floor, foundation and lower crowns of the log house. The system will dry the lumber of the base of the house, which means it will protect the entire building from rot and fungus

All wooden house structures must be regularly dried with air currents

Particular attention should be paid to the base: foundation, ceiling, floor system. Basic principles and rules for base ventilation:

Basic principles and rules for base ventilation:

- Installation of vent holes (diameter - 10 cm) on the windy and opposite side of the log house base. The distance from the ground to the center of these holes should be at least 33 cm.

- Construction of the floor using a floating scheme with gaps around the perimeter of the premises. The gaps are loosely covered with a plinth, so that the air entering the vents can freely escape.

- Formation of ventilation holes in the floor structure that communicate with the underground. They are covered with gratings, suitable if the floor covering was not natural floorboards, but linoleum, carpet, laminate and similar material that does not allow air to pass through.

During the frosty period, the vents selected in the base or foundation are closed with dampers, which significantly reduce air exchange, and in the summer, grilles are placed on them.

The distance between the vents themselves is about 2 meters if the house is located in a lowland. If the log house stands high, then this distance should be increased, since the strength of the wind increases, and therefore the intensity of the blowing.

Particular attention should be paid to the air exchange system of attics and attics, on which the condition and durability of the roof largely depends. Ventilation of the attic and attic will increase the total amount of vents to 500th share of the total area of the entire house

To organize natural air exchange in the attic or attic, pediment ventilation and dormer windows are installed. The type of ventilation structure is selected based on the shape of the roof. It is clear that in pitched versions it is easier to create an opening in the pediment; hip and hipped ones are equipped with dormer windows.

To remove the exhaust air mass, ventilation shafts will be required. They are most often planned in the center of the building, closer to the ridge. In summer, ventilation shafts can be equipped with fans, so the operation of the entire system on hot, windless days will be ensured.

If the air exchange within both the cold attic and the equipped attic space is insufficient, mold fungus spreads and multiplies with amazing speed

Roof ventilation requires careful attention to the following nuances:

- Between the insulating layers, insulation and roofing it is necessary to leave gaps of 3-5 cm.

- The specified distance is ensured by the installation of lathing and counter-lattice.

- Thermal insulation from the inside must be protected by a layer of vapor barrier.

- The insulation layer in the roofing pie must be protected from the outside by waterproofing, separated from the roofing by a ventilation gap.

Compliance with established norms and rules is necessary to develop a competent ventilation project in a private home. Knowledge of building regulations and pre-prepared drawings will help you do without designers, and at the same time achieve your goal - to keep a wooden house in a condition suitable for living.

Regulatory requirements for air exchange

The presence of ventilation must be provided for at the design stage of the house itself. The study of building codes (SNiP) is recommended for both independent builders and customers of construction crews.

Not all migrant workers can be trusted; most have to be carefully monitored.

Designing a ventilation system for a wooden house is a very important stage of construction; this is the only way to avoid many mistakes and protect yourself from additional financial costs in the future. Insufficiently thought-out ventilation in a house made of logs or timber is easiest to improve, but the ways to solve the problem will be significantly limited

SNiP number 41-01-2003, which regulates the rules for the design of ventilation and heating systems, sets standards for air circulation speed both in the building itself and in its individual rooms:

- for living rooms, living rooms, bedrooms, the norm is 30 m3/hour;

- for kitchens and bathrooms where humidity is high, the norm is from 50 to 70 m3/hour;

- for utility rooms the norm is 15 m3/hour.

Regardless of the type of ventilation system, it must provide the required volume.

The designer's task is to select the type that suits the needs. You also need to immediately decide on the equipment and calculate the area of the air ducts if they are planned for use.

Wooden houses - they breathe, why do they need a ventilation system?

A home built from wood provides an opportunity to admire peace and comfort. In buildings of this type, you can almost physically feel the positive energy of Mother Nature; they are filled with the smells of forest and freshness. Almost everyone has heard that wooden buildings are breathable. People are often confident that this will be enough to create a favorable climate in their home. And this, of course, is wrong. The point is that houses built using today's technologies cannot be called breathable.

\

Every developer strives to create a house in which there are no drafts at all, and heat is saved longer. To achieve this goal, workers use various techniques, starting from installing plastic windows that do not let air into the rooms, and ending with treating all corners and joints of the building with specialized compounds and sealants. As a result of similar actions, the house becomes like a tightly locked box. It is considered to be as impenetrable as possible. It is clear that under such conditions one cannot even speak of any wood breathing.

If the building does not receive a continuous air flow, stagnation occurs. It becomes very difficult to breathe in the house, since its climate is not pleasant. Stale air turns out to be the basis for the emergence of various microorganisms and the formation of allergy manifestations in family members. People's general health deteriorates. It is impossible to come to terms with this. You can't count on breathable wood. There is only one way out - to organize effective ventilation of your own home. Such work can be entrusted to professionals. But it’s better to do everything on your own. This matter, believe me, is not so difficult if you think carefully about the main features of the improvement of various ventilation systems.

Design Features

From the very beginning, the project is developed with your own hands. This event is carried out in accordance with the requirements of building regulations and taking into account the location of the rooms.

Ensuring air exchange standards in the main rooms:

- kitchen with gas stove – 70 m³/hour;

- kitchen with electric stove – 50 m³/hour;

- bathroom – 50 m³/hour;

- living room – 30 m³/hour;

- bathroom – 30 m³/hour;

- utility room – 15 m³/hour.

Quality requires an accurate, justified project.

a competent drawing serves as the basis for determining the parameters of the ventilation system, since it takes into account the layout of a particular house

At this stage, correct marking of the location of system elements is required. You can invite a professional designer to perform this important task.

Features of air movement in winter

In order to answer the question of how to make ventilation in a private house in winter, you must first understand the basics of the ventilation system.

High-quality air exchange in a house, for example, made of aerated concrete, directly depends on a sufficient number of natural ventilation paths. Country houses in most cases have natural ventilation outlets from bathrooms, kitchens, hallways and living rooms. In order to ensure air flow into the basement, additional channels are installed; this also applies to the space under the floor surface.

At the same time, the air ducts of bathrooms, garages, swimming pools and living rooms should not be combined. As a result, in many country house projects, in addition to the main ducts, several exhaust and supply systems are used.

But such projects often do not save from the fact that in winter up to 40% of the heat leaves the house through natural ventilation along with the air. The reason is that during the winter period, air draft increases in direct proportion to the decrease in temperature. As a result, not only the efficiency of the room ventilation system decreases, but also the level of thermal insulation drops significantly.

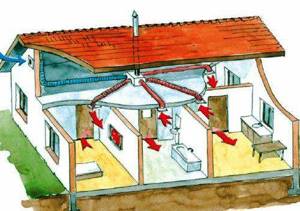

Thus, natural ventilation of the house in winter does not guarantee high-quality air circulation and heat retention. This problem can be solved with the help of forced exhaust and supply ventilation systems.

Home ventilation - where does the air go?

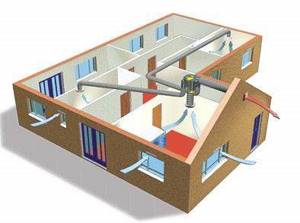

This system is based on the operation of a ventilation unit with filters, a heat exchanger (also known as a heat recuperator), fans and devices through which the process is controlled. Thanks to the heat exchanger, you can reduce the amount of energy needed to heat your home by 25%.

Design and principle of operation

To make it pleasant to be in such a building, it is necessary not only to have clean air, it must also have the appropriate temperature. Yes, and the air must arrive at a certain speed. And the lower this indicator is, the more comfortable it is to be inside the building. Air exchange using a mechanical supply and exhaust ventilation system will be significantly greater than in the case of a natural analogue. For a system with a hood, this figure varies in the range of 3-5 cubic meters per hour, and in the version with a natural one it does not exceed one cubic meter in the same time.

For this reason, natural ventilation provides slightly more comfortable conditions. But there are times when you can’t do without a mechanical type system. The lower the speed of air transportation in the pipeline, the more its cross-section will increase. For the same volume of passage in the case of using natural ventilation, a channel will be required, which will have a larger cross-section than with mechanical ventilation.

For a hood with a throughput capacity of three hundred cubic meters per hour, a channel with a diameter of 35 centimeters will be needed for natural transportation. For mechanical exhaust, you will need a channel with a diameter of only 20 centimeters. A large channel cannot always be placed in the wall. But its installation along the wall or under the ceiling, from an aesthetic point of view, may not be the best solution.

The main mistakes made when installing an exhaust system

The fact that the exhaust ventilation cannot cope with the loads can often be the cause of improper installation of the system, or damage to the ventilation ducts during repairs.

Often, when furnishing a kitchen, there is no room for a cabinet due to the fact that there is a protruding box in the wall. It seems that nothing will happen if you reduce it a little. But this is a satellite channel through which exhaust air is removed from the kitchen. If you reduce its size, its throughput will also decrease - which will lead to stagnation of the masses not only in one apartment, but also in neighboring ones.

The second common mistake is the desire to speed up the removal of polluted air. To do this, install a fan with more power than necessary in the ventilation hole. But, from a physical point of view, this is wrong. The device closes the ventilation hole when it is turned off - no natural draft is formed in the channel. When a powerful fan is running, the room does not have enough inflow to fill the volume of air removed. The device begins to overheat, which reduces its service life.

Note: a similar effect will be achieved by installing an overly powerful hood in the kitchen.

Exhaust ventilation is necessary in both residential and industrial buildings. It allows you to remove contaminated exhaust air, excess moisture, unpleasant odors, and harmful emissions. This system, if properly installed, will provide a favorable sanitary and hygienic environment for people, the building itself and the property located in it.

Natural air exchange

Do-it-yourself hood in a wooden house is a labor-intensive process and requires certain knowledge. There are several types of ventilation. One of them is natural. Air is supposed to enter the home through cracks in window and door systems. For effective air outflow, care should be taken to ensure that the outflow tract is taken care of. For this purpose, air ducts are installed. Modern construction technologies greatly complicate the process of natural air entering the room. To create conditions for free circulation of air flows in the rooms of the house, holes are made in the door leaf (decorated with grilles). Strong exhaust is ensured by the large length of the air duct.

Nuances to consider when installing a hood in a private home

When the hood is installed in the wall, it is necessary to make the holes correctly and secure the device. The level of vibration should be taken into account if the fans are powerful. Otherwise, over time, the fasteners may become loose and fall out. The pipe should be given smooth bends so that air moves freely to the ventilation shaft.

If the owner has basic construction skills, he can easily install any type of hood in an apartment or house with his own hands.

Forced ventilation

The supply of fresh air to the premises of a house from timber can be organized mechanically (using a fan). In this case, the exhaust ducts should be installed vertically so that they do not have bends or turns. This will ensure high-quality removal of recycled air from the house. The outlet of the exhaust line must rise above the roof by at least 50 cm. For additional protection, special mushrooms are installed on them.

The advantage of such ventilation is its low cost, the ability to clean and regulate the volume of incoming flow. Disadvantages of the system:

- the room loses heat by heating the clean air supplied by the fan;

- dependence on electricity;

- noisiness.

Forced exhaust ventilation will allow the recycled air to be removed from the rooms. Fresh air enters the house naturally (through window and door cracks). It is pumped out using a fan. Exhaust ducts can be additionally equipped with check valves designed to ensure that the air does not change its direction. In harsh climates in winter, it is necessary to organize heating of these elements to prevent them from icing.

This system for ventilating a house made of timber has a number of disadvantages: it does not allow you to control the amount of clean air entering the premises, it requires an electricity supply, and it makes noise during operation.

Based on the above, we can come to the conclusion that for a house made of timber, supply and exhaust ventilation of the recovery type is best suited. It not only allows you to regulate the volume of incoming and outgoing masses, but also ensures their cleaning. The energy efficiency of the installation is guaranteed by the recuperator, which allows the heat of the exhaust air to be transferred to the incoming one. Although the installation of such a ventilation system is labor-intensive and expensive, it can provide high-quality air exchange for large multi-storey timber buildings with an area of over 200 m2.

Advantages of the system

There are several aspects in favor of exhaust ventilation:

- Maximum comfort from a continuous supply of clean and fresh air

- Environmentally friendly materials that are used in this ventilation guarantee a cozy atmosphere in the house, and are also a good prevention of various airborne diseases

- When toxic substances enter the air, the risk of becoming infected is minimized, but this should not be neglected

Depending on the complexity or simplicity of a particular building, the installation and ventilation scheme, accordingly, will be constructed differently. If you are not a master in this field, it is best to entrust this matter to good specialists, at the same time concluding an agreement with the company providing the services.

When installing exclusively exhaust ventilation in a house, old air will be exhausted from damp rooms, and fresh air will be supplied through wood, windows, and vents. The main advantage of this method is the ability to control the air removed from the room.

In the case of an apartment building, hoods can be installed individually for each resident of the house, or for all apartments at the same time.

What features should ventilation have?

Wood is a unique material that has an unusual ability to breathe, due to which there is usually no need for ventilation in many rooms of such a structure. The fact is that even through the walls, fresh air comes in from the street, and an optimal microclimate for life is constantly established by maintaining high-quality and natural air exchange.

But for rooms such as the basement, kitchen and bathroom, even this property of wood is not optimal, so it is imperative to arrange high-quality air recirculation in these rooms. Ventilating a wooden house with your own hands is considered quite easy and possible, since today you can purchase special elements that are easy to install and use, and you can also take care of the formation of a natural system

There are several main types of systems that are used in a wooden house:

Natural ventilation in the house

- Natural ventilation is considered the easiest to create, however, it is not very effective. There is no need to buy or install any devices or devices. It involves creating the opportunity for unhindered and constant penetration of fresh air into certain rooms of the building. To do this, even during the construction of the house, small gaps are left between the logs, and also in a certain wall in the kitchen or bathroom, a hole can be left at the top and bottom. One will be designed to remove air, and the other to supply it. Moreover, these holes can be closed with special elements, so they can be opened only when necessary. Such a ventilation device has certain disadvantages, which include the fact that cold or heat from the street will penetrate along with the air. These disadvantages can be reduced by connecting pipes to these holes that lead to the roof of the building.

- Forced ventilation can also be installed in a wooden house, however, for its operation it is necessary to purchase specialized equipment, which must be installed in a strictly defined place, and must also correspond in its parameters to the room or the whole house where it will be installed. The positive aspects of this type of system include the fact that it has high efficiency and is also easy to use. However, there are also disadvantages, which include the fact that you will have to spend quite a lot of money on its creation, and also during operation it will consume a certain amount of electrical energy. If you focus on not too expensive equipment, then it will make quite a lot of noise during operation, and if it does not have a heating element, then cold air will penetrate through it, just as in the case of natural ventilation.

- There may even be mixed ventilation of a toilet or other room in a wooden house. To do this, the supply of fresh air is usually ensured through a natural process, for which there is a corresponding hole in the wall, but the removal of exhaust, humid or polluted air will be done using special exhaust equipment, which will have access to the roof of the building. To do this, a fan that is optimal in terms of performance is usually selected, ensuring high-quality and uninterrupted air intake from a certain room.

Exhaust ventilation type

The positive answer to the question of whether ventilation is needed in a wooden house is based on many years of experience in the construction and operation of private households. The organization of air flow is the basis of the principles of exhaust ventilation. Air intake must be ensured unobstructed. Natural supply ventilation supplies the house with air from the street. Main advantages:

- efficiency;

- simplicity of the ventilation system design;

- availability.

Exhaust ventilation in a private wooden house is provided for at the design stage. It is a central main line with branches that are designed to ensure the outflow of air from all rooms of the house. To increase operating efficiency, exhaust ventilation is equipped with fans mounted at the entrances of the ventilation ducts. The power of fans varies, so it is selected based on the volume of the room. The fans are economical; there are models with automatic operating modes.

Installation of the supply valve

The supply valve is needed to replenish the air reserves that are removed during operation of the exhaust system. The valve can be autonomous (wall) or additional (window).

During installation:

- Disassemble the valve.

- Mark the outline on the wall.

- Drill a hole and insert the sleeve.

- Place the insulated valve tube into the hole.

- The body is attached to the dowels.

Next, install the filters and check the operation of the damper.

Which type is most suitable

It is impossible to say unequivocally which type of ventilation system is most suitable for a wooden house. It all depends on the type of material from which it is created, as well as on some other parameters.

Usually a natural ventilation system is sufficient. If there is a lack of fresh air flow, it is necessary to install additional fans; if the exhaust air mass removal rate is insufficient, a hood will come to the rescue.

Roof of a wooden house and ventilation features

One of the main problems that arise when operating a house is the so-called “dew point”. Natural cooling of the air heated in the house leads to condensation in attic structures, which causes gradual destruction of structures. To ventilate gable roofs, they resort to arranging natural ventilation by making holes. This system is not suitable for flat roofs. Supply ventilation can solve the problem. This type of ventilation involves mechanical air injection. A heater is required for the cold season. The air in the room should enter at a temperature of 18 degrees Celsius, and a filter should be installed to prevent dust from entering. The system is controlled automatically to prevent overheating.

Size selection

The main problem at the initial stage of construction is what optimal size of vents should be chosen.

Based on the official requirements for construction work, you can find out that the size of all holes should occupy 0.0025 of the base space. This meets the installation requirements of 25 sq. cm of air ducts every 100 sq. meters of foundation.

The hole should not be less than 5 square meters. cm in area. The best option is a rectangular vent with sides 22 cm or round with a diameter of 22-25 cm.

For those who do not like to make large holes in the foundation, you can suggest constructing several small vents instead of one large one.

Ventilation of individual rooms and elements of a log house

We talked about the three main types of general ventilation of a log house, but ensuring air exchange in the following rooms is paramount. About each of them in order.

Attic ventilation

Ventilation in a wooden house with an attic floor has its own characteristics. An attic is a residential attic space that is located above the main living spaces. Properly installed ventilation prevents the harmful effects of condensation on the roof structure. Proper air exchange in the attic prevents overheating of the attic in the summer and the formation of ice in the winter (and as a result, corrosion of the metal elements of the roof, wetting of the insulation, the appearance of moisture and mold).

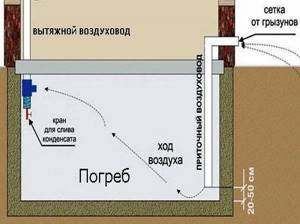

How to ventilate an underground floor in a log house if you have one?

To prevent stagnant air in the underground from leading to the appearance of fungus, mold and the house simply starting to rot, small vents are left in the foundation. It is important to close all these openings with anti-rodent bars. To prevent the subfloor from freezing and becoming covered with frost, the vents are completely closed during the winter.

Air exchange in the bathroom

Ventilation in the bathroom of a wooden house is designed to get rid of excess moisture (as a result - mold, rotting wood structures, rusting of metal structures). Proper ventilation will ensure:

- comfortable temperature conditions;

- normal humidity;

- influx of fresh air.

Ventilation can be made natural or forced. The second option is much more effective. The costs of electromechanical means of air injection will be recouped by the durability of the structure. The fan check valve solves the problem of the spread of unpleasant odors. Ventilation in a wooden house in the bathroom provides the owners with comfort and health safety, as well as extending the life of the bathroom and the house as a whole.

How to ventilate a bathroom in a log house?

In the bathroom, the walls and floor of the log house are most susceptible to moisture absorption, so natural ventilation alone will not be enough. We recommend installing forced ventilation, with a separate outlet. This is necessary to prevent unpleasant odors from spreading throughout the living rooms. For convenience, the exhaust fan can be connected to a switch, so when you turn on the light in the bathroom, the hood will work automatically.

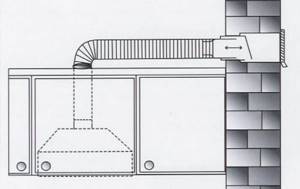

How to ventilate a kitchen in a log house?

This is where a classic hood will come to your aid. It must be placed directly above the stove, at a height of about 0.7-1 meters above it. It is advisable that the hood itself be at least 10 cm wider than your stove. It is not necessary to route the exhaust ventilation duct into the roof; it is enough to route it into the wall near the kitchen.

The kitchen hood occupies the first place in the disposal of dirty air. Main characteristics when choosing equipment: type, dimensions, performance and operating modes.

Depending on the configuration, mounting method and purpose, a kitchen hood can be:

- Hanging. The classic option is above the hob. The main advantage of the equipment is its availability and wide choice when purchasing. Disadvantages - not always high efficiency, the need for periodic replacement of carbon filters.

- Built-in. Mounted in kitchen furniture. Usually the kit includes 2 motors and a grease trap. Provides fresh ventilation and does not differ much in functionality from other types.

- Dome. Installed under the ceiling.

According to the types of fasteners, hoods are: wall-mounted, corner or island. Selected depending on the area.

When deciding which kitchen hood to install in a wooden house, you should pay attention to a number of factors. Whether it is price or features is up to the consumer to decide. The main thing is to look at the quality of the model. After all, a hood is not only a filter, but also health and safety.

Tips from experts on equipment selection and installation:

- If you choose a strong and durable hood, take a closer look at models made of stainless steel and aluminum.

- If you choose a fan with high power and too much air flow, this may lead to blockage of the air duct. This will cause all the smell and smoke to spread to other rooms.

- Ventilation ducts and air ducts should be cleaned periodically. Please consider this before choosing.

- If the kitchen is more than 15 square meters, two ventilation ducts are installed. One will serve to fill with fresh air, and the second will serve for exhaust.

- It is important to consider that the decorative grille and valve sometimes reduce the speed of air movement by 10 times. In this regard, do not opt for a device with minimal power.

- When choosing a hood, take into account the volume of air that needs to be purified within an hour. We take the volume of the kitchen, multiplying the area by the height, multiplying by the air exchange rate (12) and multiplying by 1.3 (minimum reserve coefficient). This way you will get the performance of the hood.

- When determining the dimensions of the hood, take into account that the area of the air intake should correspond to the area of the working surface of the stove, or better yet, exceed it.

- How to take into account a comfortable noise level? 20 decibels is like the rustling of pages, 25-35 is about like a loud whisper, 50 dB is the noise level like during a normal conversation, 89-90 is like the noise of a passing motorcycle or a hair dryer when drying, 110 is like how it works drill or hammer drill, 130 dB is already exceeding the pain limit.

- When choosing a hood, the question may arise: do you need lighting? They are automatic, touch-activated or with a button. Experts believe that the presence or absence of lighting does not in any way affect the main tasks of the hood, so when choosing, be guided solely by your budget and your own taste. Focus on how the hood design will fit with the interior design.

Air duct laying

The duct pipe can be made of corrugated plastic, steel or aluminum. These materials have different characteristics. The most common is aluminum. It is quite durable and not as expensive as steel.

The air duct is placed on the protruding socket of the exhaust unit and tightened with a clamp. Similarly, the corrugation is attached to a pipe with a valve system. The corrugation is secured to the wall in several places with a clamp and dowels and covered with a wall cabinet or casing.

Important! Before tightening the clamp in the right place, the connection is treated with silicone sealant.

If there is no casing included with the hood to mask the air duct and there is no wall cabinet provided, use a special rectangular plastic pipe or install a plasterboard box. The main condition: the box must withstand the load of its own weight and the weight of the air duct.

Algorithm for installing an air duct:

- Mark the position of all structural elements up to the attachment points.

- Holes are drilled in the wall and hangers are attached.

- Install the air duct elements.

- Seal joints.

- The pipe is attached to the wall and connected to the system.

A practical solution is to wrap the air duct with a layer of soundproofing material before hiding it behind the walls of the duct.

Application of air conditioners

Can air conditioners replace the natural circulation of air masses in a room?

Any, even the most expensive, climate systems are significantly inferior to simple ventilation. Want to think fast to keep you productive? Ventilate the room more often, and even better, do not skimp on the ventilation system, since, for example, in winter it is not always possible to open the window for a long time.

All split systems have two blocks that operate synchronously:

- External is a compressor that condenses the refrigerant;

- The internal one is a radiator that heats the air that circulates around it forcibly.

The air, which will subsequently be cooled, is also taken indoors. This means that the split system cools and passes through the same air masses.

Some models also take in outside air, but its amount does not exceed 5%, so oxygen, even in this case, does not enter the room in the required volume. The price of such innovations is much higher than standard technologies, and they do not solve the problem.

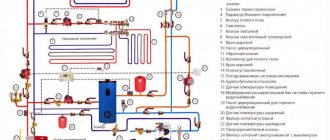

Natural and forced ventilation of the boiler room

According to the method of updating the air space, natural and artificial (or forced) ventilation are distinguished.

Natural ventilation operates without the use of fans; its effectiveness is determined solely by natural draft, and, consequently, weather conditions. The draft force is influenced by two aspects: the height of the exhaust column and the temperature difference between the room and the street. In this case, the air temperature outside must be lower than that indoors. If this condition is not met, reverse draft occurs and ventilation of the boiler room is not ensured.

Forced ventilation involves the installation of additional exhaust fans.

Usually these types are combined into one boiler room exhaust system. When calculating it, it is important to take into account that the volume of air drawn outside must be equal to that pumped into the room. To ensure this condition is met, check valves are installed.

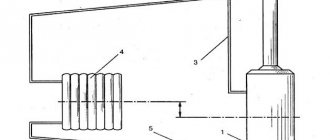

What types of recuperators are there?

At the moment, only three main types of such devices are produced:

- rotary;

- recirculating water;

- lamellar.

Ventilation in a private wooden house is most often arranged using the latest type of device. Plate recuperators really have a huge number of advantages:

- Simplicity of design. Recuperators of this type have no moving parts at all, so they break less often than other types.

- The absence of elements in the design that require electricity to operate.

- High efficiency.

Some of the disadvantages of such devices include the impossibility of moisture exchange in them. In addition, special valves have to be installed in such recuperators, since in winter their plate heat exchanger can freeze.

Methods for rational creation of ventilation

Taking into account climatic conditions and the economic component, the most rational way to organize air exchange in a private house may be combined ventilation. In summer, the house will be ventilated using natural inflow and exhaust. In winter, air exchange in the room will be carried out by a forced system, which includes supply and exhaust fans, filter elements, a recuperator and automation. The use of such a system in a private home will save up to 25% of heat and compensate for the financial costs of paying for electricity consumed by the mechanisms.

There is another way to provide controlled ventilation in a private house, in which a ground heat exchanger is used instead of a recuperator. To do this, it is necessary to organize the flow of outside air through a heat exchanger placed in the ground below its freezing level. Cold air masses will be heated by the natural heat of the earth, which will reduce electricity consumption for heating the supply air in the cold season.

Question to the expert

Many people ask whether it is possible to turn on the air conditioner for ventilation in the winter to effectively mix the colder supply air with heated air in the living room? Let's start with the fact that the operation of household air conditioners in the cold season is prohibited. If you have a winter kit, you can expand the operating range of the climate control equipment, but only for cooling (not heating)! In ventilation mode, only the fan of the indoor unit works, which drives the air masses in the room through the filter. That is why it is possible to turn on the split system in the “ventilation” mode in winter.

Checking the system operation

It doesn’t matter what kind of ventilation system is installed in a log house - natural or forced, it must show good results in operation.

An anemometer is a device for accurately measuring the operation of a system. But there are also simpler means at hand. For example, you can open a window or window in a room and hold a piece of paper to the ventilation shaft. If he reaches for it, then the system is working correctly. Instead of a leaf, you can use a candle. In this case, the fire will be directed towards the mine.

It is better not to check the old ventilation using the last method (using a flame). It often contains cobwebs and dust, which can lead to fire.

During operation, you must pay attention to the following factors:

- the appearance of condensation on windows in cold weather;

- mold near the mine;

- dust inside the ventilation ducts.

These signs indicate one thing - it is necessary to carry out cleaning and maintenance of ventilation equipment.

Having figured out how to make a ventilation system in a house made of timber with your own hands, you can do everything efficiently and on your own. The main thing is to adhere to the advice of experts and the attached diagrams and drawings.

The ventilation system of a country house should be designed depending on the building materials used to construct the building, and taking into account the design features of your home. The rather advantageous location of a country house away from the city with its polluted atmosphere, saturated with particles of dust, dirt, industrial waste, etc., suggests that natural ventilation can be used, but this method is not suitable for every home. Let's look at the ventilation device in a wooden house, as well as how to make ventilation yourself.

Drawing up a ventilation system project

It is quite possible to ensure air circulation without the involvement of professionals if you have the skills to handle the tool. The installation of ventilation in a wooden house begins with calculating its performance. In this case, it is necessary to determine the intensity of air flow, which will allow one to calculate the required level of air exchange. On average, to create a comfortable climate, it is enough for this value to be 150-200 m3/hour. After which the frequency of air exchange is determined, that is, how many times a complete change of air in the room will occur.

There is no need to worry about the fact that these devices create an increased noise effect, since the supply valves are equipped with noise-insulating material. Ventilating a wooden house with your own hands sometimes also involves installing homemade supply valves; in this case, the sound insulation is not located inside the air duct, but only at the outlet. Exhaust fans of various models and power have a certain noise limit, which will allow you to choose the quietest device.

Ventilation in a house made of timber can also be provided through a more functional device - a monoblock system with coarse and fine filters, as well as the possibility of saving energy due to a built-in recuperator. When planning ventilation in a wooden house, the air flow pattern must be taken into account. In this case, warm air rises upward, while cold air, on the contrary, settles below

The location of the supply and exhaust valves is also important. As a rule, the first of these are mounted lower than the exhaust air ducts

Installation of a basement ventilation system

As in any room, basement ventilation in a wooden house is no less important, as it reduces the risk of mold and musty air due to oversaturation of wood with moisture to a minimum. It is necessary to take care of the access and exhaust of air into the basement. To achieve this, underground ventilation in a wooden house is carried out by installing a supply and exhaust air duct. Air circulation in this case is ensured by climatic conditions: pressure, wind speed and temperature difference between outside and inside the room.

The supply pipe should originate closer to the floor, and the exhaust ventilation duct should originate from the ceiling. If you are designing underground ventilation in a wooden house, the height of the basement is less than 2 m, then you can get by with installing vents - these are through holes located on opposite walls. The entrance hole is equipped with a mesh for safety purposes against the penetration of litter and rodents. Ventilation of the foundation of a wooden house is organized in the same way, but the holes are laid directly when building the base of the house.

In order to retain heat in winter and to avoid freezing of the floor, it is recommended to close the vents during the winter

It is very important to reduce any likelihood of moisture accumulation in wood to a minimum, since excess air humidity directly affects the service life of such a natural material as wooden beams

Having decided to build a house from a log frame, you can get “breathable” walls due to the physical properties of wood, but more careful care of the structure is required due to the fact that this material absorbs moisture very well, even despite special moisture-repellent impregnations.

How to ventilate a house made of timber without making mistakes

It is correct to install an air exchange device when designing a residential structure, along with heating. The ventilation system should be provided at least minimally, in the form of ventilation ducts in “wet” rooms. But not all developers want to do this, since this activity is quite labor-intensive. Therefore, in most cases, homeowners have to solve this problem themselves. How to avoid mistakes when organizing ventilation of a house made of timber?

For the formation of natural draft in ventilation ducts, the shape of the roof slope and how much the pipe rises above the roof are important. A long release of communication is not always aesthetically pleasing, but a short one can provoke a backlash. The trajectory of the flow also depends on the roof structure. If it has a complex shape, ventilation of a timber house will not be effective.

Natural air exchange almost completely stops in the warm season, when there is no difference in temperature, and therefore pressure, inside and outside the structure. For such a case, it is necessary to provide forced ventilation.

The removal of recycled air from the bathroom and living quarters must be organized separately, otherwise if a failure occurs, there is a possibility of unpleasant odors spreading throughout the house.

It is better to place the ventilation openings of the ducts near the ceiling (not lower than 150 mm from this surface). In this case, air exchange in the room will always occur efficiently, regardless of temperature indicators.

A house made of timber, despite the assurances of manufacturers, needs ventilation. The integrity of the structure, the health and comfort of its inhabitants depend on this. It is better to provide for it at the stage of drawing up the house design, together with the heating system.

If the timber building is small and is used as a summer house, you can ventilate it naturally. Large structures made of timber, in which people constantly live, need better ventilation, which will be provided by a recuperation-type supply and exhaust system. Despite the higher cost compared to other ventilation methods, it will not cause heat loss in the house.

It is important to properly allocate a place for installing equipment so that it does not occupy living space and does not interfere with the inhabitants of the house. The optimal places for its installation are the attic or a separate room.

Why do you need ventilation in the kitchen?

When cooking food, various harmful substances accumulate in the kitchen. Some of them may be hazardous to human health. One of these is carbon monoxide, which accumulates in the air after the combustion of “blue fuel” or when cooking food in a wood-burning stove. Its smell is not noticeable, and the substance itself cannot be properly selected by carbon filters. High concentrations of carbon monoxide lead to poisoning and then death. This is why it is important to develop an effective kitchen air exchange system and remove this hazardous product.

When you turn on the burner of a gas stove, as well as when the water heater is operating, a certain amount of natural gas that has not had time to burn gets into the interior space of the room. Properly functioning natural ventilation installed in the kitchen can easily cope with such emissions, but its power will not be enough if fuel leaks from the pipelines. If you detect a persistent odor of ethyl mercoptane, you must call emergency services.

There are other substances that pollute the air in the kitchen:

- Fumes from frying foods are released in the form of processed particles of fat and sunflower oil. As a result of strong heating, such substances become dangerous for the inhabitants of the house; they settle on the walls of the room, dishes and furniture, as well as on our lungs. To effectively remove such particles, it is necessary to select the correct size of ventilation in the kitchen.

- In addition to the fumes, water vapor is released in the room. It is relatively harmless, but can affect the indoor climate.

From the above, the only correct conclusion can be drawn about the need to use a high-quality ventilation system. It will remove kitchen odors and excess moisture.