Today, gas boilers and water heaters are used everywhere both for heating water and for heating houses. For the most part, separate single-circuit boilers or one single-circuit boiler and an indirect heating boiler are used for heating and hot water supply, which creates certain inconveniences in their placement. Therefore, in houses and apartments with low hot water consumption, the installation of double-circuit gas boilers, which combine water heating for both household needs and heating, is becoming increasingly popular. The installation of gas boilers is associated with a number of specific difficulties, related more to compliance with the norms and requirements for boilers than to the process of their installation.

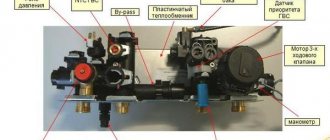

Double-circuit boiler design

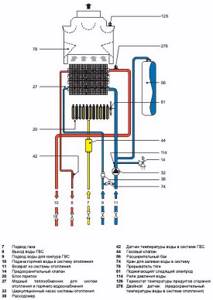

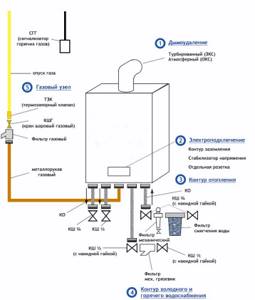

The design of double-circuit gas boilers is essentially similar to the design of a conventional single-circuit boiler, where a gas burner heats a heat exchanger with a coolant. The main difference is the ability of double-circuit boilers to simultaneously heat water for heating the house and for household needs. This is achieved through the combined placement of pipes for heating and hot water supply in the heat exchanger.

At first glance, the heat exchanger of a double-circuit boiler looks like an ordinary coil with a radiator grille. But it is necessary to note the following: the coil of a double-circuit boiler is most often a combination of 2 in 1 pipes. Inside the main pipe through which water for heating flows, there is another one for hot water supply. At the same time, one more very important point should be noted. Water in such a double heat exchanger circulates in opposite directions in each of the circuits. This was done specifically to improve heat transfer and this must be taken into account when designing and connecting the water supply and heating system to a double-circuit boiler.

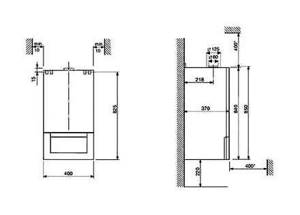

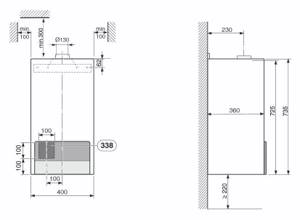

The presence of two heating circuits at once also affected the number of connected pipes. In contrast to the single-circuit one, where there were only three pipes, supplying and discharging water and one supplying gas. There are five such pipes in a double-circuit boiler. The diagram depicting a double-circuit gas boiler shows the following (from right to left):

- pipe with incoming coolant for heating;

- supply pipe for hot water supply;

- gas supply pipe;

- pipe with outgoing hot water for water supply;

- pipe with outgoing coolant for heating.

Important! Before using the above diagram when connecting your own boiler, carefully study the manual for it. It is quite possible that your boiler will be connected slightly differently. For example, both inlet pipes are on the right side, and both outgoing pipes are on the left.

It is also worth noting that today on the market you can find a double-circuit gas boiler, both wall-mounted and floor-standing. In addition to the installation method, the difference between them is that the floor-mounted one requires a separate room - a boiler room, while the wall-mounted one can be installed in the kitchen or in a place reserved for the boiler. We will look further at where exactly and how to install gas heating boilers.

Standards and requirements for the installation of gas boilers

It should be noted right away that the installation and connection of a double-circuit gas boiler can only be carried out by specialized organizations that have permission and a license for this activity. Self-installation and connection is fraught with fairly high fines. But still, you will have to do some work on preparing to connect the boiler and obtaining the necessary permits yourself.

The following recommendations and rules are excerpts from the main regulatory documents, such as SNiP 42-01-2002 “Gas distribution systems”, as well as SNiP II-35-76 “Boiler installations”, Code of rules for the design of autonomous heat supply systems SP-41-104 -2000. These regulatory documents describe in detail what can and cannot be done when installing gas equipment. We will consider the main most important requirements for installing gas boilers.

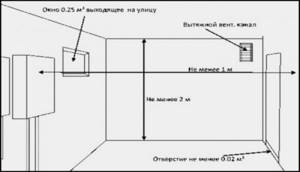

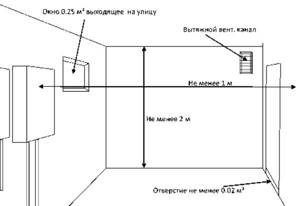

1. The room where the gas boiler will be installed must be at least 4 m2 with ceilings not lower than 2.5 m;

2. The doorway in the room must be at least 80 cm wide;

3. The room must have a window opening. The size of the window is calculated based on the following requirements: for 10 m2 of area, a window with an area of 0.3 m2;

4. It is necessary to have high-quality ventilation in the room to ensure constant gas combustion. The hole area should be 8 cm2 per 1 kW of boiler power. This also applies to boilers with a closed combustion chamber, for which coaxial chimneys are used, combining the functions of removing combustion products and supplying air to the boiler;

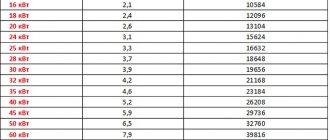

5. The diameter of the chimney is selected according to the power of the boiler itself and is calculated using a special formula. In general, boilers from 30 kW to 40 kW are most often used for heating a house. Accordingly, chimneys with a diameter of 130 mm and 170 mm are installed;

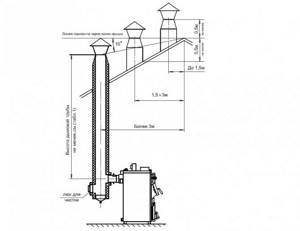

6. The upper end of the chimney should protrude 50 cm above the roof ridge. If a coaxial chimney is used, its outlet end should protrude from the air intake by at least 20 cm;

What are the rules and regulations for installing a wall-mounted gas boiler?

Installing a heating boiler is not an easy task. The boiler cannot be hung haphazardly, since the safety of the people living in the house often depends on how correctly the wall-mounted boiler is installed. This is due to the fact that the installation of this device is carried out in strict accordance with the technical requirements and standards adopted in Russia at the legislative level. That is why installing a wall-mounted boiler with your own hands is an extremely labor-intensive and difficult process for a beginner.

Stages of preparation for boiler installation

Before the home owner begins installing the heating system, you will need to collect some documents:

- agreement on supplying the house with gas;

- technical specifications and installation diagram of the gas system, approved by the relevant authorities;

- written permission from the gas inspector to install the equipment.

Boiler installation rules and regulations

Gas heating equipment is installed in accordance with developed and approved technologies that ensure the safety of its operation.

- The question of how to install a wall-mounted boiler begins with preparing the room for it. The room must meet certain requirements: the boiler room can be located anywhere in the house, except for the bathroom, living rooms and toilets. However, when installing wall units, this requirement may be relaxed depending on the type of boiler. The volume of the room is from four square meters, the ceiling height is from two meters. The width of the doorway is at least 800 mm. Also in the room there should be natural lighting of the boiler through the window. In this case, the window size must correspond to 0.3 square meters. for every 10 sq.m. premises.

- The rules for installing a wall-mounted gas boiler regulate the supply of a certain volume of fresh air through supply ventilation to the place where the boiler is used. An insufficient amount of incoming air may be due to the accumulation of a substance hazardous to health and life in the room.

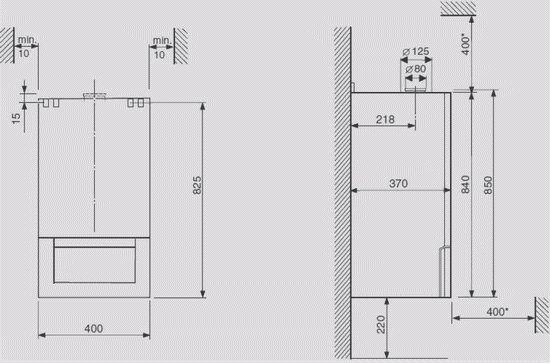

- Installation of a wall-mounted gas boiler: the standards for its placement are such that there must be more than 10 cm from the wall to the surface of the boiler. If this distance is less than required, the wall must be protected with a fire-resistant coating.

- Gas pipes can be metal, but not plastic.

- The chimney opening must correspond to the power capabilities of the boiler. In this case, its height must be at least 5 m, provided that the chimney is installed above the ridge on the roof of the house. When installing a chimney, it can have no more than three bends.

- When organizing a power supply system, it is necessary to provide a circuit breaker with current protection and thermal protection.

- In the room where the boiler will be located, there must be a gas sensor connected to a relay. In the event of a gas leak, the sensor must send a relay signal to block gas flow. In addition, an audible alarm should sound.

- Installation of a wall-mounted gas boiler; when starting it up, regulations require that the device be provided with a gas meter.

- If there are other gas appliances near the boiler, then the distance between the appliances is set at at least 20 centimeters.

- When installing a wall-mounted boiler, the requirements even apply to the completeness of the equipment. The boiler package must comply with the standards and contain: a manual, fasteners, a paper template for installation, special keys and fasteners.

- The installation height of a wall-mounted boiler is 80 cm - 160 cm from the floor surface.

If all these requirements are met, then there is no doubt about the reliability and fire safety of the gas heating system. It should be kept in mind that the heating system must be regularly maintained by employees of the city gas service.

More on this topic on our website:

- Installation of a gas wall-mounted boiler - piping and connection diagrams Often, private houses do not have access to centralized systems, so the owners have to independently decide how to implement it.

Correct piping of a wall-mounted double-circuit gas boiler - device, diagram, connection. Correct, competent, high-quality organization of heating at home contributes to the uniform distribution of heat throughout the entire living space. Piping a gas wall-mounted boiler with two.

Trimming a wall-mounted double-circuit gas boiler - photos and diagrams A simple wiring of a wall-mounted double-circuit gas boiler, the photo of which you see on this page, can be done by your craftsman, or you can.

Coaxial pipe for a gas wall-mounted boiler - installation with photo In order not to spend money on a full-fledged chimney, you will need a coaxial pipe for a gas wall-mounted boiler. The installation, the photo of which is published on this one.

Norms, requirements

To install a gas , you will need to obtain permission from the local administration, gas and fire services.

Without permission, installation of such heating is considered illegal.

Gas units are explosive and fire hazardous. In addition, if there is a gas leak and poor-quality removal of combustion products, the residents of the apartment or house may be poisoned.

When installing a gas heating boiler, it is necessary to comply with the legal requirements for the room and the system:

- a wall-mounted boiler with a power of up to 60 kilowatts can be placed in the kitchen and even in the living room;

- with a power of 150 kilowatts or less, the boiler can be installed in any non-residential room (kitchen, bathroom, etc.);

- More powerful models require a boiler room. Preferred location - first or basement floor;

- when installing a gas wall-mounted boiler in the kitchen, the required minimum space is 0.2 cubic meters per kilowatt (what are wall-mounted gas boilers for heating a house);

- fire resistance level of boiler room walls – at least 45 minutes;

- the required cross-section of the ventilation grille is 8 square meters. see per kilowatt;

- the cross-section of the chimney corresponds to that specified in the model passport, not less than the diameter of the boiler smoke exhaust pipe (how to properly make a chimney for a gas boiler);

- on pitched roofs the pipe protrudes above the ridge by half a meter;

- the number of chimney bends is no more than three;

- The installation height of a wall-mounted gas boiler from the floor is 0.8 meters minimum. There should be half a meter left to the ceiling;

- the section of the wall under the wall-mounted boiler is left free;

- a floor-standing boiler is placed on a sheet of metal or asbestos-cement (floor-standing gas boilers for heating a house);

- when installing wall-mounted boilers, non-flammable gaskets are used to line the walls;

- The wall for mounting the wall-mounted model must be level and strong enough to support the weight of the unit (plasterboard is not suitable).

The gas supply is equipped with an emergency shutdown device in case of leakage. The unit is installed so as to provide free access to all working units. The chimney pipe is equipped with inspection hatches for cleaning, and the passages through the ceiling and roof are treated with fire-resistant materials.

What is connecting a solid fuel and gas boiler into one system?

Installation of boiler equipment is regulated by II-35-76 SNiP, gas distribution systems - 42-01-2002 SNiP, design of autonomous heating - 41-104-2000 SP.

How and with what to finish the walls behind a gas boiler

According to the joint venture, the wall in the boiler room under the boiler can be sheathed with an asbestos board covered with stainless or galvanized steel. The protective screen should protrude along the perimeter of the boiler by 10 cm. It is allowed to cover a brick or concrete wall, ceramic tiles, or plaster.

The requirements for finishing materials when installing a wall-mounted boiler used for the ceiling are specified separately. According to existing standards, it is prohibited to use plastic for cladding or to cover the ceiling with wallpaper. Installation of gypsum fiber or plasterboard boards is allowed, followed by leveling with plaster mixtures and putty, and painting with water-based paints.

If a gas heat generator is installed in a wooden house, the safety requirements become more stringent. When installing wall-mounted boilers, the wall is covered with basalt insulation, at least 5 cm thick. The top is covered with sheet steel.

Thermal insulation material for installing the boiler on a wooden wall must be selected from among non-flammable materials, with heat resistance and the ability to withstand heating above 1000°C. For work, basalt (not mineral) wool is optimal.

How to install a boiler on a plasterboard wall

A plasterboard wall is made by attaching sheets to a metal structure and implies the presence of voids. Firmly fixing the heat generator to drywall is problematic, but possible. At the stage of manufacturing the metal frame, a place is provided for installing the boiler. The mounting point is reinforced with a wooden beam and a metal profile.

There are special fastenings for gas boilers to plasterboard walls, which are plastic plugs that are screwed directly into the facing material itself. Installation anchors are screwed directly into the plug. As practice shows, ready-made fastenings become loose over time and lose the strength of their fixation to the wall.

Fire safety when installing a mounted boiler

When installing a wall-mounted gas boiler, fire safety requirements are required. Minimum fire breaks are provided:

- At least 10 cm from the wall surface on which the unit is mounted.

- From the opposite wall, at least 40 cm.

Fire safety rules indicate the need to install a thermal insulation shield on the wall under the gas boiler. When connecting the chimney and passing the pipe through the roof and interfloor slabs, fire breaks are provided.

READ Telescopic stick for clearing snow from the roof

Between the room used for the boiler room and the living rooms, a partition made of non-combustible materials with a high degree of fire resistance is installed. When connecting to a pipeline, a corrugated metal pipe is used. Hoses that are completely rubber or protected by metal braiding are prohibited.

How to hang a wall-mounted boiler

Fastening the boiler to a wall made of foam concrete, gas silicate, aerated concrete

To hang a wall-mounted gas boiler on a wall made of blocks of foamed porous material, several methods are used:

Mounting fasteners are installed during block laying.

The installation of the boiler is carried out strictly after the mortar masonry mixture has completely hardened.

Special “screws” for foam concrete are used. In their structure, they resemble similar plasterboard plugs. They have a deep thread with a large pitch and are hollow inside. After screwing into foam concrete, gas silicate or aerated concrete, any anchor can be screwed into the screws.

Using studs - in this case, two studs are installed at the required distance from each other. On each side of the wall, a strip is installed, secured with bolts.

How to hang a boiler on a wooden wall

According to SP 41-108-2004 “Apartment heat supply of residential buildings with gas-fuelled heat generators”, it is possible to hang a boiler on a wooden wall, provided that the following conditions are met:

- Material with a high degree of flammability, in the place where the boiler is installed, is treated with pyrine retardants.

An alternative to the above is cladding a section of the wall with gypsum fiber board, followed by cladding with ceramic tiles.

Correctly hang the gas boiler on a wooden wall, installing an additional reinforcing beam placed under the facing material (lining) to ensure reliable fixation of the heat generator.

How to hang on a brick wall

The standards separately stipulate the conditions for installing the boiler on a brick wall. Brick is a non-combustible material, therefore, the heat generator can be installed directly on the wall. But sometimes, when putting a boiler installed in this way into operation, certain difficulties arise.

To satisfy all the wishes of gas workers, installation is carried out as follows. The walls are plastered. While plastering the surfaces, a plate is installed for mounting the boiler. After plastering, a seat (two bolts) remains protruding from the wall, onto which the boiler is installed.

How and with what to finish the walls behind a gas boiler

According to the joint venture, the wall in the boiler room under the boiler can be sheathed with an asbestos board covered with stainless or galvanized steel. The protective screen should protrude along the perimeter of the boiler by 10 cm. It is allowed to cover a brick or concrete wall, ceramic tiles, or plaster.

Requirements for installing a wall-mounted gas boiler

The requirements for finishing materials when installing a wall-mounted boiler used for the ceiling are specified separately. According to existing standards, it is prohibited to use plastic for cladding or to cover the ceiling with wallpaper. Installation of gypsum fiber or plasterboard boards is allowed, followed by leveling with plaster mixtures and putty, and painting with water-based paints.

If a gas heat generator is installed in a wooden house, the safety requirements become more stringent. When installing wall-mounted boilers, the wall is covered with basalt insulation, at least 5 cm thick. The top is covered with sheet steel.

Thermal insulation material for installing the boiler on a wooden wall must be selected from among non-flammable materials, with heat resistance and the ability to withstand heating above 1000°C. For work, basalt (not mineral) wool is optimal.

Installation of a wall-mounted gas boiler in a private house

The installation of a wall-mounted gas boiler is carried out using a simplified technology, which allows most of the work to be organized by the buyer of such equipment.

Simply put: you can install a wall-mounted boiler yourself, involving hired specialists only at the stage of connecting the equipment to the gas main. And in this article we will tell you how this is done.

Wall-mounted gas boiler

Installation on different walls

Boilers are quite heavy, and therefore problems can arise if you do not take into account the reliability of fixation to the wall. There are certain standards for installing boilers, which indicate that installation work must be carried out only on a rigid wall.

Requirements may vary greatly depending on the material that was used to build the walls in the house. There are standards for wooden, reinforced concrete, plasterboard and brick surfaces.

Installation on a reinforced concrete wall

Reinforced concrete walls are the most suitable option for installing a wall-mounted gas boiler. They have increased strength and are completely non-flammable. Therefore, there was no need to use additional methods of protection in the form of cladding. To fix the heat generator body, metal anchors are used, onto which the mounting plate is fixed. After this, the unit is installed on the prepared site. Any type of heating system can be installed on concrete walls: those with high power or a conventional storage-type broiler.

Installation on a brick wall

The installation standards separately stipulate the conditions for fastening to a brick wall. Brick is another high-quality non-combustible material, and therefore the equipment is installed directly on the wall, but this time you will have to prepare the surface.

Photo source: obustroeno.com

In order not to violate the requirements of gas workers, the wall must be plastered before installation work. During this work, you will need to install a special strip. After finishing the plastering, two bolts should protrude from the wall, which serve as a seat for the equipment.

Is it possible to hang a boiler on a wooden wall?

Installing a wall-mounted gas boiler in a wooden house is a difficult task due to a number of nuances. A wooden wall can catch fire, so you need to take safety precautions.

To properly install a heating boiler, you will have to fulfill several special conditions:

- Carefully treat the wood at the installation site. It’s quite easy to do this with your own hands - there are special fire retardants in hardware stores. They will need to treat the wall generously.

- The wall must first be covered with plaster (thickness – 15 mm). This is the minimum value that guarantees protection against high temperatures. You can also line the wall with roofing steel.

If you do not want to use plaster or metal cladding, you can put a gypsum fiber board in the place where the heat generator is mounted, and then cover it with ceramic tiles.

To prevent a heavy heating boiler from falling from its installed place, it is necessary to strengthen the platform with a powerful beam, which is placed under the facing material. Thus, it will be possible to securely fix the heat generator on the wall.

Can it be hung on drywall?

When installing drywall, voids cannot be avoided. This creates problems with fastening a heavy heat generator. However, there is an option to eliminate this shortcoming.

Boiler on a plasterboard wall. Photo source: primtara.ru

When the metal frame is being manufactured, it is necessary to select in advance a place to fix the boiler and carry out preparatory work. It is necessary to reliably strengthen the site using wooden beams and metal profiles. For installation on fragile drywall, special fasteners are used. These are plastic plugs that are screwed into the facing material. The hardware must be mounted into the already installed plug. Experts say that ready-made fasteners gradually become loose, which leads to deterioration of fixation.

Mounting the boiler on foam concrete and aerated concrete

If the house is built of aerated concrete or foam concrete, then several methods can be used to install the boiler:

- The fastenings are installed in advance at the moment when the blocks are laid. The boiler is installed when the masonry mixture has completely hardened.

- In stores you can find screws for fixing in foam concrete. They are very similar to the cork used for drywall. But they have a deeper thread and a larger pitch. As soon as the material is screwed into foam concrete or aerated concrete, any anchor can be installed in the screws that will reliably hold gas equipment.

- Another reliable method of fixation is with studs. They are installed with a small gap from each other, and a strip is mounted into the wall (on each side), which is firmly fixed with bolts for maximum reliability.

- You can also use liquid, chemical anchors. They provide a strong hold, but are more expensive than previous options.

General requirements for installing a wall-mounted gas boiler

Heat-generating devices with a power of up to 60 kW can be installed in any non-residential area of a house or apartment, with the exception of the bathroom and toilet. For a more productive installation, you will have to build a special room - a boiler room.

However, both the local area where the boiler is located and the specially prepared site (boiler room) must meet the following requirements:

- In a gas boiler room or a room allocated for placing a boiler, there must be a window with an area of at least a quarter of a square meter. The exact footage of the window opening is calculated using the formula - width x length x height of the room x 0.03. That is, for every cubic meter of boiler room volume there is at least 0.03 m2 of window area.

- The ceiling height in this area cannot be less than 2.2-2.5 meters.

- The recommended area of the boiler room or dedicated room is calculated according to the proportion 0.2 m2 = 1 kW of boiler power.

- The fire resistance of the walls at the location of the gas boiler is at least 75 minutes. Fire resistance of the door leaf is at least 30 minutes. If the natural fire resistance of building materials is not enough, it should be increased by finishing the walls with plaster (layer thickness of at least 10 millimeters) or tiles.

- In addition to an opening window of a certain area, the room/boiler room must have a natural exhaust - a through channel in the wall with a diameter of 150 millimeters, supplemented by a facade air duct.

- Air flow into the room will have to be ensured using a valve in the wall or a gap under the door leaf. The dimensions of the supply channel are calculated according to the proportion - 8 cm2 = 1 kW of boiler thermal power.

- The installation height of a wall-mounted gas boiler is chosen arbitrarily, but taking into account the mandatory 100-centimeter distance of the heating device from the ceiling.

- The distance from the heat-generating installation to the walls “neighboring” the supporting surface should not be less than 1 meter.

- The distance from the boiler to the gas main valve should not exceed 2-2.5 meters.

Typical gas boiler connection diagram

Try to follow these recommendations when choosing a place to install the boiler . Well, if you don’t find a suitable room, then you will have to re-equip one of the rooms of your house, “adjusting” the parameters of windows, supply and exhaust ducts to the above requirements. And only after this you can begin installing the heating device and connecting the boiler to the chimney, water supply and heating system.

How to install a wall-mounted gas boiler - process overview

At the very beginning, you will have to start arranging a channel to remove combustion products.

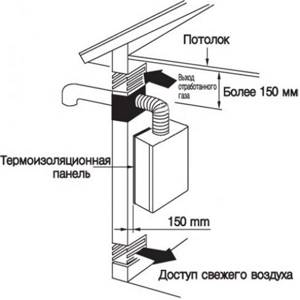

Moreover, most gas boilers are equipped with a turbocharged coaxial chimney, which requires the following installation procedure:

- in the supporting surface (wall), at a distance of 100-120 centimeters from the ceiling.

- On the outside, an external flange is mounted over the hole, into which the chimney pipe is passed.

- From the outside, the pipe is fixed using a heat-resistant seal and closed with an external flange.

Next, you will have to deal with mounting the heat-generating device itself, fixed to the wall.

To do this you will have to do the following:

- The boiler is “fitted” to the chimney by connecting the exhaust pipe to the socket of the coaxial hood.

- At the same time, the position of the left or steam upper corner of the boiler body is marked on the wall. And only one.

- Using the marked mark, attach the heater bracket to the wall, determining the position of the opposite top point using a level.

- After this, you can fix the lower part of the fastening structure.

- Upon completion of installation of the bracket, the boiler is “hung” onto the fasteners, fixing its location with screws.

Installation of a heating boiler by specialists

The next step is piping the boiler, which involves the following actions:

- American fittings are screwed onto the fittings of the water heating and main circuits - special adapters that facilitate installation of the boiler.

- Ball valves are screwed to the American ones, shutting off the supply of water and coolant if it is necessary to dismantle the heating device.

- Two filters are placed under the valve of the incoming fitting of the water heating circuit - a magnetic one for fine cleaning and an ordinary one for coarse cleaning.

- A coarse filter is installed under the valve of the incoming (return) fitting of the heating system.

- All free ends of the filters and valves are connected to the distribution outlets of the heating system and the pipelines of the hot water supply system.

Wall materials when mounting a gas-mounted boiler

The most common installation errors are related to insufficient fixation of the heat generator to the wall of the house. Existing standards indicate the need for rigid installation of boiler equipment. The boiler must be firmly fixed to the wall, strictly observing the vertical and horizontal levels.

READ How to make a boiler for a bathhouse with your own hands

The fastening requirements for installing a wall-mounted gas boiler largely depend on the material of the walls. Installation standards for wooden, plasterboard, reinforced concrete, brick, and hollow walls are specified separately.

Rules for installing gas boilers:

- A contract with the supplier regarding the supply of natural combustible material will be required;

- Installation of gas equipment must be carried out by an installation organization that specializes in providing this type of service;

Important. Compliance with the rules and requirements are mandatory measures for equipping a private home with a gas boiler.

The following are the features of installing a wall-mounted gas boiler.

Sequence of work:

- The installation work of the gas device must be carried out reliably, correctly and efficiently;

- Be sure to check the location using a level, and then set it as level as possible. To do this, place a hard and non-flammable material under one leg of the device (a piece of plastic ruler will do);

- Next, the boiler is connected to the chimney. If the equipment is not equipped with forced draft, then it is imperative to check the draft in the chimney;

- The connection to the internal heating system is made as follows;

- A hard filter installed before the return pipe enters and after the outlet to fill the heating system In this way, clogging of the heat exchanger will be avoided in the future;

In addition to being connected to the heating system, double-circuit equipment needs to be connected to a cold water supply;

By following all the steps to install and connect gas equipment to the heating system, observing the requirements of regulatory documents, knowing the rules and listening to the recommendations of experienced professionals, a high-quality work process and subsequent reliable results become possible.

Requirements for the premises for installing a gas boiler

The premises in which the gas boiler will operate are specified in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000 - these documents eliminate or minimize any emergency situations. Premises for placing gas boilers fall under the classification of fire and explosion hazards, therefore, when designing, planning, installing and setting up equipment for gas heating, all requirements for the premises for installing a gas boiler must be strictly observed.

General requirements for the installation of gas appliances

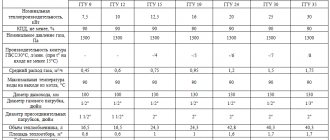

In the room intended for the installation of a gas boiler, according to the above standards, there must be good natural lighting: per 1 m 3 there must be at least 0.03 m 2 of window opening area (but not windows - partitions, frames and imposts are not taken into account). It is imperative to equip the room with a supply and exhaust ventilation system according to the following rules: the total volume of forward and reverse air flows per hour, multiplied by 3, is equal to the volume of the entire exhaust device. In addition to a window equipped with a window, a door with access to the street is installed in the room. The table shows the requirements for room volume:

For gas-fired units with a power of more than 6000 W, 0.2 m3 should be added for each extra unit of power.

Supervisory requirements for the premises for installing a gas boiler stipulate that the operation of any appliances for heating an apartment is permitted on each floor of a multi-storey building and in any room of the apartment. Kitchens in multi-storey buildings also meet these requirements, since they are already equipped with appropriate communications. The only condition is that the total thermal power of all devices for heating water and heating the apartment (boilers, boilers, heating elements, heating radiators, batteries or registers) should not exceed a total of 150 kW.

The ceiling height in the room is 2 meters or more. The room in which the gas boiler will be installed and operated must be separated from adjacent rooms by solid fire-resistant walls. Material for walls or partitions must have a fire resistance time limit of 0.75 hours (45 minutes). The boiler room must be designed so that in the event of an operational fire there is no possibility for the fire to spread throughout the apartment.

Gas boilers of the TLO brand, operating on the principle of natural coolant circulation, can be installed and should be operated only in the basement of the house or in the basement.

Requirements for individual premises

Boiler rooms located in separate rooms must meet a number of requirements, which are very similar to the previous ones:

- The ceiling must be at a height of over 2.5 m;

- The area and volume of the room are selected depending on individual preferences, but the minimum allowable volume is 15 m3;

- Each boiler room wall must have a fire resistance limit of 0.75 hours and no flame spread (brick, concrete and building blocks meet this requirement);

- Ventilation is subject to the same requirements as when installing a boiler in the kitchen - three times the outflow and the same amount of air intake, increased by the volume of oxygen consumed during the combustion process;

- The room must have at least one window with a glazing area of 0.03 m2 per 1 m3 of room volume.

Rules for installing a floor-standing gas boiler

- In a house under construction, it is necessary to plan a separate room for installing a gas-fired boiler. The room should have a natural flow of air through a grille in the door or through a hole in the wall.

- A separate hole must be made for supply and exhaust ventilation - it must be located under the ceiling.

- A hole in the wall for the chimney pipe, a hole below the chimney for a soot brush (for cleaning the chimney pipe), which is made below the main chimney by 20-30 cm.

- The chimney is made airtight so that smoke and carbon dioxide do not flow back into the room. To ensure tightness, a smaller diameter pipe is installed inside the large chimney pipe, through which gas combustion products are discharged.

- The room intended for installation and operation of a gas boiler must be spacious and provide easy access and operation, maintenance and repair of the boiler. The floor in the furnace room must be made of non-combustible materials - concrete screed, natural stone, paving stones. The furnace room must be connected to the water supply for the operation of the water heating device, and be equipped with a sewerage system.

- The area of the room for the boiler is 4 m2, the height of the ceilings in the room is at least 2.5 m2.

- The outer door must be 80 cm wide.

- The top of the chimney should be higher than the roof. The cross-section of the chimney pipe must be larger than the diameter of the boiler outlet.

- To supply power, the boiler room must be equipped with an electrical panel with grounding.

- The gas line is brought into the room in advance. A separate valve must be installed for each gas appliance.

- The walls of the boiler room are plastered - it is strictly prohibited to decorate the walls with flammable materials (MDF, fiberboard, plastic).

It is prohibited to store flammable liquids and objects near the furnace room and in the room itself. The foundation under the AOGV (gas heating unit or gas heating water heating unit) should not freeze in winter, therefore its depth should be below the level of soil freezing in a given region. The air from the vent should be clean, that is, the chimney should be located far from the vent. The room or building in which the gas boiler is installed cannot be equipped for other purposes.

Installation and piping of a wall-mounted double-circuit boiler

You need to start this stage of work after purchasing all the components, they may differ slightly in each individual case, this is due to the choice of connection diagram, there is a connection between a double-circuit boiler and a boiler.

The purchase of small things should also be taken seriously; due to a lack of fittings, the process will have to be suspended, which will cause a lot of frustration and increase installation time. If the necessary materials were purchased according to the list, then there will be no problems; you should double-check the availability of components before starting work or calling the experts.

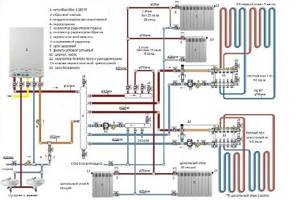

Strapping scheme

Thanks to this visual aid, you will be able to quickly find your bearings and choose the right sequence of manipulations. I always use one document to implement my plans, which I consider to be as accurate and practical as possible, and I want to share it with you.

When installing a double-circuit boiler, the following components should be provided:

- Cranes.

- Filters.

- Sgony.

- Corrugated hose.

- Pressure gauge.

- Thermostat.

- Chimney pipe.

- Safety valve.

It would be a good idea to first lay out the tool at the installation site and check its availability before doing so. If you are missing one of the keys, you should not buy a whole set; an adjustable wrench will help solve the problem; it will not be suitable only in those places where space will be limited, since the main part is quite large.

Mounting double-circuit boilers on the wall

At this stage, everything starts with choosing a location; it is worth highlighting a load-bearing wall if a coaxial chimney will be used in the future.

An interior partition is also suitable for straight structures; such solutions are typical for a private house. To secure the wall-mounted unit, special strips are included; the height should be adjusted in relation to the floor; it varies from 0.8 to 1 m.

To carry out installation, you need to drill holes in the wall; for this it is better to avoid hollow spaces in the partition, otherwise the device will not be securely fastened. Anchors are very popular; they are much safer than ordinary self-tapping screws with dowels.

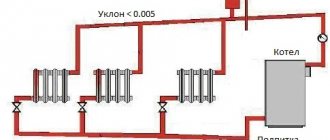

Connecting a wall-mounted boiler to the heating system

If the preparatory work is carried out correctly, problems will not arise at this stage, but do not forget that the circuit of the heating and hot water equipment must be flushed. During assembly at the manufacturer's factory, various small debris could get there; such actions should not be ignored.

Before connecting the incoming pipes, taps are placed on them, the same manipulations are performed with the outlet pipes, this solution will help to cut off the equipment at the time of dismantling without loss of coolant and liquid from the hot water system. After equipping the structure with squeegees, you can proceed to connecting the heating main; at this stage, install a circulation pump, if necessary.

Connecting the chimney pipe

When using a coaxial structure, which is chosen by 95% of owners of apartments and houses, one point should be taken into account; it concerns the creation of a slope of 3-5 degrees. This solution will help prevent the resulting condensate from getting into the equipment; all accumulations will be thrown out into the street.

If the power of the unit without a water heater is quite large, then only a vertical chimney can handle the removal of combustion products; in private houses, such devices are created with the least number of turns, the upper part should rise above the roof by at least 0.5 m.

Connecting a double-circuit boiler to the network

In most situations, there are no difficulties when performing manipulations of this kind, as in the case of an electric boiler, just plug the plug into the outlet. But every owner should know about safety rules and requirements.

An important point is the presence of grounding; a circuit breaker is also very popular, but its location should be thought through in advance. At the time of an emergency, no liquid should enter the device, otherwise a short circuit will occur and the device will not perform its main function.

Generally accepted standards include the following:

- The presence of a wire with grounding; if the equipment package does not include a cord, then the element is purchased separately.

- It is prohibited to use steel pipes for grounding the hot water supply.

- When laying the cable, it is equipped with corrugation.

When installing turbocharged units with a water heater from foreign manufacturers, inexperienced craftsmen often confuse phase with zero; it is worth paying attention to this point and double-checking the correctness of the work. If you make such a mistake, the unit simply will not start the system, which will cause confusion among specialists and the owner.

Rules for installing wall-mounted gas boilers in an apartment

Typically, in an apartment, a gas boiler is installed in the kitchen, since it already has a gas line, water supply and sewerage. That is, a priori, all requirements for the installation of gas equipment have already been met - all that remains is to connect the boiler. This state of affairs automatically reduces the cost of laying utilities and energy resources. It is prohibited to install a gas boiler in rooms with high humidity - in a bathroom, laundry room, etc.

There are several additional requirements for wall-mounted boilers:

- The wall or partition for hanging the boiler must be able to support it - equipment cannot be hung on a plasterboard or other light partition.

- If the wall is decorated with flammable materials (wallpaper, vinyl, plastic, MDF, fiberboard), then a 3 mm thick gasket of non-flammable material is installed between the gas wall-mounted boiler and the wall. In this case, the boiler must be secured with special hardware that ensures a distance from the boiler body to the wall of at least 4-5 cm.

- The minimum distance from the boiler to the ceiling and walls of the room is 0.5 meters. The distance from the boiler to the floor is 0.8 meters.

Before installing and starting up gas equipment, you must obtain all relevant documents. The main condition when installing a boiler in a private house that runs on gas is that an agreement on connecting the gas main is first concluded, and a project for the installation of gas equipment and gasification of the house is drawn up. These documents are developed and approved by the gas supplier in the region.

How to install a gas boiler

Installing autonomous heating in a house or apartment is expensive. Connection to the gas mains may only be carried out by certified specialists, but the rest of the installation of the gas boiler and heating/DHW system can be carried out independently.

How to secure a chimney for a wall-mounted boiler

The rules for installing a chimney depend on what type of boiler they plan to install. Atmospheric heat generators use natural draft. Boilers with a closed combustion chamber are connected to a coaxial chimney, and combustion products are removed and air is taken in using a forced method.

Features of the operation are reflected in the connection requirements:

- Rules for connecting to a classic chimney - the boiler is lowered two chimney diameters from the point of connection to the smoke exhaust duct. For combustible walls, the thermal insulation substrate is extended on the wall behind the boiler, lifting it upward by at least 25 cm. When passing through the floor slab and roofing pie, a special groove is installed. It is prohibited to install decorative decorations on the chimney head. To increase traction, a deflector is mounted. height of the pipe is calculated depending on the distance from the roof ridge.

Installation rules with a coaxial chimney - the pipe is connected to the boiler and removed from the building in a horizontal direction. The maximum length of the horizontal section is no more than 3 meters. Fasteners are installed every 0.5 m. Fixing fittings are mounted taking into account joints that require fasteners to be installed on each side. Exit through the wall is carried out through a special penetration. Self-production of the passage unit is allowed. To do this, drill a hole 2 cm larger than the diameter of the pipe on each side. The coaxial chimney is installed in the center. The gap is filled with basalt insulation.

To fix chimneys, ready-made fasteners are used with the ability to change the distance to the surface.

How to attach to a reinforced concrete wall

Reinforced concrete is the optimal wall material for installing a gas heating boiler. Precast concrete structures are durable and belong to the group of NG (non-combustible) materials. To install the boiler, no additional conditions are required.

The work is carried out using metal anchors, through which the mounting plate is fixed strictly according to the level. The boiler is hung on the prepared site. A reinforced concrete wall is suitable for installing any type of heater: high power, with a built-in storage boiler, etc.