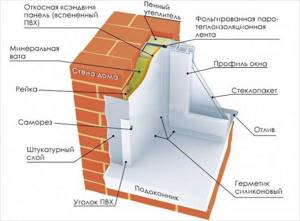

Effective thermal insulation of a room implies insulation of all parts of the building. Particular attention is paid to those points where there is a risk of the formation of cold bridges. Therefore, an obligatory step is the insulation of window slopes from the outside using different materials and technologies.

Insulating the slopes protects the window opening from freezing and condensation.

Features of insulation of window slopes

Thermal insulation of external window slopes affects the comfort of living in the house, because... maintains an optimal and correct microclimate throughout the year. The procedure does not require the involvement of specialists or professional equipment. You can implement it yourself using available tools.

Since there are seams between the window frame and the wall, they are usually filled with foam to prevent drafts. This substance has good thermal insulation parameters, but can be destroyed by moisture. Boxes that do not have additional lining are not sufficiently protected from negative factors. If there is no insulation, the joints will be exposed to water, so over time the fasteners will begin to wear out and the window will sag.

After the structure shrinks, voids appear between the opening and the frame, which provokes freezing and the formation of cold bridges.

Insulated windows do not accumulate condensation inside the building, and therefore prevent the appearance of mold in residential areas.

We insulate the inside

Having decided how to insulate the slopes, we move on to practice. Sometimes it happens that when a plastic window is installed, despite good treatment with foam, the glass gets wet and there is a strong blow from the slopes. This is often the result of careless installation, as a result of which the structure will have to be put in order yourself.

Primary tasks:

- Remove any remaining foam.

- Treat the surface with a primer with an antibacterial effect to prevent the appearance of mold in the future.

- We plaster the window area, achieving a flat surface onto which foam plastic can then be easily glued.

- We thoroughly clean the plastered areas, apply primer and begin laying insulation.

- In the case of polystyrene foam, the surface must be scratched with an emery sheet to reduce the smoothness. After which the material can be safely glued to the slopes. When cutting out the required pieces of foam, measure out slightly larger sizes, which can always be trimmed instead of gluing the missing pieces.

Before gluing the foam, it is recommended to scratch its surface - Let the structure dry and putty the corner.

- After laying the foam, we proceed to the finishing coating, chosen to our own taste. This can be plasterboard covering or decorative plastering.

Having figured out in practice how to insulate the slopes of plastic windows inside, we move on to external work.

Reasons for passing cold air

The key places where heat escapes and cold air enters are:

- Double-glazed window fasteners.

- Sealing rubber around the perimeter of the window.

- Elements under fittings, etc.

There are several reasons explaining the intense heat loss. Most often, the problem occurs due to non-compliance with the rules for installing double-glazed windows and deviations from technology.

Negligent actions of the installation team, poor quality treatment of voids and lack of tightness of joints provoke the appearance of cold bridges. If you do not properly line the slopes, then over time environmental factors will provoke the destruction of the insulating layer in the form of construction foam.

Often, cold bridges appear due to the natural shrinkage of a new building or wooden structure, which causes the window frame to warp.

Associated reasons include improper care of the structure, for example, lack of regular washing.

Experts note that to maintain the functionality of the system, it is necessary to wash the window seal 1-2 times a year and treat it with glycerin. This will prevent it from cracking during operation.

Cold air enters the building when the pressure flaps are loosened. The problem is resolved by adjusting the fittings.

Adjusting the clamping mechanism

During the operation of a building, windows and doors are exposed to climatic and mechanical influences. This provokes a loss of seal volume and cold penetration into the room. To fix the problem, you need to adjust the clamping element without replacing the sealing gasket.

Scheme for adjusting the pressure of a plastic window.

To do this, find a special protruding cylinder at the point where the mechanical plug is placed. Next you need to move the hooks to the optimal level or adjust the trunnions. To adjust the position of the hooks, the bolts are unscrewed. If you move them towards the street, the pressure will be increased, and if you move them back, it will be decreased.

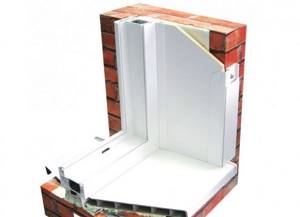

Types of designs

Slopes are the outer or inner surface of the window opening from the frame to the wall. These elements perform several functions. First of all, their presence gives the window a complete and more aesthetic appearance. Slopes also prevent noise from entering the room and provide thermal insulation. There are several types of structures that differ in finishing techniques, materials used and functionality. Let's take a closer look at the main types of slopes:

- Slopes made of plasterboard material. They have good thermal insulation properties and a relatively affordable cost. However, the performance characteristics are inferior to subsequent types of structures, since they can only be installed from the inside of the room. The reason for this is the instability of the material to moisture.

- The most economical option is considered to be slopes using plaster. The plaster composition is applied to the surface of the opening in two layers, and after it dries, the primer mixture and paint are applied. Such a slope can last quite a long time, but has a number of disadvantages. Plaster slopes have relatively low heat-saving properties, and as a result of temperature changes, cracks can form in them; the installation process is quite labor-intensive. In addition, plastic and cement are incompatible materials, which may result in the need to eliminate gaps between the window and the slope.

- Plastic-based slopes are recognized as the most durable. They are resistant to moisture and sunlight, and also go well with plastic windows. Insulation of plastic slopes can be done using mineral wool or polystyrene foam. The working surface must be thoroughly cleaned of dirt and all defects must be eliminated. Then cut the insulation to the required size and secure it with glue. Then along the perimeter of the slope it is necessary to drill holes into which to hammer plastic dowels.

How to determine where a draft is coming from a window

Even if there is one defect in the window structure, this will lead to drafts. To find out which direction it is blowing from, you can use the following methods:

- Run your hand around the perimeter of the window and check where there is a draft.

- Using a lighter, evaluate where the intensity of the flame changes.

You can also place a sheet of paper in an open window and then close the sash. Next, you should pull the tip of the sheet: if it comes out easily, the seal is not pressed well enough.

Thermal insulation materials

Various materials are used as insulation for thermal insulation of slopes. They differ in cost, characteristics and installation technology.

Expanded polystyrene

It is considered an effective insulator among all slab modifications. The material does not deteriorate in an environment with high humidity, and is not afraid of the effects of pathogenic organisms and mechanical loads. It can be used both for external and internal work.

Expanded polystyrene is an inexpensive and easy-to-use material for insulating slopes.

The structure of polystyrene foam contains many air bubbles. They form solid foam and retain heat efficiently. Extruded grades have zero vapor permeability. For foam modifications this figure is 0.019-0.015.

Styrofoam

It is produced in the form of slabs measuring 100x100x2 cm. It is characterized by low price and ease of installation. The negative aspects are associated with the rapid absorption of moisture with the subsequent loss of initial properties. During operation, the foam takes on the appearance of dust.

Polyurethane foam

Using polyurethane foam, you can close all the voids in the window sill space. The substance is a compound of polyol and isocyanate with the inclusion of a number of additives. Foam series with varying degrees of rigidity and expansion are offered for sale. When all components are combined, the mixture is transferred to an aerosol can and used for its intended purpose. Under the influence of the propellant, the mass comes out, reacting with the liquid that is on the structure being treated and in the environment. The material is distributed in several layers until the insulation thickness reaches 3 cm.

Sandwich panels

Suitable for interior and exterior finishing of slopes. Using the panels, you can protect the polyurethane foam, which is located between the PVC plates, from the negative influence of the environment and the appearance of cold bridges. When laying the material, it is necessary to seal the ends to securely close the filler.

Sandwich panels are used for both external and external types of insulation.

Plaster

Combines the properties of putty and foam. Since the substance is in a liquid state, it fills voids efficiently, forming a durable window frame. After drying, the mixture creates a high-quality temperature barrier between the building and the street. The insulating parameters of the solution are increased as a result of the inclusion of polystyrene foam balls and various additives in the initial raw material.

Basalt wool

Sold in slab and roll versions with a thickness of 50, 100 and 150 mm. The insulator is distinguished by its effective air permeability and is suitable for insulating frame or wooden structures where it is important to maintain good ventilation.

Since the material is hygroscopic, it should be covered with membrane fabric, followed by the installation of plastic panels or a layer of plaster.

Other

As an affordable alternative to polystyrene foam, penoplex is used, which is suitable for treating slopes inside and outside the building. Insulation is also carried out by plastering surfaces with further lining with a decorative composition. Fiberglass is a good insulator. It is characterized by high-quality heat conservation and protection against moisture penetration.

Fiberglass fabric with a foil base does not allow moisture and does not let air in from the street.

No. 7. Finishing slopes with metal

Metal slopes are used only for exterior decoration; they began to be used back in Soviet times. This is one of the most successful ways to protect slopes from the outside. Among the main advantages we note:

- resistance to moisture, temperature changes, microorganisms, sunlight;

- metal does not crack like plaster and does not require regular coating renewal;

- metal tolerates low temperatures well, unlike plastic;

- metal with a polymer opening has enormous durability, does not rust, retains its shape and color, and protects windows from blowing;

- the color of the metal can be any, so the finish can be successfully combined with any façade material;

The main disadvantage is only the high cost, but every year you will not have to whitewash, tint the slopes or seal cracks in the plaster. It is best to install such slopes immediately after the installation of the window is completed.

Preparatory work

Before the main stage of slope insulation, several preparatory measures must be completed. First, you should seal the seams, especially the external ones, to avoid blowing through the windows. It is important to ensure that the voids are well sealed with the foam used during installation of the structure.

Visual inspection of the window system is a mandatory stage of preparation, regardless of the method and material of thermal insulation. If the installation of a double-glazed window was carried out a long time ago, and the installation seam is not processed, the foam layer may collapse and crumble. Defective areas are determined by using a lighter, which is passed around the perimeter of the window. When identifying cold bridges, you need to clean such sectors and re-treat them with the composition. Excess foam should be cut off.

Technology of work on the internal slope

To begin with, prepare the slopes yourself. They need to be cleared of debris and the cracks covered with cement mortar. Next, apply the primer with a brush to the entire surface. While the primed surface dries, we prepare the blanks (cut them to size).

Then, an adhesive solution is applied to the surface of the foam plastic with a notched trowel, and the workpiece is pressed against the slope. You can immediately pick up a building level, checking how level the installation is, because if the surface is uneven, this will significantly complicate the installation of windows. For a clearer installation, we recommend fixing the foam plastic to dowels at several points, then the plate will definitely not move away from the slope.

Next, all the foam plates are installed, with careful joining. If possible, you can additionally putty the joints to ensure that there are no gaps.

Now we apply the starting putty to the surface, attach the reinforced mesh, and apply the finishing layer of putty on top. So the internal slopes made of polystyrene foam are ready. What about the outside ones? Let's take a look now!

Required Tools

The work is performed using the following tools:

- Level.

- Hammer.

- Miter box.

- Marker.

- Stationery knife.

- Personal protective equipment.

- Set of brushes and spatulas.

- Hacksaws.

- Roulettes.

Necessary tools for insulating window slopes.

The list of required materials includes an adhesive mixture on a synthetic or organic basis, putty solution, facade plaster, deep penetration primer, antiseptic, and heat insulator.

Taking into account the specifics of thermal insulation, the set can expand and vary.

Stages of the installation process and their characteristics

Having decided on the key characteristics and advantages of the insulation, it is necessary to follow the installation technology

It is important to know how to insulate windows with polystyrene foam in such a way as to create excellent conditions for tightness and long-term operation. To do this, it is worth doing the work step by step, giving each stage great importance:

cut out strips of polystyrene foam to the required length and width. As a rule, a sufficient size is 5–8 cm. The thickness of the insulation should be at least 5 cm, otherwise the effect will be barely noticeable; We clean the external window openings. Expanded polystyrene adheres well to brick, so it is advisable to clean the surface of foreign building materials, especially if they adhere weakly

It is important to fill existing cracks with cement mortar and treat areas where mold or mildew has formed. The façade can be further strengthened by using a deep penetration primer; install polystyrene foam slopes

Special glue or dowels can be used as a fixer. The combined use of fasteners ensures greater durability of the structure. It is important to know that for better drying of the glue, a temperature of at least +5 degrees is required - keep this in mind when planning insulation. When using polystyrene foam, it is recommended to play it safe and install both types of fasteners to significantly increase durability; We blow out the cracks that have arisen with polyurethane foam, after which has dried, you can begin to apply the plaster. The process is mandatory, since even a material that is relatively inert to the influence of the external environment is subject to aging under the influence of environmental factors. It is important to use a reinforcement mesh during the installation process - it will provide additional protection for the surface. Plaster will give the product greater strength and provide it with a long period of operation. After plastering, the surface is painted.

How to insulate window slopes with polystyrene foam in order to extend the period during which the material will remain airtight? It is important not to rush in the process of installing slopes - in order for the insulation to stick better, it is necessary to allow both the glue and the mounting foam to dry well. In general, we can say that having an understanding of how to insulate slopes with polystyrene foam, even a non-specialist can cope with the task

Do you have the skills to work with the necessary building materials? Can you carry out each stage of the work carefully and accurately? The procedure does not require the use of special equipment, so feel free to start insulating window slopes.

How to insulate the slopes of plastic windows from the outside

To ensure high-quality protection of your home from heat loss, you should insulate the slopes in a timely manner. Penoplex is suitable for such work. In addition, you will need to purchase a sealant.

Next you should follow the following algorithm of actions:

- The surface is cleaned of dirt, dust, old paint and building material residues and leveled with a cement mixture.

- After the preparatory layer has dried, the insulator is cut into the required lengths.

- The sheets are coated with glue and placed on the slopes. To strengthen the installation, dowels are used, which are installed at different points. The adhesive layer should be 1-3 mm thick.

- At the next stage, the corners are installed. They are necessary to obtain smooth and high-quality insulated slopes.

- The outer part of the insulator is treated with special glue and reinforced with reinforcing mesh.

- The layer is leveled with putty.

- Finally, water-based paint or other facing materials are distributed.

Finishing options

After completing the insulation work on the slopes, if desired, they can be given an attractive and original look. There are several ways to do this.

- The most common method of finishing a slope is painting. There are several technologies for performing this type of work. The easiest way is to apply paint with a sponge. Imprints are made on the surface with a sponge pre-moistened in paint. You can make a combination of several colors. Another way is to apply paint using a stencil.

- An interesting solution would be to use balsa wood. This material has good thermal insulation qualities. Therefore, its use will solve not only a decorative problem, but also make the slopes even warmer. If desired, balsa wood panels can be coated with a layer of varnish.

- You can also put wallpaper on the slopes.

Common Mistakes

The key mistake when insulating slopes is to use exclusively polyurethane foam. During the expansion process, the material has a deforming effect on window systems, breaking their tightness.

Often, inexperienced installers violate the ventilation regime by not maintaining the gap between the components of the structure.

A common mistake is using low-quality insulation, which not only does not improve thermal protection, but also harms the microclimate in the room.

Video “How to insulate slopes”

In the video you can see what technological solutions are used by European developers of installation technologies. Watch the recording and find out how the process of insulating slopes and walls occurs, as well as what materials are needed for this.

We recommend that you read

Finishing window slopes with sandwich panels - the final stage of installation

Instructions for installing slopes with your own hands

How to make high-quality finishing of external window slopes

Other options for dealing with drafts

If it is not possible to carry out insulation work, and you need to get rid of drafts in a short time, you can consider alternative ways to solve the problem:

- Glue a sealing layer around the perimeter of the window. This is done before winter, when frequent opening of windows is not planned.

- Secure mounting tape at the joints and crevices of the structure. The method was used back in the USSR.

- Install heat-saving film on the glass unit.

- Fill the cracks and joints with available materials (wet paper, pieces of fabric, cotton wool, etc.).

- Hang thick curtains to reduce heat leakage to the outside.

Expert advice

For high-quality insulation of slopes, take into account the recommendations of experts:

- If it is not possible to buy polystyrene foam, you should use separate pieces of this material, leaning them against each other.

- To obtain good bonding of the parts, they are treated with an adhesive mixture, and then a reinforced mesh is applied over this layer. It is important to adhere to the permissible dosage of the mixture.

- To increase the thermal insulation properties, it is necessary to use a sealant, especially if the voids between the window and the frame reach 3 mm or more.

- For convenient work, you should prepare thermal liners that repel moisture and retain heat indoors.

The voids between the frame and the window are filled with a special sealant.

How to insulate plastic windows for the winter

The material is selected depending on the area that needs to be insulated.

| Insulation | Mode of application |

| Polyurethane foam | The voids between the window opening and the frame (installation seam) are filled around the entire perimeter |

| Mineral wool (for interior work) | Insulation of window sills and internal slopes with a mounting seam width of 30 mm or more |

| Foam plastic, polystyrene foam | Insulation of external and internal slopes with a mounting seam width of less than 30 mm |

| Dry building mixtures (plaster, putty for exterior work) | Insulation of slopes, protection of insulation from the influence of the external environment outside |

| Silicone sealant | Sealing gaps between plastic window elements |

| Construction tape | Glued on top of the sealant or instead of it |

| Energy saving film | Adheres to the inner surface of the glass unit |

| Rubber compressor | Replacing dry or damaged seals on the sash and frame |

To protect insulation from mechanical damage and as decorative coverings for slopes indoors, plastic panels and plasterboard are mainly used. The latter requires additional puttying and painting.

User reviews

Vladislav, 43 years old, Kirovsk: “The problem of cold in our region is not uncommon. Trying to reduce heating costs and improve thermal insulation in the house, I insulated the slopes. I used basalt slabs for this. The result of the work is about 30% savings and effective heat retention in the room.”

Egor, 29 years old, Vladivostok: “When arranging a private house, I did not pay enough attention to thermal insulation of the slopes from the outside. As a result, cold bridges began to appear in winter, and the efficiency of heating the building decreased sharply. I solved the problem by insulating the window structure with polystyrene foam and warm plaster.”

conclusions

Having warm slopes for plastic windows is a necessity. Now, which option to choose to insulate window slopes from the outside or from the inside depends on:

This article highlighted the theoretical aspects of window insulation. Also, practical points were noted: for example, do you remember how to properly seal the joint between a profile and a wall and why exactly? This was described above.

Be sure to leave any remaining questions in the comments.