Advantages and disadvantages

Advantages of the material:

- Thin and invisible material.

- It is possible to paste both plastic and wooden windows.

- Simplicity and speed of installation - no auxiliary labor or special tools are required.

- Low cost.

- Environmentally friendly material.

- The film does not burn, but melts at high temperatures.

Some disadvantages:

- The material may tear (burst) upon strong physical contact.

- The service life is not long - 1-2 years.

Maintenance for plastic windows

It is possible that the question of how to seal the windows for the winter will disappear by itself after adjusting the fittings. You can do this process yourself using a hex wrench. It is better to carry out adjustments 2 times a year: before the onset of summer and in the fall, before it gets very cold.

By rotating the key from side to side at a specified distance, you can change the degree of pressing of the sash and get rid of the draft. Such maintenance will not allow the fittings to sag and deform, which inevitably happens with temperature changes.

Do-it-yourself window insulation

There is nothing complicated in the process of finishing a window with film - not only a qualified specialist, but also the owner of the house can handle this task.

No special skills or tools are needed, but some rules must be followed. Required materials and tools:

- film;

- special colorless double-sided tape;

- roulette;

- long ruler;

- pencil or marker;

- construction knife or scissors;

- cotton gloves;

- regular hair dryer;

Step by step guide:

Initially, you need to make sure that there are no cracks in the window frame. In plastic windows this unpleasant nuance practically does not occur, but in wooden windows it may be present.

Wooden windows contain frames in their design, which entails the presence of many joints through which cold air can pass through. For high-quality sealing of seams and other cracks, transparent sealant or silicone is used.

You can proceed with further actions only after they have completely dried:

- The inside of the window frame needs to be washed. To do this, you can use household chemicals or soap solution.

- Afterwards, the frame is treated with degreasers (preferably ethyl alcohol 96%).

- Double-sided tape is glued along the edge of the frame (along the perimeter).

- Next, the film unfolds on a large table. If it is folded in half, it needs to be stratified. To do this, it is advisable to blow on the joints. Holding the two edges, it gradually separates.

- It is necessary to measure the horizontal and vertical dimensions of the glass unit in advance with a tape measure.

- The recorded indicators are transferred to film, with a tolerance of 1.5-2 cm for attaching it to tape.

- You can cut the material with a knife or scissors, because it is very pliable to cut.

- The protective paper layer is removed from the adhesive tape attached to the frame.

- First, the cut out area must be leaned against the upper horizontal plane of the tape and pressed carefully.

- Next, you need to pull it a little and press the edges of the film against the vertical strips of tape.

- In the lower part, the fastening process is identical to the previous ones. Thus, the film is fixed in the desired position and is ready to serve for a long time.

Recommendations in progress:

- Before completely sealing the window with film , you must thoroughly wash the glass.

- (fingerprints or other contaminants) remain on the canvas,

- If folds appear on the surface of the material during the process , this can be corrected using a regular hair dryer. To do this, it is necessary to spray the film with a stream of hot air escaping from it - which causes shrinkage.

- During the process of gluing the film , it is not recommended to stretch it too much, because the surface may burst. And it is almost impossible to repair it, unless you stick a strip of tape, but over time the defect will become noticeable.

- If the window is large enough , it is better to carry out the work together.

- Do not allow the film to sag or touch the glass - this will not provide good heat conservation.

Thermal insulation of plastic double-glazed windows

High-quality plastic double-glazed windows are equipped with special rubber seals, which, due to their tight fit to the frame, prevent the passage of air from outside to inside the room.

The areas through which cold passes are:

- the junction of the plastic frame with the window sill and slopes;

- glass.

So, what methods of metal-plastic double-glazed windows can be used for insulation?

Seam sealing

The photo shows the consequences of cold air circulation through the gap between the frame and the window sill

Even after high-quality plastering of the slopes, a micro-gap remains. If this micro-gap is not sealed, it will cause cold air circulation and condensation. As a result, fungus may appear at the junction of the slopes and the frame.

Everything you need to close the gap

To close the gap you will need the following materials and tools:

- Sanitary silicone in a tube;

- Mounting gun for working with sealant;

- White Spirit;

- Sharp knife

- Awl;

- Paper napkins.

Instructions for sealing seams are given in the following diagram.

Insulation of plastic windows with silicone sealant

Let's consider the listed stages in more detail:

- Using the tip of an awl, we widen and level the gap along the entire frame;

- We moisten a paper napkin with thinner and carefully wipe the joint between the slopes and the frame;

- We prepare the tube for work, namely, we cut off the plastic tip with a knife, insert it into the gun and screw on the cone of the nozzle;

For plastic frames we use sanitary silicone or acrylic sealant

- Fill the gap with sealant around the perimeter of the glass unit;

We process the window sill of a plastic window from all sides

- If necessary, level the seam and clean the adjacent surfaces from contamination.

Sanitary sealant is completely removed with white spirit within 20 minutes after application. After 20 minutes, the sealant will be very difficult to remove.

Now the most important thing you need to know when filling the gap between the slopes and the frame with sealant.

Instructions for installing heat-saving film

The installation procedure for an auxiliary product is not complicated and does not require the purchase of special tools; you just need to follow a number of rules.

Materials and tools

In the process you will need:

- film;

- roulette;

- marker or pencil for marking;

- cotton gloves,

- transparent double-sided tape;

- scissors or stationery knife;

- long ruler;

- an ordinary household hair dryer.

Before starting work, you should make sure that there are no gaps or cracks in the frame structure. This problem is not typical for plastic profiles, but it occurs often in wooden ones. In the latter case, the presence of bindings leads to the formation of numerous joint zones through which cold air penetrates. This effect can be avoided by using silicone or any transparent sealant. After application, they should be left untouched until completely dry.

First of all, the window is thoroughly washed

Step by step guide

Warming is carried out in the following order:

- It is necessary to thoroughly wash the windows from the inside, preferably using a soap solution and household cleaning chemicals.

- The frame must be treated with any degreasing compound and double-sided tape applied around the perimeter.

- The film roll should be unrolled on a clean horizontal surface, preferably on a large table. A product folded in half must first be delaminated by gently blowing on the joints. Next, you need to grab the edges with both hands and pull so that they separate without damage.

- You need to measure all the parameters of the glass unit using a tape measure, then you should mark the film based on the obtained geometric parameters. You need to leave an allowance of 1.5-2 cm on all sides so that you can properly fix the product with tape. The material is cut according to the markings.

- Remove the protective layer of paper from the tape already attached to the frame. Next, fix the cut piece of film, starting from the top, carefully pressing the edges to the adhesive strip.

- The fabric needs to be stretched a little before aligning the edges with the vertical adhesive strips.

The last step is to fix the bottom edge, followed by additional smoothing along the perimeter.

The canvas needs to be stretched a little before aligning the edges with the vertical adhesive strips

To make the process easier, you should use the following recommendations from the experts:

- to ensure complete sealing of the opening, the glass must be thoroughly washed;

- cotton gloves will help avoid the formation of fingerprints, streaks and marks on the film;

- If during installation the surface of the material becomes covered with folds, they can be removed using a household hair dryer. The fact is that the product will inevitably shrink if it is sprayed with jets of hot air. In this aspect, shrink film is most convenient for installation;

- Do not over-tighten the product during installation, as it is easily deformed and torn;

- The arrangement of a large window is easier to do with two people.

Tips for preparing for insulation

Before you begin installing thermal film for window insulation, it is necessary to carry out careful preparation so that the effect of its use is maximum.

Before you begin insulating windows, you must perform the following steps:

- Inspect the windows, clean them from dirt and dust, degrease them and let them dry;

- If the opening parts do not fit tightly enough to the frame, then use rubber or foam rubber to eliminate the gaps;

- Inspect the window frames, if you find cracks in or around them, seal them with special putty;

- To improve the effect, it is best to glue the seams with either special tape or white paper;

- Make sure that the glass fits tightly; correct any imperfections using transparent silicone;

- Remove the handles.

Price

The cost of the material is influenced by several factors, the most important one was mentioned above. The rest are:

- Manufacturer of heat-saving film - German and Polish versions are often more expensive than domestic ones;

- Canvas size - larger materials are cheaper (in terms of size-price ratio).

Countries producing heat-saving films for windows:

- South Korea;

- China;

- Türkiye;

- Ukraine;

- Russia;

- Germany;

- Poland;

- Other.

Most often, the following brands can be embedded in online stores:

- Thermo Tap;

- NANOFILM;

- USB (Ultra SolarBlock);

- ESB technologies (Russia);

- Heat technologies (Poland).

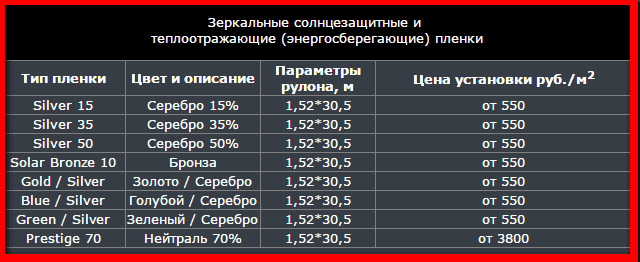

The screenshot below from one online store shows prices for energy-saving (more expensive) window films.

There are, of course, cheaper options. For example, film from the Polish brand “Heat Technologies” can be purchased at a price of 500 rubles per set. There are two types of sets: 1.1 by 6 meters and 2 by 3 meters. The average price per square in this case will be 85 rubles. As a bonus, the set contains a 20 meter roll of tape.

The cost of insulating one window with film

A window measuring 1400 by 1300 mm will require approximately 1.82 squares of film and 5.4 meters of tape. Thus, the cost of thermal insulation with Polish film will be 150 rubles per window.

Examples of popular brands and brands

Transparent window film Ultra Solar Block, a South Korean multifunctional protective product, is in demand in Moscow and the regions. The brands “Heat Technology”, Thermo Tap, “ESB-Technology”, NANOFILM have also proven themselves well. The cost of products depends on both the brand and the thickness of the canvas, dimensions (small pieces are more expensive than large pieces), complexity of installation, service life and additional options.

Plastic windows are an excellent barrier to cold air in winter, but in severe frosts, if they are not insulated correctly and on time, problems may arise. Warm air will begin to go outside, and cold air, along with moisture, will come into the room and cause icing of the glass. To get rid of this, you can insulate the opening by sealing all the cracks. A fairly common method is to insulate a plastic window with film : it gives good results at minimal cost.

Thermal insulation film

Thermal insulation film is an affordable and reliable thermal insulator for windows, which is manufactured using new technologies. The thinnest layer of this material is coated with a special molecular substance, which provides a thermal insulation effect. At the same time, it is absolutely transparent and does not damage the surface of the glass.

Main characteristics of this material:

- Can repel dust.

- It can be used both in the summer and winter seasons.

- They can be used to insulate not only windows, but also greenhouses, doors and loggias.

Also, the thermal insulation coating can have an opaque structure, which makes it stronger. This material can be used several times.

Installation of this material is carried out using the following technology:

- First you need to prepare the surface of the window - clean it from dust. You will also need the following tools:

- Hair dryer.

- Knife.

- Scissors.

- Scotch tape (double-sided).

- If the window has gaps or cracks, they should be repaired.

- After this, you need to glue double-sided tape to the frame.

- Next, take out the covering and cut off the desired part. Carefully stick it on the tape. At the same time, it is very important not to forcefully pull the film itself, otherwise its integrity may be damaged, which will lead to deterioration of thermal insulation.

- The material must be glued tightly so that it adheres well to the entire surface of the glass.

- Next, you should turn on the hairdryer and heat the material so that it “fits” even better to the glass and seems to completely merge with it.

Peculiarities

The product is made of PET, the thickness directly affects the performance characteristics of the coating. Thanks to its qualities, it can make glass stronger.

Under mechanical stress, glass covered with a thick thermal insulation film will not shatter into small pieces, but will hang almost like in a car. Thanks to its elasticity, it is convenient to use and easy to stick to a flat surface.

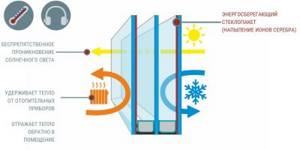

The surface is coated with a very thin layer containing silver or chromium-nickel composition. These components block infrared rays. Consequently, thermal energy is returned back to the room. At the same time, the layer of material transmits daylight from the street.

Polyethylene film

This is the simplest and cheapest way to reduce heat loss.

This material has the following advantages:

- Low cost.

- Easy to install.

- Easy to care for.

Its disadvantages are:

- Insufficient heat conservation.

- The opacity of a material that does not transmit light.

- Possibility to use only once in one segment.

- It will collect dust.

Installation of polyethylene covering is carried out according to the following principle:

- Measure the required length of material based on the size of the window.

- Prepare the frame itself.

- Using sharp pins or tape, carefully attach the film along the entire frame, leaving no gaps through which heat could escape.

It is not difficult to care for such material; you just need to remove dust from it in time.

Energy saving film

It is considered the most practical and effective because it has the following advantages:

- Maintains the desired temperature in the room.

- Increases sound insulation.

- Keeps out the cold.

- Does not allow moisture to pass through.

- Protects the window from freezing, which increases its durability.

- Increases strength in glass (especially if it has a third glass effect).

- Does not transmit infrared rays.

However, energy-saving insulation also has its disadvantages:

- In spring, it may limit the amount of sun rays.

- If installed incorrectly, it will be difficult to re-glue the film.

Installation of this material is carried out according to the following scheme:

- Degrease the surface of the window frame with alcohol.

- Apply double-sided tape around the perimeter and remove the protective strip.

- Layer the film itself (it is folded in half).

- On a clean surface, cut it to the size of the window (also allow for a few centimeters to add for tape).

- Carefully (it is better to do this with someone’s help) glue the film with tape, holding it on the top and bottom sides. In this case, the material itself should only be glued to the frame and not touch the glass!

- Use warm air from a hairdryer to heat it up until the insulation itself stretches across the window.

What is Third Glass?

The third glass (third window) window insulation film is called heat-saving or thermal film. Sellers claim that it reflects heat, keeping it indoors. The temperature inside a room with insulated windows rises by 3-6 or 4-8 degrees.

To insulate windows, you need to stick double-sided tape on the frame around the perimeter. A film is stretched over it from above. To even out the folds, warm it up with a regular hairdryer. After gluing, the film acts as a third glass, and the space between it and the double-glazed window acts as a third window.

Reflective film

It differs from others in that it may not allow the sun’s rays to pass through at all, but at the same time effectively retain the heat that is in the room. It can be used all year round.

The advantages of this material:

- Durability.

- Big choice.

- Effect even at a temperature of -35 degrees.

- Suitable for any interior.

- Retains heat coming from radiators and heaters.

- Minimizes heat loss.

- Thanks to a special aluminum coating, it reflects the heat emanating from the outside.

- Protects furniture, wallpaper and plants from overheating and loss of color from the sun.

- Creates a comfortable microclimate in the room.

- Thanks to light reflection, it protects from prying eyes from the outside, but, nevertheless, does not in any way impair visibility from the inside.

- Helps eliminate the problem of overheating and has an air conditioning effect.

- It has absolute transparency, exactly the same as ordinary glass.

- Softens the light and makes it more pleasant to the human eye.

The main disadvantage of reflective insulation is its high cost.

This material should be glued in this way:

- Prepare window cleaner, a knife, a rubber spatula and a spray bottle of water.

- Thoroughly wash the entire surface of the window and glass on both sides. Wipe dry so that there are no streaks.

- Using a spray bottle, apply a soap solution, which was previously diluted with water, to the adhesive film surface and glass. At the same time, you don’t need to shake it too much, otherwise a lot of soap bubbles will appear. This is necessary so that the soap makes it possible to calmly move the film along the surface of the glass to the desired position.

- Apply the film to the stack. As soon as it “sits”, it should be carefully smoothed with a spatula from the center to the edges, and all bubbles should be removed from there.

- After the entire surface becomes smooth, you need to let the film dry.

- Finally, trim the edges with scissors or a knife.

What to do if the film is inflated or minor damage appears?

The insulation can “play” for two reasons: to inflate - if the sealing work is poorly done, to sag - if the film was glued in a room with sufficiently large temperature fluctuations.

In the first case, the film will have to be removed, the flaws removed, and pasted again. In the second case, you need to wait until the heating is turned on and the room is warmed up, and then use a hairdryer to fix the problem.

If damage occurs, there is no need to completely change the film, since this problem can easily be fixed with tape.

Features of applying energy-saving film to windows

If you have to install the material yourself, it is advisable to order a variety for soap solution. Film coatings with a self-adhesive or heat-shrinkable base must be applied by specialists; lack of experience will most likely affect the quality of the result.

Before gluing the material, it is necessary to perform the following preparatory steps:

- Wash the glass and wipe thoroughly with a dry cloth.

- Degrease surfaces using alcohol or a product based on it.

- Take measurements of the glass unit, lay the canvas on the table and trim off the excess with a utility knife or scissors.

- Apply soap solution to the glass surface using a brush or spray.

After this, you can stick the film; work is carried out starting from the top. The material is smoothed with a spatula with a rubber working surface or a roller, working from the center to the edges and from top to bottom. It is important to remove all air bubbles before the adhesive hardens. After this, the treatment is carried out with a household hairdryer, turning on the flow of hot air: the insulating coating will be completely straightened.

To install the variety on a self-adhesive base, you will need to degrease and clean the surface of the glass unit in the same way, cut it to size and place it on the window as evenly as possible. The backing layer is removed starting from the top side, the corners are first fixed, then smoothly removed further, while gluing the film.

The process is complicated in that it is necessary to carefully monitor the uniformity of application, immediately straightening the material and preventing the formation of bubbles. As for the shrink film, it is fixed with a special tape located around the perimeter.

How to install thermal film correctly?

Thermal film for window insulation is attached by performing the following simple steps:

- We glue the double-sided transparent tape that was included with the film onto the previously prepared frame;

- Upon delivery, the material arrives folded in two layers, so it is necessary to separate them;

- Cut the film, taking into account the need to apply about 20 millimeters to the tape, check whether you have measured correctly;

- Remove the protective paper strip from the tape glued to the frame;

- Attach the film to the tape, not yet paying attention to the small wrinkles that appear (it is better to do this step together);

- Since the film is heat-shrinkable, in order for it to level out and become smooth, we blow it with warm air from the center to the frame; for this purpose we will need a hairdryer;

Anti-fog PET film for windows: pros and cons

Thermal-saving material has many advantages:

- Effective protection against cold. Your apartment or house will have a comfortable microclimate both in winter and summer; you won’t need to spend a lot of money on heating or buy a split system or air conditioner.

- Preserving the integrity of glass under minor mechanical impacts. If, however, the window breaks, for example, from a stone, the fragments will hang on the film and will not spill into the room. This reduces the risk of accidental injury.

- The applied coating does not create glare, protects textiles, floor coverings and furniture from fading when exposed to sunlight.

- Relatively low price, due to which you don’t have to spend too much on insulation. Installing such a film is cheaper than installing reinforced double-glazed windows with several cameras.

- Easy installation. On sale you can find self-adhesive window film, the application of which takes a minimum of time.

- A rich list of insulation films available on the market, produced by both Russian and foreign brands. In stores you can purchase products from A-Solar and other companies.

It should be noted that the use of insulating film for insulation is not without its drawbacks. The disadvantages include the following factors:

- It becomes difficult to keep indoor plants on the windowsill. The amount of ultraviolet radiation decreases, so they begin to wither. To solve the problem, you can install phytolamps that provide a 12-hour lighting cycle. The disadvantage of this option is the increase in energy costs, which makes the energy-saving properties of the film meaningless.

- Reduced effectiveness of thermal protection coating in spring and autumn. It prevents the room from heating by the sun's rays, and if the heating has already been turned off or has not yet been turned on, the room will be cold. In some cases, condensation also forms on the windows.

- Some films that create a “thermo” effect are capable of reflecting most radio waves, and cellular communications will work poorly in the room.

Properties and principle of operation

Energy-saving film for windows looks like the usual polyethylene; polyester is used as the base material in its production. The special molecular structure of raw materials and modernized processing technology make it possible to create products that retain heat and fully transmit light. The thin film serves as additional glass; when used, it creates a thermos effect.

Characteristics of heat-saving material:

- the transparent product is practically invisible on the glass; in the standard version it does not create glare or specular reflection;

- the surface thickness varies between 0.1-0.15 mm, it is adapted to a tensile force of no more than 25 kgf/cm²;

- the product is electrostatically inert, that is, it does not attract small debris and dust;

- the film is not afraid of contact with household chemicals;

- the material serves as an additional barrier to infrared and ultraviolet radiation;

- raw materials are harmless to human health.

The width of the products varies between 60-300 cm, the length is 100-600 cm.

Energy-saving film for window insulation

Heat-saving film for windows “third glass” - recommendations for selection

Before ordering material, you need to pay attention to the main characteristics of the coating.

Based on the method of application, window film is divided into several types:

- Self-adhesive . It is similar to protective film for screens of mobile equipment and electronics. The material comes with a hard backing; you need to be very careful when gluing it yourself, otherwise there will be bubbles or wrinkles on the surface.

- Heat shrink . For installation, a special consumable material is used - thermal tape. Due to this, a layer of air is formed between the glass and the film, which perfectly retains heat. When applied, the surface has a crumpled appearance; when heated with a regular hairdryer, it smoothes out and acquires an ideal texture.

- Under a soapy solution . It is similar to film for tinting car windows, durable, practical, and retains heat well. This heat-insulating film is very easy to use; for gluing you need to use simple soap without aromatic fragrances.

The most effective are self-adhesive varieties that block most infrared radiation. In addition to the application method, you need to pay attention to other criteria:

- Manufacturer. The most reliable products are those of German, Polish, British and American origin; Chinese and Russian materials cost less.

- Size, delivery form (in sheets or rolls).

- The presence of an anti-reflective surface, dimming, and other additional effects.

How to keep warm

In winter, most of the heat is lost through the windows. There are two ways to transfer thermal energy:

- Convection;

- IR radiation.

Convection cannot be avoided; the thermal conductivity of the window can be reduced. For this purpose, there are double-glazed windows. The more chambers and glasses, the less heat loss due to convection.

More than 99% of infrared radiation passes through glass. Due to it, the room cools down in winter. The amount of heat loss through windows is 25-40%. Of these, IR radiation accounts for 15-30%.

If you have an infrared heater installed, then a considerable part of its heat can escape through the double-glazed windows. Read more about the operating principle and types of infrared heaters in this publication.

Advice from the experts

Most experts recommend applying this material to windows for warmth only during the winter season: in March or April it is worth removing the film to reduce heat loss. During the period from October to February inclusive, the difference between the temperature outside and inside the house is most significant, so an additional heating surface is most useful. The rest of the time there is no point in leaving the coating on. If carefully removed, the film can be reused in the future.

During installation and operation, it is necessary to protect the material from damage: it is afraid of the impact of piercing objects, especially when deployed. It is advisable to trim the film with a margin; excess can be removed after application, using, for example, a stationery knife.

It is also important to make sure that the glass does not have external defects that could negatively affect the quality of the anti-fog film after installation.

If it is necessary to remove the material, carefully pull it by the corners, this allows you to remove the coating so that there are no traces of glue left on the glass surfaces.

How to destroy cold bridges

Any seam, joint or junction between two parts or structures is a potential passage for frosty air. They call it a bridge of cold and try to bridge it using various materials. There will be constant blowing through a poorly foamed installation seam; the most expensive and high-quality window unit will not save you from low temperatures.

We can repair slopes made of plastic panels with our own hands. It will take place in several stages.

- Insulation of windows along slopes begins with the dismantling of old structures.

- Old foam must be cleaned out.

- Re-foam all corners and crevices.

- Collect slopes.

Do the same with foam under the windowsill. Repair and insulation of PVC windows around the perimeter should be planned for the summer. The point is not that it is inconvenient to carry out any manipulations outside in the cold. There are simply temperature restrictions when you can use polyurethane foam and silicone sealant.

When is it advisable to use film?

Most manufacturers recommend sticking heat-saving film on the windows of an apartment or balcony only during the cold period - from October to March. It is during this period that protection against heat loss through windows takes effect. The rays of the Sun, trying to penetrate into the room through the windows, carry practically no heat with them in winter, so the reflection of the UV part of the Sun’s light does not cause discomfort, since the films are absolutely transparent and do not give a tinted effect. But the IR (infrared) rays emanating from heating devices, trying to leave the room, are, on the contrary, reflected into the room. This is where the heat-saving properties of the film manifest themselves. Another important factor in which the heat-saving effect is most fully manifested is the technology of applying heat-saving film to glass.

Possibility of application of the solution

Polyester is actively used not only for thermal insulation of plastic windows; it is used to create reflective, tinted, sun-protective, and anti-glare surfaces. High quality and technical indicators contribute to the spread of energy-saving films in the following areas:

- for additional insulation of glass facades:

- when arranging greenhouses and greenhouses;

- for the purpose of insulating balconies and loggias;

- during the finishing of transparent roofs and natural solariums.

Thicker variations are often used to retain heat in rooms during construction and renovation.

Negative properties of film

In addition to the positive ones, the film also has negative properties.

The most serious of these is the almost complete reflection of the sun's UV rays. Indoor plants growing on a windowsill or balcony suffer the most from this negative property of the film; they begin to wither and die. Therefore, if you use heat-saving film on windows in winter, be sure to provide 12-hour illumination with phyto-lamps for the plants located on your windowsills, which provide the correct radiation spectrum necessary for normal plant growth and allow you to compensate for the lack of natural light from the Sun. True, in this case, there can be no talk of any “energy saving” in your apartment. Even very economical phytolamps on LEDs, with daily illumination of plants for 12 hours, will completely “absorb” your savings on heating the room.

The second negative effect of heat-saving film applied to the windows of an apartment or balcony is its complete ineffectiveness in the spring and autumn. When the heating in the apartment is not yet turned on, or is already turned off, the film prevents the penetration of the sun's heat from the street. It becomes cold and damp on the balcony and in the apartment, especially in spring.

Another disadvantage of heat-saving films is their ability to reflect radio waves. The radio signal coming to your television antenna or mobile phone will be reflected by the metal coating of the film, and the signal coming from your mobile device will also be reflected inside the apartment.

Therefore, cellular communication in houses where heat-dispersing film is glued to the windows is, as a rule, very poor.

Keeping your home warm - energy-efficient double-glazed windows

In modern plastic windows, 70% of the total area is allocated to double-glazed windows, therefore many functions of window systems depend on their quality and efficiency. Double-glazed windows differ depending on their structure and purpose.

There are several types of double-glazed windows:

- energy efficient;

- soundproof;

- shock-resistant;

- armored.

In this article we will talk specifically about double-glazed windows, the role of which is to preserve thermal energy inside a glazed room - about energy-efficient double-glazed windows.

Structure of double-glazed windows

The structure of a double-glazed window is based on two or more glasses, along the perimeter of which there is a spacer frame. The resulting structure is treated with a special glue along the edges, which makes it completely sealed. Air chambers are formed inside between the glasses.

The air chamber is the main element in double-glazed windows; it creates an insurmountable barrier between the outside and the heated part of the room, which prevents heat leakage and contributes to more efficient operation of the heating system. Double-glazed windows with one or two air chambers are often used.

Experts do not recommend purchasing three-chamber (or more) double-glazed windows, since this is simply not advisable - a large number of air chambers does not increase the heat saving coefficient, only the cost of the double-glazed window increases. Basically, single-chamber double-glazed windows are used in premises that are not designed for permanent residence - office premises, cottages, terraces, etc.

Undoubtedly, they can also be used in residential premises, for example, balcony blocks, but provided that this is not the main glazing, but secondary glazing. In all other cases, it is customary to use double-glazed windows with two air chambers.

Choosing quality glass

Glass markings for double-glazed windows according to the standard nomenclature are “M1”, “M2” and more. The lower the number, the higher the quality of the glass. The main features are its physical properties - the refractive index of light rays and the flat surface plane.

The transparency of the glass depends on the refractive index; the glass should not distort the appearance of the surrounding space, and the quality of its cutting (under production conditions) and installation depends on how smooth the glass is, which subsequently affects the level of energy efficiency of the glass unit.

When purchasing a double-glazed window, make sure that you have high-quality glass by requesting the appropriate documentation from the manufacturer; serious companies will be happy to provide you with this information.

Filling the air chamber

There are double-glazed windows in which the air chambers are filled with ordinary air; this technology has a relatively low price, as well as a low heat saving coefficient. In energy-efficient double-glazed windows, the air space is filled with argon or krypton. These are inert gases that have a denser molecular structure, due to which the package transmits less heat, thereby retaining it inside the heated room.

Krypton is a more expensive gas compared to argon, so it is more often used in European countries; in the CIS countries it is generally customary to use argon filling. When purchasing windows with gas-filled double-glazed windows, you need to ensure the quality of the product.

At the moment, there is only one way to determine the presence of a gas filler, but it is very expensive and is used only in production, so it is necessary to purchase double-glazed windows from a high-quality and reliable manufacturer who can provide a quality certificate for their products with the subsequent fulfillment of all warranty obligations.

What is a spacer frame

The spacer frame is an important element; thanks to it, the glasses are joined together, which makes the double-glazed window completely sealed, increasing its energy efficiency. The main percentage of frames are made of profiled aluminum, steel or a polymer substance, onto which illumination holes are applied. The cavity of these profiles is filled with a hygroscopic desiccant (adsorbent), which absorbs moisture inside the air package, preventing windows from fogging up from the inside, which often occurs when condensation forms on the glass surface.

Recently, flexible spacer frames of a new generation have begun to be used more often. The base is the same aluminum, but the profile shape has a wavy structure, which allows the frame to fit more tightly to the surface. A rubber seal is applied on top of the profile; it gives the frame strength and makes the surface smooth.

This entire structure is lined on three sides with a water-resistant barrier that prevents moisture from entering the air chamber. A layer of absorbent substance is applied on top of the hydrobarrier; this substance completely absorbs all possible moisture from the chamber and gives the glass unit a beautiful finished look. The flexible spacer frame has an adhesive layer on both sides, thanks to which it is perfectly fixed inside the bag.

The glue that forms the basis of this layer is not exposed to the harmful effects of ultraviolet rays, which significantly increases the service life of double-glazed windows.

1 - adhesive layer, 2 - absorbent layer, 3 - water barrier, 4 - seal, 5 - corrugated aluminum

Recently, the American company Edgetech offered an alternative to aluminum profiles by manufacturing a spacer frame from structured polymer foam. Such a frame, according to the developers, retains heat 900 times better than an aluminum-based frame, which allows reducing heating costs by about 6%.

How to mount film

It depends on what kind of film you are using - heat-shrinkable, self-adhesive or soap-based. In any case, you will need an assistant. The film can be sold in sheets folded in half or in rolls.

The first preparatory stage is washing and drying the window.

After which a layer of soap solution is applied to it from a household sprayer. To prepare it, you can use children's shampoo not colored with pigments or colorless dishwashing liquid. After that, a film cut to the size of the glass is applied to the generously moistened glass of the window. Be sure to first use the top edge, and use a soft rubber roller or a rubber scraper for washing windows to remove excess soap solution from under the film. First, from top to bottom - in the middle of the glass, and then - from the glued middle of the film to the sides. If possible, avoid the formation of large air bubbles. The film will not stick in these places. Small wrinkles and liquid bubbles will disappear on their own as the film dries and the film will completely straighten out.

Self-adhesive films are also applied in a similar way. Only the base protecting the adhesive layer is not removed from the entire film at once, but a narrow strip is peeled off from the upper edge of the film. It takes two people to work. Having glued the top edge, the person at the top smoothes the glued film with a soft cloth, and the person at the bottom gradually removes the protective layer, pulling it towards himself. The main thing is not to rush.

Installation of shrink film is also best done by two people. Double-sided tape is glued along the perimeter of the window frame, a blank 2 cm larger than the glass is cut out of the film and glued to the tape along the entire perimeter. Top first, while an assistant must pull the bottom edge of the film by the corners, preventing premature gluing of the film. The resulting wrinkles and folds are not scary.

After gluing, the film is blown with hot air from a hairdryer, and it straightens and stretches itself. Shrink film is especially effective on the balcony, where it acts as a second or third glass.

Manufacturers of heat-saving film, their prices, the cost of insulating one window with film

We list the main manufacturers and the names of their thermal films:

- USB heat-saving film (manufactured by ultra solar block) is distinguished by its gray tint and the ability to block up to 2/3 of infrared and thermal radiation. You can purchase the product at a price of about 1,500 rubles per linear meter.

- Energy-saving tint film (manufactured by Sun Control Ice Cool) 70 GR has a thickness of 56 microns and is capable of transmitting up to 70% of the rays of the visible spectrum, the cost is about 1200 rubles / linear meter.

- Energy-saving shrink film “Third Glass”, 6 m2, having a thickness of 20 microns can be purchased at a price of 600 rubles/set (covering, double-sided tape). A film with a thickness of 30 microns costs about 800 rubles. for 6 cu. m.

- SaveEnergy 30 has a long service life of up to 10 years, the cost of 1 linear meter is about 600 rubles.