Forced movement of water in water supply and heating systems is provided using pumps. Reliable and efficient operation of the pump, when heating rooms, supplying cold and hot water, will provide all domestic needs, and in some cases, industrial needs.

Normal operation of the Wilo pump is possible only if the operating rules are followed, timely maintenance (preventive maintenance), high-quality diagnostics and repairs.

Operational Requirements

In order to avoid premature repair of Wilo pumps, the following should be adhered to:

- exclude idling operation (in the absence of water in the system);

- do not block the water flow when the pump is on;

- set the operating mode in accordance with the minimum and maximum capabilities of the equipment;

- follow the manufacturer's recommendations on permissible pressure in the system;

- do not allow the coolant approaching the pump to heat up above 65 °C;

- avoid long periods of downtime;

- use filters to purify water circulating in the system.

Model range of Vilo pumps

If these rules are observed, the switched on pump will produce a uniform sound and maintain a stable pressure, which is evidence of its normal operation. Most pumps operate without repair for 5 years or more, until the main elements are completely worn out, provided that all operating rules have been followed.

Prevention

In order to avoid the need for repair of the Vilo pump, it is necessary to carry out periodic preventive maintenance. You can carry out simple maintenance of the device yourself, without resorting to the services of specialists. To do this, inspect the pump at least 4 times a year and, if necessary, clean it. As practice shows, cleaning is necessary after 2-3 years of operation, depending on the quality of the coolant and the general conditions under which heating and water supply systems operate.

Checking the rotor water jacket

When inspecting the equipment, be sure to pay attention to the following points:

- no leaks at connections;

- grounding performance;

- absence of extraneous sounds during operation of the device (clanging, knocking);

- no vibration;

- pressure in the system in accordance with technical standards;

- dry and clean device body.

Wilo pumps, in most models, are reliable and do not require regular repairs. But prevention, provided that the warranty period has expired, can be carried out independently.

For this you will need:

- spanner;

- Phillips screwdriver;

- flat screwdriver;

- cleaning brush.

Before dismantling the pump, water is drained from the system or the area is closed to dry disconnect the device. After which the pump is removed, and the following steps are performed:

- Using a spanner, unscrew the bolts (4-6 pieces) connecting the electric motor housing and the shell of the pump part.

- Removing the shell will provide access to the drainage holes, and the impeller will remain on the engine rotor.

- Using a narrow flat-head screwdriver, pry up the jacket separating the engine compartment and the impeller, causing the rotor shaft and impeller to come out of the stator shell.

Disassembling the circulation pump

Having completed these steps, the main disassembly is completed and the internal surfaces of the shell, impeller and rotor are cleaned of scale or dirt deposits.

Surfaces are cleaned using a stiff polymer brush with a small amount of cleaning agent containing hydrochloric acid.

In case of severe (sticky) contamination, it is permissible to use zero grade sandpaper.

The main malfunctions of Wilo pumps are wear of the support bearings. If such a factor is identified, it is difficult to replace them with your own hands, so it is better to contact a service center.

Before reassembly, all gaskets and seals are checked for cracks or breaks. But since the pump has already been disassembled, it is advisable to replace them with new ones.

Electrical repair

The electrical part of the pump includes the following components:

- inductor;

- starting capacitor;

- connecting wires;

- control terminal.

If the stator winding breaks down, the pump becomes unrepairable; all other components can be repaired or replaced. To analyze the condition of electrical parts, you will need an ohmmeter.

Photo of the circulation pump Wilo MTSL 15/5 HE – 2.

Main symptoms of malfunction

If the boiler display shows an error code corresponding to a water circulation problem, and it is not reset, the problem may be hidden in the electronic part of the device.

Circulation pump with cover removed.

To identify the problem you must:

- Turn off the heating mode in the boiler, and after stopping all components, turn off the power (soft stop).

- Open the front panel of the case.

- If the pump is covered with a large layer of dust, clean its surface.

- Using the information in the diagram, remove the control terminals and remove the terminal with the capacitor.

- Visually examine the condition of the pump contacts and terminals; they should be free of oxides, burnouts and mechanical damage.

- Using a tester in diode testing mode, determine the integrity of the connecting wires that go from the control board to the pump.

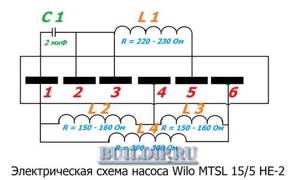

- Use an ohmmeter to determine the resistance of the inductors. On a working device, the instrument readings on the contacts will correspond to the following values:

- No. 1, 4 – 150 – 160 Ohm;

- No. 1, 6 – 290 – 300 Ohm;

- No. 2, 3 - 0 (contacts connected together);

- No. 3, 5 – 220 -230 Ohm;

- No. 4, 6 – 150 – 160 Ohm.

- The device will be considered faulty if the ohmmeter reading on any of the above pair of marks is 1 (winding wire break) or 0 (short circuit, except for contacts 2,3).

- Check the condition of the starting capacitor. To do this, switch the tester regulator to the 20 microfarad capacity test mode. Connect the probes of the device to the terminals of the capacitor and determine its capacitance. It should match the nominal ± 10%. Loss of capacity leads to a decrease in pump performance; it will emit an uncharacteristic hum.

Electrical diagram of the pump Wilo MTSL 15/5 HE – 2.

Measuring the resistance of the circulation pump windings.

Basic problems and methods for resolving them

In cases where vibration appears during operation of the device, extraneous noise occurs, or the pressure in the system changes, you should determine the cause and, if possible, troubleshoot the problem yourself.

When turned on, the pump hums, but the shaft does not rotate:

- The shaft jammed due to prolonged downtime. Remove the protective cap on the motor housing and rotate the shaft using a flat-head screwdriver;

- if foreign objects get in, disassemble the pump and clean the impeller, after which replacing the cleaning filter, which is installed in front of the device;

- problems with power supply (insufficient voltage in the network).

When turned on, the device does not work:

- there is no voltage in the network. Electrical wiring and protective automation are checked;

- The fuse has blown. Replaced with a new one.

Automatic shutdown of the device after a short period of operation:

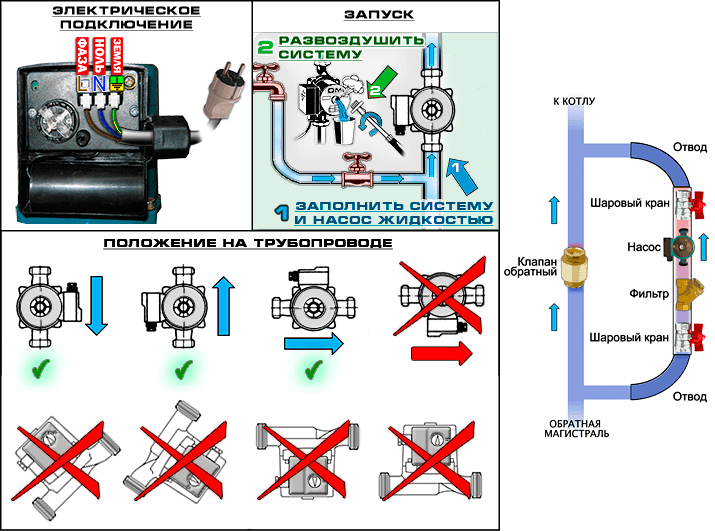

Rules for installing and connecting the circulation pump

- accumulation of limescale in the stator cup. The glass and rotor of the electric motor are cleaned.

Diagnostics and prevention of breakdowns

You can determine whether the circulation pump requires repair based on a number of signs. The easiest way is to turn on the equipment and check if it makes noise. Sometimes extraneous sounds are accompanied by noticeable vibration. It is recommended to ensure that the pump motor does not overheat.

Check whether the water pressure in the pipe corresponds to the parameters in the technical data sheet of the device. The features of coolant circulation do not depend on the characteristics of the heating boiler and are completely determined by the operational properties of the pump.

Visually inspect the pump housing to ensure there are no leaks. The most vulnerable point is considered to be the connection between the pipe and the unit. Check the condition of the gaskets and fastening of the bolts, as well as the presence of grease on the threaded flanges.

Pay special attention to the electrical circuit: check the fixation of the wires, get rid of moisture in the electrical wiring and, if necessary, attach the housing ground to the appropriate terminal

1 Design and technical features

Vilo pumps significantly increase the efficiency of the heating system and the heat transfer of the coolant. Their use makes it possible to use pipes with a smaller cross-section when assembling the main line, which will reduce fuel consumption, reduce carbon dioxide emissions, and allow for savings to be achieved without loss of quality of operation. This is achieved through a properly thought out and designed design designed for continuous operation.

Checking the rotor water jacket

The Wilo pump consumes no more than 250 W per day, operation is silent, since there is no fan or similar technical elements that produce noise. There are two types of circulation equipment on sale - with a dry and wet rotor. The latter are used when installing heating systems, usually inside small buildings. The difference also lies in the power and volume of the pumped medium. The weakest model can make the heating system more efficient over an area of 200 sq.m.

The powerful one is designed for heating buildings with an area of up to 1000 sq.m. Both units have the most simplified design and small dimensions. Technical characteristics regarding pressure height allow you to lift water from 8 meters at a flow rate of 5 m3/h.

Distinctive features are the strength and corrosion resistance of the Wilo pump material. For example, the body is cast from cast iron, the shaft located inside it is made of stainless steel. Its fastening is possible thanks to graphite bearings. The water supply speed is equipped with three-stage adjustment.

The permissible coolant temperature in household products should not exceed +110° C; for industrial products the temperature limit is increased. As for the operating pressure, units used in everyday life can withstand 10 Bar, and industrial ones - 16.

The operation of the system is controlled automatically. Some models of circulators have a thermostat. The functions of the mechanism are displayed on the liquid crystal display. You can also control the shaft rotation speed by manual switching. Connecting the device is simple and quick, which is facilitated by the presence of springy terminals. Voltage surges are not a problem for the pump, since the motor and rotor have a multi-stage protection system.

Design and principle of operation of the circulation pump

If you do not know what the principle of operation of the circulation pump is, then it will be difficult for you to both carry out repairs and perform maintenance.

The circulation pump is constructed from the following elements:

- body, which is made of stainless steel or non-ferrous alloys;

- an electric motor whose shaft is connected to a rotor;

- the rotor on which the wheel with blades is mounted is the impeller (its blades are in constant contact with the pumped medium; they are made of metal or polymer materials).

There are two types of circulation pumps:

- with wet rotor;

- with dry rotor.

Types of circulation pumps are described in this article

For units with a wet rotor, this part is always placed in a liquid medium. Such pumps are usually supplied to domestic heating systems. Due to the fact that the rotor is located in the liquid, all moving parts are not only lubricated, but also effectively cooled.

The main advantages of this type of circulation pump:

- During operation, they make virtually no noise, since the water in which all the parts of the device are located absorbs vibrations well.

- They are easy to install; just insert them into the pipeline; repair and maintenance will not take much time and effort.

The disadvantages of wet rotor pumps include low performance; they should be mounted exclusively in a horizontal position. Also, if there is no liquid in the heating system, such devices may fail.

Circulation pump and pump

The drive motor of pumps with a dry rotor is allocated to a separate group. Rotation from the electric motor shaft is transmitted to the impeller using a special coupling. Compared to the previous type, this one has higher productivity, efficiency reaches 80%. Also, the design of units with a dry rotor is more complex, and therefore maintenance and repair are also somewhat more difficult.

Repair of Wilo pumping stations in our company is profitable!

Firstly, we use original spare parts, which eliminates repeated breakdowns due to incompatibility of replaced parts. In addition, components and work performed by craftsmen are guaranteed.

Secondly, you can count on:

- Comprehensive support of specialized specialists;

- Possibility of repairs at the customer’s site;

- Prompt departure of a team of craftsmen in Moscow and the Moscow region;

- Adequate, affordable prices, comfortable payment terms;

- Discounts and bonuses for regular customers.

Thirdly, you can get additional information on services, as well as ask all your questions by phone. In addition, we will be glad to communicate with you in mobile messengers, as well as directly in the Remguard workshop in Moscow!

Preparing the pump for the heating season

To ensure that your heating system does not fail during the winter, it is necessary to check the operation of the entire system, and in particular the circulation pump, before the start of the heating season.

It is necessary to check the serviceability of the device:

- There should always be lubricant on the gasket and pipes. If it has dried out, then it is necessary to lubricate the elements again; It is necessary to check the mesh filter. It often becomes dirty and interferes with the normal operation of the pump. If you notice blockages, you need to clear them;

- The circulation pump must be connected to the pipelines correctly. The best installation option would be in front of the heating boiler. With this arrangement, the formation of air pockets is minimized;

- The correct connection of heating equipment to the network can be checked with a special tester;

- Before the start of the heating season, it is necessary to check the operation of the pump. You can perform a test run.

DIY water pump repair + video

A Wilo centrifugal water pump in the heating system of a private house provides forced movement of the coolant. Vilo is a household heating circulation pump, characterized by its compact size, high performance and reliability.

The device requires minimal maintenance and rarely fails. If a breakdown occurs, it is not difficult to repair the water pump yourself.

The content of the article

Before we begin to consider the features of repairing this type of pump, we recommend reading a review article about heating pumps.