Homemade heater from a cast iron battery

How to heat a living space if there is no central heating or gas?

The same change house, dacha or small country house? We will consider the option of a homemade safe heater made from a cast iron radiator; it can be used as an auxiliary or main source of heating in a room.

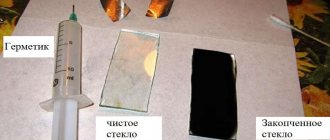

To make a homemade heater you will need:

- The battery is cast iron (aluminum or metal will not work).

- Closed heating element with a power of 0.3 to 0.8 kW (depending on the number of battery sections).

- Air thermostat.

- Silicone seal.

- Futorka.

- Plugs for cast iron radiator – 2 pcs.

- Valve for bleeding air from heating radiators STD 7073V (Maevsky valve).

Homemade heater made from a cast iron battery and heating element.

Construction stores sell stainless steel heating elements with a brass threaded plug specifically for a cast iron battery.

You need to select a heating element based on power depending on the number of battery sections.

An electric heating element is screwed into the cast iron battery into the lower threaded connection through a gasket.

The opposite bottom hole and one top hole of the battery are screwed in with a plug.

In the opposite part of the battery from the heating element, a cast iron fitting is screwed into the upper threaded hole. We screw a faucet with a handle for releasing air into the futorka (Maevsky faucet).

The installed battery is filled with water; to do this, you need to unscrew the top tap, insert a hose with a watering can into the hole in the fitting and fill with water. The battery is filled until water begins to flow out of the battery opening. You can use ordinary water, but it is better to use distilled water so that there is less scale on the heating element. The capacity of one section of a cast iron radiator is approximately 1.45 liters.

Why is it not recommended to use steel and aluminum radiators? The volume of water in an aluminum heating radiator (1 section) is about 0.3 l. This amount of water does not ensure proper circulation throughout the entire battery.

An electric heating element can be immediately connected via a cord and plug to the electrical network, but it would be correct to connect an air thermostat and set the temperature value.

A homemade heater made from a cast iron radiator reaches a temperature of 80°C in 1.5 hours and then maintains the set temperature.

Technical characteristics of homemade heaters

In most cases, home-made heat generators are a copy of those devices that are commercially produced by official companies. They may be inferior in quality to the original in terms of technical characteristics, but for a number of reasons, apartment owners still want to assemble such a unit on their own.

The fact is that when making it yourself, the equipment is several times cheaper, since improvised means are used during assembly. It will also be possible to assemble the unit of the required size and dimensions, and independently select a housing with the desired strength. This means that the master chooses all the technical characteristics himself, based on the size of the room that needs to be heated. For example, if heating elements are used to assemble the apparatus, then only two samples will be suitable for heating one room. More than 4 heating elements per room are usually not used.

A DIY battery heater may violate operating conditions

But it should immediately be noted that a self-made heater may violate the operating conditions drawn up by official manufacturers. A homemade product is not as safe as a purchased unit. The heating device will be unpredictable and may result in unpleasant consequences for others. This is due to many factors:

- Homemade heating devices often cause fires.

- There are also no legitimate manufacturer warranties.

- The technical characteristics of a homemade device are uncertain, and if assembled inappropriately, the result will be an unaesthetic design.

But if all these shortcomings do not frighten the master, and there is no desire to purchase a heating device in a store, then you can proceed to assembling the heater yourself.

Homemade heaters: pros and cons

As a rule, heat generators made by hand are copies of devices produced industrially. These copies, with rare exceptions, are inferior to the originals in many respects, but due to certain circumstances, the consumer often chooses a home-made unit.

“Pros” of using homemade devices:

- relatively low cost (when made with your own hands and using improvised means);

- the ability to assemble a unit of the required dimensions and manufacture a housing with the desired strength characteristics, up to vandal-proof design.

The main argument against it is the uncertain degree of safety of homemade heating devices during operation, which is fraught with unpredictable negative consequences not only for the owner of the unit, but also for others.

This argument is due to many factors, and its validity is confirmed annually by numerous fires caused by homemade air heaters used in violation of the Decree of the Government of the Russian Federation. “On the fire safety regime” No. 390 of April 25, 2012 (as amended on November 18, 2017)

Excerpt from the Resolution on the fire safety regime in R.F. banning the use of homemade heaters

As for the secondary arguments “against”, they are as follows:

- lack of legitimate manufacturer guarantees;

- uncertainty of some characteristics of homemade devices;

- low aesthetics and degree of automation of handicraft units.

If familiarization with these arguments still does not prompt you to purchase a factory-made heater in a store, let’s consider how to make a heater yourself so that the likelihood of an accident when using it is as small as possible.

Criteria for selecting the required materials

Since a homemade device is assembled from units that have already been used, first of all it is necessary to assess the condition of the pipes. Particular attention will need to be paid to their walls. Their thickness should be several millimeters. If corrosion occurs, it is undesirable to use such pipes or be sure to eliminate all defects before use. All rust will need to be thoroughly removed from the metal with a brush, and then covered with an anti-corrosion compound so that the problem does not arise in the future during operation.

For production, pipes with a diameter of approximately 12 cm are usually used. Sheet metal of the appropriate size is used to plug the ends.

To make bypass channels and fittings, you will need to use pipes of a smaller diameter, which can eventually be connected to the heating system. The threads on the fittings are pre-cut, for this reason the appropriate equipment is required - a tool (for creating external threads) and a tap (for cutting internal threads).

A DIY oil radiator can be made portable. In this case, small pipes will be used, and oil will be used as the coolant. Heating elements are used instead of heating elements. The choice of this component depends on the area of the room that needs to be heated. Home craftsmen often install an additional thermostat on such a device, which periodically turns the heating element on and off.

For good fastening to the wall, you will also need strong hooks that can support the weight of the resulting unit. To create a more aesthetic appearance, they can be purchased in the store. But if you don’t want to spend additional money, then strong reinforcement bars that need to be fixed in the wall are also suitable. It is advisable to first paint the hooks in the same color that was used to paint the heating device - this way the fittings will become invisible.

Types of homemade heaters

The most popular are two types of homemade heaters. This is a heater made from a heating element battery, as well as an oil unit made from a battery. In most cases, it is these that home craftsmen try to recreate with their own hands. To carry out the procedure correctly, you must familiarize yourself with all the information about the design before starting work.

Heater made of battery and heating element

Electricity and liquid/solid fuel for space heating are quite expensive options. That is why residents of apartments or private houses are interested in the question of how to make a heater from a cast iron battery so that it costs as little as possible and consumes little energy. For this purpose, heating elements are installed, the benefits of which consumers have long known about.

The main merit of a heater made of a cast iron battery is that if it is connected correctly, the device is able to effectively heat small rooms without additional heat sources. For example, such equipment is often used to heat workshops and greenhouses.

Heater made of battery and heating element

A battery with a heating element is an effective autonomous device for heating small rooms or an additional source of heat in apartments or private houses. The heating element is a small metal cylinder with a spiral attached inside. The housing does not touch the spiral due to the insulating filler.

Such a device has a number of advantages:

- High-quality and reliable construction, absolutely safe for human habitation.

- Great efficiency.

- Ease of manufacture and durability.

- Heating elements are unnoticeable because they are installed directly into the heating system, which means they do not spoil the appearance of the room.

- Equipped with a thermostat that helps save energy resources.

- Current consumption is much lower than factory electric heaters and modern floor heating systems.

- To manufacture a unit using heating elements, you do not need to purchase special permits. You just need to place the unit in the pipe.

It is noteworthy that even a person who has never done electrical work can assemble the equipment. You just need to screw the heating element into the radiator socket and connect the equipment to the network. After this, the homemade heating device from the battery is ready.

It is important to note that the heating element must be located exclusively in a horizontal position. The heating device is connected to the electrical network only if there is a coolant in the system. To control safety, the heating element is equipped with special protection against overheating.

The heating element should only be located in a horizontal position

The modern device is equipped with several operating modes, so it can be used as the main source of heating and periodic or emergency. In the second case, it is very beneficial to use such technologies if it is necessary to heat a dacha where a person does not live permanently.

For the manufacture of heaters, heating elements are selected with the required power - depending on the area of the room that needs to be heated.

Oil heater from battery

Typically, oil heaters are used not as the main type of heating, but as an auxiliary one. In the event that central heating cannot fully heat the room, then this option comes in handy. Often this type of heater is installed in small rooms where factory heating is not provided.

Depending on the heating power, from 1 to 4 heating elements are used to manufacture the structure. Usually one or two is enough.

To work you need to purchase the following materials:

- Cast iron pipe grade MS-140.

- Heating element of the required power.

- Technical oil. Experience suggests that the best option is curling oil in a transformer. It can withstand high temperatures and is safest for humans. But there is also a drawback - high cost.

Oil heater from battery

To assemble, you need to follow the instructions:

- The heating element is placed in the end part of the lower collector of the battery.

- The back wall of the equipment is grounded.

- The oil drain hose must be moved to the lowest point of the battery. This is very important to do, because if the unit is large, then to drain the oil it will need to be tilted, which is inconvenient to do due to its weight.

- A plug is installed in the upper end.

- The hole above the tap is plugged with a Mayevsky tap.

The homemade heater is ready. Making a heater is not difficult if you follow the instructions.

It is important to know that the oil will expand very strongly when heat is applied to it, and therefore it will require space inside the cast iron radiator. This means that the container must not be filled completely - 80% is enough.

Types of heaters

A home craftsman who wants to acquire a homemade “hot water bottle” can choose from several options:

Oil

The main element of the heating element is a spiral made of nichrome or other material with high electrical resistance, which begins to heat up when an electric current is passed through it. The spiral is placed in a copper tube filled with sand.

The oil removes heat from the heating element, distributes it over the surface of the body and, in addition, serves as a heat accumulator (after a power outage, the device continues to heat the surrounding air for some time).

Steam-drip

In its design, a vapor-drip heater is very similar to an oil heater, only water vapor is used as a medium that distributes heat. It is formed from a small amount of water, which is poured into the body.

This solution provides two significant advantages:

- When freezing, the vapor-drip heater will not burst, since water occupies only a small part of its volume.

- Steam is an extremely capacious heat accumulator. More precisely, not so much steam as the evaporation process: it is during the transition from liquid to gaseous state that water accumulates a large amount of thermal energy, which is returned when steam condenses on the walls of the heater.

Having transferred heat to the body of the device, the condensed steam in the form of water flows to the lower part, where the heating element is installed. The power of the heating element and the volume of water are selected in such a way that rupture of the heater by steam pressure is excluded.

Due to the fact that the device body is hermetically sealed, its internal walls do not rust due to high humidity.

Candlestick

A candle flame is known to emit not only light, but also some heat.

Only it usually evaporates to the ceiling in the form of convective air currents and is “smeared” over the entire area of the room.

Why not place a heat trap above the candle? We will tell you what it is in the next section.

Infrared (IR)

Any substance with a temperature different from absolute zero emits “thermal” electromagnetic waves, which are called infrared.

The intensity of this radiation is directly dependent on the temperature of the substance. Water and oil radiators also emit IR waves, but in very small quantities because their surface is relatively cold.

To turn a metal object into an IR emitter, it is enough to heat it to a red glow temperature. If you use special materials, for example, graphite, then quite noticeable “heat” waves can be achieved at relatively low temperatures.

Knowledge of these subtleties will help us make our own IR heater, which will give us heat directly, that is, without the participation of air as an intermediary.

Other types

Since electricity is not available everywhere, structures running on gas or solid fuel have the right to life. The latter include potbelly stoves.

Heater made of battery and heating element

When it comes to deciding how to heat a room: electricity or solid/liquid fuel, consumers are confused by both options because of their high cost. Therefore, many are interested in the question of how to make a heater from a cast iron battery so that it is cheap and does not require special care.

Craftsmen have long been using the advantages provided by installing a heating element. Its main merit is that, with proper connection, it can easily heat small rooms, for example, a greenhouse, garage, workshop or chicken coop, without additional heat sources.

A cast iron battery with a heating element is, in fact, an effective way to autonomously heat a small room or use it as an additional heat source in an apartment in a city heating network.

A heating element is a metal cylinder with a spiral installed inside. The walls of the tube do not come into contact with the spiral due to insulation with a special filler. Installed in a heating device, such a homemade heater made of a cast iron battery has the following advantages:

- This is a reliable design, completely safe for human life.

- This device has high efficiency.

- They are simple and durable to use.

- Heating elements are almost invisible, as they are installed directly into the heating system.

- Since they are equipped with a thermostat, they help save energy resources.

- The amount of electricity it consumes is significantly lower than that of conventional electric heaters, boilers or underfloor heating systems.

- To make such a heater from a cast iron battery with your own hands, you do not need any permits. The heating element is simply mounted into the heating network pipe.

Even a person far from electrical work can install and connect the heating element. As a rule, they are sold complete with parts for installation and protection, control devices and elements for connecting to the electrical network. The heating element is simply screwed into the radiator socket and plugged into the outlet.

It should be remembered that the heating element must be installed in a horizontal position. You can turn on the device for heating the room when there is coolant in the system.

To control safety, the heating elements are equipped with double overheating protection. Control sensors are located both inside the device and outside.

Modern heating elements for connecting to cast iron radiators are equipped with two operating modes, which allows them to be used as the main source of heating, and then they are turned on at full power, or as an emergency or periodic one. In the latter case, it is beneficial to use such technology, for example, in dachas where people do not live permanently, but care must be taken to ensure that pipes and radiators do not freeze.

To make efficient heating from cast iron radiators with your own hands, you need to choose a heating element of suitable power. To do this, a calculation is made taking into account the required heating of the coolant and its quantity in the battery.

Selection of materials

As is clear from the above, to obtain a homemade heater you will need to get the following components somewhere:

- frame;

- oil;

- heating element;

- mobile stand;

- control and automation devices.

As a housing, you can borrow an old radiator from a central heating system, sheet or sectional. A car, or any similar product, the design of which will allow fluid to circulate inside naturally or artificially (using an electric motor), is also quite suitable. You can also make a closed loop from steel pipes with your own hands.

The main thing is not to forget that an indispensable condition for the normal functioning of the system will be to ensure the tightness of the housing. If the liquid begins to leak, then it is unlikely that such a homemade device will bring more benefit than it will cause trouble.

As for the oil, firstly, its quantity should be based on the calculation

85% of the body volume. The rest of the cavity is filled with air. This 15% area is maintained so that during operation the oil does not crush the housing due to thermal expansion.

Secondly, the quality characteristics of the liquid must satisfy at least two criteria: purity and heat resistance. Dirt and impurities will shorten the life of the heating element by causing scale to settle on it. A decent temperature of the heating element indicates that you should select technical oil of the appropriate brand. A suitable option would be, for example, a transformer.

The number and characteristics of heating elements are selected depending on the required power of the heater (and taking into account the overall dimensions of the housing). Conventionally, we can assume that to create a comfortable atmosphere in a room with normal ceiling heights, you need

1 kW per 10 sq. m. For rooms with high ceilings, poorly insulated, located in cold areas, etc., several times more powerful products are needed.

Of course, the capabilities of the power supply network in the place where you plan to use the hand-made device must also be taken into account.

In terms of durability, it is also important to consider possible combinations of metals of the heating element and the body. For example, it is not recommended to use heaters with a magnesium anode

combine aluminum and regular steel (not stainless steel) with copper.

Installing a heating element into the heater body

Since the structure, in all likelihood, will have an impressive mass, a mobile platform on wheels, if one is planned to be included in a home-made device, must withstand the load placed on it. It can be made, for example, from rolled steel - angles, channels, etc. materials.

Switches or a rheostat are selected in accordance with the total power load of the device.

A bimetal plate (taken, for example, from an old iron) should be used as a thermostat. When choosing a setting for it with optimal temperature characteristics, you need to proceed not only from considerations of energy savings, but also from the fact that excessive heating can cause the pressure inside the case to increase to too high a level.

To better guarantee safety, an additional thermal fuse can be provided. Or a similar switch that triggers at a certain pressure.

Oil radiator from MS-140 battery

As a rule, oil heaters are used as additional heat sources if central heating cannot cope fully. Sometimes they are used to heat small rooms where heating is not installed.

In this case, knowing how to make an oil radiator from a cast iron battery, you can save a lot on both the purchase of a new device and its operation.

Depending on the power required from the heater, its manufacture may require from 1 to 4 heating elements. As a rule, one or two heating elements are enough to use such an oil radiator in everyday life. To work you will need:

- Classic cast iron battery, for example, brand MS-140.

- Heating element of suitable power.

- Technical oil, but according to craftsmen, the best option would be to use electrical oil, which is poured into transformers. It is resistant to high temperatures and therefore safer. The only drawback of transformer oil is its high cost.

The modern market of thermal technologies offers heating elements specially adapted to work in the MS-140 cast iron radiator. It is better to look for and buy a ready-made device than to try to calculate on your own what power, shape and size of the device will be required.

It is very easy to make an oil cooler by following the steps in the right sequence:

- The heating element is installed in the lower manifold of the cast iron battery from the end part.

- The rear wall of the structure is grounded.

- Move the oil drain hose and ball valve downwards. This is important because if the media drains, the heavy battery case filled with oil may be difficult to tilt.

- A plug is placed on the upper end hole above the heating element, and the hole above the tap is closed with a plug with a Mayevsky tap.

When heated, oil expands greatly and will require space inside the cast iron radiator, so fill the container only 80-85%.

Advantages and disadvantages of oil heaters

Among electric heating devices, oil ones are the only ones that are called electric radiators. Oil heating has many advantages:

- does not dry out the air;

- radiators transfer heat mainly through thermal radiation;

- has a safe design;

- the surface almost never heats up above 50-60 oC;

- easy installation and management.

All this is true, but there are also disadvantages. The main thing is a fairly large inertia. Oil, which serves to transfer heat, has a high heat capacity. And until it warms up, the air will not begin to warm up. But this same property allows you to smooth out temperature differences when turning on/off.

The biggest problem is high inertia and low efficiency: too many heat transfer stages

The second disadvantage is that the safety and durability of the work depends on the quality of workmanship. An incorrectly designed structure can simply burst when heated, the seams are poorly sealed, and oil will leak. Therefore, buying cheap but unknown brands is a risky business.

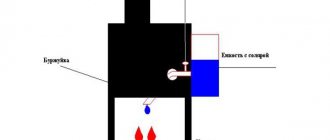

Heat exchanger for a boiler made of cast iron battery

Many craftsmen, in order to save money on heating in autonomous heating systems, install heat exchangers in furnaces or boilers. Their main task is the transfer of heat that is generated during the combustion of solid fuel.

For a design to be truly effective, it must have the following characteristics:

- The larger the heated surface area, the more heat it can transfer.

- The material from which the heat exchanger is made must have high heat transfer.

- The device must be resistant to temperature changes.

As practice shows, the best and cheapest option is to assemble a heat exchanger from a cast iron battery. It is suitable for the following reasons:

- From the radiator sections you can assemble a device with the required heating area. If you use old cast-iron batteries, you first need to disassemble and wash them, and then, knowing how to assemble a cast-iron battery, make a structure of the required length from it.

- Cast iron has sufficient thermal conductivity and is at the same time resistant to the aggressive environment that forms inside the furnace.

- Sufficiently wide channels of the cast iron battery are able to freely pass water from the heating circuit, which requires high movement speed to effectively heat the house. To ensure such circulation, it is necessary to create a significant temperature difference between the incoming and outgoing water. The larger it is, the faster the coolant flows through the network.

When assembling cast iron heating radiators with your own hands to mount a heat exchanger from them, you need to replace the gaskets with special asbestos threads, pre-impregnated with graphite lubricant.

Depending on the size of the stove, you can use several sections of cast iron radiators or even arrange them in two rows. Assembly is carried out in the same way as for connecting to the city heating network. For this, adapters, bends and corners are used, and after connecting all sections, the structure must be checked for leaks. To do this, water is supplied to it under pressure.

You cannot install a heat exchanger in a furnace without checking its reliability and tightness.

The best place for such a device would be a chimney. There the cast iron will be protected from open flames, which will ensure its safety. If you place a heat exchanger in a firebox, then the flame on one side and the cold water that enters it through a pipe on the other can cause strong temperature changes that it cannot withstand.