As required by the legislation of the Russian Federation, biological waste must be destroyed in accordance with established rules, compliance with which significantly reduces the risk of the spread of infection and the negative impact on the environment. To fulfill them, most large enterprises whose activities are related to meat processing, livestock farms, veterinary clinics and hospitals install cremators for the disposal of biowaste.

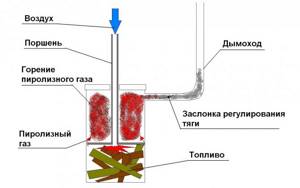

Furnace pyrolysis and its consequences

The pyrolysis furnace has the greatest versatility and efficiency. Due to the combustion temperature of 800 degrees or more, biological waste is completely destroyed. As a result, only safe ash remains, the volume of which is no more than 5% of the loaded products.

A furnace for incinerating biological waste consists of several blocks. In the center there is a working chamber in which, without oxygen supply, preliminary decomposition of combustion products occurs at high temperatures. As a result, a steam-gas mixture is formed in the furnace for burning biowaste, which enters the afterburning chamber. It is in this unit that the complete neutralization of toxins and hazardous substances occurs.

The operating principle of pyrolysis is that products do not burn at one moment, but decompose into solid residues and pyrolysis gases, which at the next stage completely burn out without emitting harmful substances into the atmosphere.

Methods for processing solid waste

The problem of waste disposal is solved with the help of authorized and coordinated waste processing. The following processing methods are available:

- disposal and partial processing in landfills;

- burning in waste incineration plants;

- waste sorting and recycling (reuse);

- composting (conversion into fertilizers);

- pyrolysis (heating without access to oxygen).

The most logical possible way to solve the problem of waste disposal is to transform illegal landfills into authorized ones. They reach a height of up to 60 m. Garbage is transported layer by layer using a bulldozer. If there is waterproofing, harmful substances do not enter groundwater. The landfill should be equipped in accordance with modern requirements that ensure safety for the environment.

Composting is a method of processing food waste. Fertilizer is obtained by oxidation of organic substances under the influence of oxygen; it is later used in the agricultural industry.

Incineration of waste in Russian factories does not involve gas treatment, which causes dust, gas and soot to be released into the atmosphere. Burning 1 cubic meter of garbage results in the release of 3 kg of harmful substances. Abroad, waste is pre-sorted and goes through 2 stages of processing, which significantly reduces air pollution.

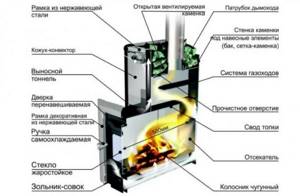

Cremator design

To understand the operating principle of pyrolysis furnaces, you need to familiarize yourself with their design.

The crematorium for the disposal of biological waste consists of fifteen elements:

- Combustion chamber.

- Door for loading combustion products.

- Burner.

- Afterburner chamber.

- Controller.

- Sensors

- Winch.

- Ash removal door.

- Steel body.

- Fire resistant thermal insulation panel.

- Protective covering.

- Grate.

- Loading window door with heat-resistant gasket.

- Furnace skids for biowaste disposal.

- Smoke exhaust pipe.

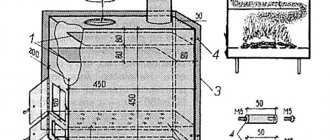

Classic drawing of a pyrolysis furnace

The technological flow diagram for the operation of a pyrolysis furnace includes four main stages:

- Loading. The waste is placed in the working chamber and the hatch is tightly closed. The amount of fuel depends on the power of the unit.

- Burning. After turning on the burner, the operating temperature is maintained in an automatic state.

- Cooling down. When the device turns off, you need to wait a while.

- Cleaning. The cooled ashes must be carefully removed so as not to damage the thermal insulation layer.

The furnace for recycling biological waste has an undeniable advantage - ease of operation. After loading waste into the chamber, you simply need to activate the combustion system. After the time has expired, the timer will turn it off. While the biowaste is burning, the presence of the operator is not necessary. Other disposal methods require much more time and effort.

What does a wood waste disposal stove consist of?

The equipment has a fairly simple design and operating principle. To operate the unit, there is no need to undergo lengthy additional training, and the recycling process itself takes place with absolute safety for the company’s employees.

So, a furnace for burning wood waste has the following design:

- loading chamber made of fireproof reliable steel;

- productive grates that provide optimal temperature and uniform heat distribution;

- an afterburner chamber, where combustion products undergo additional purification, which ensures complete safety of the equipment for the environment;

- secondary air heater and heat exchanger;

- fan and chimney.

By purchasing a stove for burning sawdust and other wood waste, you will also save significantly in the future. Maintenance and maintenance of cremators and incinerators does not require large financial and resource costs. This purchase will pay for itself in the near future, and you will have in your production a highly efficient and productive unit for recycling unusable material, which also generates heat.

Do-it-yourself pyrolysis oven for garbage

The production of pyrolysis furnaces can be not only industrial. You can make a similar device yourself. Moreover, long-burning stoves are used both for heating premises and for recycling household waste.

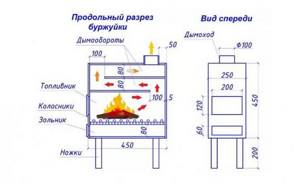

The simplest homemade oven for pyrolysis is a potbelly stove. The design has gained enormous popularity because it can be made from any available materials. Barrels, cans, pipes and even metal sheets are suitable for this. Below is a diagram of a pyrolysis furnace based on sheet steel. The dimensions are approximate, so they can be changed if desired. It all depends on how much power the equipment needs to receive. The larger the working chamber, the more powerful the unit will be.

How to make your own waste incinerator

To independently create a stove for burning garbage and waste in the country, you need to decide what will serve as its basis.

Country stove made from a metal barrel

A barrel is the most popular item for burning garden scraps and rubbish. It can be found in almost any area. It usually serves as a container for collecting water. When over the years it becomes covered with rust and becomes unusable, holes appear in it, then it can be turned into a fireplace for burning.

The main advantages of this option:

- Mobility of the structure.

- No open flame when burning.

- Full control of the combustion procedure.

- Ability to quickly extinguish flames.

The downside is that regular exposure to high temperatures gradually deteriorates the barrel to the point of being completely unusable.

The main stages of creating a furnace:

- Drilling several holes in the bottom, creating traction at the bottom of the container.

- A brick base is erected taking into account the distance for air intake.

- Placing the barrel on a brick base.

- Making a fire and loading waste.

Horizontal stove made from a barrel with a pipe

This design is a container turned on its side on supports, with a pipe for the smoke to escape.

Main stages of creation:

- You need to cut a door on the barrel for storing garbage using a grinder and a jigsaw.

- You need to drill holes in the resulting door to allow air to enter.

- If the barrel is rusty, it must be sanded and free of rust.

- The support or legs are made from a profile.

- Handles are attached to the door using any convenient method.

- Then you need to make a hole in the body for the chimney using a grinder. The cuts are made in the form of petals and are bent.

- Then the chimney is attached to the surface with self-tapping screws.

- A grate is placed in the oven.

- The back cover is secured with bolts.

Upgraded barrel

An unusable barrel is best suited for a country stove. Its upper part needs to be removed with a grinder, but not completely. Then attach loops to it and return it to its original place. Weld a chimney into the hole. A handle and stop are installed in small holes. Cuts are made in the lower part and the material is bent. A valve is created from an additional sheet of iron and installed in curved sheets.

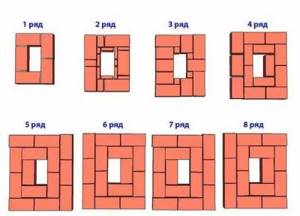

Brick stove for waste disposal

You can create a waste incinerator at your dacha out of brick. It will have a longer service life and an attractive appearance. The stove will need about 115 medium-sized bricks.

Main stages:

- On an area with a perimeter of 0.7 * 1 m, carry out preparatory work and pour a layer of sand.

- Lay the first row without mortar.

- The first row of masonry will require 8 bricks, and a lattice will be laid right there.

- The ash pit is also formed from brick, steel sheet, and filled with cement-sand mortar.

- The next row should also consist of 8 bricks.

- In the rest, gaps must be maintained.

- The final row is made continuous with the subsequent installation of an iron cover.

As an alternative to a square oven, a cylindrical oven can be used. But you need to remember about the air gap for traction.

Heater stove

If you have an unsuitable sauna stove, you can try to create an outdoor waste disposal unit. First you need to remove all internal parts from it, leaving the body and grille. The internal part should be reinforced with sheet iron welded to the base. Garbage is loaded through the top. When disposing of large waste, you need to light a flame in advance. After loading the waste, the oven is covered with a metal sheet.

Classic scheme of a pyrolysis furnace

The long-burning furnace consists of the following modules:

- The combustion chamber. The products here break down into solid residues and pyrolysis gases.

- Afterburner chamber. It is in it that the complete combustion of pyrolysis products occurs.

- Chimney.

- Doors for the working chamber and for the ash pan.

To make a pyrolysis furnace of the “potbelly stove” type, you need to take sheet steel, the thickness of which must be at least 0.3 centimeters, since thin metal quickly burns out and the device becomes unusable. The optimal service life of the furnace is achieved through the use of steel with a thickness of 3 to 5 millimeters.

First of all, blanks of the required size are cut out of steel - these are the two side walls of the furnace, the bottom, front and rear.

The base is made from the bottom and side parts by welding. Next, a grate is welded at the required distance from the bottom of the resulting structure. Before attaching the front side to the structure, the doors for the combustion chamber and ash pan must be welded to it.

Now you will need two more metal sheets to create the afterburning chamber. We immediately weld one to the front and side walls. Before taking on the second one, we weld the back sheet into which we first install special tubes for supplying secondary air. Only after this can the second sheet be welded to the back and side walls.

The pyrolysis furnace for waste disposal is almost ready - all that remains is to make the lid. We cut a hole in the metal sheet that corresponds to the diameter of the chimney pipe. Then we connect them. We weld the finished top sheet into place.

The pyrolysis furnace for burning waste is ready for operation.

There are many options for making such structures. First of all, you need to decide what materials the unit will be made from.

The use of homemade pyrolysis equipment as a heating device in a bathhouse, home or country house requires increased attention to tightness. Doors must close tightly to prevent carbon monoxide from entering the room. Suitable fuels include coal, wood and household waste. Building a chimney is not an easy task. Not every skilled person can cope with it. Even the presence of drawings and diagrams does not guarantee the correct chimney.

Why build a waste incinerator?

Incineration is the most effective way to dispose of plant waste for owners of private houses and land.

There are several ways to burn unnecessary things:

- at the stake;

- in a suitable metal container, such as a garden barrel;

- in a special oven.

Of course, lighting an open fire is the least environmentally friendly and safe option. After all, gusts of wind can carry sparks and burning masses to the sides, which can cause a fire. In addition, the scorched and burnt earth under the ashes becomes “dead” for a long time.

From this point of view, putting waste for burning in an iron container is the safest, but it also has a number of disadvantages:

- used containers with fairly thin walls quickly burn out and become unusable;

- due to the lack of traction, a compressed mass of waste remains untouched by fire at the bottom;

- Flying sparks and burning pieces can also cause a fire.

So, with the burning of garbage, the owner of the house faces various pitfalls.

An acceptable solution is to burn waste in a special furnace that meets all fire safety requirements. You can also burn garbage in a barrel at your dacha.

Advantages and disadvantages of a long-burning stove

A pyrolysis furnace as a heating device has a number of advantages:

- Environmental Safety. Almost complete combustion of products without the formation of toxic smoke.

- Economical. Longer combustion requires less fuel.

- Possibility of connecting to a heating device with any type of circuit.

- Recycling. Instead of fuel, garbage is loaded into the unit.

- The efficiency is 85%. With low fuel consumption, the room is heated in a short period of time.

- Availability. It is possible to install the stove yourself without the help of specialists.

The main disadvantage of pyrolysis plants is their dependence on the alternating current network. Powerful units cannot provide themselves with sufficient thrust, so additional fans are built into them.

Rules for installing a stove in a summer cottage

When placing a stove on a garden or personal plot, it is necessary to comply with the requirements of the legislation of the Russian Federation in the field of fire safety. In particular, the Fire Regulations in the Russian Federation, approved by Decree of the Government of the Russian Federation of September 16, 2021 No. 1479 (with amendments and additions) and Order of the Ministry of Emergency Situations No. 26 of January 26, 2021.

According to these documents, the source of non-open fire must be located on the site:

- freed from flammable objects;

- away from trees at a distance of at least 15 m, and from any buildings - at a distance of at least 25 m;

- remote from gas pipelines, communication lines and power lines.

Failure to comply with mandatory requirements creates a potentially unsafe environment and, based on Article 20.4 of the Code of Administrative Offenses of the Russian Federation, threatens the owner with a considerable fine.

Children and animals should not be allowed near the fire, which must be constantly supervised. The entire fuel supply is stored out of reach of the flame, and nearby are extinguishing agents: water, sand, fire extinguisher.

How does a pyrolysis oven work?

First, we will look at the operating principle of a pyrolysis furnace. Traditional wood stoves use the principle of direct combustion. Firewood loaded into the combustion chamber (furnace) is ignited and begins to emit thermal energy. This energy heats the walls of the unit, after which it penetrates into the heated rooms. Combustion products immediately fly away into the chimney. At the same time, another 10-15% of the heat flies there.

The disadvantage of a conventional oven is large heat losses. Combustion products fly into the chimney hot, they are full of heat, which can be collected and sent for heating. In the simplest case, users extend the pipe, making the horizontal section longer - it runs through the entire room. This reduces heat losses.

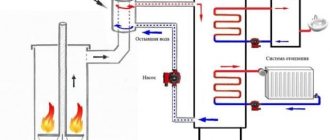

Pyrolysis ovens are designed somewhat differently. They have two chambers - in the first the fuel is burned, in the second the combustion products are burned. During the combustion of wood, pyrolysis products are released - these are flammable gases that burn at high temperatures. To burn them, secondary air is required - it enters the afterburning chamber, mixes with pyrolysis gases, resulting in the ignition of this mixture.

Long-burning pyrolysis stoves are the optimal equipment for your home, cottage or bathhouse.

Advantages of pyrolysis ovens:

- Higher efficiency compared to traditional stoves - the pyrolysis process allows you to extract a higher amount of heat from the same amount of wood.

- The ability to control the combustion process - by adjusting the draft or air supply through the ash pan (and the supply of secondary air), you can set a certain combustion intensity, setting the desired temperature regime.

- Long burning - usually pyrolysis furnaces are equipped with large fireboxes that can accommodate a significant amount of firewood. The duration of combustion also provides the ability to control this process (the adjustment range is from 10 to 100%, depending on the design).

- Fuel saving - with a not very complicated device, pyrolysis stoves save up to 10-15% of firewood.

- A wide range of applications - from baths to residential buildings.

Furnace for burning wood waste - advantages and benefits of such equipment

In our country, the forestry, woodworking and pulp industries are one of the most developed. At such enterprises, waste is always generated in large volumes: various sawdust, wood shavings, tyrsa, trimmings, etc. All these production wastes have no demand, which is why the issue of their disposal is so acute. Moreover, every enterprise operating in this industry strives to ensure that the disposal of wood waste moves from an unprofitable item to an item of economic benefit.

A stove for burning sawdust, grass, leaves and wood waste can solve this problem. With its help, you can not only solve the issue of effective disposal of unusable raw materials, but also produce heat. Buying such fireboxes for burning wood waste is economical.

As you already understand, it is especially advisable to use waste from wood processing enterprises, furniture factories, sawmills and other industries to generate heat. Why throw away raw materials that are unusable and have no demand if they can be used as fuel for special furnaces for recycling wood waste.

You can purchase this equipment - cremators or incinerators - on our website. We are engaged in the development and production of specialized installations for the disposal of various types of unusable material. Especially according to your order, we can also manufacture a furnace for burning wood waste, dry grass and leaves - everything that contributes to the production of heat during the combustion process.

Interesting Disposal of construction waste

Purchasing this equipment will allow you to solve two problems in one fell swoop: optimize the work process by efficiently and quickly disposing of “waste” in large volumes at once and significantly save on heating bills for production workshops, since you yourself will produce heat.

How to make a pyrolysis oven with your own hands

First, we will look at the process of making a simple pyrolysis stove. Let's take the following drawing as a basis:

This is the simplest potbelly stove with smoke circulation. There is no pyrolysis here, but this is not a problem - to organize it we need to implement the supply of secondary air to the first smoke circuit.

This oven is made according to the following scheme:

A couple of metal tubes for air supply - and an ordinary wood-burning stove turns into a pyrolysis stove.

How to make a metal stove

A portable pyrolysis oven with your own hands is very simple. Make sure of this by reading the drawings in our review. To assemble it you will need sheet metal. We recommend choosing sheets with a thickness of 3-4 mm, which is necessary to extend the service life of the unit. Thin iron will quickly burn out, and the efficiency of the stove will begin to decline. A year or two of such operation - and it can be thrown into a landfill.

By the way, if you need a pyrolysis stove for a sauna, pay attention to the following diagram - here we see an enlarged combustion chamber, the same smoke circulation, only in the very top part there is a heater.

The design of the stove needs to be modified so that its firebox goes into the next room, and not into the steam room (it protrudes forward).

When starting to assemble a sauna or pyrolysis stove with your own hands, prepare sheets of iron and mark them in accordance with our initial diagram. The stove body consists of six metal plates, two more form smoke circuits. You also need to assemble a grate - to solve this problem, use fittings with a diameter of 12-15 mm. The grate is attached at a distance of 80 mm from the bottom of the oven using welding.

The most difficult task is preparing the doors. Cut holes in the sheet intended for the front wall; save the cut pieces. Weld 2 cm wide pieces of sheet metal around the perimeter of these pieces, welding them from the outside. As a result, we will get tightly closing doors. They will only need to be equipped with loops and simple hooks for fastening.

Pyrolysis furnaces for heating a home should produce maximum heat. This is what smoke circulation systems are for. Mount them according to the above diagram. Now all that remains is to make holes in the back wall and weld hot air tubes into them. Final assembly steps:

- Weld a piece of pipe with a diameter of 100 mm into the top cover - the chimney will be connected to it.

- Welding door hinges to the body.

- Preparing the legs - make them from sections of an inch metal pipe.

Our homemade wood-burning pyrolysis oven is ready. It turned out to be compact, thereby ensuring ease of transportation from place to place. Install it on a non-combustible base, connect the chimney and start it up.

How to make a brick stove

You will also need a machine that is suitable in size and power. Finding a normal order on the Internet is a real problem; only traditional stoves are publicly available. We recommend ordering its development from specialists or experienced people.

The metal stove is easy to assemble. If you have suitable hardware, cutting and assembling it will take a maximum of a few hours. But a brick pyrolysis oven is not easy to manufacture. You will need:

- Refractory brick for laying out a heating unit.

- Special fire-resistant cement mixture - it must withstand up to +1500 degrees.

- Experience in bricklaying - if you don’t have it, seek help from more experienced people.

Buying a finished stove

A factory incinerator is a more expensive, but also more reliable design. Their advantages over homemade ones are:

Increased fire safety.

Durability. To do this, a fire-resistant coating is applied to the metal. The metal itself is thick and durable.

Aesthetics. The finished products are beautiful, neat and look good.

Factory-made country stoves are often equipped with a chimney for greater combustion speed and intensity. The downside is the high price.

Criterias of choice

Factory fireboxes are selected based on the following parameters:

Size

Ready-made fireboxes are generally quite compact, but there are also large options that can accommodate a lot of waste at a time. If the oven is needed for recycling large items: boards, long branches and twigs, logs, then the internal volume must be large. Otherwise, you will have to load waste several times in small portions and wait until each batch burns out, which will be inconvenient and take a lot of time.

Weight

The specific gravity depends on the thickness of the metal walls. Minimum thickness – 3 mm. The thinner the metal, the faster the structure will deteriorate and burn out.

Therefore, it is better to pay attention to medium-weight options. The thickest-walled stoves, although they will be the most durable, will weigh too much, and they will be difficult to transport and move around the site

Ease of service and equipment

A good garden stove should be equipped with a chimney, a container for collecting ash, and protection against the spread of sparks, smoke, and loss of coals. The design must be well thought out so that it is easy to clean, because carbon deposits will form on the walls from the inside.

Some incinerators are equipped with smoke filters. This is an excellent option from an environmental point of view.

Appearance

The market can offer a variety of configurations. The purchased firebox must match the design of the buildings on the site, be neat and please the eye with its appearance.

Examples of models and their prices

Buyers often choose cylindrical and square models with a chimney. The approximate price in Moscow is 15-20 thousand rubles. Collapsible stoves for burning waste and garbage, as well as options with wheels for ease of movement, are also popular.

Examples of popular models:

| Name | Configuration | Displacement, l | Metal thickness, mm | Price, rub |

| Dark-skinned girl | Cylindrical | 250 | 3 | 14 900 |

| Dacha hit | Rectangular | 210 | 3 | 14 500 |

| To the yard | Square, collapsible | 450 | 3 | 15 900 |

| Cinderella-2 | Cylindrical | 240 | 4 | 15 500 |

Stove modernization

A blower fan will ensure temperature stability in all heated rooms.

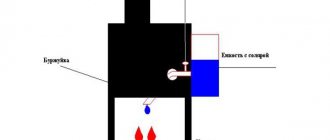

Almost any pyrolysis furnace can be converted into a boiler for water heating. To do this, ready-made or homemade (from metal pipes) heat exchangers are built inside. Radiators are installed in the rooms, water is poured into the system - full heating is ready.

For these purposes, it is best to adapt a pyrolysis furnace with a blower fan - equip it with an external control unit that monitors the temperature and controls the operation of the fan.

Hobs and built-in ovens are what else you can equip any oven with. The energy of pyrolysis combustion is enough not only for heating, but also for cooking. Cooking surfaces and oven boxes are purchased in specialized stores. You can make your own oven from sheet iron. As for the hobs, they are made of cast iron - you can’t do this yourself.

Pyrolysis of solid waste should help earthlings cleanse the environment of debris and reduce the burden on the oil refining industry. This is a production that can provide significant income to the businessman who has established it, since the raw material is cheap garbage, of which 3.5 billion tons are generated in Russia alone per year.

Safety regulations

Whatever oven you decide to dispose of waste in, you need to remember the basic fire safety rules:

the structure must be installed away from buildings, trees, bushes and dry grass; Do not burn garbage in windy or hot and dry weather; it is important to protect the stove by placing extinguishing agents nearby - water and sand; it is necessary to prevent small children from accessing the fire; Be sure to constantly monitor the combustion process.

Disposal of garbage and other waste by burning in a furnace or boiler is possible only in dachas and personal plots, observing all fire safety measures.

Thus, last year’s leaves, collected in the city during the spring cleanup, contain a large amount of toxic substances accumulated over the winter. The combustion of this waste is accompanied not only by a pungent odor and a smoke screen, but also by the release of carcinogens.

What is pyrolysis of solid waste, its advantages over simple combustion

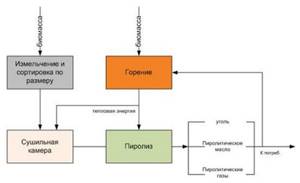

Pyrolysis is the decomposition of heavy organic substances into lighter ones when heated and in the absence of oxygen. In Latin, “pir” means fire, and “lizios” means I decompose, the literal translation of the term is “I decompose with fire.” The meaning of solid waste pyrolysis (see diagram below) is that the compounds that form garbage, when heated, are broken down into substances with a lower molecular weight. As a result of pyrolysis, three main products are formed:

- pyrolysis gas (pyrolysis, pyrolytic gas or synthesis gas) is a mixture of gases capable of burning and non-flammable;

- pyrolysis (pyrolytic) oil and water. Pyrolysis oil has a different composition and can subsequently serve as heating oil or raw material for processing;

- picarbon (solid carbon-containing residue - coal).

During pyrolysis, four processes common to all types of pyrolysis occur: drying of waste (in a drying chamber), dry distillation (pyrolysis), combustion of solid residues, production of pyrolysis gas, pyrolytic oil and carbon residue.

The diagram shows that heating of some stages occurs due to the heat generated during pyrolysis.

Pyrolysis of solid waste can occur in different temperature conditions. At low temperatures, the gas output is less, and more pyrolytic oil and picarbon are formed. With increasing temperature, the equilibrium shifts towards the formation of synthesis gas.

Pyrolysis of solid waste has undeniable advantages over waste disposal by incineration. Firstly, there is no environmental pollution, and secondly, the raw material is waste, and it is noteworthy that pyrolysis processes waste that is difficult to dispose of, for example, old tires. Pyrolysis residues do not contain aggressive substances, so they can be stored underground, and such waste is generated in smaller quantities than after combustion. During pyrolysis, heavy metals are not reduced, but go into ash. The resulting products are easy to store and transport. The equipment is not massive, and it is relatively inexpensive.

Types of Incinerators

Several types of devices are used for rapid waste disposal, each of which has both pros and cons.

Stationary and mobile

Permanent structures are spacious and comfortable. They, as a rule, have huge dimensions and considerable weight, and are installed in one place. Their main advantage is that they allow you to quickly get rid of huge volumes of garbage.

Despite their increased capacity, stationary stoves should not be filled more than halfway.

Mobile structures are suitable for occasional use and the destruction of small amounts of waste. They are compact and save space. Since mobile stoves for burning waste in the countryside usually have little weight, they can be transported even in a passenger car.

The small incinerator is inconvenient to use. The collected waste has to be disposed of in several approaches; large waste needs to be shredded.

Ready-made and homemade

To destroy waste (biological, medical, animal, industrial, household), factory stoves with a chimney are produced - incinerators. Their structure is similar to those that summer residents make with their own hands.

All of them have a grate, an ash pan, and a chimney. The design of purchased units is much more functional, although they are more expensive. The heat produced by such stoves can be used for cooking.

In addition to factory-made stoves, summer residents often use homemade devices. A simple example: using an unnecessary metal barrel or rectangular container as a stove. It is also possible to install stone and brick stationary stoves.

Plasma furnace for waste disposal, which reaches temperatures above 4000 °C, environmentally friendly (smokeless). The output is electricity sufficient to supply enterprises.

What kind of garbage can and cannot be burned in garden stoves

A lot of different waste is collected on the territory of the dacha, but only the following waste can be disposed of independently:

- dried grass;

- branches, tree trunks;

- paper, wood waste;

- weeds;

- cardboard packaging;

- dry tops.

It is prohibited to burn in the stove:

- plastic and glass waste;

- aerosol cans;

- electronics elements;

- metal;

- synthetic material;

- painted wooden elements (not taking into account water-based coatings);

- chipboard;

- other materials with chemical inclusions.

The last listed waste releases dangerous toxins when burned. For this reason, they should be sent to special centers for processing.

Types of pyrolysis

Based on the effect of different temperatures on waste, pyrolysis is divided into low-temperature and high-temperature. The first occurs at temperatures up to 900 0 C, and the second - at temperatures above 900 0 C.

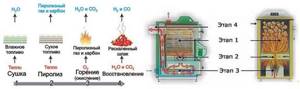

Low temperature pyrolysis. The technology for processing waste using this method consists in heating the raw materials in the mine to 350 - 450 0 C without air access, that is, in the absence of both oxygen and nitrogen. Stable temperature and the complete absence of oxygen ensure that the raw material will not burn, and there will also be no interference with the intensive occurrence of processes such as heating, melting, evaporation, and decomposition of carbon compounds. With this type of pyrolysis, it does not matter what the chemical composition of the waste being processed and what the proportion of organic substances are in it. Pyrolysis gas has almost the same composition:

- flammable component: carbon monoxide, methane, ethylene, hydrogen sulfide, hydrogen;

- non-flammable component: carbon dioxide and nitrogen.

It is important that the combustible component significantly exceeds the non-flammable content, which means that pyrolysis gas can be used in the same way as extracted natural gas. The yield of the resulting flammable gas depends on the qualitative composition of the raw materials: for example, food waste forms a gas saturated with moisture, which cannot be said about plastics.

High temperature pyrolysis. Technological chain:

- Sorting of waste with removal of large objects, non-ferrous and ferrous scrap metal.

- Grinding and drying of selected waste.

- Decomposition of dried raw materials to form pyrolytic gas, pyrolytic oil, slags and by-products such as Cl2, F2, N2.

- Eliminate pollutants and reduce the temperature of the resulting gas.

- The use of pyrolytic gas to produce steam, electrical or thermal energy. Most often, this gas is used reversibly to initiate pyrolysis.

- After storage, pyrolytic oil is sent as raw material to petrochemical plants for the production of fuels and lubricants, fuel oil substitutes and firewood.

Homemade options

To make an outdoor stove with your own hands, you need to prepare separate materials. Most likely, an old metal barrel, a pipe with a diameter of 50 cm, and a container will come in handy.

The door should be made at the end (cut in a circle). Then attach loops and a handle to the segment. Make holes on the opposite side to allow oxygen to enter the firebox. The barrel stove is installed on stands.

It is necessary to build a grate inside the structure and provide for the location of the ash pan. You need to make a hole in the upper half of the barrel and weld a chimney.

Construction made of metal corners or fittings

This garden waste stove usually has a pyramidal or rectangular shape. The elements of the device must be attached to the bottom, maintaining a distance of 3-5 cm. The latter will ensure sufficient air supply during combustion. It is necessary to lay a grid made of reinforcement at the bottom. This stove will last a long time.

Its main drawback is its massiveness, which creates difficulties in case of movement.

Heater stove

A sauna stove, even if it is damaged, can be converted into a garbage disposal.

First, you need to remove everything from the heater, leaving the grate and body. Then sheet steel is welded from the inside to the base, which will strengthen the entire structure well.

The waste can then be thrown from above. But on the eve of loading large parts, you need to light the flame. When disposing of waste, it is advisable to cover the stove with an iron sheet, placing pieces of brick to ensure unimpeded escape of smoke.

Pros and cons of solid waste pyrolysis

Positive aspects of low-temperature pyrolysis:

- there is no urgent need to sort hydrocarbon residues (even completely unsorted waste yields twice as much pyrolysis gas as compared to food waste alone);

- city landfills act as a source of raw materials for production;

- absence of toxic sulfur and nitrogen oxides.

Disadvantages of low temperature pyrolysis:

- complex design of large furnaces;

- high cost of stoves;

- the need for a large number of workers;

- There is no complete breakdown of dioxins contained in raw materials;

- heavy metals do not melt, but precipitate along with the slag.

What waste can be processed using pyrolysis

Note! MSW - municipal solid waste - different substances that cannot be reused in human household activities without treatment.

Solid waste is a mixture of substances of organic and inorganic origin that have different properties. In Russia, waste is not sorted. However, abroad, and in our country too, there is a tendency to reduce the share of food waste in garbage and increase the share of packaging materials: plastic, cardboard, paper. Studies have shown that approximately 30 percent by weight and 50 percent by volume of solid waste comes from packaging material. And 13 percent by weight and 30 percent by volume of packaging material falls on the share of plastic products, the vast majority of which are plastic tableware. The organic component of garbage is divided into:

- compostable (kitchen waste, sawdust, tree bark and branches, wood chips, old newspapers, cardboard);

- non-compostable (plastics, rubber, leather, discarded old tires, cables, viscous pasty waste such as motor oil, oil sludge, soil contaminated with fuels and lubricants).

Compostable and non-compostable components of waste are subjected to pyrolysis.

Combustion time

The average burning time depends on the type of wood waste, oven temperature, humidity and type of wood.

Ignition occurs at a temperature of 200 ° C, but hemicellulose burns first, and only then cellulose. The time for complete combustion always differs among different types of trees due to volatile substances having different ignition temperatures. Thus, 50 grams of birch sawdust are disposed of in 14-15 seconds at a temperature of 250 °C; complete combustion of waste from pine of the same size requires 30 seconds. Burning wood pellets takes 1.5 times longer.

It is also possible to make similar equipment on a smaller scale with your own hands and use it for domestic purposes.

A stove for recycling wood waste is one of the tools for maintaining a normal environmental situation. Burning branches and sawdust in special units also makes it possible to obtain secondary commercial products, which are subsequently used as liquid or solid fuel.

Pyrolysis equipment for waste processing

Modern equipment can operate using raw materials obtained from almost any type of organic waste using its own energy. A mandatory component of the pyrolysis apparatus system is the reactor.

Interesting! Initially, the first pyrolysis devices appeared in Russia in the nineteenth century. In those days, kerosene was pyrolyzed to make gas and gasoline, which were used for lighting.

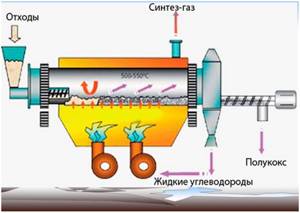

Processing of raw materials is carried out in the reactor zones (diagram below):

- at the top the temperature is maintained at 100 - 200 0 C and here the raw materials dry out (stage No. 1);

- in the middle, at a temperature of 1000 - 1200 0 C, thermal decomposition of the organic mass and its coking occurs, while part of the carbon burns with the release of heat, maintaining the desired temperature (stage No. 2);

- at the bottom, the solid residue is cooled to a temperature of 100 0 C, the remaining carbon burns out and is converted into ash - picarbon, carbon (stage No. 3);

- removal of pyrolysis products for storage and reuse (stage No. 4).

Currently, the industry offers the following types of equipment for pyrolysis of solid waste:

- Pyrolysis plant for tire recycling:

- Pyrolysis plant for recycling wood waste, manure and droppings:

- Universal pyrolysis plant (T – PU1) for recycling waste from wood processing, oil refining, medical, food and other waste.

If you simplify industrial pyrolysis mechanisms and use non-volume devices, you can create a small pyrolysis installation that can be used for personal purposes by ordinary people. In everyday life, using this installation, you can obtain thermal energy, and in industry, you can obtain popular chemical products.

Video about the operation of a pyrolysis plant located in Tatarstan, about the technology of the process, and about the advantages of this method of recycling solid household waste:

Oven operation

During combustion, sparks are formed that rarely reach the ground, but otherwise the stove is simple and trouble-free to operate. If you are lighting your creation for the first time, it is worth considering the following.

- Before ignition, pour the soil (with a hose from a watering can) within a radius of 2 meters from the masonry.

- For kindling, use paper, birch bark, dry branches of blackcurrant, raspberry, dry wood chips and firewood. Do not use flammable liquids.

- Place the next portion of green tops into the barrel when the previous one is half burned. Do not press the tops in the barrel.

- Don't be afraid of flames coming from the barrel, this is normal. Hot air from the firebox accelerates combustion.

- To make it easier to load tops, install a reliable stand with a height of 15-25 cm near the stove.

- Use a fork when loading tops and avoid contact between the fork and the barrel. Use a poker to guide the overhanging parts of the tops into the barrel.

- Do not throw firewood into a barrel, it is ineffective; place firewood only in the firebox. Try to use less wood.

- Drizzling rain does not interfere with combustion. In case of heavy rain, place the poker on the barrel and cover it with an iron sheet, continue burning the garbage.

- Do not touch the firebox door handle or the barrel itself with your bare hands; it gets very hot.

- After burning the garbage, cover the barrel with an iron sheet and place the poker between them. The result is a roof with a slope.

Interesting Waste management system in medical organizations: classification, morphology, education standards