Contrary to the popular belief among many women that tow is a bad hairstyle on their pretty heads, in fact it is a material necessary in construction and plumbing work. Shipbuilding enterprises and organizations involved in the laying and subsequent maintenance of pipelines and cables will also not be able to do without it. As you can see, tow is a substance that is in great demand in many highly specialized industries. But every man can easily find in his pantry a small piece of fibrous material that is hard to the touch.

What sealants does the building materials market offer?

There are several types of sealing materials that differ in cost, ease of use and reliability of use:

- FUM tape (fluoroplastic sealing material)

- Sealing thread

- Linen thread

Among all the FUM proposals, tape is quite difficult to use, sealing thread has good qualities, but is too expensive, and only flax is an impeccable product that has proven itself over many decades.

How to properly wind flax on a thread?

To ensure a strong and tight connection, the threaded areas must be cleaned of rust using fine-grained sandpaper

At this stage it is important not to damage the threads. Then you should check whether there are notches on the thread - with them, the laid flax threads are fixed and do not move when connecting the parts

If there are no notches, they can be applied with a file or a plumbing wrench.

If there are no notches, they can be applied with a file or a plumbing wrench.

Proper winding of flax consists of several steps:

Check the tightness of the connection with a clean, flax-free thread to understand how thick the winding should be. Take a bunch of flax and separate a strand of sufficient thickness from it to obtain a tight connection. The flax hairs should be the same length, without lumps, straw or debris. Twist the strand into a loose rope of such thickness that it can fill one thread groove. Holding the end of the flax rope at the edge of the thread, wind it in the direction opposite to how the nut is tightened. Each subsequent turn should fit tightly to the previous one

Here it is important not to overdo it with the number of layers, there should be no more than two, otherwise the connection may burst when tightened or from hot water during operation. If the bundle turns out to be short, winding should be continued with the next bundle. Inspect the reverse side of the winding and make sure there are no bald spots.

Apply a layer of special paste or silicone on top of the flax and tighten the connection until the paste hardens

Inspect the reverse side of the winding and make sure there are no bald spots. Apply a layer of special paste or silicone on top of the flax and tighten the connection until the paste hardens

The use of a sealing composition contributes to the durability of the connection, prevents rotting of the flax, and makes it easy to disassemble the structure in the future. Sealant should not be used as a sealant; such a connection is difficult to disassemble.

Using a sealant when threading pipe systems is easy. This approach does not require the use of expensive equipment, and can be easily performed by both a professional and a home plumber.

1. Purpose of tow and how it works.2. Types of sealing materials.3. Method of sealing pipe threads with tow.

In plumbing work, tow is used to seal pipes and transitions connected by threads. It is made mainly from flax waste and is a coarse fiber of small size. If you wind the tow correctly, protection against leaks will be provided throughout the life of the pipeline. Answering the question of how to wind tow on a thread, it should be said that the quality of workmanship prevents the risk of a leak in the plumbing system. There is a gap between the threaded connections through which water freely flows out of the pipeline. If it contains properly laid plumbing tow, then the gap becomes smaller, and as water penetrates into such a connection, the flax swells and the leakage stops.

What is tow made from?

For right-handed threads, the fibers are wound clockwise; for left-handed threads, the fibers are wound counterclockwise.

You can determine the amount of tow winding experimentally. To do this, you need to perform a test turn on the water. Water leaking through the joint indicates that there is not enough tow. Don't try to wrap too much tow. Excess will create unnecessary stress, which can lead to thread failure and the connection becoming unusable.

Regardless of the type of sealant used for pipe connections, wait for it to dry completely. The instructions for use will help you with this. Experienced plumbers advise starting to operate the water supply system after two days from the date of installation. This time is enough for any plumbing pipe sealant to dry.

Characteristics of tow

Linen has many valuable qualities. It contains cellulose components, wax and pectin. These natural details give the material some special properties:

- high strength;

- presence of pores;

- high hygroscopic indicators;

- wear resistance;

- bactericidal;

- does not provoke allergies.

In production, the material is numbered from eight to twenty-four units. A higher number means better fiber quality. A high-quality tow should not contain a large amount of foreign impurities.

The beige color of flax is a clear indicator that indicates the natural origin of the substance and the absence of harmful additives.

Material soaked in plumbing solution serves as a good external sealant when matching pipes, which allows you to monitor their condition. This point is necessary in a situation where you urgently need to eliminate a leak in a structure without unnecessary disassembly of parts. Effective resin tow is widely available on the market.

Natural plumbing material with paste is wound onto the threads, and the result is a cheap and high-quality solution for strengthening connections in all kinds of structures.

Tow for caulking

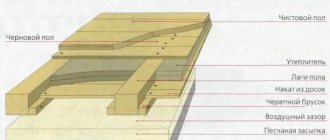

During construction, a product such as tow is used to fill the gap between the beams. This is most necessary when constructing wooden buildings. Tow is widely known for being easier and more reliable to use than the old version with natural moss.

Tow prevents shrinkage of the house, has hygroscopic properties and efficiently fills all kinds of gaps between the crowns.

Features of the material and its advantages

Tow flax is a waste product that arises after the processing of bast crops. This is an environmentally friendly material that does not require special certification. It is quite safe for humans if the rules of storage and use are observed. In addition to tow, materials are used, for example, a special paste, which acts as a protective and sealing layer for it.

Due to the presence of cellulose, wax, pectin and lingin in its composition, tow for pipes acquires such qualities as strength, porosity, hygroscopicity and wear resistance. The advantages of this sealing material are:

- Can be used for a variety of connection types.

- Reliability - swelling occurs under the influence of water, which appears as a result of leaks. The tow layer is compacted and blocks the leak.

- Maintaining tightness due to greater resistance to various types of mechanical actions.

- Due to its higher heat resistance, tow is more suitable, for example, compared to fluoroplastic sealing material, for sealing hot water supply pipes.

- Affordability.

At the same time, there are a number of disadvantages that encourage craftsmen to limit the use of this sealing method. The effectiveness of the application depends on the quality. If the plumbing tow is of low quality, then there is a serious risk of rotting under the influence of water and air.

For protection, it is recommended to cover the winding with a layer of special paste. Also, in many cases, for more reliable fastening, it is necessary to form notches on the thread, since flax can roll and get knocked down

This is especially important if the thread is large in size with the diameter of the pipe following it

Brass and bronze connections require special care when working to avoid thread breakage.

Why tow (plumbing flax) is better than fum tape

To seal the threads, you can use fum tape, plumbing flax (tow) and anaerobic sealants.

The last option is not used so often because it has specific application features. As for sanitary flax and fum tape, these two sealing materials are most widely used today. At the same time, sealing threads with tow and fum tape also has its own characteristics.

And if you don’t know what to give preference to - fum tape or sanitary flax, then this article from the construction magazine samastroyka.ru is just for you.

Is it necessary to caulk a house made of timber?

When constructing timber houses, insulation is laid on each crown. Under its own weight, the log house invariably shrinks. This is a natural process and cannot be avoided. The wood dries out and changes its geometric parameters: the timber “sits”, the insulation wrinkles in places, and cracks appear. This may not be noticeable to the eye, but on average a log house 3 meters high can shrink by 10-12 cm after a year.

Gaps in timber after shrinkageSource content.onliner.by

To improve the thermal performance of a timber house, the timber must be caulked. This procedure is needed for the following purposes:

- Prevent heat leakage. During shrinkage, cracks appear between the crowns of the log house, the so-called “cold bridges”. Drafts appear and heat is blown out. Caulking allows you to retain heat and improve the thermal performance of your home.

- Elimination of icing of walls. In the absence of caulking, heat will escape through the cracks formed when the timber shrinks. Due to the difference in temperatures during the cold season, moisture entering the cracks of the timber freezes, which leads to further cracking of the wood.

- Increased home performance. After caulking, a full thermal balance will be created in the log house. Heat conservation will save resources on heating your home. The log house will be in more comfortable operating conditions in the complete absence of icing on the external and internal walls.

This is what caulked timber looks likeSource 1brus.ru

Caulking is a mandatory step in construction. It will keep the house warm, save heating resources, and also increase the service life of the building as a whole.

Fum tape

I'll start with fum tape, this is probably the most common sealing material! I usually use it for sealing threaded connections of small diameters 3/4, 1/2 and smaller, and almost always for plastic threads. The tape comes in different thicknesses, from 0.075 to 0.2 mm and more, the width is also different. For work, I use a thick tape, make 3-4 turns per thread, the diameter of which is indicated above.

It is the most difficult thing for an inexperienced craftsman to work with tape, and no one will tell you exactly how much you need to wind, since you need to write a whole article for this! That is why I try to work with it less, since connections sealed with tape most often leak, it’s enough not to rewind or rewind a little and that’s it, problems cannot be avoided. I use one type of tape, I know exactly how much to wind and leaks occur very rarely, I usually buy tape without a casing, you can see which one in the photo below. If you have little experience, I advise you to practice before using!

Some tips for working with tape:

A huge disadvantage of fum tape is that the threaded connections sealed with it cannot be adjusted, which means that if you need, for example, to unscrew the tap a little to align it, the connection will definitely leak!

Description of species

Tow is divided into several varieties. Each product has its own distinctive characteristics and even external differences. Let's take a closer look at the different types of raw materials in question.

Beige

Linen, which has a characteristic beige tint, is natural. Its very shade indicates this. The beige tow does not contain any additional chemical or harmful components. This material is environmentally friendly and safe and is sold in many stores. The tow has a beige color, which is used for the further caulking process.

When working with this material, small flagella are first formed, which are then pushed into the interventional seams using a special tool. The most convenient to install is tape beige tow, sold in different formats. The canvas varies in width and length (from 10 to 50 meters) and thickness.

Brown

There is not only beige, but also darker brown tow. Such products are in most cases used as a sealant when installing pipeline systems. Brown tow allows you to quickly eliminate pipe leaks without the need to dismantle a large number of important parts and connections.

Unlike bale or rolled tow in a beige shade, sanitary products have a special impregnation. Brown tow is processed in a special way, so it is ideal for installing plumbing or heating systems. The material in question has long proven itself and demonstrated its effectiveness.

Thanks to brown tow, craftsmen can seamlessly join pipe joints to prevent the formation of leaks. The dark material has a special fiber structure, thanks to which it is very easy to wrap on the necessary bases, perfectly absorbs excess moisture and expands when wet.

Tow differs not only in its color and purpose, but also in the type in which it is sold. Thus, darker products, which are intended for high-quality plumbing work, are most often sold in the form of skeins of different sizes. But tow, which is intended for further caulking, is sold in bales of different weights or in rolls.

Tow for caulking

During construction work, tow is a material that is used to seal the joints between the crowns. It is most often used for the construction of wooden buildings. Previously, moss was used for this, but tow is a more durable, reliable and easy-to-use material. It prevents shrinkage of the building, has excellent energy-saving properties and allows you to reliably fill the seams between the timber.

Material in bales is sold at 10, 20, 40, sometimes 60 kg. During work, flagella are manually formed from tow, which are pushed into the seams using a special tool - a caulk. Tape tow is more convenient to install; manufacturers offer it in several formats. The width of the canvas may differ - 10, 15, 20 cm, its length (10, 20 or 50 m) and thickness (5-15 mm). Experts recommend caulking the building twice: the first time - directly during the process of laying the walls, and this should be done in a circle, and not with each wall separately, and the next time - after a year.

Description of tow

Tow is an insulating material made from natural plant fibers. It is a tangled fiber that is slightly rough to the touch. In fact, tow is waste obtained after the primary processing of various bast crops. Its structure is rarely perfectly clean; it may contain fire, particles of straw, etc. Tow can be sold in the form of pressed bales, in rolls or in strips (tape inter-crown tow).

The tow is not eaten by moths over time, and biological pests do not appear. The structure of this material does not crumble or erode. It does not deteriorate from exposure to ultraviolet rays. It is hygroscopic, natural and environmentally friendly. It is impossible to name any specific characteristics of tow, because they may be different. It all depends on the plant fibers used to produce this insulating material, their length and the cleaning method used.

Purpose of tow

Construction tow is made for use in wooden housing construction - the assembly of log houses and bathhouses. It has proven itself well as a material for caulking log walls, sealing connecting seams between joints of logs or beams. Tow is also actively used to fill voids between door and window frames. As a result of using this insulation, wooden houses are breathable and warm.

Tow is also used in plumbing, mainly to ensure a strong connection of pipes and other plumbing parts. It is wrapped around the places where the pipes will be connected in the future. Tow is also used in heat supply and water supply, because it is able to withstand both high temperature and temperature changes. It is also used in the construction of ships, because... she is not afraid of sea water (salt).

Terms of use

Tow must be used correctly so that it demonstrates all its positive qualities and high performance indicators. Let's look at the rules for using tow using the example of sealing joints.

- Most plumbing jobs cannot be done without tow. It is very simple and easy to work with. If there are no notches on the threads, and their presence is necessary for stronger and more reliable fastening, then it is advisable to use a needle file or file for application.

- Many craftsmen apply notches with simple pliers by gradually squeezing the thread, making circular movements. The presence of small notches will prevent the material for fastening the pipes from slipping in the future.

- Next, you need to separate the first strand of fiber from the general “braid” of tow. The thickness of the selected piece should correspond to the connection to which it is planned to be applied. If even small lumps are noticeable, they must be removed immediately.

- Both fluffed flax and pre-rolled flax into neat braids can be wound onto the joint.

- It is allowed to use material that has been pre-treated and impregnated with a special paste. You can apply tow on the first layer of tow that has already been pre-wound. Both the first and second methods are equivalent and significantly reduce the risk of damage to the material during its operation.

- The material should be wound crosswise. The first turn must be secured with a lock. For example, the master can start from the very end of the threaded connection. The starting turn will need to be overlapped. The coils must be made as tight and strong as possible.

- After the starting one, you can make all other turns, but with movement to the starting point of the threaded base.

- When the beginning of the thread is reached, it will be necessary to return to its end again. However, the maximum density in the middle should not be neglected. The end of the linen braid should be returned to its starting mark. The tip will need to be brought out of bounds.

- You will definitely need to make sure that the winding made is of sufficient density. Please note that under no circumstances should the tow rotate on the surface of the fitting. If the material moves along the surface of the base, the winding will have to be done again to correct the situation. A special protective sealant paste will need to be laid on top of the layer.

- All excess that remains from the tow can be left in its place, or you can carefully cut it off with scissors. It all depends on the wishes of the owners. These residues will not affect the seal in any way.

Let's consider other features of using tow for caulking.

- Tape tow, which consists of natural ingredients, is used most often. It is permissible to use it during primary caulking.

- The master only needs to carefully unfold the tablet on the beam or log of the base. The material should be fixed in either one or a couple of layers.

- If this is a bale tow, then it is advisable to use it in situations where there are heterogeneous gaps with different widths between the logs.

- Fiber that is made shorter will be an ideal solution if it is necessary to fill inhomogeneous empty spaces, since the amount of material used is determined by the master himself.

Working with tow is extremely simple. Using completely simple technologies, builders can build a real long-lived house that will be warm and cozy.

Builder tips

Tow has many advantages over synthetic insulation materials. It can last for a long time without losing its properties. Tow has bactericidal properties that prevent the formation of fungus and other biological agents. Tow is very durable and does not contain any dangerous or harmful substances for people. Its loose, cotton-like structure allows you to easily adjust the size of the sealing seam. It is easy to use and there is no need for any preparation work. Tow has a low cost; you can purchase it at any hardware store, but it is still better to buy it from a specialized company.

Tow can also be used for the primary insulation process in the construction of wooden houses, i.e. for laying between the crowns of logs and beams. At the same time, it must be laid in an even layer, leaving a supply of material on both sides, so that in the future it can be tucked and hammered to create more reliable insulation. It is better to purchase tape tow in rolls for this process; it has an aesthetically pleasing appearance and is easy to lay in an even layer.

It is better to use tow in bales or rolls for caulking. This type of insulation can eliminate even the smallest cracks and cracks in wooden material. To do this, you need to make a small rope out of tow and drive it into the crack. From this type of tow you can easily tear off the required size piece of insulation.

How to caulk a timber house

Deciding how to caulk a log house is not so easy. Manufacturers offer many different materials, each of which has its own pros and cons. But there are certain requirements that the materials used must meet:

- Durability. The minimum service life without loss of thermal properties must be at least 20 years.

- Low thermal conductivity. The main task of the material is to retain heat and be immune to fluctuations in outside temperature and humidity.

Materials for caulking Source yandex.net

- Air permeability, hygroscopicity. The insulation should form natural air exchange, but not allow cold air to pass through. It should absorb moisture when necessary and release it when required.

- Similar properties to wood. A wooden house “breathes”; the insulation must comply with the life principles of wood and correspond to its basic characteristics.

- Ecological cleanliness. The material should not be subject to rotting, mold, insects, be non-toxic and made from natural materials.

People have been caulking wooden log houses for centuries. From current practice, two main categories of materials can be distinguished: traditional and modern. Let's take a closer look at the materials used for caulking and note their advantages and disadvantages.

Traditional materials

The use of traditional caulking materials has a long history.

Previously, the question of how to caulk a timber house was solved simply: they used improvised materials.

Moss

Advantages:

Environmentally friendly, not subject to aging and decay.

Moss in the masonry of timberSource Kostromskaya-terem.rf

- Durable.

- Has antibacterial and antiseptic properties.

- Hygroscopic.

- Breathable.

- Calm to changes in temperature and humidity.

Disadvantages: labor intensive when caulking, attracts birds.

Flax tow

Waste from the production of linen products is used in many areas of production.

Linen tow Source e-uteplitel.ru

The material is also good for caulking.

Advantages:

- Tow has excellent antiseptic properties.

- Impregnated with wood resins, it is environmentally friendly and highly resistant to operation in a humid environment.

- Inexpensive.

Disadvantages: it is produced in only one standard width - 15 cm.

Hemp hemp

It looks something like tow, but the fibers are much coarser. This kind of hemp contains lignin, which makes it similar in composition to wood.

Hemp hempSource wikimedia.org

Advantages:

- Suitable for use in wet conditions.

- Not afraid of temperature changes.

- Not subject to rotting.

Disadvantages: hemp is rarely used in caulking, due to its limited production and the high cost of the fiber.

Modern materials

When creating new modern materials, people strive to maximally improve the properties of existing materials and reduce the cost of the process of obtaining them. Today, common materials for sealing log joints are jute and linen felt.

Jute

The most common material for caulking.

Jute as insulationSource ykt2.ru

Pros:

- It has a fairly strong fiber;

- Does not rot, is not susceptible to mold;

- Jute is hygroscopic and breathable.

- Ideal in combination with wood. Doesn't get pulled apart by birds.

Disadvantages: short-lived material, afraid of moisture, so it is not recommended to carry out insulation in rainy weather, coarser material compared to linen counterparts.

Linen felt

A material based on flax fibers, similar to jute, but the fibers are much softer. Available immediately in rolls.

Linen felt (eurolinen, flax wool) Source recn.ru

Advantages:

- Convenient to use.

- Has good thermal properties.

- Repels moisture and does not rot.

Disadvantages: high cost in comparison

Fum tape: alternative or not?

Today, manufacturers are increasingly offering modern materials; they claim that working with new sealants is becoming easier and faster. These are marketing tricks.

Fum-tape refers to synthetic sealants, in the manufacture of which fluoroplastic film (PTFE) is used. The price of the reel depends on the quality of the material, as well as on the width and thickness of the tape. In each case it is selected separately, it all depends on the thread diameter.

Among the advantages, I highlight the following points:

- It is much easier to work with fum tape on a plastic pipe;

- it is convenient if winding connections with fine threads is required;

- the material has an excellent level of elasticity and high tensile strength;

- very simple installation that does not require any knowledge, skills or craftsmanship, I coped with the tape the first time;

- allows you to quickly dismantle the connection and eliminate the leak;

- the material, even after long-term use, is not observed to rot, fungus and other microorganisms do not appear on it;

- fum tape can be used even in the most extreme conditions; it shows excellent results at high and low temperatures.

Another significant advantage, in my opinion, is the versatility of the fum tape; it is used on plastic and metal-plastic pipes. In addition, it is suitable for thin-walled fittings.

Fum tape also has disadvantages, I highlight the following:

- It is difficult to determine when purchasing how high-quality the material is, since there is no way to know how it stretches, how quickly it breaks, I ended up with defects several times;

- before winding, it is necessary to carefully inspect the thread, remove any existing notches, burrs, roughness, they simply tear the tape;

- material under the influence of high temperatures, more than 260 degrees, releases toxins harmful to the body;

- I think it is inappropriate to use tape with a large diameter (from 50 mm), this is due to the high consumption of material, since the maximum thickness of the tape does not exceed 0.14 mm;

- amplitude temperature fluctuations often break the tightness of the connection; this process must be constantly monitored so as not to miss leaks;

- due to the smooth surface, it is difficult to determine the required number of turns of the winding; if it is not enough, then it simply does not hold water; if there is excess, then the material breaks;

- the presence of sharp edges often simply cut the sealant, which disrupts the overall uniformity and solidity of the seal.

In addition, from time to time I encounter troubles when the synthetic material loses its tightness due to a slight rotation of the reinforcement. It was necessary to carry out dismantling with additional work in the form of thoroughly cleaning the threads from the previous tape.

We recommend: Is it possible to freeze bananas in the freezer: culinary tricks

Plumbing flax: cheap and cheerful

Linen is a classic winding. Sometimes it is called tow in the old fashioned way.

Advantages of flax for plumbing work:

Low price. Cheaper than any other winder

When purchasing, you need to pay attention to quality. Good flax is sold in a braid or loose coil, has no lumps, and is clean (light in appearance). Versatility

Suitable for any type of connection. Of course, with proper winding

Versatility. Suitable for any type of connection. Of course, with proper winding.

The ability to increase volume during swelling. That is, if immediately after the connection there is a small leak, it very soon “closes” itself. Flax fibers get wet and, swelling, cover small leaks.

Mechanical resistance. The only material that allows you to more accurately orient plumbing fixtures. You can, if necessary, make a half-turn back without losing the tightness.

But there are also disadvantages:

It is mandatory to use accompanying materials with it (lithol, grease, fum-let, sealing paste, silicone, oil paint). Linen is of organic origin. And like any organic matter, it has a tendency to rot, especially under the combined influence of water and air. And air enters the water supply or heating systems during repairs or preventive inspections, which must be carried out annually. The accompanying material is designed to prevent rotting.

Requires special thread preparation. Many manufacturers of fittings make their threads already prepared for winding with flax. The threads have notches. If they are not there, then they need to be applied to plumbers (with a file, pliers, or less often with a hacksaw). They are needed so that the flax, during the joining process, does not slip along the turns of the thread and does not come together in a bundle.

Requires caution in brass and bronze connections. A layer that is too thick can break the thread and cracks will appear. Plumbing linen is the only material that is very demanding in terms of compliance with winding rules

In addition to the already mentioned preparation of the thread, you need to prepare the flax itself: soak it with the accompanying material to prevent rotting. Then wind, observing the direction of the thread turns, that is, against the winding. Bring the ends of the fibers beyond the thread area, pull them and, holding them with your finger, screw the connection onto the thread, tighten

Plumbing linen is the only material that is very demanding in terms of compliance with winding rules. In addition to the already mentioned preparation of the thread, you need to prepare the flax itself: soak it with the accompanying material to prevent rotting. Then wind, observing the direction of the thread turns, that is, against the winding. Bring the ends of the fibers outside the thread area, pull them and, holding them with your finger, screw the connection onto the thread and tighten.

Disadvantages include the fact that the accompanying materials (not all) prevent the dismantling of connections (for example, to replace part of the system, connect new elements, or in the event of a leak). Silicone and paint glue the parts of the connection to each other in such a way that the process of separation can be quite difficult, sometimes simply impossible. The same problems arise when separating steel elements, when incorrectly wound flax (or without accompanying material) as a result of rotting allows rust to occur in the threaded connection.

The procedure for winding plumbing tow

How to wind tow on a thread? Before winding tow, it is necessary to carry out preliminary preparation of the thread. Since the surface of the thread is most often flat, the winding will begin to slip and bunch up. And it is not possible to seal it. The threads must have serrations that allow the fibers to engage on the threaded surface. The winding will not slip and will provide high-quality sealing.

You can make such notches or notches using a file or needle file. If you don't have these tools, you can use pliers. Using them you need to squeeze the thread in a circle. But it is better to purchase threads on which the manufacturers have already made notches.

Then you need to separate a strand of fiber from the braid. Choose a strand that will suit the thickness. The material should not be too thick, but not too thin. The fiber strand should not have any lumps. If there are lumps, they must be eliminated. The winding process can occur in different ways.

Many specialists twist the product before winding, others braid thin braids, and some wind it loose. It depends on the person himself. The overall result will be the same.

You can first apply additional material to the thread, then wind the dry fibers of the strand and then apply one layer of the product. You can immediately wind it using the impregnated product. The result will also be the same. It depends on convenience.

How to wind tow correctly? In any chosen option, the winding of turns is carried out in the direction of the thread. Beyond the thread boundaries, the end of the fiber strand must be clamped with a finger. The first turn is applied in the form of a “lock”. Be sure to twist the strands tightly, leaving no gaps. Once the winding is completed, a strand of fibers must be glued to the accompanying product closer to the outermost part of the thread. Winding of tow on the thread is done crosswise.

These are the most common and popular methods for sealing threaded connections. All of them are great, but you need to follow certain rules and nuances.

Comparison with other materials

Tow is a popular material, but it also has equally relevant analogues. These include moss, modern types of insulation for inter-crown seams and many other products in this category. In certain situations, instead of tow, you can use regular polyurethane foam.

It makes sense to understand in more detail what the main differences between tow and other similar materials lie. First, let's compare tow and moss.

- When using both tow and moss, builders and craftsmen have to resort to additional caulking of the crown joints. Moss will not give a beautiful and even seam, but flax tow will look much more attractive.

- If the material is selected for installation in inter-crown seams, then craftsmen often choose tow, since it is easier to work with than moss - it is not so easy to carefully place it in the cracks.

- Birds are more interested in tow than in moss. They often pull jute and linen material apart, pulling its fibers out of the inter-crown seams. They are much less attracted to moss.

- Tow often harbors wood parasites that never appear in moss.

- Moss is used less often in construction because it looks less attractive than tow. It immediately catches your eye.

The material in question can also be compared with other raw materials used in construction. We are talking about insulation called polytherm. Let's look at the differences between these materials.

- If the raw material is used for laying in crown joints, then polytherm will not require additional caulk, unlike tow.

- Caulk made of flax or jute can absorb moisture, but polytherm is not subject to such problems.

- Jute or linen caulking cannot boast of vapor permeability. Polytherm is a vapor-permeable material.

- It will not be possible to use tow again, but polytherm insulation can be used multiple times.

It is worth mentioning the service life of linen or jute materials - it is much more modest than the service life of polytherm. The latter can last almost 100 years, but the tow between the crowns often lasts only a couple of years. Tow is often compared to other materials of a similar type. In some ways it is inferior to them, but in others it turns out to be of better quality. Much depends on the specific purposes for which such raw materials are selected, and what effect users expect from it.

Hemp and flax tow: description

Hemp tow is insulation made from hemp, an annual plant whose stem reaches 3 m. Two types of hemp are common in Russia - Central Russian and southern. Due to the high yield of hemp, materials made from its fibers are inexpensive. The southern variety is coarser because it contains a high amount of lignin.

The characteristics of flax tow are similar to hemp, but are more expensive. Linen material is used more often as the production of hemp fiber products is constantly declining.

Tow is in demand for filling crown joints both outside and inside a building, as well as for insulating window and door openings.

Sealing thread

If my memory serves me correctly, it appeared on the shelves in a plumbing store (at least in our village) 7-8 years ago, correct me in the comments if I’m wrong. It was Tangit Uni-Lock from Henkel. Everyone began to actively buy it, there was such a laudatory advertisement, everyone really liked it, but after a while people began to make repairs, change the plumbing, heating and other appliances.

We were faced with a very unpleasant problem, especially on large thread diameters; the connections were either very difficult to unscrew or simply impossible, we had to burn the thread with an acetylene torch! And all because the thread was almost not lubricated with anything, that is, the metal began to rust, since it absorbed moisture and, it seems to me, let oxygen through, because I can’t find any other explanation. The threads were just in terrible condition, I don't use it anymore. I agree that it is very convenient to pack and the connections are reliable and do not leak, although you also need to practice! I can recommend additionally lubricating it with sealant or plumbing paste.

Plumbing flax

This is my favorite sealing material, which I use all the time, and if everything is done correctly, the connections are reliable and very rarely leak! Some wind flax without using lubricants or sealant; this is a huge mistake, since this material absorbs moisture very well and allows oxygen to pass through, as a result of which it begins to rot and rot. This leads to leaks and corrosion of the metal; connections sealed in this way quickly become unusable, and just as in the example with the thread, difficulties arise when unpacking!

Therefore, always use flax using special lubricants or silicone sealant! Many people smear flax with paint the old-fashioned way, and when I come across such connections, I grab my head, because without an acetylene torch, it’s simply impossible to unpack them!

The most important advantage of this material is that connections sealed with flax are very easy to adjust, for example, you packed a faucet and it became uneven, you can always unscrew it half a turn and the connection will not leak! In my opinion, this is the best sealing material that I use most often and in 99% of cases there are no problems! Regarding compaction with flax, I will write an article and tell you everything in detail, since this is a separate topic for discussion! That's all, write comments, I hope the article was useful to you! Please like and subscribe to my channel!

Source