Rules for electrical installations on grounding

In industry, grounding has been used for a long time; in housing, it began to be used relatively recently. True, a lot has been written about grounding in the electrical installation rules (PUE). It clearly describes how the grounding loop should be carried out, what elements should be used in it, the parameters of the grounding loops and everything else. That is why this current leakage protection system must be treated with full responsibility, meaning installation, calculation and maintenance. So, grounding (the PUE is the basis) determines the safety of operation of electrical networks.

Grounding system terms

Before moving on to considering the rules for installing grounding, it is necessary to define the terms used by specialists when carrying out this type of work.

- Firstly, what is a grounding device? This is a structure consisting of a grounding conductor and grounding conductors.

- Secondly, what is a ground electrode? This is a metal conductor that is directly connected to the ground.

- Third, what are grounding conductors? This is a system of metal conductors that connect the ground electrode to electrical equipment.

Please note that grounding an electrical installation artificially is called intentional. There is such a thing as grounding device resistance

This is, in fact, the sum of the resistances of the grounding conductor and grounding conductors. If we talk about the resistance of the ground electrode itself, then this is the voltage relative to the ground to the current passing through the metal conductor.

Artificial and natural grounding electrodes

We have understood the terms, now we can consider which conductors can be used as a grounding conductor. From the title of the section it becomes clear that they can be either natural or artificial.

Natural ones include metal systems of underground pipelines (water supply, sewerage, wells) or metal structures of buildings and structures that go deep into the ground.

Attention! Pipelines laid underground can be used as natural grounding only if the pipe joints were connected by gas or electric welding. It is prohibited to use oil, gas and petrol pipelines for these purposes.

This is clearly stated in the PUE.

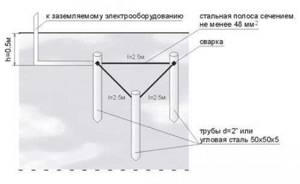

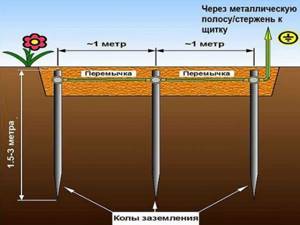

As for artificial grounding conductors, metal profiles are most often used for this, which are driven into the ground to a depth of 2.5 to 3 m. Most often, steel corners with a shelf width of 50 mm, fittings or pipes are used for these purposes. A prerequisite is to leave 10 cm of protruding profile above the ground surface. There should be either four or three grounding electrodes; they are installed either in a square or in a triangle. The protruding ends are tied with round reinforcement with a diameter of 10-16 mm or a steel strip 30 mm wide. All joints are made only by electric welding.

How to make 220 V grounding in a private house with your own hands

| Illustration | Action to be performed |

| Installing a ground loop for a private house with your own hands begins with a trench for the future loop. The optimal side length of a triangle is 3 m, but many do not pay attention to this. After the circuit is completely installed, it will be possible to add pins if the resistance does not suit us. | |

| We drill wells at the corners of the triangle, about half a meter deep. They won’t be deep, but they will help a little to drive the electrodes into the ground. |

| For wells, you can use a manual or gasoline hole drill. |

| In our case, a steel corner is used as a pin, which must first be sharpened. This is easy to do using a grinder with a metal cutting disc. |

| Now you need to lower the electrode into the well and drive into the ground what did not go in. |

| We only have 15÷20 cm left from the three-meter corner. We fill the well with alumina and we can proceed to installing the tires. |

| The tires are attached to the electrodes only by welding. Bolted connections are not suitable - they do not provide the required density. |

| Having finished welding the tires to the pins, we paint the connecting seams. The circuit itself cannot be painted, but the welding seams are susceptible to corrosion, which can render the entire grounding device unusable in a couple of years. |

| Next, the grounding bus going to the house is welded. The length is determined by the distance to the building plus the height of the foundation. |

| We fasten it to the foundation using simple dowel-nails with aluminum plugs. |

| Having drilled two holes in the upper part, tightly screw the bolts to which the grounding cable going into the house is fixed. |

| The last step is to paint the part of the tire that is above the ground. The bolts are also closed. Because they are stretched, there will be no need to twist them, and the paint will protect them from external weather conditions. The installation of the ground loop is completed. |

It becomes clear that it is possible, although not easy, to make a grounding loop for a private house with your own hands.

What is a natural grounding agent and how to use it

Let's look at how to make grounding at your dacha with your own hands without digging trenches and laying a circuit. To do this, you can use natural grounding conductors, which are pipes or metal structures located underground.

Diagram of a lightning rod in a private house

Very important! Fuel and lubricants pipelines and sewage systems cannot be used as a natural grounding system. Metal structures should not be painted or coated with anti-corrosion compounds.

Considering the grounding of a 380 V private house with your own hands, we note that there are no differences in the installation of circuits, as was already mentioned earlier.

Grounding of individual household appliances and equipment

It often happens that owners of private houses (especially country houses) do not see the point in installing full grounding. We cannot justify or condemn anyone, which means it is also worth considering this option. Let's figure out how to ground a water heater in a private house without installing the entire protection system.

Grounding sign GOST-21130

This is quite easy to do using a natural grounding electrode. From it you need to lay a cable directly to the device or to the outlet from which the device is powered. Often, a gas boiler in a private home is grounded in this way, but any other household appliance can be protected in this way.

There are “electricians” who, when asked how to ground an outlet in a private house, advise throwing a jumper from the neutral contact to the grounding one. It is clearly not worth listening to such advice - it is fraught with problems. We will definitely talk about such errors today. And now it’s worth taking a closer look at how to check a finished grounding loop to see if it meets the necessary requirements.

How to choose the right ground electrode?

Steel pipes, corners, and strips that are driven into the ground are chosen as an artificial grounding conductor. The requirements for the grounding conductor and circuit element are:

- carrying out special anti-corrosion treatment (copper plating or galvanizing);

- the presence of at least two contacts with individual parts of the boiler surface when using natural grounding.

Depending on the level of circuit resistance (optimally 30 Ohms for a voltage of 220/380 volts), circuit materials, tires, and the number of electrodes are selected. The circuit electrodes are made of pipes with a diameter of 2 inches or angle steel material with a cross-section of up to 50 square millimeters and a length of two meters. The tire is knocked out in the form of a steel or copper strip.

Grounding quality requirements

When installing grounding, it is necessary to pay attention to the type of material and cross-sectional area of the wires that connect the circuit to the zero phase of the electrical panel. When using copper wire, the recommended cross-section is more than 10, aluminum - at least 16, steel - more than 75 square millimeters

Steel pipes and angles (electrodes) are connected to the busbar using spot welding.

Ground loop resistance

The type of soil also matters. A circuit can be installed in silty soil if its resistance does not exceed 10 Ohms (with a standard voltage of 220 volts or a three-phase voltage of 380 volts). A ground loop can be installed in sandy soil with a resistance value of up to 50 ohms (for devices operating at 220 or 380 volts). If such requirements are met, there will be no claims from the gas service.

Correct choice of ground electrode

The easiest way to ground a gas boiler is to connect the ground terminal on the body of the heating system to a metal pipe leading into the ground, for example, to a water supply or sewerage system. As a result, if you open a hot water tap and touch the stream, you can get a noticeable electric shock. This method is not only ineffective, it is also unsafe for residents.

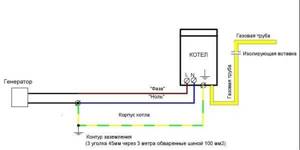

The worst option for "earth"

The second option, more common, involves connecting the grounding of a double-circuit gas boiler to a common “ground” in a private house. It turns out that all electrical appliances are located on one grounding bus, from a washing machine and electric kettle to a computer and TV. In this case, a strong surge in voltage only when the refrigerator or washing machine heater is turned on can easily damage the electronics of the gas boiler.

Therefore, the general requirements for grounding arrangement can be formulated in two points:

- The boiler body must be connected to a separate grounding loop, welded according to the rules of the Electrical Installation Code and installed in the ground in close proximity to the building;

- The resistance of the ground loop must comply with the standards and should not change or increase depending on weather conditions and seasons.

In addition, it is advisable to equip the circuit in a hidden version, so that it cannot be removed from the ground. Metal parts often become easy prey for scrap metal seekers, so for residents of apartments and country houses, the best option would be to equip a ground loop for a gas boiler somewhere in the basement with your own hands.

How to ground a gas unit?

How to properly ground a gas boiler? First, you should consider a number of important nuances:

- For a grounding metal structure installed in the ground, the following are suitable: angle, channel, profile pipe.

- The metal surface must be protected from corrosion: galvanizing, copper coating or anti-corrosion paste.

- The cross-sectional area of the wire connecting the zero phase of the shield to the ground loop for a gas boiler depends on the type of metal. For copper, 1 cm² is considered optimal, for steel – 7.5 cm², for aluminum – 16 cm².

- The grounding resistance for sandy soils should not be more than 50 Ohms, for alumina - up to 10 Ohms.

- The electrodes must be made of a material that matches the circuit resistance. The best option is two-inch pipes or corners with a length of 2 m and a cross-sectional area of 6 cm².

- The bus must be made only from steel or copper strip.

Compliance with the above conditions will relieve you of claims from inspection authorities.

Easy calculation of circuit parameters

The easiest way is to ground a gas boiler experimentally without using complex formulas and calculations. In this case, the work is performed according to the following algorithm:

- the basis is a contour of three rods 3 m long in the shape of an isosceles triangle;

- connect conductors;

- take an ohmmeter that measures resistance and measure the circuit readings - the optimal value is 4 ohms;

- if the result is significantly higher than optimal, then another element is added to the circuit and the resistance is measured again; continue to add until the value approaches the ideal or at least the maximum allowable of 10 ohms.

If desired, you can determine the number of electrodes using formulas that are available in specialized literature. But for optimal operation of the gas unit, the simplest calculation of parameters is sufficient.

Grounding installation

The installation of a system for grounding a gas boiler should be carried out no closer than 1 m and no further than 5 m from the house. This place cannot be further used for extensions, cultivation or other purposes. It is better to fence the area with a border and decorate it with a stone composition.

In the selected area, first draw a contour diagram. In most cases, it has the shape of an isosceles triangle, but if there is not enough free space, it can take the form of a square, line or polygon. The shape depends on the number of electrodes and the position of the house.

For installation you will need the following tools:

- welding machine;

- grinder for cutting and adjusting pipes;

- drill or hammer drill;

- shovel, sledgehammer or hole drill.

Now let’s take a step-by-step look at how to properly install and connect the circuit:

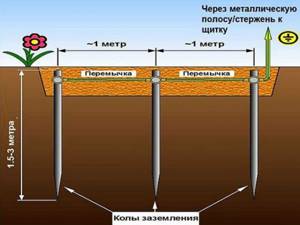

- Along the lines of the drawn layout, trenches are dug 35-40 cm wide and 50-70 cm deep. From the vertex of the triangle closest to the house, a trench is made to the foundation.

- Using a sledgehammer or a hole drill, electrodes are driven into the vertices of the triangle - metal rods from pipes and angles about 3 m long. They must be driven in so that they protrude 15-20 cm from the ground.

- Then the electrodes are connected to each other. To do this, steel strips with a cross section of 4.8-5 cm² are laid along the bottom of the trench. The structure is connected by spot welding.

- Now a metal strip is welded to the electrode closest to the house, which is led through a trench to the place where the grounding will enter the building itself. This strip should extend at least 50 cm from the ground.

- Next, they bring the system into the house: they make a hole in the wall with a hammer drill, insert a copper wire through it, which is fixed with one side to the terminal on the grounding bus, and the other to the metal plate on the base.

- Now the gas boiler is connected to the panel via a machine using a three-wire wire. It is also recommended to connect a voltage stabilizer.

Before burying the structure, you need to check the resistance of the current divergence along the circuit. If the result is less than the permissible value of 10 ohms, then you can bury it. If the resistance is greater than the control value, more electrodes should be added until the value reaches the norm.

Common reasons why a gas boiler makes noise

Everything about possible gas boiler malfunctions and how to eliminate them is here

There is another correct method for checking the resulting grounding for operability. To do this, you will need a 100 W bulb inserted into a socket with a carrier. One end of it is connected to the 220 V phase, and the other is connected to a metal strip on one side of the system. If the paw lights up as if it were plugged into a socket, then the grounding is working. If the light is dim or flashing, you should check the system joints. If the light does not light, you need to check the entire structure.

What can a contour be made from?

The grounding system can be natural or artificial. The first option includes structures made of metal or reinforced concrete that are in direct contact with the ground. This could be the foundation of a building, a pipeline or other underground utilities.

But for a gas boiler, natural grounding requires the presence of at least two contacts with individual parts of the housing, and sewerage, heating and gas pipes are excluded in this case. Therefore, during installation, an artificial system is often used, the organization of which we will consider.

What material to choose for grounding conductors

For artificial grounding, rods or pipes become conductor-electrodes, which are connected to each other by metal strips. They are installed vertically in the soil to ensure operation of the system even in winter, when the top layer of the earth freezes. An important condition is that metal elements should not be protected from corrosion by insulating material.

The service life of the ground loop largely depends on the presence of anti-corrosion protection on its electrodes - copper-plated and stainless steel elements will last the longest

You can also find ready-made kits for a grounding system on sale, which consist of steel rods (usually copper-plated) and special pointed tips for soil of varying densities.

The kit also includes an anti-corrosion agent for treating the system before installation and connecting elements - brass couplings, clamps. The main advantage of this solution is that the circuit can be assembled without welding and lengthy preparation.

Although regulatory services advocate for ready-made grounding kits, it is feasible to make the structure yourself - this will not be a violation, but will cost several times less

To assemble a system from scrap materials, you should consider several important nuances:

- Metal structures intended for installation in the ground can be made from a profile pipe, an I-beam, a channel, or an angle.

- The metal of the grounding conductor must be protected from destruction by galvanizing, copper plating or, as a last resort, anti-corrosion paste.

- The cross-sectional area of the wire connecting the zero phase of the shield to the ground loop depends on the type of metal from which it is made. For copper, the optimal value is 1 cm2, for steel - 7.5 cm2, and for aluminum - 16 cm2.

- The grounding resistance for sandy soil should not exceed 50 Ohms, for clay soil - a maximum of 10 Ohms.

- Electrode materials must also be selected taking into account the circuit resistance. The best option is two-inch pipes or corners with a length of 2 m and a cross-sectional area of 5 cm2.

- The grounding bus is made of copper or steel strip (aluminum is prohibited for this case).

Compliance with these requirements and correct installation of the circuit will help eliminate claims from gas service inspectors, regardless of whether you used a ready-made modular system or assembled it yourself.

Calculation of circuit parameters

The list of requirements for grounding arrangement contains several indicators, the algorithm for obtaining which may be incomprehensible to a beginner in the electrical business - for example, exactly how many electrodes are required for the correct operation of the system or how to measure the resistance of the circuit. Let's try to clarify the basic principles for determining these parameters.

You can find out the resistivity of the soil, grounding devices of any configuration, and even the presence of a connection between the electrodes using a special meter

Most often, grounding a gas boiler in a country private house is done experimentally. This practical method is suitable for those who are afraid of getting bogged down in complex theoretical calculations.

The algorithm for performing the work is as follows:

- Let's take as a basis a contour in the form of an isosceles triangle of three metal rods 3 meters long.

- We connect the conductors.

- We take an ohmmeter (a device for measuring resistance) and measure the indicators for the circuit. The ideal value is 4 ohms.

- If the result obtained significantly exceeds the optimal value, we add another element to the circuit and check the resistance again. We continue until we get the ideal value or at least the maximum permissible value for the boiler circuit of 10 ohms.

But you can determine the required number of electrodes using formulas, choosing the appropriate options for your case.

Using this formula, you can find out the resistance for one electrode if, in the area where the house is located, the soil is homogeneous and does not lie in layers

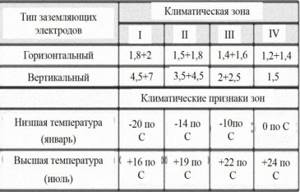

In the formula you need to substitute the average value of resistivity, depending on the type of soil in which the ground electrode will be located:

- wet sand – 500 Ohm*m;

- clayey gravel and sandy loam – 300 Ohm*m;

- clay-sand mixture – 150 Ohm*m;

- loam – 100 Ohm*m;

- semi-solid clay and chernozem – 60 Ohm*m;

- garden soil – 40 Ohm*m;

- plastic loam – 30 Ohm*m;

- peat – 25 Ohm*m;

- plastic clay and salt marsh – 20 Ohm*m.

Stone and rocky soil are least suitable for installing a ground loop. In this case, an artificial embankment will have to be erected.

For heterogeneous soil, it will be more difficult to calculate the resistance for one electrode, but this can also be done by substituting your data in the indicated formula

The value of the seasonal climatic coefficient of soil resistance depends on the area where your home is located. They are conventionally divided into 4 groups.

Correction for climatic features is especially important for areas with cold winters, since in frozen soil the efficiency of grounding is significantly reduced

There are also more complex algorithms for accurately determining the parameters of the electrodes and even special programs for their calculations. But for the gas boiler to operate correctly, it will be enough to follow the general recommendations for arranging a standard grounding loop.

Why is grounding necessary?

Static charges are formed on the metal surfaces of the boiler, which form an electric field. Without grounding, it affects the electronic component of the gas boiler (board) and the electronic regulation and control system may fail.

The second reason why it is necessary to ground a gas boiler is the opportunity for the home owner or his family members to feel for themselves what static voltage is. A very unpleasant, and sometimes painful, sensation. To avoid such misunderstandings (electric shock), steps should be taken to ground gas heating equipment.

And finally, without proper grounding, the boiler may explode, since the electrostatic field can cause a fire in gas-fired equipment, which will cause an explosion. As you can see, without grounding carried out in accordance with current standards and technical conditions, the gas boiler will not last long.

Boiler grounding methods

Grounding systems are divided into natural and artificial. Natural grounding electrodes are metal or reinforced concrete structures that have contact with the ground. Artificial grounding conductors are steel pipes or angle steel. The task of installing a grounding system is greatly simplified if there is a main ground bus (GShZ) near the house. But most individual private houses and cottages do not have such a bus. Therefore, it is necessary to carry out a set of actions for the safe operation of gas heating equipment.

Why is grounding done?

When heating equipment is operating, static voltage is always generated. It does not matter what type of boiler is used and what degree of automation it has. Based on this, we will highlight two main reasons for the need to ground in a private house or apartment:

- If you have a boiler with a built-in electronic microprocessor, even minor fluctuations in the power supply can cause a breakdown. Static voltage can also lead to damage. If the boiler is not grounded, its service life is reduced. And replacing the automation board costs about 50% of the cost of the boiler itself.

- Without grounding there is a real danger of explosion. Voltage gradually accumulates, becoming one of the most common causes of fire in gas equipment. With proper grounding, the operation of the unit becomes safer and prevents the formation of a spark that could lead to an explosion.

How to check grounding on a gas boiler

The quality of grounding for a wall-mounted boiler in a private house must be checked by the relevant authorities. Gas service employees draw up a report and put the kit into operation. In another case, in accordance with the PUE standards, the electrical laboratory is required to carry out the inspection. Representatives of this organization take readings from the panel and measure the resistance of the structure using a sensor. In case of compliance with the rules of electrical installations, a permit for the use of a ground loop is drawn up. If the sensor indicators do not reach the specified measurements, then the kit for a private house is subject to further refinement.

Types of gas heating boilers

According to the installation method, modern gas-powered boilers are divided into wall-mounted and floor-mounted. The wall-mounted version is used to heat small rooms. Wall-mounted heating devices are compact and are made either with a combustion chamber or with a flow-type heating system. Floor-mounted gas heating units are installed in specially equipped rooms with an area of about 9 square meters. The boiler is mounted at a distance of half a meter from the wall. The pictures show options for floor and wall mounted boilers.

FloorWall

For the manufacture of heat exchangers for gas-powered boilers, steel, stainless steel or cast iron are used. Structurally, boilers are made with a closed firebox or an open combustion chamber. Products differ in the number of contours. Single- and double-circuit boiler systems have their advantages. But gas boilers of any model and modification are subject to one indispensable requirement - they must be grounded.

Types of boilers

In homes that do not have access to a centralized heating system, it is necessary to use alternative heating options. Due to their technical and operational characteristics, boilers are one of the most popular heat generators. These heating devices are usually classified according to several criteria.

There are floor and wall mounted ones. The former are characterized by high power and are suitable for heating rooms whose area reaches 200 m². Can function in conjunction with water boilers. The latter are compact in size and equipped with various devices that ensure safe operation (locking thermostat, draft and flame sensors, auto-shut-off mechanism, and so on).

In this video we will look at a gas boiler for heating a private house:

Read more: which water heater is better to choose - instantaneous or storage.

There are electronic and manual ignition methods. The first allows the boiler to turn on and off automatically in accordance with the set program. Due to the absence of an igniter with a constantly burning flame, gas is consumed more economically. The manual mechanism operates by pressing a button on the body.

Smoke and soot are removed from the equipment due to natural and forced draft. Natural draft requires constant circulation of air flows and can only be used in small rooms. The forced exhaust method implies the presence of a closed combustion chamber and a special type of chimney.

This is interesting: a chimney with a pipe with your own hands.

Another important aspect is the energy efficiency of gas equipment. It depends on what calorific value is used during operation. Traditional boiler models use the lowest rate, so when installing them it is necessary to prevent the deposition of water vapor on the walls of the firebox, chimney and heat exchanger. Convection devices use the highest calorific value of gas and heat the air due to water vapor generated as a result of fuel combustion.

Grounding installation

To install the system in a private home, you need to carry out a number of works. You need to find a place no further than 5 meters from the house, where no other work, planting, or construction will be carried out. You cannot enter the site when it is ready; it is better to securely fence it off with a stone, fence, or curb.

Preparation and drafting of the project

As with the installation of a lightning rod, for a gas boiler a circuit with a grounding electrode must first be designed. The layout should be drawn on paper: usually the diagram is an equilateral triangle with sides up to 2.5 meters long, less often - a square, pentagon, or line. The last option is done to save space near a private house.

Preparation includes collecting the necessary equipment and checking its serviceability:

- welding machine;

- drill, hammer drill;

- Bulgarian;

- shovel, sledgehammer;

- motor drill for hard soil.

After this, you can go directly to work.

Loop connection

The first stage of installing a lightning rod for a gas boiler is digging a trench up to forty centimeters wide and up to seventy centimeters deep. The near corner of the triangle (or other selected element) is directed towards the house, and a straight groove is dug from it towards the base. Then slightly pointed steel conductors are taken along the vertices of the triangle (their ends are sharpened with a grinder). The upper edge of the electrodes should protrude 20 cm from the ground; at the end of the work they are covered with earth.

Next, a metal strip is spot welded to the contour and taken to a private house at the site of the intended entrance. You need to raise the strip by fifty centimeters using a steel pin, weld an M8 iron bolt, attach a copper cable, and lead it home. The boiler itself is connected to the panel via an RCD with a three-wire wire.

Checking work

Testing the device involves assessing the current loop resistance. The indicator should not exceed 10 Ohms; if the result is successful, you need to dig a trench. If there are problems, add electrodes and measure the resistance again. For digging, use high-quality soil without stones. The entry point of the home wire is covered with a visor that protects from water.

When ready, you can call specialists to draw up a grounding report. When checking, the technicians will compare the indicators with the resistance standards and evaluate the correctness of the wire connection to the panel. The completed report should be kept at home in case of an inspection.

Lightning rods and grounding conductors for gas boilers are an integral part of heating; they must be planned without fail. This will protect people from accidents and protect equipment from damage.

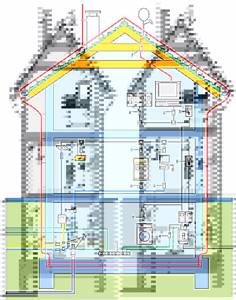

Grounding device for a private house

Some older power lines have no protective ground at all. They all must change, but when this will happen is an open question. If this is your case, you need to make a separate circuit. There are two options - do the grounding in a private house or country house yourself, with your own hands, or entrust the implementation to a campaign. The company's services are expensive, but there is an important advantage: if problems arise during operation due to improper functioning of the grounding system, the company that carried out the installation will compensate for the damage (must be specified in the contract, read carefully). If you do it yourself, everything is on you.

Grounding device in a private house

The grounding system of a private house consists of:

- grounding pins,

- metal strips combining them into one system;

- lines from the ground loop to the electrical panel.

What to make grounding conductors from

A metal rod with a diameter of 16 mm or more can be used as pins. Moreover, you cannot take the reinforcement: its surface is hardened, which changes the distribution of current. Also, the hardened layer in the ground breaks down faster. The second option is a metal corner with 50 mm shelves. These materials are good because they can be driven into soft soil with a sledgehammer. To make it easier to do this, one end is sharpened, and a platform is welded to the other, which is easier to hit.

You can use pipes, a corner, a metal rod as rods

Sometimes metal pipes are used, one edge of which is flattened (welded) into a cone. Holes are drilled in their lower part (about half a meter from the edge). When the soil dries out, the distribution of the leakage current deteriorates significantly, and a saline solution can be poured into such rods, restoring the functioning of the grounding. The disadvantage of this method is that you have to dig/drill holes under each rod—it won’t be possible to hammer them in with a sledgehammer to the required depth.

Pin driving depth

The grounding pins should go into the ground below the freezing depth by at least 60-100 cm. In regions with dry summers, it is desirable that the pins be at least partially in moist soil. Therefore, corners or a rod 2-3 m long are mainly used. Such dimensions provide a sufficient area of contact with the ground, creating normal conditions for the dissipation of leakage currents.

What not to do

The job of protective grounding is to dissipate leakage currents over a large area. This happens due to the close contact of metal grounding conductors - pins and strips - with the ground. Therefore, grounding elements are never painted. This greatly reduces the current conductivity between the metal and the ground, making the protection ineffective. Corrosion in welding areas can be prevented with anti-corrosion compounds, but not with paint.

The second important point: grounding must have low resistance, and for this good contact is very important. It is provided by welding. All joints are welded, and the quality of the seam must be high, without cracks, cavities and other defects

Please note once again: grounding in a private house cannot be done using threaded connections. Over time, the metal oxidizes, breaks down, the resistance increases many times, the protection deteriorates or does not work at all.

Use only welded connections

It is very unwise to use pipelines or other metal structures located in the ground as a grounding conductor. For some time, such grounding works in a private house. But over time, the pipe joints become oxidized and destroyed due to electrochemical corrosion, activated by leakage currents, and the grounding becomes inoperative, as does the pipeline. Therefore, it is better not to use these types of grounding conductors.

How to ground a gas boiler in a private house

Grounding diagram in a private house

1 m is retreated from the outer wall of the heating unit installation and markings are made on the ground in the form of an equilateral triangle. The length of the rib should be 2 m. A trench is dug along this marking. Its depth depends on the level of soil freezing, but must be at least 50 cm. Holes are drilled at the vertices of the triangle to install ground electrodes.

As a ground electrode installed in pits, you can use a steel corner or copper-coated plates, which are immersed in the ground to a depth of 4.5 m.

Immersion of grounding conductors occurs in stages. They are successively deepened into the ground in sections that are connected to each other as they are immersed using special couplings or welding. After installation, the ground electrodes are connected to a pin fixed to the foundation of the building. This is done using copper wire, which is secured with bolts.

Next, it is important to correctly connect the pin to the communication unit of the gas equipment. The connection can be made using steel, copper or aluminum wire. Gas equipment has a three-pin power socket or control panel with zero phase current. The wire stretched from the pin is connected to it.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

There is another way to ground a gas boiler. An alternative option is to connect two ground electrodes immersed in the ground with a straight metal strip. Such a grounding arrangement is not prohibited by the control unit.

Three types of pins can be used in such grounding loops:

- copper-plated;

- galvanized;

- steel.

Advantages of a modular-pin grounding system

The main advantage of installing such a grounding loop is the ease of assembly and the ability to independently manufacture structural elements. Installation of the module requires a minimum of preparatory work. Ease of transportation and storage of industrial grounding kits. The circuits have a long service life and a high degree of safety.

How to properly ground a gas boiler

The PUE stipulates the need for grounding, but does not stipulate that it is necessary to purchase a ready-made grounding kit (although this is recommended by representatives of the gas service). The outline can be made with your own hands.

In order to do the work yourself and correctly, take into account the following nuances:

- Possible type of grounding system.

- Resistance parameters.

- Recommended materials for making a grounding loop.

- Cost of work.

The grounding loop for connecting a gas boiler must strictly comply with the standards and parameters specified in the PUE. If the inspection shows a deviation from the standards specified in the documentation, the representative of the Gas Service has the right to refuse to put the equipment into operation.

Preparation and drafting of the project

As with the installation of a lightning rod, for a gas boiler a circuit with a grounding electrode must first be designed. The layout should be drawn on paper: usually the diagram is an equilateral triangle with sides up to 2.5 meters long, less often - a square, pentagon, or line. The last option is done to save space near a private house.

Preparation includes collecting the necessary equipment and checking its serviceability:

- welding machine;

- drill, hammer drill;

- Bulgarian;

- shovel, sledgehammer;

- motor drill for hard soil.

After this, you can go directly to work.

What materials are needed for grounding

Grounding requirements when connecting a gas boiler also affect the types of materials used during installation work. The following recommendations exist:

- The grounding wire from the shield to the circuit laid in the ground must be of the following cross-section: copper - at least 10 mm², aluminum - 16 mm², steel - 75 mm².

- As vertical pins driven into the ground, steel pipes or angles are used, connected by a tire to each other using spot welding. Ready-made kits include galvanized or copper-plated electrodes.

- Automation and RCD - the boiler is connected to a panel with installed electrical fittings. The PUE prohibits the installation of an RCD with a gas boiler without grounding. But duplication of the safety system is allowed when the grounding loop is simultaneously installed together with the residual current device.

Loop connection

The first stage of installing a lightning rod for a gas boiler is digging a trench up to forty centimeters wide and up to seventy centimeters deep. The near corner of the triangle (or other selected element) is directed towards the house, and a straight groove is dug from it towards the base. Then slightly pointed steel conductors are taken along the vertices of the triangle (their ends are sharpened with a grinder). The upper edge of the electrodes should protrude 20 cm from the ground; at the end of the work they are covered with earth.

Next, a metal strip is spot welded to the contour and taken to a private house at the site of the intended entrance. You need to raise the strip by fifty centimeters using a steel pin, weld an M8 iron bolt, attach a copper cable, and lead it home. The boiler itself is connected to the panel via an RCD with a three-wire wire.

Who and how checks the boiler grounding

Quite often, you can find conflicting information on the issue of who issues the grounding certificate. The fact is that a representative of the Gas Industry must check the correct connection and operation of the boiler.

On the other hand, the measurement of grounding resistance for commissioning a gas boiler (as electrical equipment), according to the rules of the Electrical Installation Code, is carried out by an electrical laboratory. She must also check the resistance indicators of the general lightning protection system.

The following documents regulate the standards and frequency of testing:

- The frequency of inspection is PTEEP, paragraphs 2.7.8 to 2.7.15.

- Preparation and commissioning - PUE, paragraphs 1.7.100 to 1.7.103.

The frequency of measuring current flow resistance is set depending on the technical characteristics of the heating equipment, but is done at least once a year. The maximum value of the grounding device is calculated depending on the type of soil, the presence of groundwater and other factors. If it is determined that the resistance indicators comply with the requirements specified in the PUE, a grounding certificate or protocol is issued.

Do I need to ground a gas boiler?

The position of the service and gas service workers, on the one hand, is understandable; this is what the instructions require, but on the other hand, it causes bewilderment. Why do you need to ground a gas boiler in an apartment or in a modern house, in which the wiring is in perfect order, there are circuit breakers and even an RCD.

After all, grounding is primarily required to protect against electric shock. The power of electrical equipment in a gas boiler is a maximum of 150 W less than that of a meat grinder or mixer. They do not require independent grounding.

To understand the reasons why grounding is needed for a gas boiler, just read the documentation for the heating equipment. As a result we get the following:

- The use of plastic parts of air ducts and fan pressurization of the boiler combustion chamber leads to the appearance of a large amount of static electricity. Therefore, grounding for a gas boiler is necessary in order to avoid a flash in the event of a domestic gas leak. As long as the heating system runs on methane, there is no particular danger, but if you suddenly need to use propane butane, which today is the main fuel for country houses and cottages, then the risk of fire increases hundreds of times;

- The second reason is the most obvious. Grounding a wall-hung gas boiler helps avoid damage to electronics and control boards.

For your information! The cheapest wall-mounted dual-circuit heating systems can cost hundreds of dollars in electronic components.

A power surge from a switched-on refrigerator can burn out the ignition board.

If the most modern and efficient condensate models are used to heat a house or apartment, in which an almost full-fledged computer is installed, then in the absence of grounding we are talking about costs of a much higher order. Not to mention the fact that it is necessary to ground a gas wall-mounted boiler so that the emerging static potential does not periodically knock down and affect the fine tuning of the boiler sensors.

What is it for?

Regardless of the operating principle of a gas boiler, surface stress forms on the body during operation. Grounding will help avoid the following problems when coming into contact with such equipment:

- Wear of electronics - boilers installed in a private house or apartment, as well as those equipped with computer controls, may fail under the influence of harmful surface currents. The same thing can happen from static electricity. In this regard, you should not expect long-term uninterrupted operation from gas equipment that is not equipped with a grounding loop, and correcting the situation by replacing the processor will be extremely expensive.

- Explosion hazard - electricity of a static nature very often causes a subsequent explosion of devices operating on gas under pressure. If you make grounding, the possibility of an arc will be eliminated.

How to make grounding for a gas boiler All about electricity

You are here: In order to put a gas boiler into working condition and safely use it in an apartment or in a private house, it must be grounded, guided by certain papers that specify the rules and regulations.

As soon as the grounding is completed, acceptance documents need to be drawn up. They contain information about the various indicators that the grounding circuit has.

In this article we will tell readers of the Sam Electric website how to ground a gas boiler in a private house with your own hands.

What is it for?

Regardless of the operating principle of a gas boiler, surface stress forms on the body during operation. Grounding will help avoid the following problems when coming into contact with such equipment:

- Wear of electronics - boilers installed in a private house or apartment, as well as those equipped with computer controls, may fail under the influence of harmful surface currents. The same thing can happen from static electricity. In this regard, you should not expect long-term uninterrupted operation from gas equipment that is not equipped with a grounding loop, and correcting the situation by replacing the processor will be extremely expensive.

- Explosion hazard - electricity of a static nature very often causes a subsequent explosion of devices operating on gas under pressure. If you make grounding, the possibility of an arc will be eliminated.

Heating diagram for a private house with a gas boiler: diagram for installing and piping a gas boiler

A comfortable private home should have comfortable heating. Even during the design process, it is necessary to lay out and think through the layout of the heating systems. Gas heating is often chosen as heating. Since this heating system reliably and efficiently heats the entire room.

Which heating scheme with a gas boiler is best suited for a cottage or private house?

When you plan to arrange the entire system without the help of professionals, you need to calculate the heating circuit.

There are two types of gas heating circulation:

- forced circulation is produced thanks to pumps;

- natural produces movement due to the difference in the densities of hot and cold water.

IMPORTANT. Natural works better when installing equipment at a lower level relative to radiators. For stable movement of the coolant, you need to make a natural slope of the pipelines

For stable movement of the coolant, it is necessary to make a natural slope of the pipelines.

With an artificial one, it is possible to install a pump. Installation is simple, but the pump with artificial circulation has disadvantages: uneven heating, dependence on electricity and the possible appearance of air locks.

Heating distribution is:

- Single-pipe. Suitable for a not too large area with a small number of rooms; when using this wiring, the temperature in the pipes varies.

- Two-pipe. Difficult to implement, suitable for adjusting the temperature in different rooms.

ATTENTION. When using single-pipe wiring, a big disadvantage is revealed: the lower part of the radiator does not heat up well. Radiators will warm up differently on different floors of the house

This problem can be solved by installing jumpers to the batteries and increasing the capacity of the batteries. It is also recommended to install pumps for sufficient coolant movement

Radiators will warm up differently on different floors of the house. This problem can be solved by installing jumpers to the batteries and increasing the capacity of the batteries. It is also recommended to install pumps to ensure sufficient coolant movement.

The advantage is the easy installation of wiring, which you can do yourself. During installation, a small amount of materials is consumed, which is also a plus.

Two-pipe distribution heats the pipes evenly. However, it requires a large amount of material for installation and pipe laying. The advantage of two-pipe wiring is the ability to regulate the pipes using shut-off valves.

REFERENCE. There is also a Leningrad wiring. A pipe is connected to it, which circulates liquid in parallel. This system is suitable for furnishing a cottage or private home.

Grounding check

According to current regulatory state documents, the inspection must be carried out by the gas service represented by its representative. However, an objective conclusion requires an assessment from an electrical laboratory that measures the total resistance of the ground loop. It all depends on the location of the private house and its proximity to administrative centers. In some areas, gas service representatives themselves check all the characteristics of the ground loop. After the measurements are taken and if they comply with the standard, a “Protocol for checking the condition of grounding conductors and grounding devices” is drawn up. In addition, an employee of an electrical engineering laboratory is required to submit a document confirming the registration of the laboratory. Only in this case the conclusion has actual legal force.

The boiler grounding certificate is issued by the regional gas service department. It consists of several documents:

- technical report on the tests performed;

- list of technical documentation;

- Certificate of registration of the electrical laboratory:

- protocol for checking the presence of a circuit between the boiler and the circuit;

- ground loop inspection protocol;

- list of measuring instruments used;

- defective statement.

Operation of a gas boiler is possible only after receiving the certificate, since without it, even connecting the house to the main gas pipeline may be refused.

Certificate for grounding a gas boiler: what is it and how to get it

When gas service workers come to check the correct installation of a gas boiler and connect it to the gas main, they need to make sure that the operation of the boiler unit is safe. To do this, they may require a certificate for grounding the gas boiler, which is also a protocol for checking the resistance of grounding conductors and grounding devices.

Sample document.

It is issued by companies registered with Rostechnadzor as electrical laboratories, for example, in Moscow and Moscow Region this is the fire service “Kit”, LLC “KEP” or Enerdgy-systems. Gas service workers, as a rule, do not understand grounding structures, and they should not. The cost of visiting a specialist and issuing a conclusion is 1,300-4,500 thousand rubles.

According to the official procedure, 2 copies of the conclusion are required, one remains with the owner, the second is provided to the gas service to confirm the safety of the work being carried out.

Installation work

The implementation of procedures for arranging grounding begins with preparing the territory. She suggests selecting an area free from outbuildings, and then building a model of a triangular, square or polygonal shape. Digging a trench is carried out according to a previously drawn up project. Rods are hammered into the corners of the recess. The distance from its bottom to the upper section of the electrodes should be in the range from 150 to 200 mm. From the corner closest to the building, a small ditch is created, which necessarily reaches the foundation.

A steel wire with a cross-sectional area of 48 square millimeters is laid along the bottom of the formed channel, with which the conductors are connected to each other. The master is also allowed to install a strip with a width of 40 mm and a thickness of 4 mm. The joints are connected using a welding machine or bolts. When introducing grounding into a home, a metal strip is welded to the cable. It is located on the site so as to rise above the blind area by 500 mm. A hole for the copper wire is drilled in the wall of the room where there is a gas boiler.

Its first end is fixed to the terminal of the grounding bus, and the second - to the metal base plate. The heating unit is then connected to the panel using automated protective devices and a voltage stabilizer. Before starting to dig a hole, the technician is advised to check the resistance to current propagation through the structure of the circuit. A similar operation is carried out using a light bulb with a carrier, which should be connected to the phase and circuit.

If the resistance values are reduced, you will have to install additional electrodes. The accuracy of installation work and the level of safety of self-made grounding of a gas boiler are checked by specialists. If the check for compliance with operating standards for electrical installations yields a positive result, the owner receives a certificate authorizing the use of the boiler.

Standards and requirements for grounding a gas boiler

The main characteristics and design features of the safe grounding circuit are written in the operating rules for power installations PUE 1.7.59 and 1.7.103. In order not to go too deep into the study of regulatory documents, it is necessary to note the two most important requirements. Firstly, the soil resistance should be no more than 10 ohms for clay and 50 ohms for sand. In practice, a contour is made to the depth of soil freezing, regardless of its composition. Moreover, it is quite difficult to find sand and clay in their pure form, so you have to take precautions in case of a dry summer.

The metal of the tire and contour is not painted or treated with anticorrosive

Secondly, the cross-section of the bus laid from the body of the gas boiler to the circuit in the ground must be at least 75 mm2 for steel and 16 mm2 for aluminum. If suddenly someone decides to lay a copper busbar, then its cross-section can be reduced to 10 mm2.

Grounding standards and rules

Regulatory requirements and rules describing the geyser grounding scheme are presented in the official document PUE .

According to the established standards for grounding a domestic gas boiler in a house, the equipment must be supplemented with an earth circuit, but it does not specifically indicate which circuit should be used - an industrial design or a home-made one.

A simple design of a contour line suitable for protecting gas equipment, in particular a household water heater (boiler). Uses a metal strip and one passive electrode

Meanwhile, regardless of the method of manufacturing the loop grounding system, the document PEU clause 1.7.103 stipulates the resistance parameters of the loop loop.

For a system built at home or using a team of specialists, the following requirements are relevant: “The total resistance to spreading of grounding conductors... of all repeated groundings... at any time of the year should be no more than 5, 10 and 20 Ohms, respectively, at line voltages of 660, 380 and 220 V three-phase current source (380, 220 and 127 V for single-phase current source). In this case, the spreading resistance of the grounding conductor of each of the repeated groundings should be no more than 15, 30 and 60 Ohms, respectively, at the same voltages.”

In practice, gas service representatives require that the resistance not exceed 10 ohms.

According to the standards of the PEU document, it is categorically unacceptable to use the following elements for grounding for a domestic gas boiler:

- ground lines of fixed household sockets;

- surfaces of heating pipelines;

- surfaces of sewer pipes;

- pipes of stationary gas lines and other pipelines of flammable or explosive liquids, gases, mixtures.

It is allowed to use metal water pipes laid in the ground, reinforced concrete foundation structures that have reliable waterproofing, metal structures of structures located in the ground, etc. as a natural ground electrode ( clause 1.7.109 of the PUE ).

If there is nothing nearby suitable for the role of a grounding conductor, it is imperative to arrange an individual grounding circuit.