For a heating system to be reliable and energy efficient, it is not enough to perform high-quality design and installation. It is important to carry out commissioning work promptly and correctly, which includes pressure testing the heating system and flushing it. The mandatory technical control procedure is carried out upon completion of the installation of a new heating system, at the beginning of the heating season and after repair work. In apartment buildings, such work is carried out by competent organizations. In a private house, you can check the performance of the heating system yourself. This will require special equipment and knowledge of the requirements of regulations regulating the maximum pressure for the system and the time interval for checking different heating networks.

No circulation, heating failure - why

Failure in the heating system, deficiencies, imperfections, all lead to cold radiators.

If there is no coolant circulation, then the reason needs to be determined. Most often, the answer to why the heating does not work is on the surface, obvious. Let's look in order at the main causes of heating malfunctions, why water does not circulate through the pipes, and what needs to be done first.

Let's start with the simplest and most obvious reasons.

It's clogged and clogged.

Every heating system must have a coarse filter. A very small device with a fine mesh and a sump (installed downwards! or at least to the side) saves equipment, pumps, and the boiler from coolant contamination that will be present in any system. Wood shavings, broken threads, rust, water sediment…. everything is retained by the mesh in the filter.

The sedimentation tank must be periodically untwisted and the mesh cleaned.

If the circulation in the heating system of a private house is disrupted, then the first thing you need to do is check the filter, which should be installed on the return line in front of the boiler.

Air in the system, airing

Airing can occur in any closed piping system where air removal measures have not been taken. Air is always present in the coolant, including in a dissolved state, is released during pressure changes, and accumulates at the highest points. Including in the boiler.

Automatic air vents are installed at characteristic, highest points of the system, as well as on collectors and special separators - the normal circuit is equipped with a special air catching device in which air bubbles are released from the coolant.

In addition, Mayevsky valves (manual air vents) should be on each radiator, and also possibly in other elevated places.

Checking the air supply, bleeding the air, installing air vents are common actions if circulation stops and the batteries are cold.

The circulation pump does not work

In private homes, the reason why the heating system stops working is a breakdown of the electrical equipment that controlled the movement of the coolant through the pipes.

If the heating suddenly stops working, then you need to check the functionality of the circulation pump near the solid fuel boiler or the pump in the automated boiler. In addition, the same unit can be installed in each circuit, which must work properly.

Bad polypropylene pipes

Often the consumer (customer) believes that polypropylene pipes are absolutely reliable and cannot cause heating problems or cold radiators.

But polypropylene is much more insidious than old steel or metal-plastic pipelines. Each place of soldering (welding) is a potential increased resistance in the system or a cause of cessation of circulation (weakened movement of water through the batteries), due to deposits of material inside.

It is impossible to control the quality of connections from the outside; all that remains is to cut out pieces, resolder, and remake polypropylene pipes.

Poor performance of a polypropylene system is a real problem for the home installer. Good professionals don’t take on this material at all.

Bad project

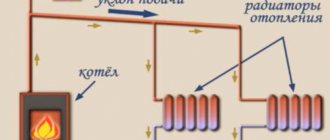

It is not uncommon for poor circulation to occur where there is poor design. Typically, the batteries are not connected correctly, according to some sequential circuit, where the last battery in the circuit receives much less coolant.

Another bad design is single-pipe circuits, where it is also difficult to establish the necessary coolant circulation through each battery.

If the radiators do not heat up evenly, or there is poor coolant circulation on individual heating devices, first of all you need to consider how the connection corresponds to the classic circuits - shoulder, associated, radial. It is necessary to bring home heating to normal design standards, and then expect good circulation and uniform heating of the radiators.

Small diameter, overgrown pipes

Old steel pipes become overgrown with rust and deposits from the inside, their throughput capacity decreases significantly over time, and there is only one solution - they need to be replaced with modern ones.

But even during installation, for the sake of economy, mistakes can be made with the choice of pipeline diameter - on mains, on groups of heating devices, diameters of 16 or 20 mm can be installed. The result is noise in the pipes, excessive consumption of electricity, and insufficient coolant flow. What pipe diameters should you choose?

A complex system

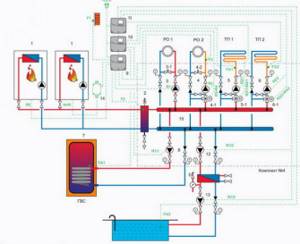

A type of bad design is an incorrectly designed complex heating system consisting of many heating circuits and several boilers. Here entire circuits will not work correctly if the work of one affects the neighboring one.

As a rule, one boiler (the backup one does not count) and three circuits - boiler, radiators, heated floors with their pumps are coordinated normally, and no questions arise. But if you connect another working boiler plus a circuit (for example, heating a garage and greenhouse), then the system will become complex. It is difficult to say how the coolant will circulate in it without equalizing the pressures at the connection points.

In complex systems, a competent design is important, installing a hydraulic arrow or an equal pressure ring; more information about the hydraulic separator can be found here

No balancing

Many home heating schemes involve balancing; balancing and control valves are installed in them. For example, between floors, between shoulders, and for each radiator. The taps cover the direction with less hydraulic resistance; accordingly, more coolant will flow to other points.

Children can play with the taps. Or the system is initially unbalanced. Setting up, as a rule, is no problem, you just need to find this tap... How to set up home heating

Neighbors don't provide heat

But complex heating project schemes are of little concern to residents of high-rise buildings, who have a separate riser for each radiator in the apartment. And if any radiator stops heating up normally, it means there is no circulation through the riser, therefore...

You need to contact the heating network, housing office (service organization) to adjust the power in the risers, and if this does not help, then with the requirement to check the neighbors.

Often, unauthorized connection or replacement of radiators and pipes in central heating systems leads to a redistribution of pressure, circulation through individual batteries decreases and disappears.

No circulation in gravity system

In gravity systems, the pressure difference is low; they are especially sensitive to air pockets, pipe diameters, and gaps in radiators.

In old circuits, gradual deposits occur in radiators and pipes; circulation may decrease over time, and the only cure for this is replacing everything with a more modern one.

You also need to pay attention to the correctness of the circuit itself - the middle heating line is below the cooling line (the boiler heat exchanger is below the radiators), and also - the hot feed rises up to the highest point, and from there it drops to the radiators... Read more about gravity flow circuits below

Various breakdowns in heating systems

- The taps and valves are closed - check that everything is open to ensure circulation.

- There is a leak in the system - there is not enough coolant, check the pressure, eliminate the leak.

- Installation with flexible pipes - the pipe is pinched.

- Failure of automatic equipment - thermal heads on mixing units, radiators, the mixing units themselves - silting, failure, it is necessary to check the correct operation. Also – electronic failure.

- Incorrect balancing on the distribution collector - in beam circuits, complex systems, collectors with balancing and tuning equipment can cause a lack of circulation anywhere due to breakdowns and incorrect settings.

- Low pressure, no air in the expansion tank - check the pressure in the pipes and the pumping of the tank; automated units will not work at all without the required pressure.

- Violation of the circuit, excess bypass - check that the installation complies with the design, the logic of the circuit, whether there are any short circuits in the jet, parallel branches to radiators and circuits.

Preparatory stage

As a rule, in warm weather the heat supply structure is not used. Therefore, before starting heating in a private house, it is necessary to ensure the integrity and reliability of its elements and carry out a number of preparatory work. Before using a closed heating system, you need to determine the amount of deviation of its actual indicators from the calculated parameters.

According to the rules, preparation for the heating season is carried out in a certain sequence. First of all, a visual inspection of communications and heating equipment is carried out. For the property owner, the first question should not be how to put the radiator into operation. First of all, he needs to make sure that there is no mechanical damage to the device body and check the reliability of its connection to the pipeline.

Also, before starting the heating system, a number of preventive measures are carried out:

- Checking the condition of the smoke exhaust system. To start a boiler, there must be sufficient draft force in the chimney to maintain combustion. For this reason, the internal cavities are cleaned of soot and the integrity of the pipe is inspected. In a brick structure, if necessary, replace damaged elements. Rust, if any, is removed from galvanized pipes.

- Visual inspection of pipes. Without this, running the heating system is dangerous. You need to find out how tight the pipes are and whether there are any cracks or noticeable defects.

- Battery condition monitoring. Before starting heating in an apartment building, the management company must warn residents about this, and they must check the integrity of the radiators. You cannot disconnect individual devices from the heating network. When filling the pipelines, make sure there are no coolant leaks.

This is a list of rules without which the first start-up of the system should not be done. In order for the heating season to start correctly, a number of measures must be taken. A test run of the heating system in an apartment building is carried out 1–2 months before heating starts. It is best for property owners to stay home during this time to ensure there are no leaks.

Causes of poor circulation

The circulation of water in the system is disrupted due to complete or partial blockage in the riser or in the supply to the heating device, airing of the main line, freezing of the network, or errors in pipe laying. This also leads to deregulation of the central heating system and the appearance of coolant leaks.

Poor pump performance

The purpose of the pump is to maintain the required water pressure in the heating circuit. A well-functioning pump must meet the following requirements:

- A necessary indicator of work productivity;

- Pressure;

- Device pressure;

- Compliance with the type of liquid;

- Matching pipe diameter;

- Dimensions of the device in accordance with the length of the line.

What to consider when choosing a pump

But you definitely need to consider whether it will work constantly or will only turn on to replenish the heating system and adjust the pressure. This should be taken into account when choosing pump power. For a pump that operates in constant mode, it is important to take into account the energy consumption indicator. If you choose the wrong pump, it will not “push” the coolant well, and as a result, the battery will heat up unevenly, and the pump itself may burn out from overheating. Poor water circulation will also be noted if the diameter of the components for connection to the system is incorrectly selected.

When the pump is selected correctly, the heating system functions reliably and fully, and the movement of water occurs unhindered.

If you have difficulties choosing a pump, it is better to contact specialists; they will help you choose the appropriate device for a specific heating system.

Wrong pipe diameter

The diameter of the pipes must be selected at the design stage. First of all, it is necessary to take into account that different heating systems have their own rules according to which pipes are selected.

If the heating network is connected to a central heating main, then the diameter of the pipes is chosen in the same way as an apartment heating system. For autonomous heating, these diameters may differ. It all depends on whether there is a circulation pump in the system or whether the work will be carried out due to the natural circulation of water.

The choice is also influenced by:

- Pipe production material;

- Type of coolant used;

- Specific features of heating main wiring;

- Planned pressure in the system;

- The speed of water movement along the highway.

Important! When calculating the diameter, the type of pipe must be taken into account, because the measurement system differs based on the material of manufacture. Steel and cast iron products are marked taking into account the internal diameter, and copper materials according to the outer section. This should definitely be taken into account when planning a pipeline, where several different materials are combined in the pipeline.

System clogged

A coarse filter will help get rid of it. Dirt that gets into the pipes is easier to remove by catching it in the filter. First of all, such a filter protects the pump. It is also recommended to install a filter at the boiler inlet. Such a water filter should be placed in front of each plumbing fixture. When installing the device, you must pay attention to the filter housing. There is an arrow on it that indicates which side to install the filter depending on the direction of movement of the coolant.

The filter should be cleaned regularly. To do this, you need to turn off the water, unscrew the cap, take out the mesh, rinse it, put it in place and screw the cap back, after which you can open the taps.

Advice! To prevent clogging of the pipeline, during installation it is necessary to control that there is no debris in the pipes; for this, the ends of the pipes are covered. It is also necessary to check the radiators, since new products may contain factory shavings or other debris.

Airiness of the heating system

They block the movement of water. To quickly solve this problem, install air vents or a Mayevsky valve. For the central system, where a lot of air accumulates, automatic Mayevsky valves are used. The air is quickly removed and the movement of the coolant through the network is restored. These devices not only improve the circulation of coolant through the central heating line, but also reduce heating costs.

Check valves

In this case, each circuit can operate independently of the others. Even in a branched radiator system with several circuits, where there are several pumps, it is better to install check valves. There is no need to skimp on installing them. The absence of these mechanisms leads to the slowing down of water movement in the system. This happens in situations where a network with several circuits is laid. To ensure that warm water flows along the circuit where the pump operates, and its movement occurs in the desired direction, check valves are used. These elements are not always installed, but only in situations where there are no other technical solutions. This is explained by the fact that these elements create high hydraulic resistance, depending on the design. Therefore, the installation of these valves in systems with natural circulation has its limitations, and the reason for the restrictions is the low water pressure in the main.

The actuator in the product is a spring that closes the valve when the normal operating conditions of the heating network change. For systems with different operating parameters, products with appropriate elasticity and spring mass are selected. Valves are a very important element; they ensure trouble-free operation of the central heating system, increase the efficiency of all equipment and improve circulation.

Leaks in the system

As a result of a leak, the network does not work correctly, the water movement is poor and the boiler begins to malfunction. The first thing to do is to find the “weak” points. Leaks occur in places where connections have become loose due to corrosion damage, or the cause is poor-quality installation of the system. If the network is mounted openly, then checking is not difficult. All such damage is determined quickly and easily. And to inspect a closed highway, you will have to call a specialist.

If a problem area is found, you must:

- Tighten loose connections and wrap them with sealing tape or tow;

- Replace components that have become unusable;

- Cut out and replace damaged sections of pipes.

A gas boiler

To live in a house in comfort, you need to know how to properly start the heating system if the water is heated by a gas boiler. For different models of units, the startup sequence is different, which is due to differences in their design.

This especially applies to condensing devices, in which condensate must form correctly during operation, because without it, heating the secondary heat exchanger is impossible.

To correctly start heating with a gas boiler, after filling the system with liquid, you need to perform certain actions:

- The valve located at the bottom of the unit should be opened to prevent liquid from entering the circuits, since it is usually closed after the end of the heating season. As a result, the pressure gauge readings change, and the pressure value cannot exceed 3 atmospheres.

- When the coolant has heated up, open the make-up valve again. In order to remove the remaining air pockets, Mayevsky cranes are used. During this procedure, the pressure decreases slightly.

- In reality, the radiators have to be started 2 times - when filling with hot water and when turning on the boiler.

- The correct operation of the unit is monitored using the values that appear on the dashboard.

If you strictly follow the instructions for starting the heating system, it will maintain a stable temperature without pressure surges in the pipelines.

It is advisable that the first start-up of a gas boiler is carried out by employees of specialized service centers for servicing this heating equipment. It also doesn’t hurt to know what to do if the gas boiler blows out with the wind, in order to solve such a problem if necessary.

How is the heating system of an apartment building balanced?

We perform an audit of the heating system with subsequent restoration of heat supply parameters.

One of the main problems when balancing is the lack of exact flow rates for the risers; only data on the total flow rate for the entire apartment building is known. Because the houses were built a long time ago, it is possible that residents will replace heating radiators and make significant changes to the heat supply scheme of the apartment buildings, which will affect consumption.

The result of balancing should be a temperature of the same value at the control points. The return pipeline of each riser should be selected as control points. By the temperature of the return riser, you can understand what the temperature of the battery of the last consumer is.

Leak test

To check the tightness of pipelines, a procedure called pressure testing is performed.

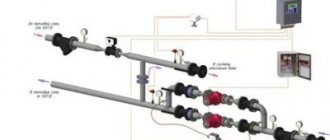

- A pressure tester - a pump with a pressure gauge - is connected to the emptied system through a special pipe.

- Air is pumped into the system until its pressure exceeds the operating pressure in the heating system by 20%.

- The system is left under pressure for several hours. If it falls, then the system is leaking. Leaks can be detected by the hissing of air or by applying soap foam to the connections.

Pressure testing of heating systems of private houses, with a relatively small volume, can be performed using inexpensive manual pressure testing machines.

How to check the heating circulation pump for serviceability

You can check in the following ways.

Ease of inclusion

To examine the performance of the equipment, it is recommended to check whether it is easy to turn on. After seasonal downtime, the condition of the unit must be checked.

To do this, it is recommended that after switching on, listen to the sounds that the equipment makes during operation. If there is no damage, the unit operates quietly .

If you hear various sounds, you will have to check the contamination of parts , the amount of water in the system, etc.

Presence of noise during operation

If the circular pump makes noise, it requires diagnostics or complete replacement. Sounds occur due to malfunction of the rotor or impeller , which can render the entire heating system unusable.

Sometimes noise occurs due to voltage drop . This happens due to imbalance and synchronization, which leads to uneven movement of the coolant.

Attention! Diagnostics are carried out only by a specialist .

If operation is stable, but the device still makes noise, it is recommended to check:

- Is the operating power of the unit equal to the initial values? If the calculations are similar, then the coolant moves too quickly or slowly, which leads to noise.

- Is the motor rotor in a horizontal position?

Bearing operation

Bearings wear out and vibrate heavily.

They are responsible for rotating the impeller, so if the part is no longer suitable for use, it needs to be replaced.

Also, bearings sometimes become damaged and make knocking or squeaking noises. To eliminate the problem, disassembly and washing are carried out. A special worker does this.

The design of check valves allows you to maintain the desired speed, pressure and direction of hot water in the pipeline. Their installation is especially relevant in systems with several circuits and pumps. The absence of such valves can lead to slower water movement and disruption of its circulation, so you should not skimp on installing them. The choice of valves of appropriate sizes and degree of elasticity depends on the load and type of heating system.

The causes of water leaks in the system may be poor-quality installation of pipes, damage to connection areas as a result of corrosion or mechanical failures. With an open type piping system, leaks can be easily detected by visual inspection. To identify damage and check the hidden system, it is necessary to involve a specialist.

You can eliminate the leak by tightening and wrapping the loose connection with tow, replacing leaking components, or cutting out and replacing damaged sections of pipes.

Pressure testing - what is it?

Pressure testing of a finished water heating system is a test of tightness and assembly quality. Whether the system can be put into operation or not depends entirely on the results of such a check. This is the first procedure that needs to be carried out after installation and before turning on the heating.

At its core, it is control without destruction. Air or water is pumped into the system, thereby creating increased pressure. If there are no leaks, you can safely put the system into operation.

Pressure testing is also carried out when checking an already operating system. After all, leaks often appear at the places where parts are connected using fittings, soldering or welding. The pipes themselves may also suffer, for example, from mechanical stress or corrosion. High temperature and pressure also cause gradual wear of pipes and parts of the water heating system. To detect and eliminate the location of the flaw, crimping is required.

This is a set of measures through which not only the heating system, but also the hot water supply, sewage system, and pipes in the water well can be checked in a private home.

The crimping procedure includes:

- pipeline testing and flushing;

- checking and, if necessary, replacing parts;

- restoration of damaged insulation.

The following are tested under high pressure:

- strength of housings, as well as walls of pipes, radiators, heat exchangers and fittings;

- fastening when connecting the elements that make up the system;

- maintenance of taps, pressure gauges, as well as gate valves.

Pump design elements

In order for the operation of the circulation pump to be problem-free, it is necessary to regularly check the condition of the equipment. A preventive inspection will help identify negative factors that can lead to serious breakdowns in the future. Their timely elimination will allow you to avoid force majeure situations and complex repair procedures.

A standard inspection includes a few simple steps:

- checking the tightness of connections. It is necessary to carefully inspect all fittings with which the pump is attached to the heating system. Some types of connecting elements may become loose over time and must be tightened. In addition, problems may arise with the destruction of the thread or seal - in this case, you need to unscrew the fitting, cut additional turns or wind a new layer of FUM tape, and then reassemble the element;

- adding lubricant. There are bearings inside the device that must be well lubricated. Otherwise, they will work worse, which will lead to overheating of the device;

- cleaning the filter. The mesh element gradually becomes clogged with dirt, even if you use a very high-quality coolant. Therefore, it is necessary to promptly remove rust and scale particles stuck in the filter.

Actually, this is a basic set of actions that need to be performed for prevention. In addition, you should follow some rules for operating the circulation pump:

- Avoid dry running. The pump should only be turned on if the required amount of coolant is present in the heating system. Equipment running “dry” will burn out very quickly, and may even drag down some other electrical appliances;

- Avoid prolonged idle time. In many regions, the heating system operates in seasonal mode - from September to May. It is clear that there is no point in launching it in thirty-degree heat. But if left idle for such a long time, some elements of the circulation pump may fail. Therefore, it must be turned on at least once a month for a quarter of an hour. Agree, it takes a little time, but it will help to avoid possible problems in the future;

- initially purchase a pump whose characteristics fully correspond to the needs of your heating system. It happens that owners, in an attempt to save money, buy a low-power device and try to use it in a system with a large volume of coolant. As a result, the device constantly works at the limit of its capabilities and, of course, fails very quickly. That is why it is important to make advance calculations of the parameters that you should focus on when purchasing. You can find information on how to do this on our portal;

- provide for overheating and “dry running” sensors. These regulators are not available on all models, but it is advisable to find and purchase a device with them. You may not immediately notice the problem on your own. For example, if there is a coolant leak in the system, then until you detect it, the pump will run idle and may simply burn out. And the sensor will react instantly, automatically turning off the equipment, and thereby preventing breakdown.

Control methods

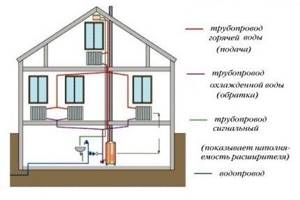

The pressure in the system is monitored using pressure gauges. They should be installed at the following points:

- At the entrance to the boiler and at the exit from it (modern heaters have built-in pressure gauges).

- At the lowest and highest points of the system (for houses with several floors).

- In branching areas: after tees, in manifolds, after two- and three-way valves.

Pressure gauges allow you to monitor pressure visually. And to reset it at a critical value, safety valves are used. Such a device must be installed on the supply pipeline immediately after the boiler - the working medium is discharged through it when it boils in the heat exchanger.

Typically this safety valve is classified as a so-called safety group, which also includes a pressure gauge and an automatic air vent. In addition, diaphragm expansion tanks are equipped with relief valves.

In addition to relief valves, bypass valves are used. Such a valve is installed on the bypass, through which the coolant can bypass the circuit. If a blockage or air lock forms somewhere in the circuit, and because of this, backpressure (increased pressure) occurs in the previous section, the bypass valve is activated. The pump begins to pump the coolant through the small counter “boiler - bypass - pump - boiler”.

Without such a fuse, the pump would be overloaded due to the formation of backwater and would soon fail.

To ensure proper coolant pressure in the system, it is necessary to maintain the correct pressure in the air chamber of the expansion tank. Typically it is 1.5 atm. If the value is lower, the membrane may rupture; if it is higher, the coolant pressure will also increase.

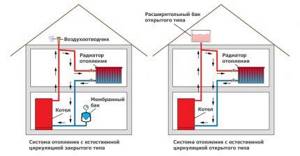

Open heating system

In an open heating system, an expansion tank is required, since heated water expands. The expansion tank is used to receive excess water during expansion and return it to the system when cooling, as well as to remove water when its volume is excessive. The tank is not completely sealed, so the water evaporates, as a result of which it is necessary to constantly restore its level. An open heating system does not use a pump. The system is quite simple. Consists of pipes, steel expansion tank, radiators and boiler. Diesel, gas and solid fuel boilers are used, except electric ones.

How does the crimping process work?

- Preparing the system before pressure testing. If the system is autonomous, then the heat generator is turned off first. If not, then taps are used to close off the area where inspection is required. The coolant must be drained.

- The system circuit is filled with water having a temperature of no higher than 45 C. The air is gradually released.

- The compressor is connected and air begins to flow into the pipes.

- At the beginning of the procedure, the pressure is brought to the working level and the area is visually inspected for violations. Then the pressure is gradually increased to the test level - this is maintained for at least 10 minutes.

- The area or the entire system is inspected for leaks at the connections. It is mandatory to visually inspect fittings, radiators and the entire length of pipe walls for fistulas. If deviations are detected, all defects and shifts are recorded. The operation of taps and valves is checked.

- Using pressure gauge readings, the drop in pressure level is determined. If it has not decreased, the system is in normal operating condition.

- Based on the results of the inspection, a report is drawn up.

Pressure in an open heating system

Unlike a closed thermal circuit, a properly constructed open heating system does not require balancing over years of operation - it is self-regulating. Boiler operation and static pressure ensure constant circulation of water in the system.

The density of the heated water following the supply riser is lower than the density of the cooled coolant. Hot water tends to occupy the highest possible point of the circuit, and cooled water tends to be at its very bottom.

The pressure developed by the water column in the supply riser promotes the circulation of the coolant and compensates for the resistance present in the circuit pipeline. It is caused by the friction of water on the inner surface of the pipes, as well as local resistance (turns and branches of the pipeline, boiler, fittings).

By the way, pipes of increased diameter are used to assemble an open heating system precisely to reduce friction.

To understand how to increase pressure in an open heating system, you must first understand the principle of achieving circulation pressure in the thermal circuit.

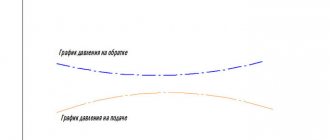

- Рc – circulation pressure;

- h – vertical distance between the centers of the boiler and the lower heating radiator;

- рг – density of the heated coolant;

- ro – density of the cooled coolant.

The static pressure will be higher if the distance between the central axes of the boiler and the battery closest to it is as significant as possible. Accordingly, the intensity of coolant circulation will be higher.

To achieve the maximum possible pressure in the heating circuit, it is necessary to lower the boiler as low as possible - into the basement.

The second reason for the drop in pressure in an open heating system is related to its self-regulation. When the heating temperature of the coolant changes, the intensity of its flow changes. By increasing the heating of water for the heating circuit on cold winter days, owners sharply reduce its density.

However, when passing through heating radiators, water gives off heat to the room atmosphere, and its density increases. And according to the formula presented above, a high difference in the densities of hot and chilled water helps to increase the circulation pressure.

The more the coolant is heated and the colder it is in the rooms of the house, the higher the pressure in the system will be. However, after the atmosphere of the premises warms up and the heat transfer from the radiators decreases, the pressure in the open system will drop - the difference between the supply and return water temperatures will decrease.

Balancing a double-circuit open heating system

Gravity heating systems are made with one or more circuits. In this case, the horizontal length of each looped pipeline should not exceed 30 m.

But to achieve optimal pressure and pressure in an open system with natural coolant movement, it is better to make the pipelines even shorter - less than 25 m. Then it will be easier for water to deal with hydraulic resistance. In a circuit with several rings, in addition to limiting the length, the condition for heating radiators must be observed - the number of sections in all rings must be approximately equal.

Balancing of the horizontal rings included in the vertical circuit is required at the design stage of the heating system. If the hydraulic resistance of any ring turns out to be higher than that of the others, the static pressure in it will not be enough and the pressure will practically stop.

To maintain the required pressure in a double-circuit heating system, it is necessary to reduce the cross-section of the pipes approaching the radiators. You can also install valves in front of the radiators that perform thermoregulation (manual or automatic).

You can balance an open-type dual-circuit system:

- Manually. We start the heating system, then measure the temperature of the atmosphere of each heated room. Where it is higher, we screw the valve, where it is lower, we unscrew it. To adjust the thermal balance, you will have to perform temperature measurements and adjust the valves several times;

- Using thermostatic valves. Balancing occurs almost independently; you just need to set the desired temperature in each room on the valve handles. Each such device will control the supply of coolant to the radiator itself, increasing or decreasing the supply of coolant.

It is especially important that the value of the total hydraulic resistance of the heating system (all rings in the circuits) does not exceed the value of the circulation pressure. Otherwise, warming up the coolant and attempting to balance the system will not improve circulation.

Circulation pump for open heating system

It happens that measures to balance the heating circuit of a gravity system have no effect. Not all causes of low pressure can be solved by adjustment - choosing the wrong pipe diameter cannot be corrected without a complete reconstruction of the circuit.

Then, in order to increase the pressure and improve the movement of water without significant modifications to the heating, a circulation pump or booster pumping device is installed in the system. The only thing that its installation will require is moving the expansion tank or replacing it with a membrane expansion tank (closed tank).

The energy consumption of circulation pumps does not exceed 100 W. Therefore, there is no need to fear that it will push the coolant out of the circuit.

The volume of water in the heating system is more or less constant, provided that the filling of the open circuit is controlled. Therefore, no matter how much water the circulation pump pushes along the circuit in front of it, the same amount will flow into it from the return pipe.

By bringing the pressure in the thermal system to the required level, the pump will make it possible to lengthen it, reduce the diameter of the pipeline and achieve circuit balance with high hydraulic resistance.

Crimping: how to do it yourself

Often, when building a private house, the heating system is installed before the water is connected. Therefore, a large water container and a submersible pump are used to pump water into the pipes. During the manipulation, you need to constantly monitor the pressure using a pressure gauge and control the water level in the container, gradually adding it if necessary.

When the pressure readings rise to 2-2.5 atm, the pump is turned off, and the remaining air is gradually released from the system using Mayevsky taps. Further, after the mark on the pressure gauge drops below 1 atm, filling with water continues. This is done until the water completely displaces the air and the pressure reaches a level of 1.2-1.5 atm.

If no leaks are detected, you can connect the boiler and start the system.

For such an important event as crimping, it is better to hire a team that has the appropriate license. These people are fully responsible for the actions performed. In this case, the customer receives all the necessary documents about the work performed.

Attention! The report on the pressure testing carried out must include the time during which the system was under test pressure and indicate its level.

Pressure testing of a heating system is a matter that requires a serious approach. This operation should be carried out with your own hands only in extreme cases.

SNiP and safety requirements

For safety and operational reasons, it is recommended:

- Do not perform long-term pressure testing on pipes made of PVC.

- Perform testing on a line that is previously disconnected from other sections of the pipeline.

- Monitor leaks only with proven instruments and equipment.

- Do not involve organizations and persons in pressure testing that do not have certificates to perform such procedures.

For all types of pressure testing, possible deviations from the calculated pressure parameters in the network and the duration of visual inspection of leaks should be taken into account.

A short video about how to carry out pressure testing of heating and water supply