Key Features

The gas generator engine has several undeniable positive features. Firstly, fuel for the device is very cheap. Secondly, during operation of the device, ash appears, which can be used as fertilizer, for example. Thirdly, the car will not require the installation of powerful chemical batteries.

Gas generator engines have proven their right to exist for a very long time. Today, their performance, of course, is much inferior to new models running on gasoline. However, for most ordinary car enthusiasts they may be quite suitable. The gas generator unit will allow you to reach speeds of up to 100 km/h, the approximate maximum mileage will be about 100 km. To increase this parameter, you will have to carry additional bags of firewood in the back seat and periodically manually add “fuel” to the tank.

Scope of application

Technical devices are actively used in practice due to their effectiveness. Generating units convert biological fuels and residues from wood production into gas.

High performance allows:

- heat the room;

- operate the internal combustion engine in a car.

A gas generating unit is used if using electricity is unprofitable. For example, it is placed near construction sites and new buildings that are not yet connected to the power grid. The units are used in hospitals or factories where continuous energy is needed. In the absence of electric current, the backup pyrolysis gas generator is activated.

There are autonomous gas generator devices of various functions. They are purchased if solid fuel units are converted to low-grade fuel.

Industrial Applications

Gas generators are installed at wood processing plants to burn waste, of which there is a lot in production. Fuel is prepared by grinders and crushers, which can be stationary or mobile. This is how fuel of the required structure is created after deforestation.

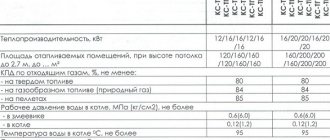

The industrial gas generator engine has the following characteristics :

- efficient burning of wood;

- cleansing the surrounding space and atmosphere;

- possibility of laying low-quality combustible materials.

Large production installations are equipped with automation , so the presence of a worker is not required.

Household installations

Home gas generators usually have a power of no more than 15 kW , but there are some models with a rating of 25 kW. For domestic use, power is provided with a reserve of about 20 - 30% . Installations are classified according to operating time, type of generator, type of fuel.

When choosing, take into account:

- number of phases;

- liquid or air cooling;

- manual or automatic start;

- open or closed housing;

Hot gas from a gas power plant for a private home can be used in a heating system , be used to dry fuel, clothes, vegetables, and other products . For drying, part of the gas pipeline is led around the firebox and placed between the loading chamber and the housing.

The safety of the unit is ensured by:

- thermostats;

- safety valves;

- control sensors;

- emergency shutdown schemes.

Electronic control modules coordinate the work, make it possible to set the required parameters, and provide remote control via a remote control and via the Internet. Be sure to provide for smoke exhaust . The minimum dimensions of the room where the gas generator is located should not be less than 15 m³ .

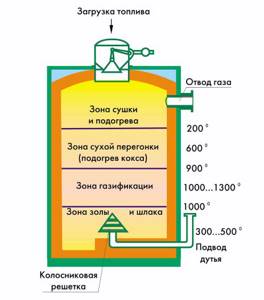

How the device works

The operating principle of the gas generator is gas synthesis. This is a process during which flammable gas will be formed when organic material is burned. In order to start such a process, it is necessary to reach the desired temperature. Gas synthesis begins when it reaches 1400 degrees Celsius. Peat, coal briquettes and some other materials can be used as fuel for a gas generator engine. However, as practice has shown, the most common and convenient material for fuel is wood. Although it is worth noting here that firewood has one drawback - a decrease in the charge of the working mixture. As a result, the power of the installation is somewhat reduced.

It can be added that a wood-burning engine of this type is usually used with an already installed internal combustion engine.

Wood-burning cars. Consumption of 20 kg of firewood per 100 km.

The history of wood-burning cars

The idea of a gas-generating car, the engine of which runs on gas obtained from solid fuel, is not new; it was invented at the end of the 19th - beginning of the 20th century. The first classic gas-generating car, which used wood and charcoal as fuel, was designed in 1900 in France. Within a year, a patent for the production of such cars was issued in Russia.

Cars that ran on wood were very popular during World War II. They are still widely used in some countries. In particular, there are quite a lot of them in rural areas of North Korea. In Sweden, South Africa, China and the Philippines, the development of gas generator technologies is supported at the government level.

Alexey Lagunov cars with gas generators

“In May 2013, I accidentally found out that there are cars that run on wood, that is, using a gas generator. Then I found out that there is old Soviet literature from which you can learn how to build the same devices yourself. I told my fellow friends about this, and we did the calculations ourselves and collected everything ourselves. Of course, there were some mistakes at first, but in the end we ensured that everything worked perfectly.”

“During the ride, the firewood burns in a metal container, which is very easy to build,” Sergei explained the principle by which the mechanism works. - There is little oxygen there, and therefore they burn differently than in a fire. Carbon monoxide is produced, enters the engine and there performs the function of gasoline or propane. What comes out is carbon dioxide, just like opening a bottle of soda. No harmful emissions, it is ten times more environmentally friendly than gasoline. It also has a very beneficial effect on plants.”

Two kilograms of firewood is the equivalent of a liter of gasoline. And if you fill your car with charcoal, then a kilogram of coal corresponds to a liter of gasoline. Although you can even ride on pine cones.

Re-equipping the car costs $1000. But most importantly, according to the inventor, after upgrading the car, the driver does not feel the difference. The car can still reach speeds of more than 100 km/h. A wood-burning gas generator turned out to be a popular idea: Sergei has a group dedicated to devices on the vKontakte social network, and in it he conducted a survey asking why users joined the community. The absolute majority, 46.7%, answered that they need to save money and they are also going to make a gas generator for their car.

Evgeniy Kolyvan, Opel on wood

“My Opel can run on both gasoline and wood,” says Evgeniy. — The car is not new, produced in 1986. I decided to remake it last winter. Due to the rise in gasoline prices, commuting to work has become expensive, so I came up with an alternative option. It is easier to ride on wood than to pedal a bicycle. It was not difficult to modify the car. By profession I am a physics and mathematics teacher. I worked at a school for several years, and now I repair cars at a private service station. I attached a metal barrel and a can into the trunk, into which firewood is placed. They smolder, releasing gas, which is filtered, cooled and piped into the engine.”

It’s both convenient and cheap for me to drive with wood. I think this is a good option for rural areas. 20 kilograms of firewood goes 100 kilometers. So only 10 hryvnia is spent for such a distance. The savings are significant when compared with gasoline prices - on average 20 hryvnia per liter. The car accelerates to 100 kilometers per hour with wood in 1 minute and 35 seconds. In general, it depends on the quality of the firewood and its moisture content. I can also throw plastic bottles into the firebox, but most often it’s ordinary pine firewood. The best fuel is from dry mulberry. You don’t ride on it, you fly! Driving with wood is also environmentally friendly. Only water vapor and carbon dioxide come out of the Opel exhaust pipe.

One day traffic cops stopped me to ask how I had converted my Opel like that. They didn't even ask for documents. It will soon be a year since I started driving wood, and I have never regretted it. During this time, I covered more than 7,000 kilometers. I saved about 15,000 hryvnia. Since the area in the Chernihiv region is wooded, there are plenty of gas stations along the road. I took a saw out of the trunk, which I jokingly call the “Refueling Gun,” cut down the dry branches, and off we went. If you don’t have time to stop or drive into a field, you can switch to gasoline.

The idea was also supported in Latvia. This Latvian Moskvich also runs on a gas generator:

Based on materials from: Nadrovah, Ecotown

Technical indicators

If there is a choice, for example, between buying a car with a traditional engine or with a gas generator, then you need to dwell in detail on the consideration of the technical data of the second option.

The weight of the engine on wood is quite large, due to which some of the maneuverability is lost. This disadvantage becomes dangerous if you develop high speed. For this reason, bringing the car even to 100 km/h is not a very reasonable solution - you will have to drive slower. There are several other important technical data of such equipment.

A wood-burning gas engine has a higher compression ratio than gasoline truck engines. As for power, the gas generator naturally loses to a gasoline engine.

The last difference is not in favor of the gas model - it is the carrying capacity, in which it also loses to a car with a gasoline engine.

It is also important to note here that wood gas has a low energy value when compared with natural gas. A car running on wood will inevitably lose its dynamic properties, which should also be taken into account by the driver of such a vehicle.

Some people prefer to install a volumetric gas generator on a trailer rather than on the car itself. In this case, you won’t be able to accelerate quickly, and you won’t be able to maneuver much. The trailer will act as a kind of limiter.

How to make a wood-burning car with your own hands

If you want to try converting your car to wood burning, there are many obstacles that will stand in your way. When designing a gas generator installation, you will need to make it small, fairly light, and at the same time highly efficient. If finances allow, the best solution would be to follow the path of craftsmen from abroad and use stainless steel for the body of the gas generator itself, the filter and the cooler.

This will give you a noticeable gain in the mass of the entire structure, without losing strength. However, stainless steel will cost you a pretty penny, and therefore domestic craftsmen often replace it with ordinary steel.

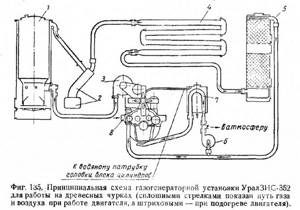

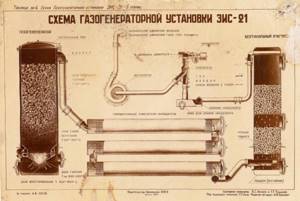

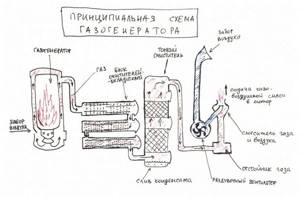

The image below shows a diagram of the most advanced automotive gas generator unit, which was equipped with production cars (we are talking about the UralZIS-352 truck, produced in the 1950s). It is its design that is best to focus on when assembling your gas generator:

First, you will need to make an outer container - a strong iron barrel or a rolled and welded sheet of metal with a thickness of at least 1 mm is perfect for this purpose; for the inner container, a gas cylinder (for propane) or a receiver from a truck (KAMAZ, for example) will do. Be sure to cut a door into the housing to access the ash pan, otherwise you will not be able to clean it. A neck should be located at the bottom of the combustion chamber - resins will be deposited there. The grate can be easily made from durable fittings, and for the nozzles you will have to find pipes of a suitable size and diameter. A sheet of metal 5 mm thick makes an excellent lid and bottom. Use asbestos cord as a seal (don't forget to impregnate it in the form of graphite grease).

You can use a used fire extinguisher on the coarse filter. In the lower part it is equipped with a cone-shaped nozzle with a fitting, and a pipe is welded on top through which the purified gas will exit. On the side, another fitting is cut into the body to supply combustion products. The general diagram of the cyclone is shown below:

Since the gas mixture has too high a temperature, it cannot be used in an internal combustion engine. Therefore, the gases need to be cooled. As a cooler, you can use either an ordinary “accordion”, used in heating systems, or a more advanced bimetallic radiator, placing it so that it is well blown by the incoming air flow.

After the cooler, the gases must be cleaned again using a fine filter. The housing from an old fire extinguisher will also work here, but choose the filter element at your discretion. Units and assemblies should be combined according to this diagram:

In addition, you will need 2 more parts. The first of them is a mixer with which you will regulate the fuel-air mixture for the internal combustion engine. The second is a fan with a relay, which is necessary to pump gas during ignition (after starting the engine, a vacuum appears in the system, and the fan must be turned off at this stage). By the way, the fan is installed in an air distribution box equipped with a check valve. The box is not part of the gas generator, but is installed separately.

Conclusions and recommendations

Although the idea of converting a car from gasoline to wood seems very attractive, an equivalent replacement will not work. Despite all the advantages of a gas generator, an engine running on a mixture of flammable gases is simply unable to develop power comparable to a liquid fuel engine. As a result, the dynamics leave much to be desired (even 70-80 km/h is a practically unattainable speed). It’s another matter if a gas generator installation is created for the purpose of heating housing in non-gas-free settlements. In this case, this is a very good option, which is definitely worth paying attention to.

Advantages of gas generators

If we talk about the advantages of cars with gas generator engines, then the possibility of using renewable fuel without pre-treatment immediately comes to the fore. For example, to convert biomass into suitable fuel, say ethanol or biodiesel, energy is consumed, including CO2 energy. Moreover, in some cases, more energy is consumed for transformation than the original substance contains. As for the wood-burning gas engine, it does not require energy to produce its fuel. Unless you need to cut and chop the wood itself for ease of loading.

If we compare a car with a gas generator and an electric car, we can highlight the following advantage: there is no need for a powerful chemical energy source - a battery. The disadvantage of such chemical batteries is that they have a self-discharging property, and therefore, before operating such a car, you must remember to charge it. If we talk about devices that generate gas, they themselves are “natural” batteries.

If the gas generator is properly assembled and operated in a car, it will pollute the environment significantly less than any gasoline or diesel engine. Of course, when compared with an electric car, which does not create any emissions into the atmosphere, the gas generator loses. However, charging electric cars requires a lot of energy, and it is still extracted using traditional methods that heavily pollute the air.

Disadvantages of gas generators

Despite certain advantages of such installations, their installation still remains a very individual solution and not the most optimal. The gas generating installation itself takes up a lot of space, and it weighs several hundred kilograms. In this case, this entire bulky structure will have to be transported with you. The large dimensions of the gas installation are due to the fact that wood gas is characterized by a low specific energy coefficient. For example, we can compare the specific energy value of wood gas, which is 5.7 MJ/kg, with the energy released during the combustion of gasoline - 44 MJ/kg, or 56 MJ/kg - the result of the combustion of natural gas.

Running a car on a gas generator

When operating such a gas engine, it will not be possible to achieve the speed and acceleration possible when using a gasoline analogue. The problem lies in the composition of wood gas. It consists of 50% nitrogen, 20% carbon monoxide; the remaining 18% is hydrogen, 8% is carbon dioxide, 4% is methane. Nitrogen, which occupies half the specific gravity of the gas, is not at all capable of supporting combustion, and carbon-based compounds reduce the efficiency of combustion. A large amount of nitrogen reduces the total power of such a generator by about 30-50 percent. Carbon reduces the rate of combustion of gas, which is why it is not possible to reach high speeds. As a consequence of this, the dynamic performance of the car decreases.

Design and principle of operation of a wood-burning gas generator

The composition of the gas includes:

- flammable carbon monoxide (CO);

- methane (CH4);

- hydrogen (H2);

- hydrocarbons (alkenes, alkadienes).

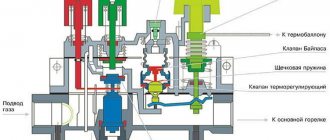

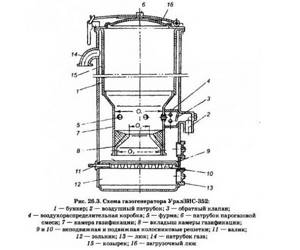

The steel cylindrical body has a loading chamber for fuel, the door is equipped with a seal. The firebox is located at the bottom; between it and the body there is a neck with a gasket made of asbestos cord. Air enters through a hole connected to the tuyere (air distribution container).

The hull has hatches :

- at the top with a shock-absorbing lining to regulate pressure;

- for laying fuel;

- to clean the ash pan.

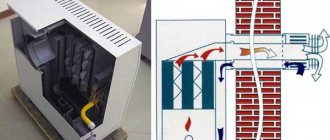

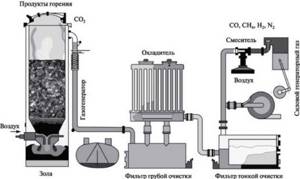

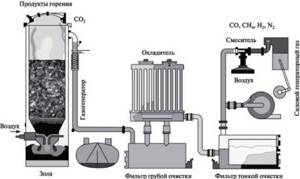

The inlet fan increases power and allows the use of firewood with high humidity (from 50%). Grate bars are installed to collect ash, their central part is movable for easy cleaning. Behind the housing there is a vortex filter for rough gas purification. Then the gas mass is cooled in a tank and delivered to a fine cleaning chamber . Before use, the gas in the mixer is saturated with air .

Application of gas generator

It should be noted that there is one more small problem with gas-generating cars, which is related specifically to their use. It is due to the fact that the installation needs to reach operating temperature, and only then can it be driven. The time required to reach this temperature is approximately 10 minutes. In addition, before the next loading of firewood, it is necessary to clean out the ash with a spatula each time. Another maintenance problem is the formation of gums. Now it is not as severe as before, but you still have to clean the filters from contaminants. All this leads to the need for frequent maintenance of the generator.

If we talk in general about caring for such a device, we can say this: there is a lot of hassle with maintenance, which is completely absent in gasoline engines.

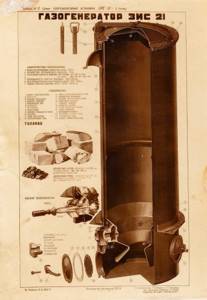

Generator set for ZIS-21

As already mentioned, the basic principle of operation of the generator is the conversion of solid fuel into gas entering the cylinders. The ZIS-21 gas generator mainly ran on fuels such as oak and birch. Sometimes brown coal was used, since it was the least hygroscopic and produced the most gas at the outlet.

As for the design of a typical gas generator for the ZIS-21, it consisted of the following elements: the gas generator itself, a cooler-purifier, a fine purifier, a mixer and an electric fan.

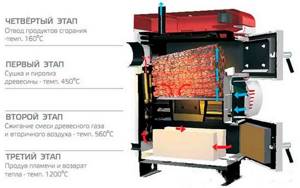

Installation operation on ZIS

At the top of the generator there was a hopper into which solid fuel was loaded. Directly under the bunker itself there was a firebox. Wood was burned here. As the old fuel burned, an “automatic supply” of new wood was carried out. In fact, it simply fell from the bunker into the firebox under its own weight when space became available. The gas generating unit itself was located on the left side of the car.

In the same firebox, carbon monoxide was also formed due to the drawing of air through the burning fuel. Oxygen was sucked in either due to the vacuum in the cylinders or due to the operation of an electric fan. These methods were forced, but there were also installations with natural air draft. However, in this case, preparation for launch could take up to an hour.

An ash pan was located under the firebox, as in any ordinary stove. Combustion products accumulated here. Every 80-100 km it was necessary to clean it of ash. However, it is fair to note here that this fact caused problems only for the driver of the vehicle.

Gas path in the installation and cleaning

All the gas produced during the combustion of wood entered the jacket that surrounded the bunker. In this way, heating of this compartment was achieved. This was necessary to pre-dry all the wood prepared for burning. Further, it is worth noting that after leaving the generator the gas had a temperature of approximately 110-140 degrees. Therefore it had to pass through the radiator sections. There he not only lowered his temperature, but also simultaneously cleared himself of heavy chemical impurities.

As for the cleaning, it happened this way. The purifier-heat exchanger sections were internal perforated pipes. This design was similar to current exhaust systems. The hot gas expanded greatly, causing it to lose flow speed. As he passed through the labyrinth of pipes, he slowed down even more. Impurities were screened out from it and remained on the inner walls of the outer pipes of the heat exchangers. This was followed by a fine cleaner.

How the device works

A standard gas generator is a rather bulky elongated cylinder.

@hodor.lol

The design itself looks like this:

- The internal part is almost completely clogged with coal, firewood, peat and other organic raw materials suitable for use.

- In the lower region of the cylinder, conditions are created that are favorable for fuel combustion - temperatures reaching 1,500°C. Only in such an environment are hydrogen and carbon monoxide released.

- The container is also equipped with a cooling system. The generated gas enters here, where it undergoes a procedure for reducing the specific calorie content of the fuel. Typically the system is located under the vehicle's underbody.

- The gas then passes through several filters that remove unnecessary components.

- Then the purified raw material enters the compartment, where it is mixed with oxygen.

- The last stage is when the finished composition is supplied to the power unit.

As you can see, the entire system was quite large in size and occupied most of the usable area. But it was worth it - thanks to their own and sometimes free raw materials, such equipment could be operated by enterprises located several hundred, or even thousands, kilometers from the gas station. For a long time, this “fat” plus could not outweigh the extensive list of minuses:

- low mileage per refueling;

- reduction in carrying capacity;

- reducing the usable area of the cargo compartment;

- additional repair and maintenance operations;

- long generator startup;

- reduction in engine power.

@pay.diary.ru