Installation of chimneys of gas boilers, as well as other heating equipment, must be carried out in accordance with building codes and fire safety requirements. You can read the instructions on how to repair a brick chimney here.

The photo shows a chimney for a gas boiler.

Requirements

Fire safety requirements when installing a chimney for a gas boiler:

- the height of the ceilings of the room in which the boiler equipment and chimney system will be installed must be at least two meters;

- the volume of the room for installing one heating device must be at least seven and a half cubic meters, for installing two heating devices the volume of the room must be at least thirteen cubic meters;

- ventilation must be provided in the room.

It is recommended that when installing a chimney, maintain a distance of at least 20 cm from the chimney pipe to the gas pipe.

If, during the operation of a gas boiler, partial destruction of the chimney occurs, for further use of the heating equipment it is necessary to carry out a lining procedure.

The thickness of the steel from which chimneys for gas boilers are made must be at least 0.5 mm. The steel must be alloyed and have increased anti-corrosion resistance, as well as resistance to acid-containing substances. For a gas boiler, the optimal choice would be a chimney made of AISI 316 steel; a more budget-friendly option, but also suitable for gas boilers, are chimneys made of AISI 304 steel. Read the manual for connecting a gas water heater to the chimney.

Choosing a chimney depending on the type of boiler

Equipment for the removal of combustion products is divided into several types, which have their own characteristics and characteristics. At the same time, home owners are wondering which chimney to choose for a specific type of boiler. This is exactly what will be discussed in the next paragraph.

For a boiler with an open burner

The open type burner is the simplest design. The structure consists of the burner itself, as well as a coil located under it. The coolant passes through thin pipes that lie at the base of the coil. The equipment begins to work only when exposed to air (it is for this reason that the burner received its second name - atmospheric). The operation of the boiler is based on the air that is in the room - sometimes such equipment can be attached to the main wall and a hole can be made in it for air intake.

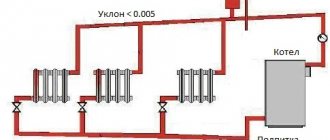

In order for the required level of traction to be created during the operation of the device, it is necessary to choose an external option: then the pipe is laid horizontally inside the house, and from the outside it stretches upward to the selected height level. You can also mount the pipe straight up: in this case, it stretches through all ceilings and surfaces. This device comes out above the roof.

For turbocharged boilers

If the owner of the house is dealing with a turbocharged boiler, then the best option would be to buy a coaxial chimney. In this case, two pipe systems work: through the first, harmful substances exit, and through the second, there is an influx of air, which ensures the combustion process. Experts believe that this type of chimney is the safest, since the process is controlled automatically - the fuel burns completely. Horizontal short chimneys can be chosen as a fallback option

For two boilers

If there are two boilers in the room, then the unit is purchased for each of them separately. In exceptional cases, it is allowed to connect a maximum of two units to one chimney, which will operate simultaneously, however, an important circumstance must be met here: the distance between two pipe inserts must be within 0.7 meters. The levels of the chimneys from these two boilers must be different in height.

Device

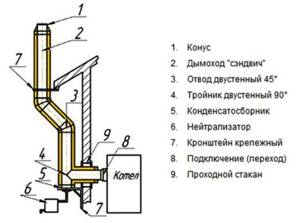

The most optimal chimney option for a gas boiler would be to install a modular chimney system made of steel sandwich pipes; a coaxial chimney system is also gaining popularity. A guide on how to install a coaxial chimney and installation requirements here: https://mykaminz.ru/dymoxod/vidy/koaksialnyj/rukovodstvo-kak-ustanovit-koaksialnyj-dymoxod-i-trebovaniya-k-ustanovke.html.

The chimney of a gas boiler in a private house can be mounted in two versions:

- exhaust pipe outlet through the wall and installation of an external chimney;

- installation of an internal chimney; in this case, the chimney is discharged outside through the roof of the house.

The calculation of the chimney cross-section for a gas boiler is carried out based on the technical documentation supplied with the gas boiler (the area of the internal surface must be greater than the area of the internal surface of the boiler specified in the equipment documents).

Conclusions and useful video on the topic

We present to your attention a video that details the procedure for installing a gas meter with the help of gas service specialists.

A correctly selected and correctly installed gas meter will bring great benefits to apartment owners. It will show the exact consumption of a natural resource, which will help you monitor its consumption.

A reasonable attitude towards the use of gas, in turn, will allow you to avoid unnecessary expenses and significantly reduce the cost of paying for blue fuel.

Do you have questions that we did not cover in this material? Ask them in the comments block - our experts will try to clarify all the points.

If you want to share your personal experience in obtaining the necessary documents and installing the meter, including further design of the device and putting it into operation, please tell us about it under our article. Add a photo of your meter, indicate how quickly in your case the investment in installing the device paid off and whether you are satisfied with the result.

Installation

A properly made chimney for a gas boiler must have a vertical position, be sealed, must be equipped with a protective cap (to prevent foreign objects from entering the chimney from the street), a condensate collector, and also when installing the chimney duct, to clean the chimney from accumulated soot, there must be additionally equipped with pockets with a depth of at least 25 cm.

When installing a chimney for a gas boiler, you must adhere to certain rules:

- to ensure high-quality draft, when assembling the chimney, it is recommended to make no more than three turns, despite the fact that the turns should not have narrowings or expansions;

- the height of the chimney must be at least five meters;

- the outer part of the chimney should rise above the roof (if there is a flat roof, and also if the pipe is located at a distance of one and a half meters from the ridge) to a height of no more than half a meter;

- the chimney should be located no lower than the axis of the ridge, in the case when it is located at a distance of one and a half to three meters from the ridge;

- installation of all components of the chimney system is carried out from the bottom up;

- to ensure the sealing of the chimney, special sealants must be used that can withstand temperatures up to 1000ºC;

- the joints of pipes and other components of the chimney must be tightened with clamps;

- the joints of chimney components should not be located in the roof and attic floors;

- the chimney is fixed with special wall brackets in increments of two meters;

- installing a chimney inside is only permitted if the walls are made of fire-resistant material, or if additional pipes are used.

The figure shows a diagram of connecting a gas boiler to a chimney.

Why insulate a chimney pipe

If the chimney pipe for the boiler is cooled in the cold, then the temperature of the exhaust gases decreases - which means the draft decreases. This problem can be solved by insulating the pipe. How to insulate depends on the material from which the chimney is made:

- Brick structures are plastered, and if the attic is not insulated, then stone or basalt wool with foil on top is used;

- Ceramic chimneys are protected from the cold with mineral wool and ceramic blocks, metal ones are insulated with any non-combustible materials;

- The most difficult thing is with asbestos structures - they can explode if they overheat, so they must be insulated competently and carefully.

Insulation

The chimney passing through unheated rooms, as well as its outer part, is subject to mandatory insulation. This is done to prevent the formation of condensation when there is a large difference in the high temperatures of the exhaust gases and low temperatures of the outside air. As a rule, slabs or shells made of basalt fiber or expanded polystyrene are used as thermal insulation material. Read the instructions on how to lay a brick chimney.

Plumbing and plumbing workConstruction equipment and machinery

Medium pressure gas pipelines

Medium-pressure gas pipelines at utility, industrial enterprises, heating and industrial boiler houses are tested for strength and density with air, and high-pressure pipelines from 3 to 12 kgf/cm2 are tested for strength with water and density with air.

Gas pipeline entries are tested separately from the internal gas pipeline network.

A low-pressure yard gas pipeline is tested for strength with compressed air at a pressure of 3 kgf/cm8 before backfilling it with earth. Connections are checked for tightness by wetting them with soapy water.

After filling the trenches with earth, the gas pipeline is tested for density again for an hour at a pressure of 1 kgf/cm2. The pressure should not drop beyond the permissible limit.

After assembling the gas pipeline and installing gas appliances, check its tightness. The internal network is tested by air pressure, which is created using a manual air pump, a compressed air cylinder or a KM-70 compressor.

The operating principle of the KM-70 (283) compressor is as follows. From the electric motor 1, through the crank mechanism 2, the movement is transmitted to the piston 3 located in the cylinder 4. Air is drawn into the cylinder in its middle part through six radial holes, first passing through the air filter 5. From the electric motor, the movement is transmitted to the fan 10, intended for cooling compressor. From the cylinder, air under pressure enters through channel 7 into a flexible hose 6 connected to the system under test. A pressure gauge 8 is attached to the channel to monitor the working pressure. The operation of the electric motor is controlled using a batch switch 9.

Internal gas equipment is accepted into operation by an acceptance committee, which includes representatives of the customer, construction and installation organization, city operating organization, etc.

The participation of representatives of Gosgortekhnadzor in the acceptance committee is determined by safety rules in the gas industry.

After acceptance of the gas supply system, the district gas operation office releases gas. When releasing gas into the network, it is necessary to displace air from it.

The filling of the network with gas and the absence of air in the pipes is checked with a gas analyzer, and if there is none, the end of the hose is lowered into a solution of soapy water, the other end is connected to the stove ramp or the gas water heater supply. If soap bubbles do not ignite from the flame of a match, then clean air flows. The ignition of soap bubbles, accompanied by popping, indicates the presence of an explosive gas-air mixture.

When clean gas enters, soap bubbles light up quietly, without popping. After checking, disconnect the hose, plug the free end of the ramp and light the burners of the stove or gas water heater.

How to check traction?

To check the draft in the chimney of a gas boiler, you can invite specialists who take measurements using special equipment - an anemometer. Also a clear sign of poor draft is a dark red flame.

Also, during the operation of a gas boiler, you can observe the “reverse draft” effect, that is, all combustion products that should be discharged through the chimney to the street will flow into the room. The main reasons for this effect may be: an incorrectly designed chimney (for example, insufficient height or diameter of the chimney pipe), blockage of the chimney duct, or lack of tightness of the chimney structure. Read about what a coaxial chimney is on this page.

When may it be necessary to relocate a gas pipe in an apartment?

Relocation of the gas pipeline and other work with it may be required for various reasons:

- Replacement of equipment. Standard versions of equipment left over from old owners or received from the developer are not always distinguished by increased quality or safety. If the owner of an apartment wants to properly equip his home, then he will have to deal with the issue of replacing gas equipment with newer and more efficient ones.

- Apartment redevelopment or major renovation. Gasified kitchens do not always have a reasonable layout. In many cases, the outlet under the stove is located extremely inconveniently for working in the kitchen. In such a situation, you need to carry out redevelopment and move the pipe to another point (extend or shorten).

- Purchasing housing in a new building. If you buy an apartment in a building with gas that has only recently been put into operation, a serious problem may arise with equipping the kitchen. Yes, most often there are basic communications in the housing, but they either do not fit the planned repairs/furniture/equipment or are located so inconveniently that it makes no sense to start equipping the housing without moving them.

Almost any work related to the transfer of a gas pipe requires the approval and assistance of specialists. The only thing that can be done without obtaining a separate permit is to move the slab approximately 40 centimeters in one direction or another. But this, too, is only possible if the connection is made using a flexible steel tube.