You can heat your house using a water heating system. To do this, you will have to install an electric heating boiler or a boiler that runs on solid or liquid fuel.

You will also have to lay out a heating circuit and install radiators. You can take a different route and build a stove or fireplace in your house. Both options for organizing heating will provide warmth and comfort in the house. However, they suffer from two significant disadvantages: they are expensive and labor intensive.

An alternative to the two heating options listed are cast iron stoves for summer cottages, which are gaining great popularity. In this material we will try to talk about the types of cast iron stoves, their advantages and operating features.

What is a cast iron stove?

The simplest cast iron stoves are not much different in design from the notorious potbelly stove. They consist of fuel and ash chambers, which are separated by a grate. Air is supplied inside the furnace unit and the flow rate is adjusted either by the ash chamber door or using a special damper.

Smoke is removed through a pipe adjacent to the fuel chamber. Heat transfer to the environment is mainly carried out by convection. A small part of the thermal energy is transferred through infrared radiation.

Fireplace stove in Russia

The cold climate of Russia forces the use of more bulky brick ovens, which occupy almost half the room. Surprisingly, even city apartments were heated using brick stoves. In Russia, fireplaces first appeared in St. Petersburg.

But revolutions and wars of the twentieth century led to the destruction of established customs and minimalism in the interior, and so “potbelly stoves” appeared - small stoves made of thin metal.

Among the positive qualities of these stoves, it should be noted that they quickly heated up from a small amount of firewood, but they instantly cooled down after the firewood burned out. Despite this, metal stoves are still available for sale.

Advantages and disadvantages

The industry offers two types of metal furnace units. Country wood stoves are made of steel or cast iron. Cast iron heating devices are more expensive, but have a number of advantages that cannot be achieved when making steel products. Cast iron wood stoves for summer cottages have:

- long service life, which, with proper operation, can reach 30–40 years;

- high heat capacity and therefore retain heat longer compared to steel stoves;

- greater corrosion resistance compared to steel products; they practically do not rust with frequent “cold” fires;

- Due to the low coefficient of thermal expansion, cast iron stoves are not subject to warping and deformation.

It should be said that cast iron has an attractive appearance. Often, manufacturers' design solutions make it possible to turn an ordinary heating device into a real work of art. Many cast iron stoves become a decoration of the interior of the room in which they are installed.

Cast iron is a fairly fragile material and is susceptible to sharp impacts, which could cause it to crack. Cast iron is also “afraid” of heat shock. Cold water spilled on a hot stove can cause the metal to crack. Therefore, a cast iron stove with a hob must have a design that prevents direct contact of the flame with the stove.

When choosing a heating method for a country house, you must proceed from the fact that using a cast iron heating apparatus it is impossible to heat the air evenly in all rooms.

A cast iron stove can provide full heating in only one room. Fire safety regulations prohibit installing cast iron stove units in such a way that they heat several rooms.

Compared to brick stoves and fireplaces, cast iron heating devices have one important advantage. With comparable thermal power, cast iron units weigh an order of magnitude less. If a brick stove weighs one ton, then the weight of a cast iron stove will be about 100 kilograms.

Therefore, the installation of a cast iron heating apparatus does not require the construction of a foundation. It can be installed directly on the floor. Naturally, for fire safety purposes, it must be installed on a metal sheet or platform made of non-combustible material.

Recommendations for choosing a stove

To choose the fireplace that is most suitable for specific conditions, a number of factors are taken into account

It is important to know the dimensions of the room. It matters what operating time is needed, what other functions are required, what fuel will be used

Even the exterior of the stove influences the choice.

Heated room area

Fireplaces have different shapes and dimensions, and therefore installation is carried out in a room of almost any size (taking into account the distances required for fire safety).

For small rooms, choose products installed against a wall or in a corner. Such ovens have one door with a glass insert, which may have one or two doors. Corner models take up less space and are therefore suitable even for very small rooms.

If the size of the room allows, a fireplace with two or three glass walls or a panoramic view will look good. The latter option is placed in the center, and you can admire the flame from anywhere.

Important! The power of the fireplace also depends on the size of the building. It needs to be chosen correctly for high-quality heating.

Additional functions

If necessary, the fireplace serves not only to heat the room in which it is located. If you connect a heat tank, water heating will heat other rooms, including those on the upper floors.

Air ducts are also used for this purpose, which are easier and cheaper to install. But with their help, only neighboring rooms can be heated.

Stoves are also used for cooking. The design provides one or two burners for this purpose. An oven is often present.

Each of these options complicates the design and increases the cost of the fireplace. For this reason, it is recommended to think about what exactly is required from the stove, as well as how often it will be used.

Power

This indicator determines how much volume the oven can heat. If the thermal insulation is done properly, 1 kW per 20 - 25 cubic meters is enough. Sometimes the power is selected with a small margin in case of severe frosts. But you shouldn’t add more than 15 - 20%, otherwise the room will overheat.

Attention! For exact numbers, the necessary calculations are made, taking into account heat loss. Quite often a lot of it escapes through windows and doors

Therefore, with panoramic glazing, you will need a stove with more power.

Term of work without interruption

In this case, the use of the oven matters. If this is the main heating device in the house, a long-burning fireplace is suitable. It is enough to heat such a device in the evening, and you will not have to get up at night to add firewood.

Due to the double afterburning technology, the upper wall of the combustion chamber heats up less. The burners located on it will not be able to boil water or cook food. That is, you will have to make a choice between heating duration and cooking function.

Fuel type

Most often, wood is used to light a fireplace. But there are models designed for fuel briquettes or pellets. This characteristic is usually in the description.

Photo 2. The Lava cast iron fireplace from the manufacturer Guca can operate on wood, briquettes and brown coal.

Furnace exterior

It is desirable that the stove matches the style of the entire room. But when choosing, you should focus not only on this. For example, corner or vertical models are suitable for small spaces. On the contrary, there are fireplaces that are installed only in spacious rooms - for example, with a panoramic view.

What is the efficiency?

It must be said that the simplest cast iron stoves for the home have a relatively low efficiency factor (efficiency factor). Usually it does not exceed 40%.

Long-burning furnace units have higher efficiency. To increase heat transfer, they are equipped with a chamber in which pyrolysis gases (flammable gases formed during smoldering wood) are burned. The air supply to this chamber is adjusted separately.

Experts are constantly working on the problem of how to improve the heat transfer of a cast iron stove. One way to increase heat transfer is to add so-called “smoke circulation” to the stove. Passing through the smoke circulation, hot smoke travels a longer distance and gives off an additional portion of thermal energy.

Sometimes, in order to increase the heat transfer time of a cast iron stove and increase the efficiency, ceramic heat accumulators are installed on chimneys.

Long burning stoves

The operating principle of the device is pyrolysis. During the combustion process, natural solid fuel decomposes under the influence of temperature and is partially gasified.

The yield of volatile substances is highest for firewood, wood waste, pellets, coal, fuel briquettes, and coke. But there are requirements for fuel moisture - it should not exceed 35% (for ordinary firewood). Otherwise, water vapor will dilute the pyrolysis gas, creating an obstacle to combustion (the process may even stop completely).

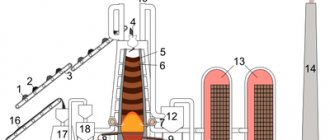

The firebox of a long-burning stove has two parts. In the first one, the fuel burns (or rather smolders—there is specially little oxygen). The gas released by the fuel enters the second part and burns there with a normal amount of oxygen. The efficiency of such stoves is much higher, they operate much longer, and are more economical (the fuel burns completely, maintenance is less frequent, the temperature is controlled by a thermostat). Disadvantages: energy dependence (forced draft) and high cost.

Diagram of a long-burning device

Types of models

Manufacturers offer several types of heating units made of cast iron. Conventionally, they can be divided into:

- conventional cast iron stoves;

- fireplace type stove units;

- heating and cooking stoves made of cast iron;

Fireplace-type stove units are equipped with transparent combustion doors and side heat shields made of heat-resistant glass. When such “fireplaces” are heated, a unique cozy atmosphere is created due to the warmth and sight of burning logs.

A cast iron stove with a cooking burner will not only provide the room with heat, but will also allow you to boil water for tea and make coffee. Not every housewife will regularly cook food on it. For this, it is more convenient to use a compact gas stove. However, this option may also not be superfluous.

Advantages and disadvantages

Each type of heating device has its own operating principle. However, the stove has a number of positive aspects, as well as negative ones. Therefore, when choosing a heating unit, you should first study them by looking at the catalog of cast iron stoves.

So, let's look at the advantages. The advantage of a cast iron stove is that one of the common types of fuel is wood. This type is called wood-burning cast iron stoves. This aspect is especially important in the modern period, when other types of fuel have to be purchased at a much higher price.

At the same time, wood in our country is unlikely to run out in the near future. The stove also heats up quickly, meaning it doesn’t take much time to warm the house.

Let us also turn to the disadvantages of stoves. One of them is heating only one room, the one in which such equipment is located. But when choosing a unit that operates on a water circuit, this disadvantage is eliminated.

Types of fuel used

The long service life of a cast iron stove is ensured by using the “correct” fuel. It is best to fire with dry hardwood firewood (oak, hornbeam, birch, etc.).

They have high heat transfer with relatively low fuel consumption. Coniferous species are less suitable. Damp wood is difficult to light, it burns “reluctantly” and does not emit enough heat.

You should not use coal as fuel. Coal has a higher combustion temperature compared to wood. Therefore, there is a high probability of overheating the stove. When cast iron is heated above 450°C, the structure of the metal irreversibly changes, causing its heat capacity to decrease. After the stove overheats, the unit will work noticeably worse.

Manufacturers

Today you can purchase models of Russian and foreign production. Let's look at the most popular ones.

Eurokom (Poland), especially the “Ambra” model, enjoy the trust of customers . It is durable (service life – 10 years) and practical. In addition to the heating function, the oven has a hob.

The power of the unit (which is 7 kW) is enough to heat rooms up to 7 m2. It has compact dimensions (width is 48 cm, depth is 36 cm with a product height of 84 cm), so it is suitable even for small rooms.

The presence of a spacious ash pan facilitates the operation of the device. The fireplace stove has an attractive retro-style design. Original patterns, noble patina - all this makes the device a worthy interior decoration. It is important that the model is affordable; its cost ranges from 20,000 to 25,000 rubles.

Also of interest is the Crown JA010 stove from the Chinese manufacturer of the same name. Its main feature is mobility, the ability, if necessary, to move the stove to another place. This product is even smaller in size compared to its Polish counterparts. The parameters of the Chinese oven are 438-387-627 mm, power is 6 kW. The design is again made in retro style. The device has bent legs, original patterns and a stylish combustion chamber door handle. The average price is 15,000 rubles.

How to choose?

The main criterion for choosing a heating device is its thermal power. Thermal power is selected based on the area of the room or its volume. Typically, manufacturers in the technical documentation indicate the volume of the room that can be heated using a particular model.

Having decided on the power of the stove unit, you need to decide on its type: a simple stove, a “fireplace” or with hobs. When choosing a stove for heating your home, you need to focus on reputable, reputable manufacturers.

Among the well-known brands we can recommend:

- Belgian heating units EFEL,

- products from the Polish manufacturer EUROKOM,

- Russian-made products from ARDENFIRE META,

- Italian EdilKamin.

Stoves and fireplaces in the interior of rooms - photos

Fans of oriental style will also find models to suit their taste - plain stove-fireplaces, distinguished by clear lines and a finished design, easily fitting into the “Zen” style.

In an original way, stoves are designed in the English style, which are placed in stone niches, decorated in the appropriate style. Such a stove will also be very convenient to use.

Fireplace stoves are widely used kitchen interiors, since such models are equipped with a built-in oven, which allows you to solve several problems at once. You can easily fry meat or bake a pie, or heat up lunch if it is prepared in advance. Such stoves are especially good in small country houses, because they will help save time, space, and reduce costs.

Converter fireplace stoves are very durable, this is due to the fact that the fireboxes in them are made of strong, durable cast iron, after which they are additionally finished inside with fireclay bricks. Heating up to 750 degrees is not dangerous for the heat-resistant glass from which the stove glass is made. Cleaning the glass will not cause you any trouble, because you will only need to clean the sight glass once a year.

Another nice thing to do is the function of adjusting the power of the fireplace by changing the flow of air supplied to the stove.

To summarize, we conclude that the use of fireplace stoves is a good, effective and aesthetically designed technique that allows you to heat any room in a short time.

How to install a cast iron stove in a wooden house with your own hands?

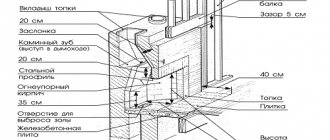

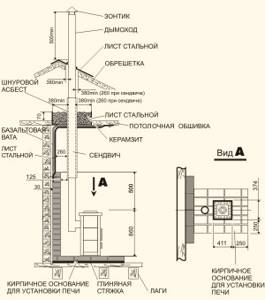

Wooden buildings are the most fire hazardous. Installing a cast iron stove in a wooden house with your own hands requires strict adherence to fire safety rules:

- As already mentioned, heating appliances made of cast iron are relatively light in weight. Therefore, they can be installed directly on the floor. To prevent fire, place a thick steel sheet on the floor or lay out a podium made of heat-resistant ceramic tiles. If the weight of the stove unit exceeds 100 kg, then the floor is reinforced from below with additional supports. You can also build a concrete or brick foundation.

- Heat screens are installed on walls located close to the heating unit to prevent heating of wooden structures. Some furnace manufacturers include such screens in the delivery of their products.

- When installing chimneys, where they pass through wooden (combustible) walls and ceilings, thermal insulation of heating parts is performed.

Reputable manufacturers provide detailed instructions for installing stoves and fire safety measures. If all recommendations are followed exactly, the operation of stove heating will be safe.