Lately, individual housing has become increasingly popular. The construction of individual houses is carried out not only in remote areas, but also within the city. Connecting a house or cottage to a central heating system is not always possible. In addition, many people think that installing stove heating with a water circuit is more profitable from an economic point of view. But is a water-heated stove as good as it seems at first glance?

Some features

The boiler configuration, its characteristics, drawings will depend on many factors:

- Material. Regular steel (sheet) will do, but heat-resistant stainless steel or cast iron is best.

- Possibility of good processing of steel, reliable connection of structural parts. Usually, a grinder, a gas cutter and electric welding are used for this.

- Type and characteristics of fuel (liquid or solid). Steel must withstand high temperatures, not deform, and not melt under their influence. Withstand internal pressure of vapors and gases without ruptures or cracks.

- Correct calculation of the coolant circulation method. Will it be natural (due to correct manipulation of pipe diameters, their slope, tank height, etc.) or forced (using a pump in the circuit).

- Taking into account vapor pressure, using valves to discharge excess gases and condensate (installation of return lines).

What parameters should you use to choose an oven?

When the question arises of how to choose a stove that will run on wood, you need to know what parameters to focus on.

Power

The first thing you need to decide on is the power. The relationship is direct - for a large heating area a more powerful model is required. The standard formula suggests the following calculation: per 10 sq. m. you need 1 kW of thermal energy. If winters are very cold, then 10-20 percent is added.

Sometimes less power is enough:

- if your region of residence is southern;

- winter temperatures remain at off-season levels;

- The home has serious thermal insulation: thick walls, small windows with three-layer double-glazed windows and an attic with insulation.

On the contrary, in very cold northern regions it is expected that per 10 sq. m. area requires 1.2-15 kW of furnace thermal power.

In order for the stove to meet its declared power, all necessary parameters must be met, which relate to the size and location of the ash pan, grate, combustion and ash doors, the length and diameter of the chimney duct.

Pros and cons of traditional stove heating

Heating a house from a wood-burning brick stove is traditional for Russia, although recently it has been practically replaced by water systems. This transition is largely due to the disadvantages of heating from a stove.

However, here are a few positive aspects of using stoves:

- Heating of the room from the stove is carried out by transferring thermal energy through waves, which have a beneficial effect on the human body - this is what scientists believe.

- A traditional stove, decorated in ethnic style, gives the room a certain flavor, and sometimes allows you to observe an open flame.

- You can increase the efficiency of a brick stove with the help of smoke channels, through which heat will be transferred throughout the house.

- The stove does not require electricity to operate.

- Some designs of solid fuel stoves allow you to heat a room on the second floor of the house due to built-in smoke channels.

Despite all the listed advantages, authentic stove heating is now practically unheard of, although sitting near a warm stove and warming up from the cold can be very pleasant.

Arguments against the use of stove heating can be formulated as follows:

- Heating from such a unit occurs unevenly - it is very hot near the stove itself, and cool in the corners.

- A Russian stove with smoke channels and other elements takes up a lot of space.

- From such a heating device, only those rooms into which its walls open are heated.

- The air temperature in different rooms cannot be adjusted as desired.

- Low efficiency. As a rule, the maximum efficiency of a furnace is no more than 60%, and for gas boilers, for example, it can exceed 90%.

- A wood stove must be constantly maintained - clean out the ash, melt it, adjust the draft with dampers and periodically add fuel. Not everyone likes it.

Some of the listed disadvantages can be compensated for by equipping stove heating with a water circuit by integrating a heat exchanger into it.

Advantages of fireplace stoves

First of all, it is worth comparing the main characteristics of traditional stoves and conventional fireplaces:

- Heating rate. The oven is quite large in size and after heating for a very long time it becomes a good heat accumulator, continuing to give off heat for several more hours. The fireplace heats up very quickly and heats the room in the shortest possible time, but after the fuel burns out, the heating effect disappears as quickly as it appears.

- Firebox type. The combustion chamber of the stoves is closed with a small blind door, which increases the efficiency of draft and significantly reduces the likelihood of smoke entering the room. Fireplaces use an open firebox, the area of which is usually almost half the area of the façade of the structure. An improperly designed or installed chimney can cause a backdraft that can fill the room with smoke.

- Chimney design. Furnaces use a rather complex configuration of smoke exhaust ducts, thanks to which most of the heat ultimately enters the room. Fireplaces are usually connected to almost straight chimneys, which are practically incapable of retaining heat within the building.

- Efficiency The heat output of heating stoves usually ranges from 60 to 80%, while the efficiency of fireplaces rarely exceeds 50%.

- Decorative properties. A traditional stove is a purely utilitarian design, and it is very difficult to integrate it into the interior (the situation is partly saved by good finishing). A fireplace, even the simplest one, by the mere fact of its presence makes the design of the room more sophisticated.

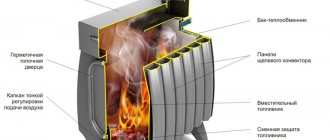

Modern solid fuel boilers and fireplaces with a water circuit combine all the positive qualities of their predecessors, resulting in the following list of advantages:

- Efficiency from 80% (connected with your own hands to a water heating circuit, a fireplace can produce an efficiency of up to 92%);

- The firebox closes hermetically, and the door itself is made of transparent heat-resistant glass, which allows you to look at the live fire;

- The design of the chimney is designed so that the heat transfer of the device is maximum;

- Excellent visual characteristics and a variety of models, allowing you to harmoniously integrate the fireplace-boiler into any interior;

- Relatively light weight - wood-burning fireplaces for a home with a water circuit can be installed on a regular floor (even wood) without installing a separate foundation;

- Small dimensions, which make it possible to use such equipment even in rooms with limited space;

- The ability to combine a fireplace stove with a water heating circuit allows you to maintain a comfortable temperature throughout the house;

- The cost of ready-made fireplace stoves is relatively low when compared with the cost of installing a brick stove or fireplace;

- Simple installation - if you wish, you can install a fireplace stove with a water heating circuit even with your own hands.

PVC installation

If in a country cottage it is planned to install water heating from a brick stove (wood-burning), the heat exchanger is designed individually, for a specific stove. Such a device is practically beyond repair, so for installation a specialist stove specialist is hired who can professionally perform all the work:

- Make a heat exchanger and double check its quality - before and after installation.

- Install the heat exchanger at the required stage (after completing the foundation), then continue laying, observing certain rules. When installing the heat exchanger, compensation gaps are left, leaving 1-1.5 cm to the walls of the combustion chamber. Gaps that take into account thermal expansion are also needed when installing pipes.

- When installing a heat exchanger with pipes and for insulation, use exclusively heat-resistant seals .

Steel pipes for the manufacture of a heat exchanger Source 36doors.ru

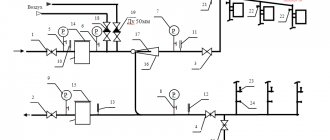

Furnace design with a water circuit

The classic design of the stove consists of a firebox divided by grates into a firebox and an ash pan, surrounded by walls made of brick or metal. When fuel burns, heat is transferred to the premises through radiant heat transfer from the enclosing surfaces of the furnace. The use of furnaces is usually caused by objective reasons:

- Lack of other types of fuel other than firewood and coal, namely natural gas and electricity of the required power;

- The relative cheapness of firewood in many regions of our country;

The main disadvantage of the heating design is the uneven distribution of heat throughout the heated rooms, as well as the cyclic mode of operation of the heating unit. In addition, the ovens are operated manually.

The introduction of a water circuit into the furnace design greatly improves heating performance. A metal heat exchanger allows you to remove part of the heat from fuel combustion and ensure its transportation through a liquid coolant - water or antifreeze.

Furnaces with a water circuit are divided into 2 types:

- Brick;

- Metal.

Brick kilns are built independently or with the assistance of specialists. Metal furnaces are made from steel or cast iron and can be built independently, but this requires professional skills as an electric welder. Moreover, industrially produced models have better characteristics compared to home-made ones - they are made of heat-resistant steels and are carefully calculated by designers.

Brick kilns take longer to heat up, but they also give off heat over a long period of time. In essence, brickwork partially functions as a heat accumulator.

Metal stoves heat up and cool down at a faster rate. Cast iron stoves are more profitable than their steel counterparts in this regard - cast iron accumulates a significant amount of heat.

Heat exchangers for water circuits of furnaces are usually made of steel. Heat exchangers have a wide variety of shapes and sizes and differ in location. In shape, these can be rectangular containers connected by round or profile pipes, coils, registers, and so on. The thickness of the steel for their manufacture is at least 3 – 5 mm.

In brick kilns, heat exchangers are most often placed in the fireboxes. It is not recommended to place devices in areas directly surrounded by flame, especially in furnaces using coal as fuel. The temperature in these areas reaches high values and the service life of the metal will be significantly reduced. Heat exchangers are placed in the edge zones of the flame and along the path of movement of hot combustion products.

In metal furnaces, heat exchangers are often made in the form of water “jackets” encircling the furnace space of the combustion chamber. In essence, stoves with a water circuit are an analogue of a solid fuel boiler.

Heat exchangers are equipped with threaded pipes for connecting heating system pipelines. Smoke removal is carried out using natural draft, that is, the construction of a chimney is required. The amount of combustion air supplied is regulated by a chimney damper and a damper on the air intake.

It is worth noting that to improve heat removal, smoke ducts are sometimes equipped with a labyrinth type or an additional heat exchanger is installed in the chimney duct for DHW or heating needs. In this case, the aerodynamic resistance increases sharply and a more accurate calculation of the parameters of the chimney will be required - and at a minimum, an increase in its height.

In addition to water heating circuits, stoves can be equipped with additional elements:

- A door with fireproof glass - a fireplace stove is created;

- Hot water preparation tank;

- Hob;

- Oven.

With an increase in the number of options, the dimensions and weight of the oven increase, and the cost increases. Some models of factory-made stoves are equipped with heating elements built into the heat exchanger (with the ability to be removed and replaced). Usually they cannot completely cover the entire thermal power of the furnace and serve as an additional or backup heat source.

Tips for setting up the system

At their core, such designs are the progenitors of modern solid fuel boilers. But unlike them, heat transfer is carried out not only through piping and a radiator system, but also from the stove itself.

Plus, installing brick stoves with water heating yourself is much easier and cheaper than installing a solid fuel boiler.

A few words about the register

Without exaggeration, the metal register can be considered the heart of the entire heating system. This design is installed directly in the firebox itself and is responsible for the heating level of the coolant.

Lateral arrangement of registers.

The simplest and most affordable option is to install a rectangular metal tank directly into the firebox. Such a tank is made of heat-resistant steel, with a thickness of 3 mm or more, most often from stainless steel.

To heat a house of 200 m², a tank 750 mm long, 500 mm wide and 300 mm high is sufficient. The outlet is made from the top of the structure, the return line cuts into the bottom of the tank.

Registers welded from stainless steel pipes with a wall thickness of at least 3 mm are considered more functional. In this case, the heating area increases several times, hence the efficiency of the system is disproportionately higher.

Advice: it is not difficult to find cast iron registers on the market now; according to most experts, they are the best option. Firstly, cast iron is little susceptible to corrosion, practically does not burn out, and most importantly, this material is considered the best heat accumulator.

Stainless steel registers.

During installation, pay attention to the location of the register. The more contact with fire, the higher the productivity

But at the same time, regardless of the configuration of the tank, there must be a compensation gap of at least 5 mm between it and the walls of the furnace. Otherwise, during heating, the metal will begin to expand and the walls of the firebox will crack.

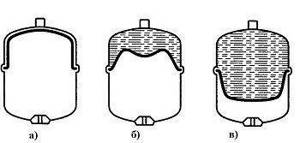

Diaphragm tank

Installing a register into the firebox is only part of the story; it is equally important to properly arrange the piping. Any heating system built on this principle must be equipped with an expansion or membrane tank

As a rule, it is installed on the return pipe, but this is not important; some craftsmen prefer to mount it at the highest point of the system.

Operating principle of a membrane tank.

In a system with natural coolant circulation, its function is performed by an ordinary metal container. But now, in most cases, owners prefer to install circulation pumps. It is advisable to install a real membrane tank in such a system.

The device is a sealed metal container, in the upper part of which there is a valve. Air is forced through the valve, creating excess pressure in the system. As the temperature rises, the coolant expands proportionally, squeezing the excess into the membrane tank. During the cooling process, the air that presses on the membrane compensates for the pressure drop in the system.

Some aspects of laying a furnace

As mentioned earlier, you can build water-heated brick stoves with your own hands, but if you are not confident in your abilities, it is still better to invite a specialist.

Although in any case, there are general rules that it is not advisable to break.

- All brick ovens are made of solid red brick. It is not advisable to use hollow brick even for cladding. The fact is that hollow blocks are a heat insulator, and in this case this can only do harm.

- If you plan to burn with wood, then the firebox can be made of ordinary baked brick. But if there is a possibility of using coke or high-grade coal, such as anthracite, then we would advise making the firebox from special fireclay bricks, which are used in the construction of blast furnaces.

- There is no need to save on wall thickness; in addition to the weight of the oven itself, the load from the registers will also be added here.

- And yet, any stone structure needs a reliable foundation; as for stoves, the foundation should be laid separately and in no case should it come into contact with the general foundation of the house, the minimum distance between them should be 50 - 100 mm.

Circulation pump in the system.

The video shows some of the intricacies of installing the system.

In this case, we were talking about heating a house. But it is worth noting that if a metal water container is inserted into the system in parallel, it will act as a passive boiler, as a result of which hot water will still appear in the house for domestic needs.

Ways to solve the problem

Obviously, in order to heat the coolant and supply it to the radiator system, the wood stove must be equipped with an additional heat exchanger. There are two ways: purchase a ready-made metal or cast-iron long-burning stove with a built-in water circuit for your home, or make it yourself. We initially follow the second path - we put in work, but save money.

There are several types of homemade heat exchangers and options for their installation:

- Tank is a boiler built directly into the firebox or into one of the chimney ducts.

- A register welded from pipes, sometimes in the form of a coil. It is also placed inside the combustion chamber or in the flue.

- Samovar-type heat exchanger (technical name - economizer). It is installed purely on the chimney to extract heat from the exhaust gases.

- Full water jacket. In a simplified version, a similar fireplace stove with a water circuit is shown above in the diagram.

Tank-boiler for heating coolant

The water circuit can be made from the following materials:

- black or stainless steel;

- cast iron;

- copper.

Steel heat exchangers are practical and inexpensive, and therefore the most popular. The price of copper is too high, but the melting point is low, which is why such a structure can “float” when burning coal. As for cast iron, you won’t be able to cast a register from it yourself, unless you install an old MS-140 heating “accordion” into the flue, as shown in the photo. But remember: the battery will instantly burst when cold coolant is supplied to a hot stove or as a result of water freezing during a long period of inactivity.

Some recommendations

It’s not difficult to create a water jacket for a stove with your own hands. And it can already be installed in any stove - metal or brick. Heating a house with wood is fraught with frequent fiddling with heating equipment, but in the absence of gas, other alternatives look more expensive. To implement more efficient home heating, use our recommendations:

- Do not skimp on the thickness of the sheet iron - remember that the service life of the furnace depends on this;

- Be sure to use thermometers and pressure gauges to monitor the operating parameters of the heating system;

- Do not use alternative coolants that are not resistant to high temperatures;

- Ensure that you get rid of heat losses - this will allow you to count on economical use of firewood for heating your home.

These tips will make heating a private home using wood more efficient.

Brick oven

So, as mentioned above, for a small building it is enough to build one stove, which will be heated with wood or coal.

The stove model must be chosen in such a way that it can not only heat the premises, but also be an assistant in cooking.

To ensure that this heating structure does not cause any inconvenience and is as efficient as possible, you need to choose a suitable location for it. A well-placed stove can easily warm two rooms and a kitchen.

Such a stove will successfully heat several adjacent rooms.

For example, this model shown in the figure would be a good option for heating three rooms. You need to know that the heat transfer from the stove depends on the surface area of the building, i.e. if one side of the stove opens into the room, it will be fully heated. In addition, the massive structure takes much longer to cool down. By heating the building in the evening, you can be sure that it will transfer heat into the room until the morning.

The stove must be laid during the construction of a house, but its foundation must be separated from the general foundation of the building. It is possible to install a brick stove in an already built house, but this will be more difficult, since you will have to raise part of the floor and make a hole in the ceiling and roof to install a chimney.

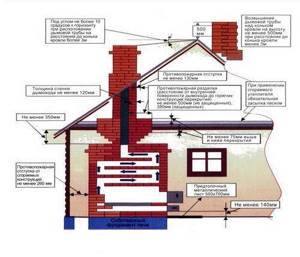

General diagram of a home stove heating system

This diagram clearly shows the structure of the building, the structure of the foundation, the chimney channels and the passage of the pipe through the floors with all the necessary parameters that must be adhered to.

Types of air heating

Heating can be organized in various ways. The main difference lies in the principles of air distribution, of which there are three:

- Direct heating from the oven

. - Natural

. Air ducts are stretched into the heated rooms, through which air from the heating equipment enters. Such a system is also called gravitational. - Forced

. The air duct system can be additionally equipped with fans, which speeds up the heating process.

In the second and third cases, air ducts are located in all rooms, and warm air enters the system directly through the casing of the heating device.

The main advantage of the gravitational system is its energy independence. But there is also a minus - any draft from an open door or window disrupts the natural circulation of air.

By installing fans in the air duct system, it is possible to make heating more controlled and efficient. At the same time, air intake can be done both from the street and from the room.

Depending on the location, such a heating system can be of two types:

- Floor-standing

. This type is suitable for installation in private homes and country cottages. Air ducts are hidden under the floor or in baseboards. In this case, warm air is supplied at foot level, which ensures comfort for residents. - Suspended

. This system is installed in commercial and industrial buildings. Pipes for supplying warm air are fixed to the ceiling or in the ceilings and masked with finishing panels. In this case, the air may cool down before reaching the floor.

The costs of an air heating device include the cost of the furnace and system elements, as well as design and installation work for installing ventilation ducts.

In modern air heating systems, the most important part is the furnace.

DIY oven

Construction of the furnace begins with the construction of the foundation

It is important that it is not tied to the foundation of the house. To do this, a concrete screed is poured into the ground; its height should not exceed the floor level by more than 5–7 cm. Only after this can the construction of the structure begin

Only after this can the construction of the structure begin.

- The first rows of the ash pan are laid in accordance with the selected pattern.

- Next, the blower door is installed and the structure is lined with brick. The door should be made of cast iron, measuring 19.5 x 24 cm.

- The combustion chamber is made in a similar way.

- It is preferable to install a ready-made chimney with a round cross-section.

It is advisable to use refractory fireclay bricks for the ash pit and combustion chamber. For cladding, you can choose ordinary sand-lime brick, as it has good heat capacity.

Furniture items

A few examples of furnishing a kitchen combined with a living room:

- 1. Sofa. It becomes an object that zones space. The sofa is placed with its back facing the place where food is prepared. In small rooms (less than 20 sq m) a corner is placed, which is placed against a wall installed perpendicular or parallel to the kitchen.

- 2. Set. According to designers, minimalist models without elaborate details look modern. The service, vases or glasses are placed on an open shelf. You can buy a fashionable display case for them. Furniture is placed near the wall. If the space is large (20 sq. m, 25 sq. m or 30 sq. m), then in the central part you can install an island, which also has sections for kitchen appliances.

- 3. Furniture set. The style should be combined with the design of both rooms. In small rooms, a compact table and chairs made of transparent material or painted in light colors look good. You can add a table with a round top to your living room interior. In spacious rooms, the kit is installed near the wall or in the central part. An elongated rectangular dining table would look good here.

Advantages and disadvantages of air heating of a private house

Experts name several main arguments for installing and maintaining air heating in residential premises:

- You can safely leave the house unattended during the cold season - the air will not freeze in the pipes like water. When you return, you will only need to light the stove; no additional effort is required.

- Constant air circulation speeds up the heating of rooms and makes it more uniform. A properly designed system can have an efficiency of up to 90%.

- Beautiful interior and maximum amount of free space without radiators and pipes. The air ducts are installed in a hidden way.

- You can independently adjust the temperature in each room if you install thermostats.

- During the warm season, you can install an air conditioning system and supply cold air through the duct.

However, there are also nuances that must be taken into account if you decide to opt for air heating:

- The system must be installed at the construction stage; technical niches are left for laying air ducts.

- If the system has fans, then the house must have a stable source of electricity. Do you experience power outages periodically? Then it’s worth purchasing a backup generator.

- Filters in pipes must be changed periodically, and the system must also be regularly inspected and tested.

This type of heating dries out the air. To solve this problem, humidifiers are used.

Classic long-burning boiler

To make a classic-looking boiler according to the prepared drawing, it is enough to follow simple assembly and connection instructions.

Tools and materials for manufacturing

To create you will need:

The material for the manufacture of the case is metal. This could be a barrel or sheet metal. Its thickness must be strictly more than five millimeters.

If you have an old metal stove, you can use its body.

Sheet steel

- Pipes made of steel or aluminum alloy. Pipes with particularly thin walls should not be used.

- Profile pipes. They usually have a rectangular cut shape.

Profile pipe

- Doors, dampers, latches.

- Fan power 300 W or higher.

Fan

The rod is from 2 cm in diameter. It is not worth taking a particularly massive and large one, but less than 2 cm in diameter will also be unsuitable.

You will need a variety of tools. Among them are a welding machine, various cutters, polishing units, hammers, pliers/pliers. In some situations, saws may be needed, sometimes even the use of a crowbar or pry bar is required. All this must be prepared for work before it begins.

Air supply device

Typically, the boiler design involves supplying air through a compartment in the housing. If the option that is manufactured in relation to the drawing made does not suggest this, the air supply device is manufactured separately.

Typically this device is a regular tube connected to a combustion chamber. It should be slightly lower than the chimney, in some cases it is cut obliquely in order to improve circulation.

The cut edges for fastening must be aligned so that soldering the parts to each other does not cause difficulties.

Housing, firebox

The boiler body, as already mentioned, can be a thick-walled barrel. You can also successfully use a piece of wide pipe (about a meter in diameter is required). In the absence of such “blanks” in stock, the body is made of sheet metal, steel is mainly used.

The bottom of the boiler is a separate part. In the case of barrels it is compacted; for pipes and steel casings it is done proportionately, the thickness should be at least 5 centimeters.

All walls are soldered together relative to the drawing, and a steel bottom is soldered to them. Partitions are required to separate chambers and different compartments.

All water tanks are manufactured separately. Doors, plugs and supports are installed after the entire structure has been assembled and is fully ready for operation.

Chimney

A chimney is required to allow gases that interfere with combustion to escape. It is required to be connected to the combustion chamber, just like the air supply device.

To make a chimney, you can use a narrow pipe. Ideally, it should be the same diameter as the air supply tube. Naturally, it is required that it be metal. Plastic pipes should not be used in a wood-burning system due to their low heat resistance and the possibility of melting. This will lead to unpleasant consequences and so-called accidents.

The chimney must be higher than the air supply pipe. It is also sometimes cut obliquely for better air circulation.

Connecting the housing and the air supply device

The air supply tube should be placed in the chamber, cutting out the appropriate hole, and soldered to the boiler. If desired, you can use special fasteners.

This kind of work needs to be done carefully.

Heat Dissipation Disc

A circle is cut out of a sheet of metal about a centimeter thick, onto which handles are attached. The diameter of the circle should be less than the diameter of the body.

Such a disk is required to simplify further operation of the boiler.

Convection hood

A cylinder will be required for the casing. It can be made from pipe or sheet steel. The casing and firebox are connected using metal bridges. You can avoid using metal jumpers and simply solder the casing to the firebox. Efficiency will not be reduced.

Lid

The lid is a fairly simple part. A circle or rectangle is cut out (depending on the shape of the body), which is slightly larger in size than the firebox. A handle is soldered to the lid.

Legs

As legs, you can solder supports made of rod

It is important to maintain the same size so that the boiler is stable. It would also be a good solution to solder the legs at an angle to the outside - this will increase stability, because will shift the center of gravity slightly

will shift the center of gravity slightly.

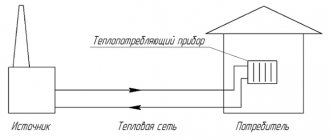

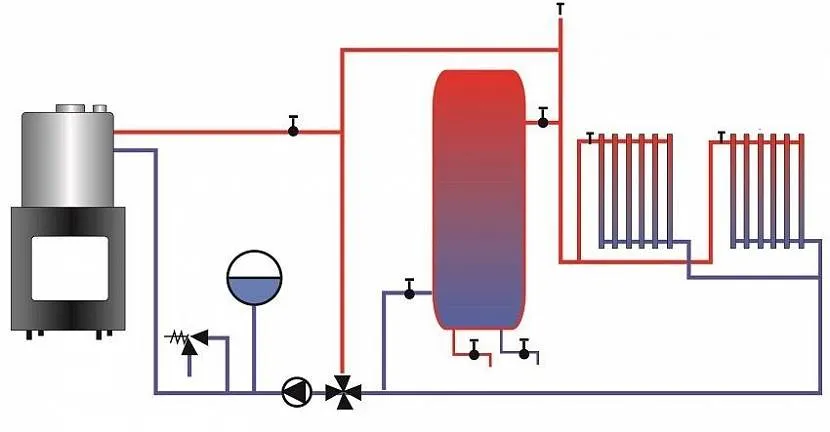

Operating principle of a water heating system

Such a system can work in two ways:

- Based on natural (gravitational) circulation of water . Natural circulation of water becomes possible due to the fact that the specific gravity of cold water is greater (it is heavier) than hot water. Such a significant difference allows cold water, which has given up heat and flows through the pipes to the heat exchanger, to displace hot water into the heating circuit. The main condition for organizing such a system: the entry point of cold water into the heat exchanger is designed below the exit points from the radiators. In order for the condition to be met, they try to place the heat exchanger as low as possible, often in the basement.

Diagram of a closed heating system with a storage boiler Source petrenco.com

- Based on forced water circulation . In private buildings with an area of more than 80-100 m2, the natural circulation system becomes ineffective - it takes a long time to warm up and is poorly regulated. The problem is solved by installing a circulation pump in front of the heat exchanger. It ensures constant movement of water along the circuit, allows you to flexibly regulate pressure and quickly increase or decrease the heating temperature. Depending on the model, the pump may have different dimensions, be integrated into the circuit differently and produce noise of varying degrees.

Where to start making hives

To make a beautiful frame hive, you need to follow the instructions below step by step. In this case, all stages will be extremely simplified and understandable. And the result will please not only the owner of the network, but also the insects themselves.

Selection of materials

It is necessary to understand the features of each material for a bee house:

- Wood is quite a comfortable material for the bees themselves. But dampness and mold can develop on it. It is necessary to take measures to process lumber, covering them with antibacterial compounds that are safe for both humans and insects. The bottom can be gnawed by mice looking for food in the bee house. To avoid this trouble, the bottom is reinforced with metal mesh.

- Synthetic hive bodies are quite common. Their advantage is the low weight of the entire structure, even when the size of the hive is quite impressive.

- You can often find a wooden body that is insulated with foam plastic. This is necessary in order to provide the required level of insulation in winter and keep the entire family of insects intact.

Necessary tool for making

In order for the hive structure to be implemented taking into account all the technological features, it is necessary to acquire tools that will help in the assembly process:

- Ruler and flexible tape measure.

- Squares for distributing the perpendicularity of the sides.

- Metal corners for fastening elements.

- Screwdrivers or screwdrivers.

- Self-tapping screws and nails.

- Hammer.

- Saw or hacksaw.

Design and rules for placing a home heating stove

The design features can be anything, but the main work in them follows one principle - to burn wood to get heat.

The equipment comes standard:

- firebox - the place where the fuel will burn;

- ash pan - a chamber for collecting ash;

- grate - a small grate on which firewood will lie during combustion, ash also escapes through it;

- chimney - needed to remove accumulated gas;

- smoke damper - with its help, the pipeline is blocked and retains heat inside.

When choosing a space to install any model, several factors need to be taken into account:

- It is advisable not to place the stove near an external wall - the street will be heated;

- do not place it opposite the exit or doors to another room - a draft will interfere with normal operation;

- the best place for placement is in the wall between rooms;

- installation must take into account all fire safety rules and SNiP.

Long burning stoves

Under any circumstances, a long-burning stove will be an excellent solution for heating your home. If the classic version requires adding firewood every 2 or 3 hours, then this model does not require attention for up to 6 hours. There are modern stoves in which fuel burns continuously from 8 to 20 hours.

Such furnaces have large combustion chambers into which large amounts of fuel can be loaded. The intensity of the stove operation is regulated by a damper in the chimney or using the blower door. The combustion chambers are made airtight, and the fuel in them smolders slowly.

This is very convenient, because after loading a portion of firewood you can go about your business. At night there is no need to get up and add firewood - such stoves will ensure a restful sleep. There are models that work with water circuits, so they can heat several rooms at once.

Pyrolysis furnaces are even more efficient, their efficiency is maximum.

Integrating a stove into an existing heating system

If you already have a heating system that has previously been used with a different type of heating, you can connect a furnace to it. For example, it can become a replacement for a gas boiler.

Modern heating equipment usually does not contain a heating tank. But, it has a heat exchanger that performs a similar function.

The cost depends on a lot of factors - material, size, efficiency, maximum permissible heated area, etc. Moreover, there are models that allow not only to heat the house, but also to provide a full-fledged hot water supply system.

Factory stoves usually allow the use of both classic wood and coal, and pellets, which is a compressed wood material used as fuel.