Difference from classic stoves and operating principle

The main difference between long-burning stoves and conventional stoves is the rate of combustion of wood: in a conventional stove, the firewood completely burns out in 3-4 hours , and in “long-term” stoves the combustion process can last up to 10 hours .

The operating principle is based on pyrolysis - a smoldering process during which high-temperature flammable gas is released and collected in a special chamber. It is the combustion of this gas that provides high heat transfer, which does not require the combustion of additional fuel.

Firewood is placed in the furnace firebox, which must be allowed to burn. After which, the air supply is limited using stove dampers, which transforms the combustion process into a smoldering process.

Required materials and tools

Before you start building a long-burning stove, prepare the following materials:

- a two-hundred-liter barrel of fuel and lubricants. It is advisable to choose a container with thick walls, without damage or heavily rusted areas. As a housing, you can use a pipe of a suitable diameter or a propane cylinder (household 50 l or automobile 80–100 l). In addition, the stove can be made from sheet steel with a thickness of at least 3 mm;

- a metal pipe with a diameter of at least 60 mm - for arranging an air channel;

- steel pipe with a diameter of 100 mm - for the manufacture of a chimney;

- steel channel or corner with a shelf 50–60 mm;

- a sheet of metal 5-6 mm thick, slightly larger than the diameter of the body - for the manufacture of an air distributor;

- a steel sheet with a thickness of at least 3 mm, which will be required to make the lid;

- hinges for the bottom door.

As for the tools, any self-respecting home craftsman will have them:

- welding inverter or transformer;

- angle grinder (popularly “grinder”);

- cleaning and cutting wheel for angle grinders;

- electric drill;

- a set of drills for metal work;

- hammer;

- anvil;

- measuring and marking tools.

If the design of the heating unit provides for the arrangement of a water circuit, then it is additionally required to stock up on sheet steel and two threaded pipes for inserting the boiler into the hydraulic heating system.

Pros and cons of heating equipment based on the principle of pyrolysis

Before installing a long-burning stove, it is necessary to carefully evaluate all the advantages and disadvantages of these devices.

Advantages:

- Cost-effective and higher efficiency compared to conventional wood-burning stoves. Depending on the design of the stove and the type of firewood, the efficiency can be 75-85% .

- Compact dimensions and light weight.

- Easy to install. To install such a furnace, pouring a concrete “cushion” is not required.

- Reduction of harmful emissions resulting from conventional combustion.

- Duration of burning - one “bookmark” can smolder for up to 8-10 hours , continuously warming the room.

- Aesthetic appearance and wide range of models.

- Wide range of fuels. In addition to firewood, these devices can operate on pellets or coal.

Flaws:

- Demanding requirements for sizing. If the chimney is installed incorrectly, the draft force will not reach the required level.

- Constant formation of condensation in the chimney, requiring regular cleaning of the chimney.

- Difficult to use. Adjusting the air supply to achieve the desired combustion intensity requires certain skills; the first time you use it, it will be quite difficult to achieve the desired result.

- During the operation of the furnace, it is necessary to constantly monitor the intensity of the air supply to the firebox.

- Demanding on the quality of the fuel used. When laying undried firewood, the combustion intensity will be less, and a layer of soot will quickly form in the chimney.

Step-by-step instructions for making a long-burning stove with your own hands

1. To make the stove body, use a grinder, which is used to carefully cut off the top of the metal barrel. Of course, in the case of using a container with a thickness of more than 3 mm, the use of a gas cutter will be more justified. We remind you once again that the work must be done carefully - the furnace lid will be made from the cut part in the future. If a pipe is used as a body, then it is necessary to weld a bottom cut from sheet metal 5–6 mm thick to it.

When cutting off the cover, remember that this element will be needed later

2. In the lower part, four legs from a channel or angle are mounted to the body using a welding machine. Note that if the body is made of metal and has a rectangular shape, then you can do without additional supports.

One of the options for arranging support legs

3. Using the same grinder or autogen, an air distributor is cut out of sheet steel 5-6 mm thick - a circle that can fit into the barrel with a small gap. The edges of the metal pancake must be thoroughly cleaned to prevent the possibility of touching the walls of the oven.

4. A hole with a diameter of 20 mm is cut in the center of the air distribution device and a pipe is welded to supply air to the combustion zone.

The blades of the air distribution device are mounted at the same distance

5. On the back side of the flat piston, four sections of a channel or angle are welded, evenly positioning them in a circle. Note that the blades should not protrude beyond the air distributor. In the future, thanks to these elements, there will be an air gap between the metal pancake and the firewood, which is necessary for fuel combustion.

As a result, the air distribution device should look like this

6. A lid is made from the previously cut off top of the barrel. To do this, a metal strip is welded from the outside along the entire contour so that its diameter allows the top of the stove to be freely installed on the body.

Making the lid

7. A hole is cut in the lid, 3–5 mm larger than the diameter of the air duct pipe. In addition, two handles made of strips of metal are welded onto its top. With their help, it will be easier to open the hatch for loading fuel.

8. A hatch for cleaning the oven is cut out in the lower part of the body. Try to do this part of the work using a grinder with a thin circle installed. This will ensure a more precise fit of the door to the body. A thin metal strip is welded along the perimeter of the hatch to eliminate the resulting gap. Then the hinges are welded, the structure is installed on the body and the valve is mounted.

9. On the other side of the stove, at a distance of 50–100 mm from its upper cut, a smoke exhaust pipe is cut in. It is used as a piece of steel pipe, into which the chimney will fit with a slight interference.

Installation of a smoke exhaust pipe

It is better to use a chimney of a collapsible design, consisting of several sections - it will be easier to clean during operation.

At this point, the production of a vertical-type solid fuel unit can be considered complete. All that remains is to install the stove in place and connect the chimney.

Long burning stove: final version

Types of stoves. Design Features

The basic design of a long-burning furnace consists of:

- Cast iron or steel body.

- Two combustion chambers - the primary one, where fuel combustion occurs, and the additional one (afterburning chamber), where gas is burned, generating heat.

- Dampers that regulate the oxygen supply and smoke output.

- Chimney.

Today, there are several types of long-burning furnaces, differing in design features:

- Furnaces with a water circuit.

- Ovens with an additional cooking surface.

- Tube furnaces.

- Long burning fireplaces.

Furnaces also differ in the duration of fuel combustion:

- Models with fast burning - firewood burns out in 3-4 hours .

- Models with average combustion duration - the process will take 6-8 hours .

- Models with long burning - 8-10 hours .

What types of fuel can be used

When it comes to the heating system for a temporary premises, such as a workshop or garage, two aspects are usually taken into account - economic feasibility and safety. In terms of economic feasibility, the most affordable type of fuel today is wood.

Liquid fuel, such as diesel fuel or used engine oil, is used for heating mainly utility rooms; in residential areas, the use of this fuel is limited because it has a specific odor. Coal is usually not used for long-burning furnaces of handicraft production; it is intended for heating boilers and stationary brick furnaces.

Thus, the most acceptable type of fuel is firewood or pallets - fuel from wood processing waste. And here lies the whole secret of long-burning furnaces. The fact is that to get maximum effect you need to use only dry firewood. In ordinary, freshly cut firewood, the wood contains a large amount of moisture; during combustion, it turns out that two processes occur in parallel - burning of wood fibers and drying, releasing a large amount of water vapor. The result is a large amount of unburned fuel and combustion at a low temperature. These processes do not allow obtaining the maximum amount of heat.

It's a different matter with dry firewood. The moisture content in them is minimal, which means that when the temperature rises to 300 degrees, the process of decomposition of wood into simple substances begins. This allows you to significantly increase heat transfer, as a result of which the firewood burns completely with minimal formation of soot and ash.

How can you reduce wood consumption?

The efficiency of “long-lasting” stoves largely depends on the quality of the fuel and the experience of the stoker. To avoid mistakes when burning, reduce wood consumption and achieve maximum efficiency, there are some useful tips:

- Carefully place the logs on the kindling, leaving a small space between them.

- It is better to pack large logs tightly deep into the firebox and leave the kindling near the door.

- Use only dry firewood. Damp logs will take a very long time to burn and will require more kindling, which will lead to a decrease in efficiency.

- You should not “check” the firebox by constantly opening the door. As soon as the wood is lit, close the door tightly - this will ensure the required level of draft.

How to correctly calculate power

The power of a long-burning stove is easy to calculate. Most manufacturers indicate how much area each oven can heat. For example, the “Fire-battery 5” model is capable of heating a room up to 100 m2 .

When calculating power yourself, keep in mind that 1 kW equals approximately 12 m2 . If the calculation is carried out for several rooms, then the power must be selected for the total area of all the rooms that are supposed to be heated.

Which oven should you choose?

Today you can find drawings and diagrams of long-burning furnaces of a wide variety of designs, sizes and performance. However, how effective will the chosen homemade equipment be, and where can it be used? Experts answer this question as follows: a homemade pyrolysis oven made from scrap materials is perfect for non-residential premises. However, it will be low-power and short-lived.

For residential premises, not only aesthetics are important, but also performance

In this case, you need to pay attention to the potbelly stove in a modern modification. Its modified air duct and water jacket will allow you to heat a room up to 25 m

sq. area To increase productivity and heat a larger house, the size of a long-burning stove cannot be increased. To solve this problem, they opt for brick pyrolysis units. Thematic video on how to make a potbelly stove with your own hands:

https://youtube.com/watch?v=aaTdm42jR1o

Some installation recommendations

Installing a long-burning stove does not cause any particular difficulties. For proper installation, just follow simple rules:

- Use a refractory sheet as a “substrate” for the oven. It is important that the edges of the sheet extend beyond the stove, creating a “mat” in front of the firebox.

- Do not install the structure close to walls. The optimal distance between the stove and the wall is about 20 cm . this will ensure a uniform flow of air and prevent heating of the wall surface.

- To ensure sufficient draft force and prevent blockages in the chimney, its cross-section must be at least 15 cm .

- The chimney must be installed while maintaining access to it. It is best to make a collapsible chimney - this will make cleaning the chimney easier.

- It is best to install the chimney against the movement of gases. This will protect the floor from condensation that settles on the walls of the pipe.

Rules for safe operation

The safe operation of long-burning stoves is based on several rules:

- Install the stove correctly to prevent smoke and accidental fire.

- Before firing for the first time, be sure to check the tightness of the structure. To do this, it is necessary to put a quick-burning material into the firebox that emits a large amount of smoke. If the seams are not sealed, smoke will leak out of the cracks during combustion.

- Clean the chimney in a timely manner and empty the ash pan of accumulated ash.

- Do not store flammable materials near the oven.

- Always close the firebox door tightly, otherwise carbon monoxide will enter the room.

- Use fuel recommended by the manufacturer. Remember - the use of liquid fuel is unacceptable for all long-burning stoves.

What to look for when choosing

Choosing the right stove will provide you with comfort and coziness in your home, eliminating problems with additional heating. However, in order not to make a mistake in choosing, you should pay attention to the following characteristics of the stove:

- Functional purpose . If you need a stove only for heating, you can purchase a regular “long-lasting” stove, but if you plan to use it as a stove or design element, it is better to opt for fireplace stoves or heating and cooking models.

- Power . The maximum volume of the heated room depends on this indicator.

- Material . Most of these stoves are made of cast iron or steel. Steel models are lighter, and cast iron models are less susceptible to deformation due to exposure to high temperatures.

Stove options that are in high demand. TOP-7 domestic market

The most popular models of long-burning stoves are:

Canadian Buleryan stoves are pioneers of technology

These are products of the Canadian company of the same name, which are widely used in North America and European countries.

The first working prototype was created by Eric Darnell in 1975 . The man noticed the low productivity of a conventional wood stove and improved the design by installing a fire-resistant metal pipe.

The modernized furnace gave excellent results, so Eric, together with two partners, founded the FREE FLOW company and set up mass production.

5 years later , entrepreneur Erhard Knofler, a German by birth, saw such a stove in one of the Canadian bars. The businessman saw great potential in this, so he bought all the rights to the invention and founded the ENERGETEC company and registered the BULLERJAN trademark.

The company operates to this day, with its head office located in the German city of Iserhagen.

Currently, the manufacturer's lineup looks like this:

- Type 00 – power 6 kW , intended for rooms with an area of 100 m2 . Weight: 57 kg .

- Type 01 – power 11 kW , heated area 200 m2 . Product weight – 108 kg .

- Type 02 – capacity 18 kW , heats rooms up to 400 m2 . Structural weight – 130 kg .

- Type 02M is a modernized version, with a power of 24 kW and a heated area of 500 m2 . Stove weight 145 kg .

- Type 03 – power 27 kW , heating area 600 m2 . Weight: 169 kg .

- Type 04 – 35 kW , which allows heating 1,000 m2 of living space. Weight: 215 kg .

It should be noted that the above models differ not only in weight and performance, but also in the diameter of the chimney. This parameter varies between 120-200 mm . An interesting solution is the Aqua stove, complemented by a water circuit.

It is permissible to use all types of fuel with the exception of coal. They are characterized by high efficiency, heating the room in 10-15 minutes . There are both standard “Buleryan” and models with a water circuit or hob.

"Breneran" - a domestic version of an overseas stove

This is the Russian analogue of the previous model. The equipment has been produced since the mid -90s of the last century, but the Breneran trademark was registered only in 2000 .

The equipment is produced using European technologies, therefore, in fact, it is an exact copy of BULLERJAN products.

The manufacturer's lineup is represented by the following stoves:

- AOT-6 – productivity 6 kW , heated area 40 m2 . Weight: 56 kg .

- AOT-11 – power 11 kW , heating area 80 m2 . Weight: 105 kg .

- AOT-14 – power 14 kW , heating area 160 m2 . Weight: 145 kg .

- AOT-16 – productivity 27 kW , useful area 240 m2 . Weight: 205 kg .

- AOT-19 – productivity 35 kW , heating area 400 m2 . Weight: 260 kg .

Products can be equipped with glass doors; models marked AOTV can be connected to a water circuit.

The main disadvantage of the Russian analogue is the insufficient tightness of the smoke fitting, due to which condensation can enter the room. There are models with the ability to connect water heating.

"Professor Butakov" - aesthetic, powerful and reliable models of furnace equipment

Unlike "Brenerans" they have a more attractive design. They have a large number of air ducts installed in the housing, which allows you to regulate the oxygen supply as accurately as possible.

The main disadvantage of Butakovs is the absence of a condensate collector, which complicates cleaning the chimney.

A patented development by Polytechnic University professor Sergei Efimovich Butakov. Products manufactured under this logo have a state certificate; all models have passed “field” tests in regions with harsh climatic conditions.

Taking into account the main specialty of the inventor, Professor Butakov ovens are presented on the market in the following varieties:

- Student. Product performance is 9 kW , which makes it possible to maintain a comfortable temperature in rooms with a volume of up to 150 m3 . The weight of the stove is about 70 kilograms , the capacity of the firebox is 20 liters .

- Engineer . A power of 15 kW heats interior spaces up to 250 m3 . Product weight 113 kg , firebox capacity: 40 l .

- Assistant professor. The furnace is designed for rooms of 500 m3 , nominal capacity 25 kW . Weight 164 kg , capacity: 200 l .

- Professor . Quite a large product, capable of heating 1,000 m3 of internal space. The stove's output is 40 kW and its weight is 235 kg. Firebox volume: 500 l .

- Academician _ Heats 1,200 cubic meters of internal space, maximum power – 55 kW . Firebox capacity 700 l , weight: 300 kg.

All models are distinguished by a reliable design, create a long-burning effect, and have the ability to be controlled.

Termofor. Traditional source of warmth and comfort

Domestic manufacturer with an amazing history. The development of the company began with the invention of a group of engineers from the Novosibirsk aircraft manufacturing enterprise.

Test samples immediately attracted the attention of the public, so a decision was made about mass production.

In 2000, the Termofor trademark was registered, which belongs to the production company. Currently, the following models are produced under this brand:

- Germa.

- Cinderella.

- Indigirka.

- Normal.

- Fire-battery.

The stoves are designed for heating rooms with a volume of 50-250 m3 , power varies between 4-13 kW . Many products are equipped with doors made of heat-resistant glass and have hobs.

VIRA is one of the simplest and most affordable offers

The history of the enterprise began in 2011 , when the Berezovsky Machine-Building Plant launched mass production of long-burning stoves Gori Yasno.

In 2015, a structural unit began operating, which registered the Vira trademark. Currently, the manufacturer's lineup includes about 100 stoves . Let's get acquainted with the most prominent representatives of the series.

- VIKING 150 . The furnace power is 8 kW , the heated volume of the internal space is up to 150 m3 . The weight of the product is 70 kg , there is a hob made of cast iron.

- LEGION 160 . Capacity 8 kW , designed for rooms with a volume of up to 160 m3 . Model weight: 61 kg .

- LEGION 200 . It efficiently heats interior spaces up to 200 cubic meters . Model power 10 kW , weight: 78 kg .

- LEGION 240 . Designed for residential premises of 240 m3 , productivity 12 kW , weight: 75 kg .

All models can be used for cooking and have combustion controls.

Teplodar - reliable and structurally simple models

appeared in 2003 after the reorganization of Narva LLC. Having accumulated experience, the company immediately launches about 20 models of wood-burning stoves into mass production.

The model range is constantly being improved and expanded, the manufacturer becomes a prize-winner at international exhibitions. Currently, the company's products are successfully sold in all regions of Russia and are expanding into the foreign market.

The model range is represented by the following series:

- T

- Pechurka

- Top

- Matrix

- Meteor

- Vertical

The products are designed for heating rooms with an internal volume of 50-300 m3 . All products are maintenance-free and easy to use. The stoves maintain combustion for up to 8 hours and have an attractive modern design.

Choosing a long-burning stove

Long burning brick stove

If you plan to live in a country house (dacha) all year round, then you should pay attention to long-burning stoves for the house, made of brick (stone). They have the greatest durability, high heat transfer, are safe and versatile.

The optimal material is red clay brick. It not only withstands very high temperatures, but during the firing process it acquires the ability to absorb moisture. The design “breathes”. Due to this property, the required air humidity is maintained in the room. The most popular are wood-burning and long-burning coal stoves.

Design disadvantages include:

- the need for a supply of firewood or coal, which affects the cleanliness of the room;

- the mandatory presence of a solid foundation, the presence of which should be considered at the stage of designing a house;

- high cost (design, masonry, maintenance).

If a country house is used only from May to October and only occasionally in winter, then installing stone heaters, which require lengthy installation and serious preparatory work, is impractical. In this case, the choice is ready-made factory designs, the choice of which is significant on the market.

Long-burning metal stoves

Long-burning steel stoves (modern potbelly stoves) can be made from either a box or a barrel. A prerequisite is the presence of a chimney with a diameter of 80 to 150 mm. On the sides of the structure, protective screens made of fire-resistant materials are used.

Metal structures have a lot of significant advantages and just as many serious disadvantages over their brick counterparts. The advantages of metal heat-resistant units include:

- high efficiency (up to 90% versus 70 for brick);

- low price (the cost per unit of heat output is tens of times less than that of brick);

- mobility, relatively low dead weight (the weight of small long-burning stoves is a little more than 10 kg);

- dimensions (the dimensions of mini long-burning stoves do not exceed 0.4 m in any parameter);

- rapid heating of the room;

- do not require special maintenance (accelerating furnaces, etc.);

- duration of operation on one stack (gas-generating furnaces with very long combustion operate for up to 3 days);

- Obtaining a fire certificate is a fairly simple procedure.

Problem areas include:

- metal does not “breathe”, which requires additional care to maintain humidity in the heated room;

- high risk of fire and injury (the metal becomes very hot during the combustion process);

- high heat transfer has a downside - rapid cooling;

- not very long service life (rarely used for more than 20 years).

Long burning cast iron stoves

Cast iron is a metal, but its properties are strikingly different from heat-resistant steel. It is much more fragile, which makes cast iron similar to ceramics. Low thermal conductivity for metal, which is combined with good heat capacity. These properties determine the thickness of the cast iron walls (ranging from 6 to 25 mm).

Cast iron, like other metals, does not “breathe”, but its chemical resistance is close to that of ceramics. The optimal use of cast iron heaters is small poultry houses, rabbit hutches, greenhouses, etc.

Long-burning fireplace stoves

Wood burning stoves and fireplaces are becoming increasingly popular. The advantages are obvious:

- affordable cost;

- device design that fits perfectly into any interior;

- possibility of aggregation with a hob.

It is not advisable to consider a fireplace stove as the only source of heating for a home. Its thermal power is inferior to a long-burning wood stove.

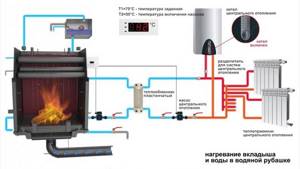

Long-burning furnaces with a water circuit

Using a water circuit allows you to heat the room where the heating device is located and other rooms of the building. This is achieved due to the ability to heat large volumes of water and due to the design features of long-burning hot water furnaces.

A technological feature is the presence of a water jacket surrounding the combustion chamber. The heated coolant circulating between the double walls of the firebox enters the heating system of the house. Long-burning water furnaces are divided into two main types:

- with a closed expansion tank;

- with an open tank.

The presence of a circulation pump allows you to move heat over significant distances. Manufacturers warn that long-burning stoves with water heating cannot be used to create a heated floor system.

Long-burning gas generator furnaces

Fireplaces, long-burning potbelly stoves, cast iron fireboxes (i.e. structures using the convection principle) are excellent for organizing a temporary heating system. Such heating devices, equipped with two chambers that process pyrolysis gas, are called gas generators. The main difference between the designs is the presence of a heat exchanger. The latter is a set of pipes surrounding the combustion chamber.

The specified system is excellent for baths (saunas). The best option would be to create a bathhouse project using a long-burning stove with a heat exchanger.

Economical long-burning stoves

One of the main advantages of modern fireboxes is their unique efficiency. Thus, a structure that runs on wood requires one laying of a small bundle and functions continuously for up to 2-3 days. Calculations show that an economical heating device consumes fuel several times less than its analogues. A long-burning pyrolysis furnace saves up to 70% of fuel.