Purpose and areas of application

Tee , as a special part of pipeline fittings, is a type of fitting and is designed to create branches from the main line in order to mix or separate flows of the working medium. Using this element, steam, gas or other carrier is also supplied to the main pipeline. The tee is mounted on the main pipeline, a branch is created in one direction. These parts are used in almost all industrial and domestic lines; in terms of material, they must correspond to the products of the main fittings. Steel tees are mainly used for transporting gas, steam, water, oil and other substances. Their use is possible in highways operating in temperature conditions from minus 70 to plus 450°C and high humidity.

The materials used for the manufacture of steel tees in accordance with regulatory documentation are various grades of steel:

- Art. 20 (carbon-containing structural);

- Art. 09G2S (low-alloy structural);

- Art. 12Х18Н10Т (cryogenic structural);

- Art. 10Х17Н13М2Т (corrosion-resistant);

- Art. 15Х5М (heat-resistant alloy).

Steel for making tees can be processed in various technological ways. For example, a metal can be coated with various polymers or plastics on the outer surface to increase resistance to environmental influences or on the inside to improve the anti-corrosion properties of the part. trinik-10

The choice of material is determined by the aggressiveness and corrosiveness of the working medium, the material of the pipeline itself, and the operating conditions created in the pipeline. It must provide tightness, high reliability, long operating time, safe installation and operation, ease of maintenance and have an optimal cost.

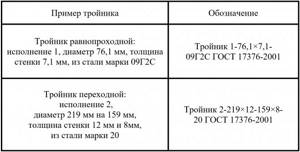

The main regulatory document on the production and technical characteristics of steel tees is GOST 17376‑2001. Products manufactured using it are operational in the temperature range from minus 70 to plus 450 ° C and pressure up to 16 MPa. Tees are produced in sizes suitable for pipes with a nominal diameter of 15-1600 mm and a wall thickness of 2-22 mm.

How to choose the right product

Products with different branch angles

Before purchasing polyvinyl chloride tees and other parts, draw up a preliminary diagram of their location and clearly determine the dimensions so as not to make a mistake in the choice. Pay attention to the following features:

- The plastic plumbing tee is suitable only for pipes made of polyvinyl chloride.

- The cross-section of the fitting and the diameter of the pipe must match.

- You should decide in advance on the angle of the branch, taking into account the pipeline layout.

- The device must come complete with an o-ring.

- If the product will not be used for some time, you should use a special plug.

Parts made of polyvinyl chloride are suitable for installing not only internal, but also external sewage systems.

Types of tees by configuration

The design feature of all tees is that the working flow can only be diverted at an angle of 90° with respect to the main pipeline.

Two types of steel tees have been designed and widely used in production:

- transitional;

- equal passage.

Transition tees are most often used in industrial manufacturing plants. They have different diameters of passage holes at branch points and allow connecting pipe sections of different diameters.

Equal bore tees, respectively, have the same diameters of holes in the places where pipes are connected, and are mainly installed in local pipelines and in household communications.

Corner fixtures

The corner fitting for plastic pipes effectively solves the problem of turning the line. The angle mechanism not only turns, but also protects the system from stress and tension. Such devices are made with external and internal threads; accordingly, using an angle mechanism, there is no need to use additional adapters.

It is convenient to work with the given elements and the fact that the rotation can be made with any level of complexity.

There are also combined corner elements, they allow you to combine parts of the highway with different volumes.

Types of tees by manufacturing method

The following technological manufacturing methods are used in the production of tees: hydraulic stamping, hot stamping, turning and welding.

The direct manufacturing process of tees consists of the stage of obtaining a workpiece on cutting machines and the stage of finalizing the part to the desired size and type by stamping, welding and turning.

Steel stamped welded seamless

Seamless steel tees are made by hydraulically extruding an additional connection into the pipe section. Further processing of the workpiece is carried out mechanically. The maximum diameter of such a part can be 426 mm. This is the most durable type of tee, suitable for use in industrial pipelines operating at high temperatures and pressures.

Steel stamped welded

Stamp-welded tees are produced by welding the main part and the neck, which in turn are usually made by stamping. Tees of this type are usually manufactured according to TU 102-488-95; their diameter can vary from 25 to 530 mm. These connecting parts can be of the following types:

- stainless steel tee;

- regular stamped-welded tee;

- stamped-welded tee with grid.

Welded

Welded tees are usually made from rolled sheet steel by welding the parts to each other. They are distinguished by the presence of several welds. Tees of this type are manufactured in accordance with OST 36‑24‑77, OST 34.10.764-97, which apply to pipeline fittings of oil refineries and steam and gas supply lines. Welded tees, as a rule, have large bore diameters, starting from 500 mm, which is due to the significant labor intensity and economic efficiency of the manufacturing process compared to other methods. The welding method for the manufacture of connecting parts is relatively simple and does not require the use of expensive equipment.

The advantage of tees manufactured using this method is the possibility of making them to order according to the dimensions specified by the Customer. To do this, it is enough to indicate the required material, design type, diameters of the neck and main body, length and wall thickness of the tee.

Turned steel

Turned steel tees are made by processing blanks on special lathes. Basically, this method is used to produce products with small connecting diameters and non-standard configurations. The turning method is quite labor-intensive and expensive. The main document in accordance with which turned tees are manufactured is TU 1462-003-37941826-2012.

In accordance with industry documentation, regardless of the manufacturing method, a particular steel tee can be either transitional or equal-bore in configuration.

Good connections – reliable backbone

These connecting parts ensure the joining of parts of the communication backbone. They are classified according to many indicators. The most important criteria are:

- Features of the form (configuration).

- Purpose of the element.

- Type of installation.

The types of fittings for plastic pipes are as follows:

- device with or without thread;

- devices in the form of a tee;

- bends;

- flanged types of mechanisms;

Experts highlight the relevance of classification by type of installation, although ordinary consumers also need to know these nuances, otherwise it will not be possible to carry out repairs correctly. So, according to this criterion, shaped elements are divided into the following types:

- compression;

- cast;

- electric welded

Watch the video

OVERVIEW OF CRIMP FITTING FOR POLYETHYLENE PIPE

Now let's look at some types of fittings for plastic pipes in more detail:

- Couplings. This is the simplest type of mechanism. In their shape they are similar to a barrel with a hole inside, and are used to work with pipelines of the corresponding volume.

- Adapters. They also fall into the category of simple devices. These types of devices have unequal diameters at different ends, which makes it possible to join tubular products of different sections.

- Corners. These mechanisms are placed in the turn zone of the highway. In this case, the required line angle is created without deformation changes in the pipe assortment. These types of couplings have an angular bend of 45 or 90 degrees, and can fasten sections of pipeline with different volumes. The corners are threaded on the outer part, which allows you to connect a faucet in the bathroom to them or connect other plumbing fixtures.

- Tees. These parts allow you to connect several highways. Moreover, these can be parts with different volumes and relief inside.

Compression (or crimp) fittings for plastic pipes are installed on pipelines for various purposes. Compression fittings for plastic pipes stand out due to their design. This consists of pressing the crimp ring onto the line, and due to this, the required level of tightness between the installed parts is achieved.

The compression couplings themselves are designed like this:

- frame;

- ring seal;

- clamping ring;

- sleeve;

- a nut that serves as a cover.

The level of tightness on compression fittings is achieved due to an elastic rubber sealing ring, which is held in place by a press-fit sleeve. And the clamping ring helps prevent spontaneous unwinding during vibration and water hammer. Even if the pipeline is bent, the crimping parts do not reduce their sealing properties.

Among the advantages that compression devices have, professional craftsmen highlight:

- simplicity and speed of installation;

- repeated use;

- resistance to corrosive formations;

- a high level of reliability of the joint, and in this case it exceeds the strength of the pipe assortment itself.

Compression devices are provided in a wide range, and this simplifies the process of finding the right crimping device.

Methods for installing tees

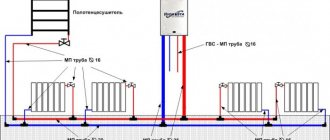

Depending on the installation method, steel tees come in three types.

Threaded tees, on the outer and inner surfaces of which a thread is applied. Tees with threads on the inner surface are classified as bolted, and on the outer surface - nuts. Such products are installed either during pipeline assembly or are subsequently cut into a section of the main pipe. Threaded parts are removable, which greatly facilitates pipeline maintenance and repair work.

Welded tees are mounted to the main pipe by welding, which ensures a strong and durable structure. Such products work well in pipelines operating at high pressures and temperatures. They are difficult to dismantle and practically cannot be repaired. trinik-3

Flanged tees are installed on the main pipeline through a flange connection, i.e.

connected by fasteners (bolts, nuts, studs) around the circumference of the flange. Mainly used in medium-diameter pipelines operating at relatively low pressures.

How to avoid breakdowns

To avoid any troubles during the operation of the pipeline, follow the general rules:

- Use exclusively 45-degree parts for horizontal wiring. If you apply elements at right angles, this will lead to blockages.

- The coupling-socket ends should be directed to the starting point of the system.

- Do not remove the O-rings. If they do not fit into the socket freely, they should be treated with a soap solution.

- It is better to secure the places where the pipeline is connected to the wiring using a clamp holder-bracket.

- Install revision tees in places where there is easy access to them. In apartments and private houses, at least three revisions should be installed along the entire length of the pipeline system.

- It is advisable to use tees only in pressure systems.

Following these recommendations will help avoid breakdowns and the need to repeatedly replace pipeline elements.

Technical documentation and designation examples

Below is a list of the main regulatory documentation that you need to rely on when choosing steel tees, and examples of their symbols.

Tees are an integral part of almost any pipeline, when choosing which you must focus, first of all, on the specified operating conditions, required materials, manufacturer, but do not forget about the price-quality ratio.

Popular models and manufacturers

Model “FV Plast”

Products from both domestic and foreign companies are presented in construction stores and on the market. Fittings are supplied by foreign companies from Germany, the Czech Republic, Turkey and China:

- FV Plast. Czech company, one of the most famous on the domestic market. It has been supplying goods for a long time and, despite the high cost, is in demand among buyers. Its products are of high quality and are made of gray polypropylene from the Hostalen brand.

- Bänninger. A German company produces green fittings made from random copolymer material. The product is of high quality and has plasticity, so it can be used outdoors and can easily withstand freezing. The cost of goods is high, but this is explained by high requirements for product quality.

Products of domestic manufacturers are in no way inferior to foreign analogues and attract buyers due to their price-quality ratio. The most popular are from the companies PRO AQUA and Politek. So, if you use a polypropylene tee from PRO AQUA on a pipe, you can supply working fluid with a pressure of up to 79 atm into the pipeline.

Features of a polyvinyl chloride tee

Polymer fittings can be made from various materials: polypropylene, PVC or high or low pressure polyethylene. At the same time, the unspoken rule of the plumber is to use connecting parts made of the same material as the pipes, since the properties of the pipe depend on the type of plastic, and it is fair to assume that where one type of polymer can easily cope with the load, another may not be able to withstand it. Therefore, PVC tee is used as a connecting piece for PVC piping systems in non-pressure systems.

PVC tee design

Externally, a tee is a part of a pipe with a side outlet, to which it is easy to attach an additional pipe and create the desired branch.

The tee can also be used for a regular connection without connecting another line, but taking into account the fact that this may be needed in the future. For example, if you plan to bring out another pipe after some time, then the tee can be installed in advance, and the additional outlet can be closed with a plug for now. Installing the branch pipe when the time comes will be a fairly simple operation: you just need to remove the plug and connect the pipe.

PVC sewer pipe tee

The popularity of plastic pipes is largely determined by the ease of installation without a welding machine, and the quality of the connection is in no way inferior to welded seams. The abundance of different fittings for connecting plastic pipes simplifies the installation of pipelines of various configurations. They all perform specific tasks, some connect pipes in a straight line, others at an angle. A special place among these parts belongs to the tee. It is designed to divide the flow of the working environment into several streams and create a branched system for the smooth passage of the working environment in different directions.

Taps and valves

This group of products belongs to the category of shut-off and control products. A modern tap for plastic pipes can be of two types:

- manual valves;

- thermostatic valves.

For work, you can choose valves that are tightly soldered into the system, or placed in a metal housing that is mounted on a thread, for example, with an American fastening on one side, so that the part can be dismantled if necessary.

The use of one or another type of valve depends on the service life of its tightness. So, if a pipeline is being installed to transport gas, coolant for a heating system or hot water supply, it is impossible to install a valve designed for cold water.

The shape of the valves can be straight or combined angular. In addition, they produce products for transition between different pipe sections.

Brass male tee

A male tee can be made from a brass alloy. This fitting is connected to the pipe using a threaded connection.

Using a brass tee with an external thread, you can attach an additional direction of the pipeline to the main line, and using different modifications of the tee, this can be done at different angles.

Brass tees have the following advantages:

- long service life;

- high degree of tightness of connections;

- sufficient strength;

- ease of installation;

- versatility.

An extremely useful fitting is a brass adapter tee, with which you can connect pipes with different cross-sectional diameters. Coating it with a layer of nickel improves the performance of the product. This significantly improves its appearance, and most importantly, increases its resistance to corrosion.

Support fittings and contours

In order to lay a pipeline at the intersection of various main lines, as well as to go around an insurmountable obstacle, bypasses are used (read: “How to make a pipe bypass for suspended ceilings - two proven methods”).

Support fittings serve primarily for rigid fixation of a system, such as heating or hot water supply. In this case, such fixation is advisable, since pipes made of polymer materials, when exposed to high temperatures, tend to expand and become more plastic.

As for sewerage pipes, such supports serve to hold the rotary elbows in their original position under conditions of increased mechanical stress.

Thus, if you have the required quantity and assortment of fittings, the installation of any, even a very intricate system of plastic pipes, will be quick and successful.

Manufacturing materials

A polymer plumbing tee does not always look like the best option. To create the most reliable pipeline bends, cast iron and steel structures are often used.

In some situations, for example, when it is necessary to connect additional elements or complex plumbing devices to the sewer system, tees made from non-ferrous metal alloys are used. At the same time, this option is the most expensive compared to all previous solutions.

Sewer couplings

Plastic sewers have recently been pulled more often than others. Such systems are distinguished by chemical inertness and resistance to decay, and other positive characteristics of plastic.

But the required level of tightness on the sewer system can be achieved using high-quality connecting parts. And they are actively used in the sewer network during the assembly and disassembly of the main line.

Experts say that fittings for plastic sewer pipes perfectly resist corrosion processes and are resistant to oxygen diffusion. The internal cross-section of sewer connecting elements does not change with temperature changes, therefore, they can stand for a very long period. The most economical option for such couplings are plastic types; in this area, this is an ideal solution for use.

Types and differences

It would seem, what types of tees can there be? After all, this is just a simple fitting.

And tees are different, which is worth paying your attention to. We, of course, mean the shape of the tees. How to connect to the pipe is an open question. Sewage is a non-pressure system. It has a huge influence on how you laid the system, at what angle, and in what direction.

An error in orientation will certainly have an impact in the future. For example, it is poorly designed underground sewerage that causes frequent blockages.

If your sewer gets clogged with enviable regularity, it means that somewhere the builders made a mistake with the angle of inclination, rotation and insertion into the pipe.

Accordingly, PVC tees are distinguished:

- straight;

- inclined;

- equal passage;

- variegated.

The straight tee is the most common and frequently encountered. Consists of a part of a pipe and an outlet at 90 degrees.

The inclined one forms an outlet from 30 to 55 degrees, that is, it allows you to connect the sewer at an angle. For inserting into the riser of an apartment building, this is the best option. The last two groups differ only from each other. And the differences in them relate to the diameters of the pipes.

An equal tee has an equal diameter in all holes. That is, the diameter of the target pipe and the tee outlet is equal to the same number.

A multi-pass sample has different diameters. In it, for example, the pipe diameter will be 50 mm, and the tee outlet diameter will be 30 mm. Multi-bore models are ideal for installation on a sewer riser. After all, the cross-section of the riser pipe is, as a rule, much larger than the cross-section of the side sewer pipe from the apartment.