Soldering technology

When heated, polypropylene becomes soft, resembling plasticine in consistency. Particles of liquid material mutually penetrate into the adjacent part. After cooling, it hardens and becomes resistant to tearing. The cooled seam is not inferior to the base material in technical parameters. To ensure a quality connection, it is recommended to meet the following conditions:

- polypropylene is heated with the device to a state of viscous fluidity, following the instructions in the instructions for the equipment;

- solder products from the same material, you should not connect polypropylene parts with different markings, the strength of the connection will be impaired;

- the ends and fittings are joined tightly, avoiding gaps and distortions; a tight fit is ensured by sanding the cut edge of the pipes with sandpaper;

- polypropylene hardens quickly, leveling is possible within a few seconds, after hardening it will be impossible to correct the defect.

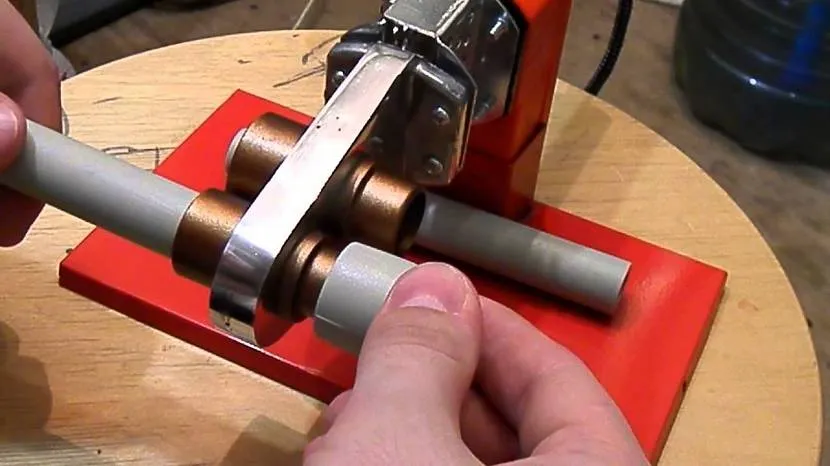

Iron for welding pipes Source nehomesdeaf.org

Thanks to the thermoplastic characteristics of polypropylene, reliable joining of elements is ensured.

A strong seam is obtained only if welding technology is followed and quality materials are selected. Let's look at how to solder polypropylene pipes below. On devices that support the installation of several nozzles, the sleeve can be installed in a convenient position. The location of the heating cartridge does not affect the quality of heating.

Pipe selection

Before making a selection, you should carefully analyze the specifics of the room, decide on the type of heating system, and also take into account the fact that certain skills and knowledge are required when installing this or that pipeline fittings, consider whether you can do everything yourself or will have to seek help from a specialist .

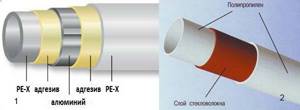

Types of polypropylene pipes: (1- with aluminum reinforcement, 2- with fiberglass reinforcement).

Manufacturers provide a wide range of products for heating installations made from various materials: metal, metal-plastic, polypropylene, each of which has its own positive and negative sides.

Today, both specialists and non-professionals recognize polypropylene pipes as the most popular and optimal option.

Metal pipeline products are the most expensive, susceptible to corrosion, which, accordingly, reduces their service life, and there are certain difficulties in assembly.

Metal-plastic pipes are well known for their low cost and easy installation process, but they are not strong and durable.

For heating and plumbing systems, the best option is polypropylene pipes, especially when doing the installation yourself. It should be noted that, depending on the purpose of use (heating, hot or cold water supply), pipeline fittings vary significantly in technical characteristics and in no case can be interchangeable.

The wide scope of use of polypropylene pipes is justified by a large number of advantages: reliability and durability (up to one hundred years of operation); corrosion resistance; resistance to chemical influence; protection from mineral deposits; easy installation and subsequent repairs.

And yet this material also has a drawback - low fire resistance.

To make a choice which polypropylene pipes are needed for the heating system, you should choose a diameter that does not affect the water pressure, but also not too wide, since then you will have to overpay unreasonably.

Difficulty of welding

Test installation and connection of the first link of the system can be performed on a table or on the floor in a convenient place. Further welding on site is carried out under various technical conditions. Some areas of the system are difficult to access with an iron.

Before soldering pipes in hard-to-reach areas, it is recommended to choose a comfortable position. An inconvenient location causes delays in work and the appearance of various defects, for example:

- overheating of parts with melting of polypropylene and its spreading;

- the connection is deeper or smaller than required by the standard;

- installation with bending or rotating the element.

When heating and connecting, synchronous actions should be observed: both parts are heated and removed from the nozzle at the same time.

There is no delay before assembling heated parts. The pause occurs due to the need to place the device on the platform. Technical downtime directly depends on the experience of the technician and his speed of work. Errors in work lead to sagging, seam mixing, cracking and damage to the joint.

Selecting the diameter of a heating pipe using tables and online calculators

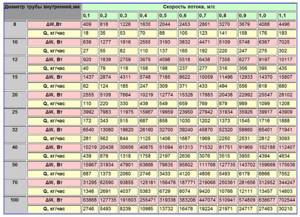

In Internet resources you can find tables of the dependence of the pipe diameter on the speed parameters of the medium V and the heat output Q. Usually the speed does not go beyond 0.2 - 0.7 m/s, and the power of boiler equipment is in the range of 3000 - 40000 W.

To approximately determine the size of PP pipes based on Q and V, one is guided by the following considerations:

- For an individual house, the power of a thermal boiler is calculated based on the consumption of 100 W of thermal power per 1 square meter of heated area. For example, if a house has a total heated area of 100 square meters, then a 10,000 W boiler will be needed for heating.

- The speed of the coolant in gravity systems is assumed to be minimum of about 2 - 3 m/s, with forced supply by a circular pump - 4 - 7 m/s.

As a result, according to the table in Fig. 10 we find that to supply heat with a power of 10,000 Watts at an average speed of movement of the medium along the pipeline line of 5 m/s, PP heating pipes with a circumference of 25 mm should be used.

It is worth noting that a more accurate result can be obtained from tables that take into account the temperature difference between supply and return, as well as their readings (80/60, 75/60).

When calculating pipe diameters using online calculators, the following information is usually entered:

- area of the heated room;

- ceiling height;

- maximum outdoor temperature;

- the number of walls facing the street, sometimes their orientation to the cardinal points and relative to the wind load;

- the degree of thermal insulation of external walls or its numerical coefficient;

- thermal parameters of the flooring;

- thermal characteristics of attic rooms;

- number of windows, their dimensional parameters in height and width;

- type of glazing (sheet or chamber), number of sheets in packages;

- the presence of doors to the street, balconies and loggias, the degree of thermal protection of the latter (cold, warm).

Rice. 11 Table of the relationship between heat flow and coolant pumping volume with its movement speed and pipe diameter

It may be useful to read about Connecting the boiler to the heating system

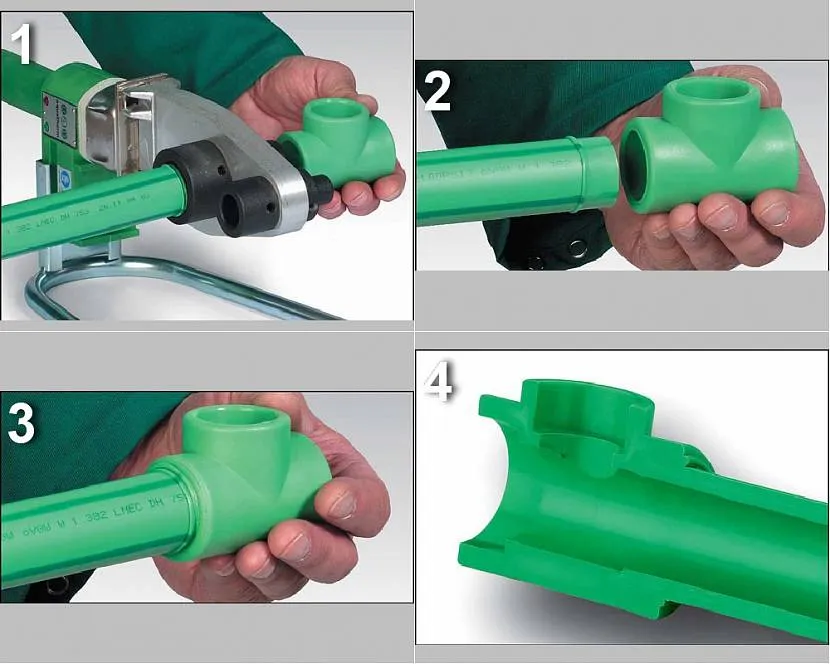

Procedure for performing diffuse soldering

The ends are joined directly by socket soldering or using couplings. The coupling is a shaped part that is used as a connecting link. It is suitable for pipes with a diameter of up to 63 mm. Instead of a coupling, cuttings of pipes with a larger diameter than the section being welded are suitable. The section of pipe and coupling at the junction melts, providing reliable fastening.

Pipe cutting Source stroy-bloks.ru

A socket connection requires precise joining of pipe elements. The edges must be perfectly protected. Irregularities and burrs after trimming are not allowed. After the ends are melted by the apparatus, their diffuse connection occurs. If errors occur during trimming, a leak or rupture of the joint will form when water is supplied.

Do-it-yourself installation

When installing heating from polypropylene pipes, it is initially necessary to calculate the laying diagrams. With this installation, it is necessary to maintain the slope level to the lowest point of the system, because a tap or valve for draining is installed in this place. The length of pipe sections must be calculated for each section of communication. If the pipeline is divided into sectors that can be shut off individually at any time, the operation of the communication system will become significantly safer. All tools and installation parts must be at room temperature, for which they must be brought into the room immediately before the installation process. This action is necessary to prevent the material from cracking during operation. Using a felt-tip pen, it is necessary to apply marks according to the calculations performed on the measured pipe sections.

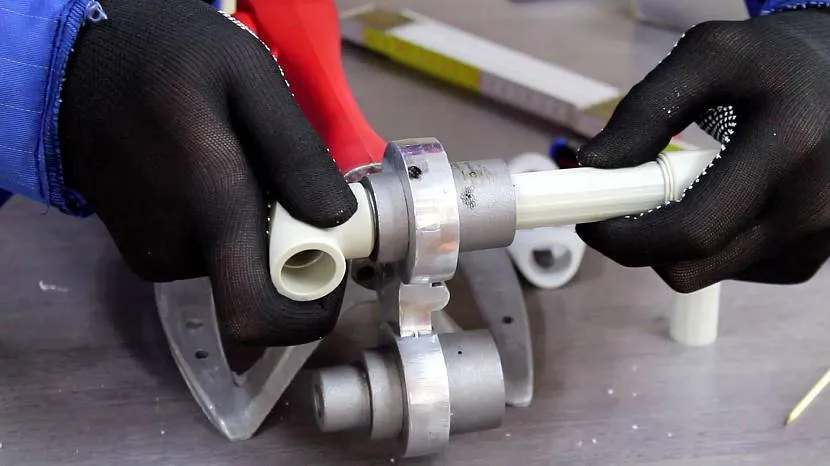

You need to cut the polypropylene with your own hands evenly and perpendicular to the surface with special scissors or a pipe cutter, after which the cut edges of the pipe are treated with an alcohol solution, and the rest of the dirt is removed with a dry rag. A nozzle with the appropriate cross-sectional diameter is installed on the soldering apparatus, which must first be degreased, the apparatus is installed horizontally and heated to 260 °C. Pre-prepared parts (pipe and fitting) are placed in the heater holes in a horizontal position, then the time is determined from the table and the parts are heated.

http:

Then the parts are removed, the pipe is inserted into the fitting and a certain period of time is maintained for the elements to completely harden; twisting the parts during the hardening process is prohibited. This method of welding (soldering) parts is reliable and the most durable. Communication parts must be dry and clean when carrying out soldering work; if installation is carried out in a working (operating) system, then the water must be drained from the heating systems. To conduct trial tests of the heating system, you should not purchase water meters; instruments that show the deaeration of pipes are quite sufficient.

Preparation for welding

Before installing new pipes, it is recommended to draw a diagram of the pipeline on the wall. A simplified diagram represents lines drawn in accordance with the location of the future highway. Markings on the wall allow you to control the orientation of the pipeline.

In order not to adjust the pipes to size during soldering, you should measure the exact length of each pipe in advance. If the connection is made using couplings, allowance should be made for their installation. When installing end-to-end, deformation changes are taken into account. When melted, the pipe decreases by 1-2 mm.

Soldering iron attachments Source opttorg-volga.ru

For ease of welding pipes with a diameter of over 40 mm, an iron with centering is required. It can be used by craftsmen who know how to solder polypropylene. The tool comes with several different Teflon nozzles measuring 14-63 mm, which act as a heating element. There are nozzles in the form of a sleeve and a mandrel. The first type of heating element is designed to melt the outer part of the pipe, the second - from the inside.

Teflon nozzles must be clean. Do not leave particles of melted material on them. Immediately after soldering, the hot body is wiped with a coarse cloth that is resistant to high temperatures, for example, a tarpaulin. It is not recommended to clean cooled elements, otherwise the Teflon layer will be damaged, which will lead to the adhesion of molten polypropylene in the future.

Security measures

When working with a heating device, it is necessary to observe personal protective measures:

- The soldering iron must be installed on a horizontal surface in a place free from materials.

- The technician must wear protective gloves (for working with hot tools) and comfortable overalls.

- Avoid bending over melting plastic as this process releases harmful fumes.

- The room should be relatively clean. The working surface is free from dust and debris.

- The connection between the soldering iron plug and the network must be tight and the cord must be loose.

We recommend that you read: Types of saddles for polyethylene pipes and features of their use

The welding tool is preheated for 20 minutes if it does not have a corresponding indicator.

Equipment preparation

Not all models include a stand. The soldering iron is installed on a level surface in an easily accessible place so that it does not tip over due to carelessness. Nozzles of the required diameter are placed nearby. Some types of irons allow you to simultaneously use replaceable components of different diameters.

Iron components Source teplo-online.com

See also: Catalog of companies that specialize in water supply and sewerage.

The heating element is heated evenly along its entire length to a predetermined temperature. The degree of heating is pre-set on the panel. For polypropylene, the soldering temperature of polypropylene pipes on the scale is set at 260⁰. Warming up the device lasts 10-15 minutes. A cold room takes longer to warm up than a heated room. At temperatures below 0⁰, welding is prohibited.

Disadvantages and methods for eliminating them

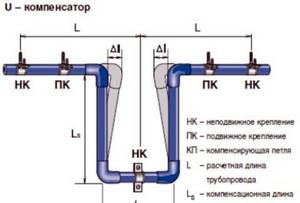

- The main disadvantage of polypropylene pipes is their high expansion coefficient. At a coolant temperature of 100°C, 10 meters of pipe lengthens to 15 cm. This leads to deformation of the structure. In order to prevent destruction, flexible supports are installed and compensation loops are made. Later, foil-reinforced pipes began to be used, which significantly reduced the expansion coefficient. Nowadays, the most practical pipes are reinforced with glass fiber: under the same conditions they extend by only 1 cm.

- Polypropylene products, especially connecting elements, are inferior to metal pipes in strength. It is not even correct to compare them: when subjected to strong impacts with hard objects, polypropylene is deformed and may collapse.

Preparing pipes for welding

The edge of the pipe is cut with special scissors at a right angle. The cut area is sanded and degreased with ethyl alcohol or soap solution. The surface is thoroughly dried. Products marked PN 10-20 are welded immediately, and those with PN 25 are additionally cleaned with a shaver, removing part of the polypropylene and aluminum to the soldering depth. They are oriented according to the size of the nozzle up to the limiter.

Important! For degreasing, it is prohibited to use any solvents, gasoline, vodka, or acetone. Aggressive liquids corrode the surface of polypropylene.

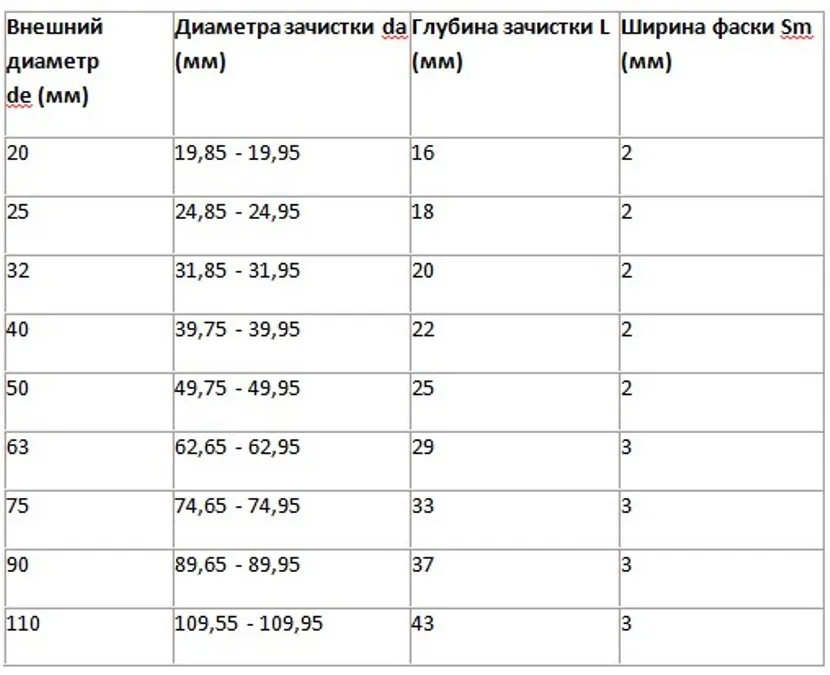

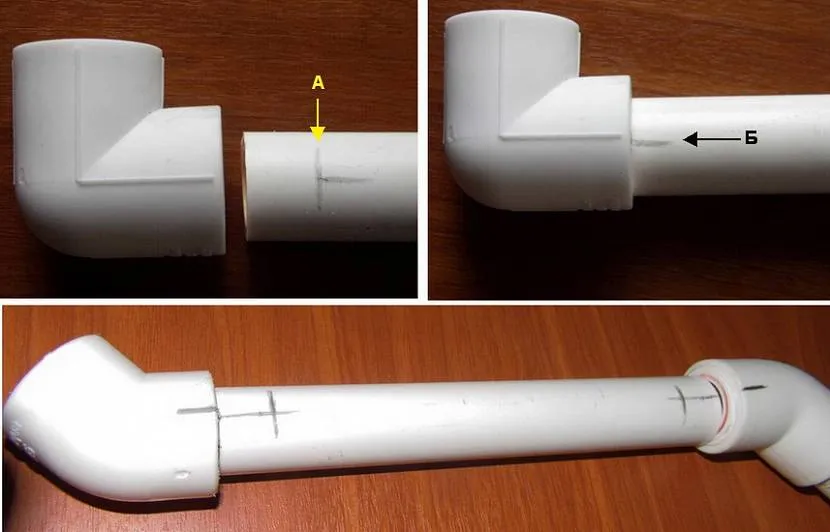

When using a socket connection, it is important to adhere to the stripping depth and chamfer width. The degree of stripping must match the depth of installation of the elements.

Table for stripping pipes of different diameters

Existing types of polypropylene pipes and their characteristics

Today, manufacturers offer a wide range of polypropylene products. And before purchasing pipes, you should understand their markings and properties.

There are several categories of such products:

- PN-10 - available with an internal diameter of 16.2-90 mm, external diameter - 20-110 mm; For such pipes, thin-walled polypropylene is used (its thickness can be 1.9-10 mm), designed for operating pressure in the system up to 1 MPa and temperature up to 20 0C, therefore it is not used for heating systems.

- PN-20 - such products can have an external/internal diameter of 16-110 mm and 10.6-73.2 mm, respectively; the thickness of their walls is 1.6-18.4 mm; they are designed for operating pressures up to 2 MPa and temperatures up to 80 0C. Despite the fact that this category is considered universal, these pipes in the heating system can only be used in the return pipeline, provided that the coolant temperature does not exceed the previously specified value.

- PN-25 is the best option for heat supply, the distinctive feature of which is multi-layering (the cross-section of the pipe consists of two layers of plastic, between which a thin layer of aluminum treated with glue is laid). Manufactured reinforced products can have an internal/external diameter of 13.5-50 mm and 21.2-77.9 mm, respectively, and a wall thickness of 4.0-13.3 mm. Such polypropylene is capable of functioning in a system with a coolant temperature of up to 95 0C and operating pressure of up to 2.5 MPa.

- PN-16 - can be used for pipelines with coolant temperatures up to 80 0C, however, this variety is not common and therefore is practically not used.

There is another variety: pipes reinforced with fiberglass, which are similar in quality to products with a foil layer. However, the first type has a slightly higher coefficient of thermal expansion, but their installation is somewhat simpler (category PN-25 requires preliminary removal of the foil on the area to be welded if it is located close to the outer surface).

Figure 4 – Polypropylene pipes reinforced with fiberglass

Warming up polypropylene

Installation of polypropylene pipes includes two stages: heating of the joining areas and connection. The part is put on a nozzle of the appropriate diameter. The pipe is installed in the sleeve up to the limiter for the entire stripped length, and the fitting element is placed on the mandrel until it stops. It is necessary to control the heating depth; the pipe must be located in the sleeve without distortion until it stops at the limiter. Maintain the necessary time to warm up. The holding time and soldering temperature of polypropylene pipes depend on the product parameters; the table displays all the important welding parameters at a room temperature of +20⁰.

The heating time must not be exceeded, otherwise the surface will be deformed, which will lead to distortion of the geometry and the inability to join the parts without gaps. When joining molten sections inside the pipeline, polypropylene swelling appears, which hardens into large ridges. Protruding material reduces the passability of the highway.

Table of welding delay values Source montagtrub.ru

Important! Temperature measurements on the iron mirror are carried out with a thermal probe.

Welding plastic pipes is impossible without a technical pause of a few seconds after heating, which is necessary to remove parts from the heating element. In a cold room, during this period the heated areas have time to cool down, which deteriorates the quality of the joining. To ensure a strong seam, it is recommended to increase the heating time by a few seconds so that the material melts more strongly. The optimal additional time is calculated by selection, taking into account :

- ambient temperature;

- nominal pipeline cross-section;

- holding time for warming up.

The temperature is set within 255-265⁰. If it exceeds 270⁰, the seam will turn out thin and unable to hold the water pressure. This occurs due to the rapid heating of the outer layer until it melts. At the same time, the material does not have time to warm up deeply, so diffuse penetration of polypropylene into adjacent areas of the parts does not occur.

Stages of pipeline welding Source svarkaspec.ru

Heating system made of polypropylene pipes

To install heating in your home, use one of three polypropylene heating systems. Each of them has pros and cons. Installation of systems depends on the size of the house and the boiler model.

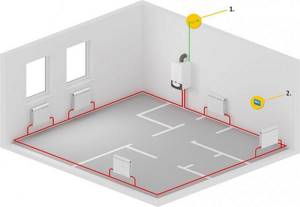

Single-pipe

A single-pipe system is a common type of heating and is effective for small houses. A pipe extends from the boiler, the second end of which is also attached to the boiler. Without breaking the line, batteries are attached to it. Systems can be flow-through or vertical, and can be closed or open.

To install a one-pipe system, you will need fewer pipes - 30-40%. Simple wiring and simple installation allows you to install the system at home yourself. The assembly can be done both in a single-story and in a multi-story building.

A Mayevsky tap is installed on each radiator; if you do not bleed the air, the batteries will remain cold. The system has a drawback: while the water reaches the last radiator, it cools down, heat transfer decreases, and heat is distributed unevenly. Therefore, a single-pipe main can contain no more than 5-6 batteries.

Advice!

To maintain and distribute heat, you will need a circulation pump.

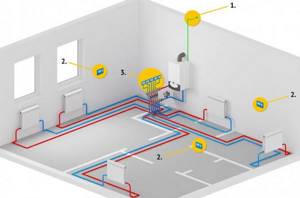

Two-pipe

A two-wire system has 2 lines, the supply and return pipelines operate in parallel. Do-it-yourself two-pipe polypropylene heating in a private house is made from a boiler. The first branch supplies hot water to all appliances in the system. The cooled liquid enters the boiler through the second line. The advantage of a two-pipe design over a single-pipe design is that heat flows evenly to all radiators.

A regulator or shut-off valve can be installed on each heating component. Then, if one of the devices breaks down, it can be dismantled and replaced without shutting down the entire system. In a two-pipe pipeline, smaller pipe diameters are used. This type of heating is expensive, but it is worth the price.

The house uses both vertical and horizontal wiring. The first option is installed in large houses, with two or more floors. The use of a single-pipe main in multi-story buildings is unproductive.

Collector

The main unit in collector heating is the comb system. It distributes the coolant throughout all branches. It includes a pump, expansion tank and safety devices. The manifold distributes the fluid supply to the pipes without loss of pressure. The manifold system simplifies the wiring of the main line. You can immediately make a diversion to the washing machine, sink, bathroom and drain tank.

The manifold cabinet must be protected from moisture; it is built into separate niches in the house. If the building is two-story, two collector units are designed - on each floor.

To distribute heat along the circuits, the heating is divided into sections. For example, it could be a heated floor, a radiator near the window, or a second heated floor on the top floor. It is necessary to make a closed return system.

Important!

The comb has an inlet diameter equal to or greater than the outlet diameter.

Soldering Features

Welding of polypropylene pipes is carried out with quick movements by applying heated sections to each other so that the pipe section enters the fitting cup to the required depth. It is necessary to monitor the edge ratio to avoid distortion at the seam. Cleaning and length adjustment must be performed before welding, otherwise the system will depressurize due to static stress.

To prevent the seam from cooling down during a technical pause, the equipment is positioned so that the distance from the installation site to the installation of the device is minimal. This nuance should be provided for in advance. Time spent moving equipment and components results in heat loss. The seam is weak due to partial diffusion between the layers of polypropylene.

Welding technology for polypropylene pipes Source provodoprovod.ru

It takes 2-4 seconds to adjust the position. During this period, the elements cannot be rotated, bent or disconnected. If the seam fails, the area is cut off and the procedure is repeated. It should be remembered that such mistakes lead to a decrease in the length of the pipe and waste of material. If you have no experience or knowledge of the theory of how to properly solder polypropylene pipes, it is better to entrust welding to a professional.

Alternative to welding

In some cases, for example, in hard-to-reach places in the bathroom or other rooms, it is not possible to carry out welding work. The soldering process can be replaced by gluing the pipe to the fitting using an organic solvent. It has a very strong softening effect, but is also highly volatile.

After lubricating the end of the pipe and the internal cavity of the coupling, the plastic softens for a short period of time, and the connection can be made. Reverse polymerization begins after a few seconds.

However, this method is more suitable for PVC pipes that are less prone to thermoplasticity.

If for some reason this option is not suitable, for pipes NOT UNDER PRESSURE it is permissible to use a supercharged lighter instead of a soldering iron. This connection method is shown in the video tutorial below. It is important to understand: uniform soldering cannot be achieved precisely because of the alternating heating of parts, therefore the technology cannot be used for critical connections.

Cooling and leak testing

The seam cannot be cooled forcibly. Due to temperature changes, cracking and deformation in the melting zone is possible. The pipeline must be given time to cool naturally. You can control the temperature by touch. The cooled area is first checked for leaks by blowing. At the end of soldering, water is passed through the pipeline, gradually increasing the pressure, and the seams are inspected for leaks and permeability.

Pipeline installation Source https://i.ytimg.com/vi/qTaP9btjoP4/maxresdefault.jpg

Heating in the house

At the first stage, you should decide on the types of radiators and options for their connection, since buildings should be prepared in advance for the selected type of heating.

A modern space heating system includes several components. These include:

Do-it-yourself polypropylene heating wiring without a soldering iron

You can find different versions of them in large quantities in our markets.

General instructions for installing batteries look like this:

- First select a place to place them;

- bring pipes to them;

- connect them together;

- perform a test run, and if everything is in order, turn on the heating at full power.

How to install heating radiators with polypropylene pipes with a jumper for quick shutdown

Errors during soldering

Most often, errors occur among craftsmen who do not have practical experience in soldering, even when they know how to weld polypropylene pipes. Many people neglect the step of measuring the length of pipes, performing installation by eye with trimming after the fact, or they measure without taking into account tolerances. If the length of the pipe is incorrectly calculated, it is very difficult to install the iron for joining the elements.

Many craftsmen try to bend the pipe in place to increase the distance between the parts. This leads to an increase in static voltage in the network links and a decrease in tightness. Such errors worsen the appearance of the highway. Attention is paid to the aesthetics of the system when laying communications externally.

Sequential heating is a mistake that leads to rapid cooling of the joined areas and the impossibility of connection. While the second element is heating up, the first has time to cool down. Partial diffusion leads to rupture of the connection when pressure increases and water hammer. This is a gross violation of technology. It is absolutely impossible to operate such a highway.

Warming up parts Source https://www.malolikto.ru/wp-content/uploads/2016/12/maxresdefault-4.jpg

PP fittings for water supply systems

The term fitting is taken from English.

Literally translated: to mount, adjust, assemble. Structurally, the fitting is a component of a pipeline, in particular made of polypropylene. This component can take the form of an angle (90º or 120º), tee, cross, etc. There are fittings with threaded inserts for connecting shut-off and other valves. There are special bypass elements that allow you to carefully bypass the places where one pipe bumps into another.

Along with polypropylene pipes, a huge variety of fittings are produced. Mounting elements - fittings - significantly expand installation freedom and allow you to choose the most appropriate technology for constructing water supply systems

Using any of these mounting elements, it is convenient to build water supply wiring diagrams in almost any configuration. So, to connect one polypropylene pipe to another in a straight line, a coupling is used.

The same fitting is used if it is necessary to make a transition from a pipe of one diameter to a pipe of another diameter in a straight section. It is easy to connect pipes with a bend using corner fittings.

Fittings of various types are produced for the installation of water pipes with polypropylene pipes. If one type of such elements is intended for use for soldering, another type is used for mechanical threaded connections.

Fittings for mechanical threaded connections allow you to create a completely strong, reliable connection using force crimping, eliminating soldering technology from the process.

In addition to traditional installation methods - soldering polypropylene and mechanical connections, the technology of gluing circuit elements is used. The advantages of this technology are obtaining a high-quality appearance of the plumbing system due to the complete absence of any deformations

In addition to the threaded connecting technique, the technology of gluing water supply parts is often used. For example, using special glue, tees and polypropylene pipes, you can easily make a distribution manifold for cold water supply with your own hands.

The actions of a master plumber in this case boil down to the following steps:

- The pipe is cut to size and deburred.

- The surface of the pipe at the junction is degreased.

- A layer of glue is evenly applied to the surface.

- The end of the pipe is inserted into the fitting until it stops.

Glue drying time is 20-25 minutes.

How to reduce the likelihood of marriage?

It is recommended that two people work together to solder elements in difficult-to-access conditions. The second specialist helps remove the second element from the nozzle and puts the soldering iron on the platform. The first master carefully joins the parts with both hands with a minimum pause. Sometimes assistance from a third party is required. His services are used when a pipe needs to be fixed in a wall in an adjacent room. Attempts to perform all operations independently in difficult areas always lead to defects and the need to perform welding again.

Planting depth marking Source files.builderclub.com

During soldering, precise movements must be observed. The correct inclination of the fitting element relative to the second part, its axial angle of rotation on the pipe, and the depth of entry into the fitting cup must be maintained. To control the depth of entry and the angle of rotation of the fitting, marks are made on the surface of both parts. In order not to measure the allowance each time on sections of the same cross-section, use a template.

The iron does not need to be turned off during the entire welding period. The technician will lose time warming up the equipment. The soldering iron is ready for use after the heating indicator goes out. A lit indicator shows that the mirror is heated to the desired temperature. If you start welding during this period, the pipe will not warm up properly. In order to comply with the technological process and holding time, it is recommended to check the parameters according to the table, which is recommended to be kept at hand.

If combined pipes are purchased, they are connected only after mandatory stripping. The chamfering depth should be 2 mm greater than the depth of the sleeve into which the element is inserted. Reinforcement reduces deformation expansion by 10 times. On products with external reinforcement, before soldering, a part of the surface is removed with a shaver to the required depth for joining. Pipes with internal reinforcement do not require stripping. Their installation is faster.

Features of materials that need to be taken into account during installation

In order for the system to function correctly, during the installation process it is necessary to take into account some features of PP hoses. One of them is linear expansion. This phenomenon causes a change in external and internal temperatures. As a result of heating, the plastic sleeve begins to sag. The linear expansion is compensated by the correct laying of the pipeline, guaranteeing freedom of its movement within the limits of the linear expansion value.

For this purpose, fastening clamps and compensators are used, the design of which includes both moving and stationary parts. Sometimes sagging can be eliminated by chipping the wall and laying a sleeve into it or installing additional clips. If these actions do not help, radical measures are used - the sleeve is disconnected in the area of the “American women”, the sagging section is cut off, the American woman is resoldered, then twisted.

Methods for installing radiators and piping

The heating radiators are connected after the windows and doors are installed and the floors and walls are prepared for final finishing. Connection options and types of radiators and pipes are selected in advance so that the room is already ready for their installation.

A modern heating system consists of a number of components. Among them are the heating boiler itself, the pipeline and heating devices - radiators, which are presented in a wide range.

The process of installing the battery is quite simple: you need to mark the installation location, connect the pipes, install the radiator itself and make the connection. Let's look at the process of installing radiators using polypropylene heating pipes in more detail. Let's find out what types of systems and connections can be used for this, what is necessary for connecting the heating system itself.