What it is, how it works

Thermal insulating paint for pipelines is a substance in the form of a mastic mass, with a consistency like ordinary sour cream. Used for processing load-bearing structures, tanks and systems involving pipe laying. It was originally invented purely for the space industry. Now it is used in the construction, installation and repair industries, and the construction of buildings.

The heat-reflecting capabilities of this coating are such that even with a thickness of only 1 mm, it well prevents heat loss where it is especially required. It can be applied to any surface: walls, ceilings, tubes and other structures.

After application, the substance polymerizes and turns into an elastic matte coating, acting as a temperature barrier. By keeping it inside the system, it does not allow it to be emitted outside. The reduction in heat loss occurs due to the fact that the coating has:

- A very small proportion of substances with heat-conducting properties. It consists of only 20% of components endowed with these capabilities.

- Conventional losses for this substance are also insignificant. The material consists of “balls” of microscopic size. Which fill rarefied air currents.

- Heat saving efficiency (90%) is achieved due to the fact that the coating operates on the principle of a classic thermos.

In addition to heat-saving functions, it serves as additional protection against corrosion and other negative processes to which pipe products may be exposed.

Such pipeline insulation is a more than worthy alternative to traditional mineral wool and other previously known heat insulators.

Traditional pipe insulation and ultra-thin thermal insulation in a comparative context

Insulation of pipes and pipelines

Various types of insulation are used for thermal insulation of pipelines. Materials for thermal insulation of pipes are produced in the form of pipe and sheet thermal insulation coatings. Thermal insulation for steel pipes is produced in the form of flexible tubes of various diameters in sections or coils, sheet rolls of various lengths and widths, flat sheets of various sizes. Pipe thermal insulation is also produced in the form of thermal insulating cylinders (shells). The type of pipe insulation is selected taking into account the performance characteristics and dimensions of the pipeline. Thermal insulation for pipes is made from various materials and is available in several main types:

— thermal insulation of pipes made of foamed polyethylene;

— thermal insulation of pipes made of foamed synthetic rubber;

— thermal insulation of pipes made of polyurethane foam (PPU shell);

— thermal insulation of pipes made of basalt fiber.

During construction and installation work on laying heating pipelines and hot water supply networks, galvanized steel pipes are usually used, pre-insulated with polyurethane foam in a polyethylene shell or molded polyurethane foam shells. These technologies are used for external installation of heating networks, for major repairs of thermal insulation of pipelines, as well as for insulation of pipelines in basements and attics.

The possibility of using and effectiveness of a heat-insulating material is determined by its physical and technical characteristics and operating parameters: density, thermal conductivity, compressibility, water absorption, water resistance, vapor permeability, non-flammability, reliability, durability, the ability to carry out installation work regardless of the season.

Liquid ceramic thermal insulation is becoming increasingly popular on the market of modern thermal insulation coatings.

What is it made from, what technical characteristics does it have?

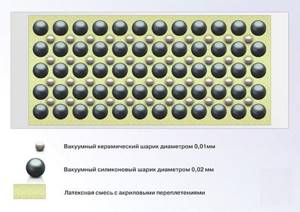

Liquid thermal insulation is an innovative material with very high thermal insulation performance. This is a composite coating made of polymers containing hollow ceramic microspheres.

Insulation composition

The structure of this substance is as follows:

- The base is a binder - a mixture of water and acrylic. Designed to promote uniform distribution over the surface and enhance the adhesive properties of surfaces.

- The filler is ceramic granules, microscopic in size, which are filled with gas. Thanks to their presence, thermal insulation increases significantly.

- Additional components - rubber, silicone and other components with properties that improve the water resistance and elasticity of the coating.

Insulating this insulation in combination with other types increases their ability to retain heat.

After application and complete polymerization, the specific gravity of the voids is scattered - 75-80%.

Molecular structure of liquid pipe insulation

Specifications

The indicators of this parameter are given in tabular form:

| Parameter | Description |

| Density (kg/l) | 0.6 (that is, a 10 liter bucket filled with paint will not weigh 10 kg, its actual weight is only 6 kg) |

| Color | Lactic |

| Presence of granules | Upon tactile contact (to the touch), a slight roughness is felt |

| Quality | When delamination occurs, a massive layer consisting of a layer of granules should be present. |

Coating under a microscope

Compound

Thermal insulating paint is quite popular in the construction market. Its composition is based on acrylic or latex, to which heat-insulating microspheres are added. These properties are achieved due to the vacuum inside such spheres. They can be made of ceramics, glass or various polymers, and sizes can vary from 10 to 80 microns. The principle of operation of heat-insulating paint is similar to a thermos - heat is also insulated using a vacuum.

Silicone and ceramic elements are added to the acrylic spheres, and after application together they form a structure similar in properties to foil: the ceramic component acts as a reflector, and the silicone becomes a vacuum layer between them. The content of such spheres in the acrylic base of heat-insulating paint can reach up to 80%.

The composition may vary and the structure of the paint depends on it. It can be similar to foam or the same as that of ordinary paint. Paint with a foam structure is used to insulate large-diameter pipelines, applying it using a sprayer. For paint that has a similar structure to ordinary paint, small surfaces with complex geometry are suitable. It is also convenient to use in hard-to-reach places where any other methods of thermal insulation are not available.

Liquid thermal insulation of pipes "Teplotortm" in the housing and communal services sector

DESCRIPTION INSTRUCTIONS FOR USE WORK PERFORMED

Every resident of an apartment building who regularly pays for utilities has the right to expect that his apartment will be warm and hot water will flow from the tap.

But is this really so?

As practice shows, hot water and heating pipes in many basements and attics of apartment buildings heat basements, attics, and the atmosphere, but not apartments, because... they completely or partially lack thermal insulation of the pipes, and if they do have it, it does not fulfill its functions.

All problems with thermal insulation of pipes in apartment buildings will be solved by liquid thermal insulation of pipes "Teplotor TM".

Liquid thermal insulation of pipes has all the necessary certificates, including a Certificate of inclusion in the Register of new technologies, equipment and materials used in the field of housing and communal services and construction of the Russian Federation, as well as a Certificate of Compliance with the norms and rules of technical operation of the housing stock.

Comparative table of the pros and cons of using various pipe insulation materials.

| Characteristics | Min. galvanized plate | PPU with galvanization | PPU with fiberglass | Heattortm |

| Thickness (mm) | 50 | 50 | 50 | 1 |

| Thermal conductivity | 0,035 | 0,033 | 0,033 | 0,001 |

| Wetness of insulation | There is | No | No | No |

| Corrosion under the insulation layer | There is | There is | There is | No |

| Theft of materials | There is | There is | There is | No |

| Environmental Safety | No | There is | There is | There is |

| Scope of repair work | big | big | big | small |

| Service life (years) | 2 | 15 | 15 | 15 |

| Aesthetics | quickly lost | quickly lost | quickly lost | saved |

Liquid thermal insulation of pipes "Teplotor TM"

Instructions for using liquid thermal insulation as a pipeline insulator

Preparation of surfaces for treatment with liquid thermal insulation "Teplotor TM"

Clean the insulated part from dirt, rust and old paint that does not adhere well, using metal brushes.

Be sure to degrease the pipe! When treating metal pipelines with liquid thermal insulation, it is necessary to apply primer.

We use Unicor-M or Kronacryl for these purposes, although any primers can be used.

When applying liquid insulation to galvanized or aluminum surfaces, there is no need to prime.

Information on heat-resistant enamels and primers:

| Name | KO-8104 | CBS 12-03 | CBS 12-01 | KO-870 | KOS 82-03 | KO-811 | KO-8101 | CBS 11-07 | Unikor-M | Cronacryl |

| Heat resistance, degrees | Up to 400 | Up to 150 | Up to 300 | Up to 600 | Up to 600 | Up to 600 | Up to 600 | Up to 300 | Up to 150 | Up to 110 |

Main advantages

Some of the positive properties have already been described earlier, but there are other features:

A very thin layer of heat-protective paint on metal and other materials that does not change the dimensions; No requirements for skills and equipment, which simplifies application; Environmental friendliness; Surfaces free of mold and condensation; Fire resistance; Low weight

This property is especially important when used for facades of buildings and pipelines; Resistance to ultraviolet rays; Full protection from mechanical loads; Rust and corrosion certainly do not appear on metal surfaces; Long service life; Reliable heat retention. High consumption and high cost become the only drawbacks for the materials, but in further operation everything pays off

High consumption and high cost become the only drawbacks for the materials, but in further operation everything pays off.

What varieties are divided into, features of each type,

The market for insulating coatings in this category offers several varieties, differing in composition and application methods:

- ceramic

- penoizol (expanded polystyrene).

General advantages - speed of coating, good thermal insulation properties. In all other respects, these compositions differ slightly from each other: in scope of use, composition, specific properties.

Heat loss indicators before and after insulation

Ceramic heat paint

In appearance, it is a substance (mastic) reminiscent of an acrylic paint coating. There are several types of this insulation on sale. However, their consistency, technical data and composition are identical:

- The binder is a water-acrylic solution.

- Additional components - silicone resin, rubber or other components with similar properties.

- Ceramic granules of regular round shape.

After application, it forms an ultra-thin layer with very high thermal insulation properties. Widely used in construction. In addition to thermal insulation functions, it is also used as protection against corrosion.

Applying paint

Surface painting is carried out as follows:

- First stir the paint. The process is carried out until the microgranules are evenly distributed in the composition. Stirring time: 10-15 minutes. The process can be speeded up to 5-7 minutes if you have a mixer. In this case, the rotation speed should not exceed 200 rpm. Too high a speed will destroy the ceramic microbeads.

- If necessary in accordance with the instructions for use, add water to the composition.

- To paint small areas, use brushes with natural bristles. For painting larger surfaces, without numerous corners and irregularities, it is more convenient to use a roller. The highest quality paint application is achieved when using a spray gun (spray gun or airless spray). When applying paint, you need to monitor the working pressure: it should not exceed 6 atmospheres, since otherwise damage to the ceramic microgranules is likely.

- After painting the surface, you need to wait a day until it dries. During this time, polymerization of the binder and fixation of heat-insulating microgranules occurs. Drying speed may vary depending on environmental conditions. The manufacturer indicates on the paint container the recommended temperature and humidity for the normal drying process of the coating.

When working with paints and varnishes, personal safety equipment should be used. You will need a respirator, rubber gloves and safety glasses. If paint gets on the mucous membranes, it is necessary to rinse the affected area with water and immediately seek medical help.

Selection of thermal paints and main manufacturers

The Russian construction market offers a wide range of liquid heat insulators from various manufacturers; when choosing paint, you need to read the application instructions and compare prices, because the product belongs to the expensive category. You can determine the required amount of material according to the consumption rates indicated on the packaging for various types of surfaces to be treated.

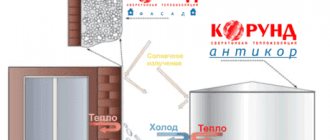

Corundum

The manufacturer produces a wide range of paints, the main brands:

- Classic - used for finishing interior and exterior objects with an operating temperature range from -60C to +250C.

- Facade – provides thermal insulation of the outer surface of buildings, is characterized by good vapor permeability and moisture resistance.

- Anticorrosive – applied to cleaned metal surfaces or with traces of rust, provides high anti-corrosion protection of objects during operation

- Zima is a brand intended for application in frosty conditions at temperatures down to – 10 C.

The average price of a 10-liter container of all Korund brands is 100 USD.

Fig. 8 Thermal insulating paint for pipes - application options

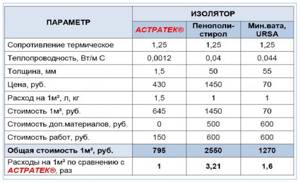

Astratek

Durable paints with a service life of up to 30 years and a temperature of coated surfaces of up to 150 C., the product line consists of several brands of gray and white colors:

- Universal is used for thermal insulation of internal and external walls of buildings; the paint can withstand several freezing cycles and is diluted with water.

- The metal is produced in gray color; during operation, the coating performs anti-corrosion functions and can be used for painting metal objects and roofs of buildings.

- The white facade

Average cost 10 liters. heat paints Asstratek is 110 USD.

Rice. 9 Popular brands of thermal insulation paints

Armor

Liquid thermal insulation Bronya consists of several varieties:

- Classic - performs the functions of a heat insulator in heating and hot water supply systems, and can be used for insulation of chimneys. The paint is not exposed to solar radiation and protects the treated surfaces from corrosion and condensation, thereby extending their service life.

- Anticorrosive – designed to cover rusty metal objects, providing them with further high anti-corrosion protection.

- Winter - additive polymers and foam glass granules are additionally included in the composition, can be used in winter at temperatures down to - 35 C. and is designed for operation in cold weather, has a fairly high price - about 162 USD. for 10 liters.

- Facade - in addition to thermal insulation, it performs protective functions, preventing the formation of condensation, mildew and mold, and has high vapor permeability.

Products under the Bronya brand are among the most budget-friendly (with the exception of Zima), the average price is for 10 liters. is 75 USD

Rice. 10 Liquid thermal protection on the roof

Compared to the use of traditional insulation, thermal paint has higher performance properties; its use allows you to quickly and effectively paint rooms, heating systems, steam pipelines and hot water supply pipelines. It is easy to paint the insulated object with your own hands using a roller or a paint brush; to obtain the desired consistency, the paints are diluted with water.

Areas of use

The manufacturer assures that with a layer thickness of several millimeters, the thermal paint can replace 50 mm of mineral wool insulation, and the reflectivity is 1 sq. m. its surface efficiency is equal to 50 sq. m. foil.

Such high performance and other technical parameters contribute to the fact that the scope of use of thermal paint is very extensive. Liquid insulation is divided according to its intended purpose: for internal and external work on finishing premises or for metal surfaces, and is used when carrying out the following work:

- Thermal insulation of roofs and facades of buildings, window slopes and cold concrete floors.

- Reducing losses in hot water pipelines, steam pipelines and various containers with high-temperature working fluid (boiler protection).

- Insulation of air ducts in refrigeration and air conditioning systems.

- Protection of water mains from freezing in cold weather.

- Insulation of automotive and special equipment, industrial equipment.

Fig. 3 Comparison of paint efficiency with popular insulation materials

Fighting condensation

Condensation on pipes is a fairly common problem. It becomes especially relevant in the summer, when the air in the apartment is quite hot. Drops of water flowing down water pipes, gradually forming entire puddles on the floor, cause a lot of trouble.

Condensation can be dealt with using various methods. Before proceeding directly to getting rid of the problem, you should establish the cause of its occurrence.

Condensation on metal pipes can form as a result of:

- Poor ventilation

- Leaks in neighbors' pipes

- Leaking faucets and other plumbing problems

As a rule, the formation of condensation on pipes is associated precisely with temperature changes. It is not possible to avoid them. However, it is possible to ensure that pipelines are adequately protected by following certain procedures.

Methods for dealing with condensate on pipes:

- First of all, you need to make sure there is sufficient ventilation in the bathroom. The normal indoor humidity level is considered to be up to 50%. If necessary, you should take care of installing exhaust ventilation in the room. After completing the water procedures, you need to leave the door to the bathroom open.

- It is also necessary to take care of eliminating leaks in the flush tank and faucet. Repair of plumbing equipment is one of the options for solving the issue of combating condensation.

- A fairly simple and effective way to solve the problem is to wrap pipes with rags and apply epoxy putty. The methodology for implementing the work is as follows. The pipe is first cleaned of traces of rust using sanding paper, then degreased using acetone. Next, the first putty layer is applied and the pipe is bandaged with fabric, which ensures epoxy impregnation of cold water supply pipelines. After the epoxy has hardened, a second layer of putty is applied. This method demonstrates sufficient efficiency and cost-effectiveness. However, it spoils the appearance of the entire bathroom, which is why it is not very popular today.

- The most effective and modern way to get rid of the problems of condensation on pipes is to create a special coating. Just a couple of decades ago, the post-Soviet space could not imagine such a convenient thing as heat-insulating paint. Today you can buy it at a regular hardware store. This thermal paint will most effectively solve the problem of moisture formation on metal pipes. When purchasing this paint, preference should be given to trusted manufacturers with a decent reputation. This way you will save your money. Akterm's products have managed to win consumer recognition. Akterm Anti-Condensate is a special product designed to solve the issue of condensation formation as a result of a sharp temperature difference on metal surfaces. The use of such thermal paint prevents the appearance of condensation on cold water supply pipelines, thereby preventing the occurrence of fungus, mold, rust and freezing on their surface. The product is non-toxic and completely safe for human health.

By using this option to combat condensation, you can significantly extend the life of your pipes. Thermal paint does an excellent job of solving the problem of an insufficient layer of thermal insulation and a decrease in the heat-protective qualities of insulation, which are the main reasons for the formation of condensation on metal pipes and surfaces.

Selection rules

First of all, you should decide on the place where the thermal paint will be applied. Usually, the jar with the product is labeled by the manufacturer. Look carefully at what surface this product can be applied to.

Carefully inspect the contents of the jar. It should be uniform, there should be no plaque or any inclusions. It is desirable that the color be white, but light shades of gray or beige are allowed. Otherwise, the product will not meet the declared qualities.

The density of the product should not be ignored. A low indicator of this criterion will give greater heat transfer. In addition, you should familiarize yourself with the service life and interaction with external environmental indicators. For example, ultraviolet light, fire or water.

Not all liquid thermal insulation has an easy application method. Make sure that the product not only meets the required protection and density parameters, but is also convenient to use.

Since there are a large number of manufacturers of this insulation on the market, it is better to give preference to a time-tested brand. This way you can be sure of the quality and reliability of the purchased product.

Scope of application

The scope of use of thermal paint is extensive. Liquid insulation is classified according to its intended purpose into compositions for external and internal work, for finishing rooms or metal surfaces. That is, there is liquid thermal insulation for walls, and there are materials intended for pipelines.

In general, the material is used when performing the following work:

- Insulation of roofs and facades of houses, window openings, cold concrete floors.

- Thermal insulation of hot water systems, heating boilers for homes and businesses, steam pipelines.

- Thermal insulation of air ducts, air conditioning and refrigeration systems installed in a home or industrial building.

- Insulation of water mains. The material is used to protect them from freezing during the cold season.

- Insulation of cars and special equipment, various equipment.

Range of applications

- Liquid thermal insulation of pipes, oriented as an active component in the insulation of pipelines, is effectively used for thermal insulation of the following types of pipes:

- heating, both outside and inside the building;

- sewer and water supply, also metal, both in the ground and on the street;

- engineering water supply systems - cold and hot;

- air conditioning and ventilation systems;

- as insulation of chimney, exhaust and stove pipes;

- as insulation for laboratory equipment.

Classification of thermal compositions

The classification of the dye is carried out in two directions.

Two types according to manufacturing method:

- water CM - covers the pipes of the heating system, does not contain toxins;

- Acrylic-based CM is universal and interacts with many materials.

Three types depending on the place of application:

- universal CM - walls inside rooms and on the street side, ceiling, floor are covered;

- energy-saving façade paint – the moisture resistance indicator is high and allows the material to be used for painting the surface outside;

- heat-insulating paint for pipes - protects water and gas pipelines, pipes of ventilation and air conditioning systems.

Material selection

In areas with a predominantly cold climate, thermal insulation for pipes is a necessary condition for the functioning of heating systems of any type - central or domestic.

When choosing a material for insulating heating pipes, the following initial data should be taken into account:

- pipe section;

- conditions in which the heating system operates;

- temperature of the transported coolant.

The cross-section of the pipe determines what form of heat-insulating material should be purchased - in a roll or in the form of half-cylinders, cylinders of available sizes.

To choose the right thermal insulation, it is necessary to consider the main types of products used.

Material advantages

Thermal insulation paint, in comparison with traditional insulation, has many advantages. Among them:

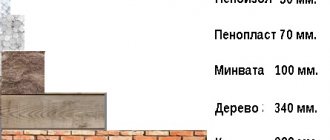

- Low thermal conductivity. A layer 0.5 mm thick can replace a 5 cm layer of mineral wool. That is, when using such a material, the volume of space occupied by the insulation is reduced.

- Good adhesion. The heat insulator can be applied to metal, wood, plastic, glass - it creates strong contact with any type of surface.

- Economical consumption. There is no need to apply a thick layer of paint. Typically the layer thickness is 1-4 mm.

- Waterproof. The coating provides good waterproofing and prevents rust and condensation on metal pipes.

- Resistance to biological effects. Mold and mildew do not develop on material coated with a heat-insulating composition.

- Resistance to temperature changes and ultraviolet radiation.

- Wide operating temperature range. At temperatures from -60 to +250 degrees Celsius, the paint will not lose its characteristics. Compared to some types of thermal insulation materials, it is more resistant to high temperatures.

- Possibility of application to surfaces with temperatures up to 150 degrees Celsius, that is, when applying the material, it is not necessary to turn off the supply of hot water or heating.

- Light weight. Thermal insulation paint consists of vacuum-filled microspheres that weigh almost nothing. Accordingly, the mass of the material is also small.

- Simple application technology. When using the material, no special equipment is required. All you need is a regular paint brush.

- Fire resistance. You can use heat-insulating paint for pipelines without using fire protection equipment.

- Environmental Safety. Liquid thermal insulation for pipes does not contain toxic substances, so it is used in medical institutions and catering establishments.

- Good maintainability. If the insulation is damaged, you can apply another coat of paint to the damaged area on the pipe.

- A universal color that can easily be changed after adding the desired shade to the color composition.

- Elasticity, resistance to mechanical damage.

- Long service life, reaching several decades.

Main parameters and advantages of insulating paint

The paint used for thermal insulation has the following distinctive features compared to traditional types of insulation:

- The thermal conductivity of the material declared by the manufacturer is 0.001 W./(m.*K.) allows replacing 50 mm. a layer of mineral wool - this allows you to reduce the amount of space occupied by the insulation.

- The material has good adhesion and can be applied to metal, concrete, wood, plastic, glass.

- When applied, the service layer of the material is usually 1 - 4 mm.

- The coating is waterproof, therefore it performs anti-corrosion functions; its use prevents the appearance of condensation on the metal surfaces of water and gas pipelines.

- The material is resistant to biological influences and inhibits the development of fungus and mold.

- The paint is resistant to sunlight and temperature changes and reflects about 85% of thermal radiation.

- The material does not lose its properties at temperatures from -60 to +250 C. and has maximum heat resistance compared to some types of insulation - this allows it to be used in conditions where other heat insulators cannot withstand temperature loads.

- Thermal paint is applied to the surface at a temperature of 5 to 150 C. This, in many cases, allows the pipeline supply system not to be disconnected.

Features of application

Before applying heat-insulating paint for pipelines, the surface must be cleaned of dust and dirt, primed and dried. The material is applied either with a brush, a roller, or a spray gun. An airless sprayer is best used for large areas. To apply the composition, do not use equipment that causes excessive mechanical impact on the material, which damages the microspheres.

You can purchase heat-insulating paint at the best price with delivery at. Call and our managers will help you choose the material that is suitable specifically for your purposes. Contacts are on the website.

Surface preparation

Before applying heat-insulating paint, the surface is cleaned, primed and dried. For larger volumes, a high-pressure airless sprayer is usually used. Other special devices for applying conventional paint can damage the microspheres - they will break on the surface, which will affect the thermal insulation properties of the material. In addition, insulating paint has a fairly thick consistency, which can make it difficult to spray. For small volumes, ordinary tools are suitable - a brush, spatula or roller.

Flow calculation

High-quality insulation materials purchased in the required volume will save money and optimize work. But at the same time, it is important to take into account certain nuances that help to correctly calculate the required volume of liquid thermal insulation paint, namely: • type of coating; • type of surface; • layer thickness; • pipeline diameter; • total area; • type of paint and structure; • method of applying material to the surface; • weather.

Let us give a calculation of the consumption of liquid thermal insulation using the example of “Corundum Classic”. Specifically, 1 liter of material covers: with a thickness of 0.5 mm – 2 m2; with a thickness of 1 mm – 1 m2. “Corundum”, according to laboratory costs, recommended 1 liter per 1 m2 with a thickness of 1 mm. There are also losses from overuse when applying thermal insulation in calm weather specifically to a vertical surface: 3–5% – with a brush on metal; 5–10% – with a brush on concrete; 15–25% – BAVD for metal; 35–45% – BAVD for concrete. Note: BAVD – airless high-pressure apparatus. The following factors also influence the overexpenditure: pipeline diameter; weather; degree of wall roughness; level of specialist training.

What is the choice of CM based on?

The thermal insulation coating is selected taking into account the location of the surface to be painted (outdoors or indoors) and its condition. The paint is selected from well-known manufacturers.

Some tips will help you quickly decide on the right type of CM:

- the high level of water resistance and heat resistance of CM is important for covering surfaces in the open air;

- interior work is done with paint without toxic components;

- Heat resistance is an important criterion when painting gas and water pipes.

The thermal insulation composition is applied in several layers, so before purchasing it, the required volume of the mixture is calculated. Calculations will be correct if the following factors are taken into account:

- estimated area to be painted;

- base material. Paint volumes increase by an additional 5-10% for wood, brick, and concrete. For metal, the margin is 3-6%;

- unevenness on the base. A reserve of about 40% is made for filling cracks and irregularities;

- multi-layer coating and thickness. A layer of 1.5 mm is applied to concrete, 2 mm to wood, 2.2 mm to metal, brick, cellular concrete and expanded clay concrete.

The required volume of CM is calculated by the formula: the product of the surface area, the consumption rate in l/m2, the number of coatings.

If walls outside are painted in calm weather, then consumption is reduced by 2-3%. With a coating thickness of 1 mm, the consumption of CM per 1 m is 1 liter.

Recommendations from specialists for selection

Experienced craftsmen advise based on the following recommendations when choosing liquid thermal insulation for pipelines:

- Carefully familiarize yourself with hydrophobicity, thermal conductivity and other properties. Comparing their compliance with the characteristics and material of the surfaces on which the composition is planned to be applied.

- Correctly calculate paint consumption, taking into account overconsumption and application thickness. Otherwise, the quality of the coating will deteriorate.

- It is not advisable to limit yourself to one layer. Especially if the pipes are too rough and uneven.

- Check the operating temperature of the composition specified by the manufacturer, compare with the conditions in which you will work.

- For exterior work, you should also buy paint for exterior use, and for interior use, respectively.

- Some formulations have limitations in freeze/thaw cycles. Pay attention to this when it comes to street use.

In general, thermal paint deserves attention, both from professionals involved in insulation and ordinary users seeking to insulate not only walls, but also pipelines in their household. And the fact that you can even apply it yourself (after all, it does not require special equipment when using it), then it will be easy to cope with this task.

Application technology

Thermal insulation paints are considered a fairly new product on the market, so they are not very widely used at present. In addition, they have a higher cost compared to conventional paints and varnishes. The use of heat mixtures can be identified with painting work. If possible, it is better to turn to professional craftsmen.

The technology for applying thermal paints is similar to conventional ones. We must not forget that each layer must be completely dried before applying a new one. The thermal insulation effect directly depends on the number of layers. This is due to the special structure of the mixtures.

After complete drying, a thermal film appears on the surface. Its thermal conductivity is lower than that of conventional insulation materials. It is very thin, which is why several layers of coating are needed. Their quantity is individual, in some cases it is permissible to apply up to 10 layers of thermal paint.