What is liquid thermal insulation

Let me start with the fact that the development of this product has been carried out since the seventies in the military space industry of both our country and America. A lightweight material was required, but with unique heat-insulating properties. Today, all advanced technologies have migrated into our everyday lives precisely from the military industry. And warm paint in this case is no exception. Now all the best is for peaceful purposes.

Insulation paint is a polymer binder made of acrylic or latex. It also contains fillers made from the smallest ceramic, glass or polymer beads and various additives that determine different areas of application. In a word, this is a complex chemical compound, the development of which took a lot of time and money.

Main manufacturers

Today, insulating paint is produced by several companies; buy brands such as:

- Corundum.

- Astratek.

- Armor.

- Magnitherm.

- Teplos-Top.

They can be found today in any construction hypermarket in plastic containers of 3, 5 or 20 liters.

The Corundum brand is available in the following modifications: Classic, Anticorrosive, Winter, Facade.

The Astratek brand is present on the market in the following types: Station wagon, Metal, Facade.

The Bronya brand produces varieties of paint: Classic, Anticorrosive; Winter, Facade.

The Magniterm brand consists of the following products: Standard, Facade, Nord, Fire Retardant, Anticorrosive, Anti-Condensate, Biocide and 600+.

The Teplos-Top brand is universal.

Moreover, this is not a complete list of brands and manufacturers.

Just by the names you can determine the scope of application of each composition:

- Classic and Standard are used for painting and thermal insulation of hot and cold pipelines.

- Anticorrosive, Metal - protection against metal corrosion.

- Facade – for exterior use.

- Winter, Nord – for work at sub-zero temperatures.

- The fire retardant has enhanced fire retardant properties and is intended for internal metal structures and wood.

- The biocide contains an antiseptic and fungicide to protect against mold and mildew.

- “Magnitherm 600+” is a paint for thermal insulation of particularly hot surfaces.

When purchasing paint for wall insulation, be sure to request a certificate of conformity for the material from the manufacturer: the cost of the compositions is high, and there are a large number of fakes on the market. The main selection criterion is thermal conductivity (for the best samples - 0.0012 W/m °C, up to 0.003 W/m °C for less efficient compositions).

How does modern insulation paint work?

Due to its unique properties, liquid insulation already begins to work at a thickness of 1 mm. This breaks the whole stereotype in our usual insulation. After all, we are used to the more the better. In this case, no more is needed. 1 millimeter of heat-insulating paint is approximately equal in thermal insulation to 5 cm of mineral wool insulation. Agree, this is a worthy indicator.

Once upon a time, while studying at school, we were taught that vacuum is the best insulator. Sound, heat, and electricity do not travel through it. This explains the phenomenal effect of using heat paint. Since there is a vacuum in the microscopic ceramic balls, the result is a kind of mini-thermos, of which there are millions, and maybe billions.

Due to such a complex molecular structure, thermal energy is reflected. All three types of heat transfer, namely convection, conduction and radiation, are almost completely reflected. The protected surface always remains pleasantly warm.

Insulation paint: characteristics, application, principle of operation

The use of the latest technologies has contributed to the production of effective and high-quality thermal insulation materials that have no analogues among traditional means.

Due to the constant rise in energy prices, the advantage of such modern materials is undeniable, so the innovative development of insulating paint has also become very timely.

This unique paint greatly reduces heat loss.

Being a liquid consistency, it is usually applied to roofs, walls, pipes, boilers, water heaters, hydrants, boilers (Find out what liquid insulation is here). This thermal insulation guarantees a comfortable temperature in our home, as well as real benefits from the work and money we spent on insulation.

Thermal insulating paint for walls: composition and scope of application

The composition of paints for thermal insulation is a mixture of:

- fillers;

- evacuated glass beads;

- water;

- acrylic-based dispersions;

- fiberglass;

- foam glass;

- perlite (in expensive types, perlite is replaced with ceramic microspheres).

Scope of material application:

- facades;

- pipes, including heating mains, water supply, gas;

- heating boilers;

- insulation of tanks and industrial equipment;

- walls in the apartment;

- basements.

The paint is applied in a relatively thick layer (4 mm), and therefore its use can replace several millimeters of external insulation or serve as an additional heat preservation system.

The condition for the thermal insulation function is an even layer around the perimeter, and therefore it is better to use a spray gun to evenly distribute the viscous consistency

Do-it-yourself method for applying thermal insulation

When using heat-insulating paint at home, you need to know in detail: how to correctly calculate and effectively apply a protective layer and how to prepare the work site.

Preparation consists of two stages:

- Cleaning. Dirt and dust are removed from the surface. Iron structures must be degreased with an anti-corrosion agent. A brick or concrete wall is cleaned of uneven plaster and dust. Deep cracks are filled with putty, leveled, and cleaned. The prepared surface must be dry.

- Depending on the composition of the paint (acrylic or water-based), it is brought to a certain thickness. Mix with a drill at low speeds or by hand.

After the preparatory work, painting is done in 2-3 layers. The consistency of the insulation is no different from thick paint. It can be applied to your home outside and inside using a sprayer, knowing some of the nuances.

Methods for applying LCD are slightly different from simple painting in some important subtleties:

- For spraying, use only airless sprayers. Using the air pump method, the protective structure of the film is lost under the influence of high pressure.

- To work with ultra-thin ceramic coatings, use only tips and guns specified in the instructions.

- Adjust the sprayer according to the parameters specified in the instructions.

- Use devices that are recommended for such work.

- During work, all filters that destroy microspheres are removed from the sprayer.

- The device must have a hose no longer than 45 meters (longer hoses affect the set spray pressure).

- The set pressure standards are observed within the range of 40 to 80 bar.

- Since the airless filter does not agitate the paint during application, frequent agitation will be required.

- A device is selected that sprays thermal insulation in an amount of 5 liters per minute.

- Do not use Chinese sprayers under any circumstances.

After use, wash the device thoroughly.

This new type of thermal insulation product is quickly gaining popularity due to its useful characteristics and advantages. Saving heat and insulating from moisture in the cold season is very important.

The price of liquid thermal insulation is high, but the time spent and quality indicators justify it.

Liquid insulation for house walls, ceramic paint ISOLLAT

, unlike other methods of insulating a house, it is free from all the “minor” troubles inherent in each of the materials listed below.

Having chosen liquid insulation for walls

, insulating the house with your own hands both outside and inside it, and eliminating wall freezing becomes inexpensive and easy.

To understand how Isollat works, you can exaggerately imagine a concrete wall with hollow expanded clay mixed in it together with hollow silicone spheres containing rarefied air. Only Isollat has an acrylic base instead of concrete. That is why, despite its very thin layer, liquid ceramic thermal insulation paint Izollat has excellent heat transfer resistance and is most suitable for insulating a house with your own hands. Agree that insulating a house by painting a wall is much easier than sheathing it.

Comparative thermal insulation performance

It should be noted that Isollat

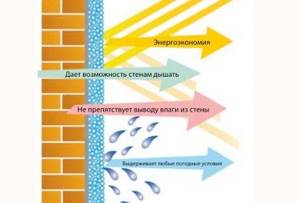

- Not exposed to UV rays - does not change color or structure;

- Vapor permeable. which allows us to solve the problem of removing excess moisture from building materials such as brick, wood, reinforced concrete;

- Resistant to external mechanical influence.

- It has excellent adhesion, making it possible to apply wall insulation to almost any surface;

So, to insulate a house with your own hands, all you need is a brush. To perform high-quality insulation of walls, it is enough to apply a layer of Isollat, only 2 mm thick, which will be equivalent to insulation with foam plastic or mineral wool slabs, the thickness of which, accordingly, should be at least 7-10 cm! The required two-millimeter layer of Isollat is formed on the surface when applied with a brush in 2 layers.

The adhesive properties of Izollat allow it to be applied to any vertical and horizontal surfaces, securely fixing on concrete, plaster, gas silicate blocks, roofing felt, metal and other building materials. Excellent characteristics of moisture resistance and adhesion determine the widespread use of Izollat.

In order to efficiently insulate a house, Isollat is applied to external and internal walls, flat and pitched roofs, basements and ground floors, and building foundations. Isollat is also used for insulating joints of building structures and insulating pipelines.

To properly insulate a house with your own hands, you need to carefully treat the cold bridges with Isollat. Spraying it will ensure reliable insulation of joints and cracks in areas of the coating, since there are no “cold spots” in the continuous layer of coating that contribute to freezing of structures

In order to insulate a house with your own hands when applying Isollat ceramic insulation, you should adhere to the technology and painting work. The walls are pre-cleaned of debris, degreased and treated with a primer. After this, insulation of the house outside and inside

carried out using a spray gun or brush. Isollat 01 wall insulation is applied to the walls in two even layers. The thickness of each layer is approximately 1 mm

By insulating your house in this way, you are putting yourself and your loved ones at mortal risk. (Remember the fire at Lame Horse). And if you decide to insulate the house with your own hands

, then you are unlikely to want to take on such responsibility. In addition, when applying PU foam, you will have to buy an expensive unit for spraying, since there is no other way to apply PU foam. Polyurethane foam applied in places not protected from light and atmospheric influences should be painted over, since polyurethane foam has low resistance to ultraviolet radiation. As for polystyrene foam, read the previous paragraph for flammability, plus the foam plastic must be cut into pieces to size, fastened, joined and coated with sealant on every crack - and such insulation of a house is a rather tedious task. In addition, cold bridges always form at the joints of the foam.

Functional Features

The quality of thermal protection of thermal paint directly depends on the applied layer and the number of stains. However, it is also not recommended to apply an excessively thick layer; the best option is 2-4 paintings, no more than 6 mm thick. The number of layers depends on the type of heat-insulating liquid material, as well as on the type of surface to be applied. The service life is 12-40 years, and the temperature characteristics are -70°C, +260°C.

Main advantages

The main advantage of liquid insulation for work inside buildings is thermal insulation without reducing space. It is important to note the material’s resistance to temperature changes, which occurs in winter during the heating season: it’s minus outside and plus inside, condensation collects, which forms a favorable environment for the development of fungus. Additional benefits:

- environmental friendliness - the paint does not emit harmful toxic compounds at high temperatures and does not react with other building materials;

- saving on heat bills due to thermal insulation;

- strengthening treated surfaces.

Description of the composition, its components

The innovative material is designed to interact with a surface that releases heat and loses it completely. Insulating materials of the previous generation are aimed at retaining heat, eliminating cold bridges. Thermal insulating paint is endowed with heat-reflecting quality. This means that the heat remains, does not go away, and 70% of it comes back. A similar effect is created due to the vacuum environment inside the filler. Infrared waves in a vacuum environment increase speed by 1000 times. This leads to the fact that only 30% is lost, 70% comes back after being reflected. This operating principle of KM allows you to effectively insulate facades, walls, roofs, and other surfaces of housing construction.

Important: heat loss is reduced by up to 40%. Despite the fact that the coating repels water and moisture, the base does not stop breathing.

Thermal insulation paints consist of:

- water-acrylic mixture is the binding base. The component affects the uniform distribution of the coating and the adhesion of the insulation to the base;

- microscopic ceramic granules that are filled with gas - fillers. A high level of thermal insulation of the material is created thanks to them;

- silicone, rubber, other elements - additional components. They are responsible for the elasticity of the coating and its water resistance.

When the applied CM dries, vacuum voids occupy 75-80%. Material 2-4 mm is applied. This replaces the use of insulation in its traditional form. Visually, the composition is as thick as homemade sour cream. The base color of the paste composition is white or gray. It is recommended to spray it. Then the coating will lie evenly.

The protective layer of the innovative material will last 12-40 years. It tolerates temperatures from -70°C to +260°C.

Distinctive characteristics and properties of thermal insulation paint

Ease of application is a big plus. Thermal insulating paint can be applied in a variety of ways, including roller or spray. When the area to be treated is large, a spray gun will be more useful.

Akterm is a liquid thermal insulation similar to paint. This is a practical consistency suitable for various types of surfaces. With prolonged exposure to air (about 24 hours), the mixture polymerizes. So it becomes a thermal barrier. In summer, thermal paint reflects 95% of the sun's rays. And in the winter months, on the contrary, they return (this volume will be about 70%). AKTERM does not require special conditions for application. So, a temperature of at least 20 degrees C is sufficient. And during operation, the product will withstand up to -60°C. And if the surface with paint becomes dirty, it can be easily washed, and it will again become not only functional, but also aesthetic.

Today, energy-saving technologies are becoming increasingly relevant as a construction issue. The modern market offers consumers innovative developments in this area, embodied in high-quality universal materials. They are designed to provide maximum protection of the home from adverse natural factors and proper thermal insulation of the premises.

Thermal insulating paint is a new product on the building materials market. Its purpose is to reduce heat loss in a building, in particular in a house. Having a liquid consistency, the material is easily applied to any type of surface, even deformed. The material is completely safe for human health and the environment, being a composite thermal paint, which includes a polymer matrix and a filler - hollow microspheres.

The range of properties of heat-insulating paint is very wide:

- Prevents cold from penetrating into the room

- Prevents corrosion on metal surfaces

- Excellent heat retention

- Prevents moisture from entering, eliminates mold

- Eliminates condensation

- Saves electrical energy

The thinnest layer of insulating paint can completely replace the traditional thermal insulation system of a house. Liquid insulation has a very reasonable cost and efficiency, which is also one of the factors in favor of its choice.

Liquid thermal insulation: name and immediately veiled lie

There are quite a lot of various rumors, exaggerations and other obscurities surrounding liquid thermal insulation, and the very first lie in this whole matter lies in the name - it is not liquid at all - it is a thick mastic with a weak degree of fluidity. They called it that in order to solve a number of advertising problems. What did advertisers put into the name of this type of thermal insulation? What did they want to emphasize with a word like “liquid”?

- First of all, ease of application - apply with a brush and that's it. And immediately the house became warm. On the one hand, this is true, but on the other, not quite - one of the options for applying such thermal insulation is just a brush, but regarding the heat in the house, alas, this is not true. We will talk about this later in more detail.

- The second thing our advertising agents wanted to put into this name was, undoubtedly, the uniqueness of the material and its unusualness compared to all others. Yes, it sounds extraordinary – and that’s all. There is nothing unique about this material - with some variations, it has long been known under names such as heat-insulating mastic or heat-saving paint. By the way, these materials have been used in Europe for almost half a century, and they are used to insulate pipelines and various metal structures - this is not only good thermal insulation for pipes, but also excellent protection of metal from corrosion.

In general, the original lie, an utter lie, hidden under such a concept as an advertising ploy - it is, of course, harmless, but it misleads people. In general, there is a lot of false information around this material, and the biggest lie among all this lies in its scope. This needs to be dealt with in more detail.

How to choose?

When choosing a thermal insulation material, it is important to consider the location of the painting work (indoors or outdoors) as well as the type of surface being treated. Before purchasing thermal paint, it is also advisable to familiarize yourself with the list of popular manufacturers and study reviews of their products.

Some recommendations for selection:

- for exterior work, you should select paint with high levels of water resistance and heat resistance;

- for indoor work, you need to purchase paint that does not contain toxic substances;

- the mixture for painting gas and water pipes must have the highest heat resistance.

It is worth remembering that when painting, quite a lot of heat-insulating composition is consumed. Before purchasing a suitable liquid insulation, it is important to calculate in advance the required amount of mixture.

When calculating, the following factors must be taken into account:

- Surface area to be painted.

- The type of material that will be coated with paint and varnish. To cover a wooden, brick or concrete surface, paint overconsumption can range from five to ten percent. Painting the metal may require an additional three to six percent of the mixture.

- Presence of defects on the surface. If there are small cracks or irregularities, it is worth considering that painting such areas will require an additional amount of liquid heat insulator. Overconsumption of the mixture can reach forty percent.

- The number and thickness of paint layers you plan to apply to the surface. Recommended coating thickness for different materials:

- For concrete - one and a half millimeters.

- For wood - two millimeters.

- For metal, brick, cellular concrete and expanded clay concrete - two and a half millimeters.

To calculate the approximate amount of paint, you need to multiply the surface area, the consumption rate (liter/sq. m) and the number of intended layers.

What it is?

Thermal insulation paint is a universal material. It has no environmental or technological restrictions.

It can be used by anyone who carefully follows the instructions. Insulating paint is used on almost any surface using all available methods: spray, rollers and brushes.

This material is also useful in that it can be used in places where achieving results using other methods is more labor-intensive and problematic.

Varieties

The type of warm paint is conventionally divided according to two characteristics:

- composition: acrylic or water base;

- by area of application: for indoor work, for pipes, facade - exclusively for outdoor work.

Thermal insulation paints for interior work

For work inside buildings, both acrylic and water-based compositions are suitable. An important task is to determine the functional load, as well as study the composition, which should not contain toxic components. To treat pipes, heating mains, and gas pipelines indoors, use interior paint, preferably acrylic-based, and for painting cold walls, you can use a water-based composition.

Insulating paints for exterior work

For outside work, it is necessary to select thermal insulation materials taking into account the functional characteristics of the surface and environmental conditions (humidity, frost, sunny side). It is better to choose a mixture with minimal water resistance and the highest vapor permeability, so that heat will be retained and the treated surfaces will not deteriorate.

Teplomet - ultra-thin innovative insulation

Severe winters in most regions of Russia and the constant rise in energy prices are forcing scientists and practitioners to develop new, more effective options for thermal protection of buildings. One of the non-traditional insulation materials is Teplomet - paint, or rather, thermal paint, the layer of which is equivalent to a layer of mineral wool 50 mm thick.

Principle of operation

It is difficult for an ordinary consumer to imagine that paint can, in principle, replace mineral wool or polystyrene foam. Here we need to remember a little physics. The mechanism of action of traditional thermal insulation is clear: the thicker the layer of thermal insulation, the less heat exchange with the environment. However, there is another way of heat transfer - infrared radiation, for which traditional insulation is not an obstacle. It is this type of heat loss that liquid thermal insulation resists, forming a kind of heat shield.

Teplomet is a latex-based paint in which glass-ceramic and aluminosilicate microgranules of different sizes are used instead of solid fillers. The gaps between the relatively large microgranules are filled with microporous titanium dioxide particles. There is a vacuum inside them. 80-90% of paint consists of such microscopic granules. They are in a suspended state, which makes it possible to achieve lightness, strength and elasticity of the coating, as well as good adhesion to various surfaces.

Advantages of liquid thermal insulation

Liquid thermal insulation has many advantages over traditional materials. First of all, this is a significant reduction in the labor intensity of work, especially on objects with complex shapes. Thermal paint is applied with a regular painting tool: roller, brush or spray. It performs its functions for up to 20 years, and after that there is no need to dismantle the old coating.

In addition to thermal protection, liquid thermal insulation plays the role of anti-corrosion protection, preventing surface contact with water and air. It works in cold temperatures down to -40°C and in heat up to +250°C. The Teplomet coating is highly resistant to mechanical stress, high humidity and ultraviolet radiation, and also protects against mold and mildew. Its environmental safety allows it to be used even in children's institutions or food industry enterprises.

Of particular note is the fire safety of Teplomet paint. Buying this material to insulate a house means protecting it from fire at the same time. Experiments have shown that charring of the coating occurs at +500°C, and it begins to decompose at +840°C. Let us recall that, for example, wood ignites at +300°C, and its combustion temperature is on average +900°C. When thermal paint decomposes, nitrogen and carbon oxides are released, which prevent the spread of fire.

The only drawback of Teplomet is the price. It is really more expensive than other insulation materials. However, if you compare the total cost of insulation work, it will be lower.

Application technology

The scope of application of Heat Met is exceptionally wide: pipelines, buildings, liquid storage tanks, boilers, vehicles, railway cars and many other objects.

Liquid insulation is paint, which determines the technology of its application. The best option is a high-pressure spray gun. The material is non-toxic, so it can be applied without forced ventilation. Surface preparation is no different from conventional painting.

The coating is applied in 1-2 layers with intermediate drying during the day. Approximate material consumption is about 1.25 l/sq.m.

Manufacturers

In order not to make a mistake in choosing a high-quality thermal insulation coating, it is better to purchase products from well-known and trusted manufacturers. Among Russian manufacturers of thermal insulation paints, four leading ones can be identified:

One of the most popular manufacturers of thermal insulation mixtures is.

Liquid heat insulators from this company can be used to treat the following surfaces:

- metal containers;

- rooms with high humidity levels;

- boiler rooms;

- facade of buildings;

- surfaces inside residential and administrative buildings;

- chimneys;

- motor transport, passenger aircraft, railway cars;

- pipelines.

produces several types of paints and varnishes, depending on their scope of application. The following modifications of Korund products are produced:

- "Classic". A universal coloring composition that is suitable for external and internal work. Widely used in building construction.

- "Facade". This heat insulator is designed for treating concrete walls. Painting can be done both outside and inside the room. The material has a high level of waterproofness and heat permeability. The coating protects the walls from overheating in the warm season and from freezing in the cold season.

- "Lotus". It has the same qualities as the “Facade” modification. This material is intended for application to the surface in the form of a final layer.

- "Winter". A distinctive feature of this modification is that the dyeing procedure can be performed at sub-zero temperatures. You can work with such material at temperatures not lower than -10 degrees.

- "Anticor". Used for painting metal surfaces. This paint and varnish material protects the metal from atmospheric influences and prevents corrosion.

"Termalcom"

produces a line of heat-insulating paints "Astratek". The paint and varnish coating is made on the basis of polymers. offers products with high performance characteristics at reasonable prices.

Liquid thermal insulation "Astratek" is widely used in the construction, industry and housing and communal services sectors. There are six modifications of this company’s thermal paint:

- "Astratek Universal". Suitable for painting all types of surfaces. It has a high level of vapor permeability, which helps prevent the appearance and spread of mold on the surface.

- "Astratek Metal". Used for painting metal structures and devices that are operated in unfavorable conditions of high humidity. Such a coating will increase the service life of products made of ferrous and non-ferrous metals, prevent corrosion and eliminate the formation of condensation.

- "Astratek façade". It is used for thermal insulation of building facades.

- "Astratek NG". It is a special fire-resistant modification of the material.

- "Astratek Universal BC". An all-season coating that is temperature and weather resistant.

- "Astratek decor-acoustic" It is used as additional thermal insulation of walls, and also significantly improves the acoustics in the room.

GC VIRTs "Bronya"

The products are widely used in various fields of construction and industry. The manufacturer offers the best conditions on the thermal paint market in terms of price/quality ratio.

Thermal insulating ceramic paint "Bronya" was previously used mainly for painting gas networks and water supply systems. However, the company regularly expands its line of thermal insulators with new modifications.

Thermal paints are divided into three groups:

- basic modifications;

- budget modifications;

- special modifications.

"Akterm"

is one of the leading manufacturers of liquid thermal insulation. The company independently develops a unique manufacturing technology for its products. In the production of heat-retaining materials, only high-quality raw materials are used.

Liquid thermal insulation currently has fifteen different modifications, differing in composition and properties.

The main functions performed by Akterm thermal insulation coatings are as follows:

- preventing the formation of condensation;

- anti-corrosion protection;

- water protection;

- thermal insulation;

- fire protection

Recommendations for application:

- Before using ultra-thin insulation, it is necessary to prepare the surface to be treated: remove rust, clean from dust and grease, and prime if necessary. It is advisable to apply the paint and varnish composition at a humidity of no more than eighty percent and a temperature of at least seven degrees Celsius.

- When carrying out external painting work, it is better to choose calm weather. Due to wind, paint consumption can increase by up to five percent. The following tools can be used to apply the coloring composition:

- roller;

- spray gun;

- paint brush.

- It will be most convenient to apply the mixture using a spray gun. If the ultra-thin insulating mixture is too thick in consistency, it can be diluted with water. Also, do not forget about using a respirator to protect your respiratory organs.

Distinctive features of thermal insulation compounds

Thermal insulation composition is a unique product. It acts like insulation and is applied like regular paint. Such products help prevent heat loss by creating a thermal insulation layer that will last more than 10 years. Paint also protects the surface from moisture penetration and mold development, and metal from corrosion.

The color of the coating is usually white. Thermal insulation paint is diluted, depending on the composition, with water, solvent, toluene or xylene. Available in plastic containers with a volume of 3...10-20 liters.

There are several types of such products. They differ in their constituent components. Any thermal insulation paint contains a base (water-based or acrylate), a filler (fiberglass, perlite, foam glass or ceramic microspheres), as well as additives that improve the elasticity and water resistance of the product. The combination of all these components makes the coating stretchable, light and flexible.

The paint adheres to almost any surface. Apply to the base using a spray gun, roller or brush. After drying, an elastic polymer coating with high thermal insulation and anti-corrosion characteristics is formed on the surface. Just a few millimeters of such a layer provide a level of thermal insulation equivalent to laying one and a half bricks.

Advantages and disadvantages

applied in a thin layer (0.5 mm), creates minimal load on the base;

sticks to any base (metal, concrete, brick, stone, wood, plastic);

there is no creeping effect;

creates a moisture-proof coating;

protects against corrosion;

ignites only at very high temperatures;

prevents heat loss by 30-40%;

the coating does not lose properties at low or high temperatures;

protective properties last for more than 10 years.

takes a long time to dry (24 hours);

high consumption (per square meter of area - 0.5 liters of solution);

high price.

Efficiency assessment from experts

Liquid insulation today is just gaining the trust of consumers, but there are already opposing opinions about the effectiveness of using “liquid ceramics”. For example, the calculations are given:

- extruded polystyrene foam in fact (50 mm) costs 300 rubles. (sq. m);

- assume thickness 1mm, price per sq. meter - 6 rubles;

- the total cost in equivalent of ultra-thin thermal insulation is 450 rubles/liter;

- With the recommended consumption of thermal paint, its price is for the same 1 sq. m. (thickness 1 mm) when applied in a single layer is 100 times higher than that of expanded polystyrene.

In contrast to such reasoning, other experts give the example that the thermal insulating properties of the extruded polystyrene foam given as an example are at least 50 times lower, and the surface emissivity due to the roughness of the thermal paint is much higher. When treating the surface with “liquid ceramics”, the effect of a “thermal mirror” is obtained. Believing one reasoning or another is an individual matter, but experts agree that there is no alternative to liquid ceramics in hard-to-reach places. It is difficult to imagine insulating with mineral wool under a window sill or in other places, but thermal insulation paint does an excellent job of this task, leaving no seams or bends.

The material's high adhesion helps insulate the surface from moisture, water and cold air, eliminating the potential for external corrosion and rust formation.

Solid thermal insulation.

Debates about the pros and cons of polystyrene have been going on for many years.

They talk about its deadly gas released during combustion, harmful fumes at normal temperatures, fragility, etc. But these negative properties do not prevent it from remaining in a leading position, leaving behind other thermal insulation materials. Experts say that all problems associated with the use of this material in thermal insulation systems arise due to violations of regulatory requirements. Everyone knows that the lower density of polystyrene foam makes it cheaper. The consumer is trying to save money, and therefore PSB-15 polystyrene foam is the most popular thermal insulation material today. But are there any manufacturers whose products with such a density can ensure the fire safety of the declared G2 flammability group, which is approved by firefighters. Therefore, in the construction of low-rise buildings it is necessary to use expanded polystyrene grade PSB-25, and this significantly increases the cost.

There is another explanation. In European practice, determining the fire safety of expanded polystyrene involves studying its flammability as part of an insulation system. This approach is more objective than considering the thermal insulation material separately. But then an interesting nuance emerges: it is not a fact that denser polystyrene foam is better. The reason is that the high density of expanded polystyrene does not lend itself to temperature deformation to the same extent as the outer layers of wet finishing. As a result, cracks appear at the joints of the plates. The only advantage of expanded polystyrene and EPS over mineral wool is their low water absorption. It becomes decisive if the waterproofing properties of the façade finish leave much to be desired.

Expanded polystyrene has two varieties: EPS and GPS. Materials vary in properties and production method. EPS (aka PSB) is produced by thermal shock from expanded polystyrene granules. Its density ranges from 15 to 50 kg/m^(3), and its strength depends on the manufacturer. GPS is known to us as EPS, produced by extrusion. With the same density as PSB, it shows higher strength, but passes steam worse. EPPS is produced with a density from 20 to 70 kg/m^(3). Regarding the toxicity of expanded polystyrene, it is absolutely safe in the wall structure, since it does not emit harmful substances into the room, does not interact with acids and alkalis, and does not react with building materials of inorganic origin. But when burned (fire), polystyrene releases highly toxic substances, the inhalation of which can be fatal. For this reason, polystyrene foam is protected on both sides with non-combustible materials (brick, plaster, etc.).

EPS obtained by extrusion is indispensable for inversion roofs and in the thermal insulation layer of basement walls where the least water permeability and high strength are required from thermal insulation. But it should not be used for thermal insulation of facades, due to low vapor permeability. The service life of PSB depends on its density and method of use in the thermal insulation system. Only when polystyrene foam is reliably waterproofed can it last for quite a long time. After dismantling the structures built in the 80s, the recovered PSB turned out to be almost unchanged, which indicates the durability of this material. But it is worth knowing that the structures were made with strict adherence to thermal insulation technology. With a slight violation of the technology, polystyrene foam quickly collapses.

Thermal insulation paint: buy or use traditional insulation?

Since its inception, liquid thermal insulation has significantly displaced traditional types of insulation in the building materials market. Without being inferior in environmental friendliness, it ensures a reduction in labor costs, consumption of building materials, and has improved characteristics:

- Minimal load on load-bearing structures - a layer of several microns instead of the standard 50 - 20 mm

- Easy to use – painting with a spray gun, roller, brush

- universal in use - treatment of walls, ceilings, the inside of the roof, basements

- Does not require cutting - no trimmings or waste requiring disposal

- Convenient to store and transport - a bucket of paint takes up much less space than a stack of polystyrene foam sheets and can be transported by car or manually

Thermal insulation paint, which you can buy in our store, is available in various packaging, allowing you to choose the right amount to reduce your repair budget. Prices can be viewed on the page of each product.

Description and features

Since the arrival of thermal paints on the construction market - mineral wool, polystyrene foam, styrofoam - they have become less common, although it is too early to talk about the complete replacement of old insulation materials. The innovative product looks like a thick mass of white or grayish color interspersed with ceramic balls filled with inert gas.

The water-acrylic base is supplemented with various fillers in the form of fiberglass, silicone, rubber, perlite. Thermal insulating paint , with a small layer thickness, provides a level of protection similar to other materials.

Thermal insulating paint "Armor"

For example, 1 mm of energy-saving paint is equivalent to the effect of mineral wool 50 mm high. Liquid thermal insulation is harmless to humans. During the application process it reduces labor costs and reduces material consumption. The advantage of the new type of insulation is manifested in the following:

- the structures receive minimal load - instead of traditional insulation sheets 20 - 50 mm thick, the height of the paint layer is only 2 - 4 mm;

- ease of surface treatment with a roller, spray or regular brush;

- universal use - for insulating walls, ceilings, pipes, basements;

- preservation of indoor space due to the insignificant thickness of the coating;

- in the absence of waste, subsequent disposal of crumbs and trimmings;

- heat resistance of paint;

- uniform application - the liquid product can cover the most non-standard parts, complex geometric structures, and hard-to-reach areas;

- accessibility of transportation and storage - instead of large stacks of sheets of foam plastic or other material, cans, buckets of paint, which can be carried manually.

The scope of application of liquid insulation is steadily expanding in all civil and industrial facilities and in the construction sector. Many housing and communal services organizations have appreciated the advantages of modern thermal insulation, effective and economical in long-term use.

Liquid energy-saving coating cannot be stolen or significantly destroyed. Over time, if necessary, the coating can be easily restored. The work can be carried out by one person without special training.

insulating paint for pipes is ideal for treating shut-off valves, any water heating devices in boiler rooms, and oil and gas storage facilities . The product is used for thermal insulation of facades, roofs, basements of buildings, interior spaces, industrial equipment, various containers, and cars.

Thermal insulating paint is used for pipe insulation

The question of whether liquid thermal insulation can completely replace traditional materials is controversial. The high cost of the product limits mass use, but as an addition to relief areas and complex building structures, it significantly increases the efficiency of work.

Thermal insulating paint for metal when covering objects provides additional anti-corrosion surface treatment. The highest thermal protection occurs when there is a significant temperature contrast between the external environment and the coating layer, most often when the pipes are extremely hot. It is more rational to sheathe large areas of walls with conventional insulation, but apply thermal paint in vulnerable places to maintain quality.

Fighting condensation with heat paint

Liquid thermal insulation allows you to avoid the manufacture of complex structures necessary for attaching a thermal insulation layer near the roofs of hangars and residential buildings. Painting pipelines of engineering systems is much cheaper than protecting pipelines with polystyrene foam shells, winding with basalt wool, and then waterproofing the insulation.

Condensation control is available to a home craftsman with minimal painting skills. Liquid thermal insulation is sold in convenient buckets and jars, is completely ready for use, and has instructions for use. The weight of the roof practically does not increase when applying a millimeter layer, while the comfort of using the premises increases many times over.

Types of insulation with liquid heat insulator and their features

We already know that liquid heat insulators come on sale in the form of three groups. Ceramic insulation before use looks like ordinary white acrylic paint. Liquid heat insulator penoizol must be applied exclusively using compressor-based equipment. Ecowool is made from natural cellulose fibers and is harmless.

The main thing that needs to be ensured when applying insulation is good adhesion to the surface. This is the key to long service life of the material. To ensure adhesion, it is important to thoroughly prepare the surface: remove dust, dirt, grease stains and rust.

Now we will learn in more detail about each type of insulation. This will allow you to find out the features, compare them and make a specific choice.

Main advantages

Some of the positive properties have already been described earlier, but there are other features:

- A very thin layer of heat-protective paint on metal and other materials that does not change the dimensions;

- No requirements for skills and equipment, which simplifies application;

- Environmental friendliness;

- Surfaces free of mold and condensation;

- Fire resistance;

- Low weight. This property is especially important when used for facades of buildings and pipelines;

- Resistance to ultraviolet rays;

- Full protection from mechanical loads;

- Rust and corrosion certainly do not appear on metal surfaces;

- Long service life;

- Reliable heat retention.

High consumption and high cost become the only drawbacks for the materials, but in further operation everything pays off.

Rust and corrosion definitely do not appear on metal surfaces.

Thermal insulation paints for interior work

The main properties here are stability and the absence of substances that can harm human health. The work usually involves mixtures with a water base. In the case of heating systems, acrylates are more relevant due to their ability to resist elevated temperatures.

The main properties here are stability and the absence of substances that can harm human health.

Types of heat-protective paints

Suspensions are divided into two groups: according to the set of components and area of application. In the first case, they are produced based on two types:

- Water.

- Acrylic.

There are more subspecies for use:

Insulating paint for walls

Intended for indoor use for thermal insulation of any surfaces - walls, ceilings and floors.

Pipe paints

They are used for painting batteries, gas and water pipes, etc. Their peculiarity lies in their water-repellent properties, fungus does not form on them, and they can withstand significant temperatures.

Facade

Relevant only for outdoor work, they are able to withstand sudden fluctuations in temperature, rain, wind and other natural phenomena.

Liquid thermal insulation of pipes "Teplotortm" in the housing and communal services sector

DESCRIPTION INSTRUCTIONS FOR USE WORK PERFORMED

Every resident of an apartment building who regularly pays for utilities has the right to expect that his apartment will be warm and hot water will flow from the tap.

But is this really so?

As practice shows, hot water and heating pipes in many basements and attics of apartment buildings heat basements, attics, and the atmosphere, but not apartments, because... they completely or partially lack thermal insulation of the pipes, and if they do have it, it does not fulfill its functions.

All problems with thermal insulation of pipes in apartment buildings will be solved by liquid thermal insulation of pipes "Teplotor TM".

Liquid thermal insulation of pipes has all the necessary certificates, including a Certificate of inclusion in the Register of new technologies, equipment and materials used in the field of housing and communal services and construction of the Russian Federation, as well as a Certificate of Compliance with the norms and rules of technical operation of the housing stock.

Comparative table of the pros and cons of using various pipe insulation materials.

| Characteristics | Min. galvanized plate | PPU with galvanization | PPU with fiberglass | Heattortm |

| Thickness (mm) | 50 | 50 | 50 | 1 |

| Thermal conductivity | 0,035 | 0,033 | 0,033 | 0,001 |

| Wetness of insulation | There is | No | No | No |

| Corrosion under the insulation layer | There is | There is | There is | No |

| Theft of materials | There is | There is | There is | No |

| Environmental Safety | No | There is | There is | There is |

| Scope of repair work | big | big | big | small |

| Service life (years) | 2 | 15 | 15 | 15 |

| Aesthetics | quickly lost | quickly lost | quickly lost | saved |

Liquid thermal insulation of pipes "Teplotor TM"

Instructions for using liquid thermal insulation as a pipeline insulator

Preparation of surfaces for treatment with liquid thermal insulation "Teplotor TM"

Clean the insulated part from dirt, rust and old paint that does not adhere well, using metal brushes.

Be sure to degrease the pipe! When treating metal pipelines with liquid thermal insulation, it is necessary to apply primer.

We use Unicor-M or Kronacryl for these purposes, although any primers can be used.

When applying liquid insulation to galvanized or aluminum surfaces, there is no need to prime.

Information on heat-resistant enamels and primers:

| Name | KO-8104 | CBS 12-03 | CBS 12-01 | KO-870 | KOS 82-03 | KO-811 | KO-8101 | CBS 11-07 | Unikor-M | Cronacryl |

| Heat resistance, degrees | Up to 400 | Up to 150 | Up to 300 | Up to 600 | Up to 600 | Up to 600 | Up to 600 | Up to 300 | Up to 150 | Up to 110 |

AKTERM Anti-condensate - 320 rubles per liter.

We present to you a new product AKTERM Anti-condensate, which prevents the appearance of condensation. Our product is ideal for insulating refrigeration and air conditioning systems, water pipes and metal structures. The properties of the product make it possible to effectively use AKTERM in pipelines with refrigerant and in refrigeration systems, protecting pipes from the formation of condensation, snow and ice.

| Thermal insulation of brick and concrete | Anti-condensation |

Paint components

Energy-saving facade paint consists of two main components, which provide the unique properties of the material:

- polymer;

- special powdery spheres.

The size of each sphere is different and ranges from ten to two hundred microns.

The percentage of spheres in the paint directly determines its characteristics. That is, the more spheres, the more effective the coating and the more reliably it protects the room from the penetration of cold into the building .

The essence of the operation of such a coating lies in the unique principle of heat accumulation, which is then returned inside the room.