Gas melting metal welding involves the use of equipment such as a gas torch. With its help, the metal surfaces to be joined are heated and melted. As a rule, all burners have a simple design, light weight, and are convenient to use. To choose the right tool for the work ahead of you, you should pay attention to the design features, as well as the types of burners.

How does a gas burner work? Operating principle

The design of a gas burner traditionally consists of an insulating sleeve, a nozzle, a diffuser, a mixing chamber, gas regulators, cable connectors, a handle equipped with a button, a cable, a connector and a tip mouthpiece. The gas burner device may include other elements - a piezoelectric element, a cooling system, and a feeding device. The presence or absence of certain components depends on the methods of supplying flammable gas.

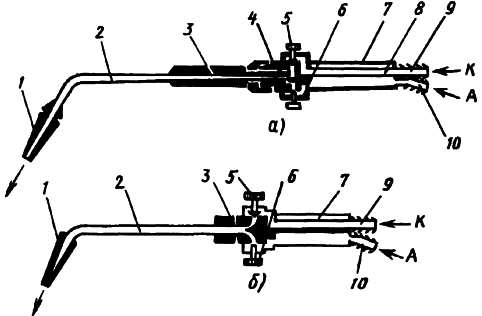

- The injection type burner circuit includes an air supply regulator, a nozzle, a mixer, and a distribution manifold. Before final mixing, the gas-air mixture is rarefied, air is sucked in, then the stream is leveled in the diffuser and enters the collector, where it is evenly distributed among the holes.

welding torches: injection - a; non-injector - b; 1 - mouthpiece; 2 — tip tube; 3 - mixing chamber; 4 injector; 5, 6 - control valves; 7— trunk; 8 - tube; 9, 10—nipples

In turn, injection burners come in two varieties:

- with full injection or high pressure burners;

- with partial injection, or low pressure burners.

Devices of the first type are used mainly in heating boilers and for heating industrial furnaces. They ensure complete mixing of the components intended for combustion. The second type is common in furnaces for heating soldering irons, autosmokers, and in the furnaces of Strel and Strebel boilers. The combustion zone of such devices is provided with only part of the required air; a sufficient amount of it is drawn from the environment.

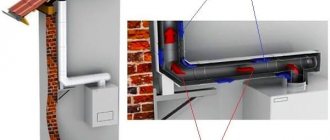

- Non-injection burners assume the same pressure for oxygen and fuel gas when they enter the mixer. Their design is complicated by a fan, an electric motor for drive, and air ducts. Due to these parts, non-injection burners can reach 1.9 m in length, which makes the tool not very comfortable to use.

Oxygen and combustion gas are delivered to the mixing nozzle in similar ways. From the cylinder, gases enter the burner through a tube, bypassing the control valve and the receiving nipple. In the mixing chamber, the gas flow rate decreases (as the cross section increases), and oxygen and combustible gas interact until a combustible mixture is formed that is homogeneous throughout the entire volume. Next, the mixture goes out through the nozzle onto the tube, where a welding flame is formed.

Knowing how a gas burner is structured and how it works, as well as how to correctly follow the sequence of parts, you can build such a device at home. However, it should be remembered that in order to ensure a constant rate of exit of the gas mixture from the mouthpiece, you need to carefully select the composition of the gases connected to each other, adjust the diameter of the outlet channel and pay attention to the design of the mouthpiece.

Popular varieties

Now let's look at the most common models.

With soldering attachment

This device is intended for heating medium-sized parts, as well as for compact soldering. This occurs due to heating from the sting flame. Such a torch can easily be called a soldering iron without wires. The gas reservoir has a capacity of 8 milliliters. When filling with butane, the flame temperature is 1300 degrees, and the tip temperature is 450. The flame length can be adjusted within 4-6 centimeters. The diameter of the burner is 1.5 centimeters and the length is 13 centimeters.

The price of this model is approximately 400 rubles.

Advantages:

- easy refueling;

- presence of a nozzle for contact soldering;

- the refill is enough to seal several medium-sized parts;

- low price;

- compactness.

Disadvantages: there is no piezo ignition.

Micro burner

There is nothing in this device except a nozzle with a gas supply regulator and a tank with a filling valve. It does not have piezo ignition and is supplied unfilled. In this regard, you will have to additionally purchase a gas can (can be used for lighters). Such a burner is enough to heat heat shrink or solder two wires without a soldering iron. The weight of such a device is 43 grams, and the length is up to 20 centimeters.

The price of the equipment is 200 rubles. This is the cheapest device of this type.

The advantages are the following parameters:

- easy refueling;

- the lowest price.

Flaws:

- there is no piezo ignition;

- the gas station runs out quickly;

- the flame is small.

Mini soldering iron KVT XZ-1

This is a remarkable device from a brand that produces gas equipment. It has piezo ignition. The set includes: 4 soldering tips, a tip cleaning sponge, and a solder spool.

For contact soldering, the stated power of the soldering iron is 137 W. For a soldering iron weighing 120 grams and 21 centimeters long, this is a lot. Electric soldering irons have never even dreamed of such weight and size characteristics. This soldering iron is not positioned as a torch, but it can be used in this capacity - the flame comes out like a pencil.

The price of such equipment is 2300 rubles.

Disadvantages: high price.

Advantages:

- high thermal power;

- good case;

- there is a set of components;

- convenient for soldering;

- famous brand.

Iris Barcelona

This type of equipment is intended for repairing jewelry and electronic equipment, welding and soldering. Its flame is adjustable. You can refill with a regular gas cylinder, which is intended for lighters. The flame can reach a length of up to 3 centimeters, and the temperature can reach 1300 degrees. It can work for approximately 20 minutes. The length of the device is 20 centimeters.

Such a device costs 1,500 rubles.

Advantages:

- brand;

- presence of piezo ignition;

- small dimensions.

Disadvantages: the flame does not allow processing large and medium-sized parts.

Butane torch KVT X-220

Intended for repair and construction work. Looks stylish. The handle is corrugated and pleasant. The flame ignition system is piezoelectric. The capacity of the cylinder for highly purified butane is 22 millimeters. This volume of gas is enough for 110 minutes of continuous operation. The flame reaches a length of 3-8 centimeters, and its shape is adjustable from wedge-shaped sharp to soft with yellow tongues. The device is 14 centimeters long and weighs 226 grams.

Such a device costs approximately 1,600 rubles.

But the advantages are:

- comfortable handle;

- presence of piezo ignition;

- presence of a stand;

- is a good option for desktop work.

Flaws:

- You can’t get into a narrow place;

- large dimensions. Because of this, it will not fit in your pocket.

Purpose of the gas burner

A gas burner is used in those areas where stable combustion of fuel is required, the intensity and extent of which can be adjusted. Such a device can carry out:

- lighting. Open flame burners, argan oil burners, regenerative burners, and incandescent burners were popular before the invention of electricity and are rarely used today.

- heating. For example, when heating rooms, for laboratory experiments or for kitchen purposes.

welding torch Welding

torches are used in the industrial and construction fields. Depending on the type of welding, they supply a continuous stream of flammable gases to the weld site (in gas welding) or provide the arc combustion zone with shielding gas (in arc welding).

A portable gas burner for a cylinder will be useful for a tourist holiday. The sealed cylinder is reliably protected from fuel leakage, and the device with piezo ignition allows you to quickly light a fire without using matches or flint. A small can of gas will last more than one season of travel.

Note that a gas burner can be useful at home if:

- there was a need to unscrew a rusty nut;

- you need to decorate a metal or wooden surface in a vintage style;

- it is necessary to trim the ends of the nylon rope or geotextile;

- there is a need to repair the garden path using baked mass;

- you need to warm up the frozen lock;

- I want to cook meat outdoors, but I don’t have a grill. gas burner with piezo ignition

Gas oven thermostat

In order for the oven to work correctly and food to cook within the specified temperature range, a thermostat or thermostat is installed inside the cabinet. They can be mechanical, electromechanical, or electronic; to control a given mode, a rotary knob, button, or other, more complex and highly accurate devices are used. What is a thermostat in a household gas stove and how does it regulate the operating mode of the oven?

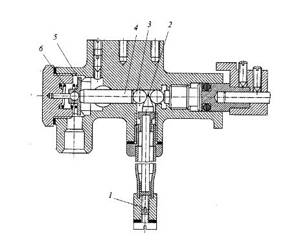

Gas stove thermostat diagram:

Diagram of a dilatometric oven thermostat: 1 - tubular rod; 2 - movable wedge; 3 - ball; 4 - pusher; 5 - spring-loaded valve; 6 - spring.

How does a gas oven thermostat work?

The operating principle of such a thermostat is very simple. The dilatometer, which records the temperature increase in the oven, heats up, causing the linear rod to expand. It activates a mechanism that ultimately acts on the spring-loaded valve. The stronger the heating inside the oven, the further the spring-loaded valve will move and close the gas supply hole. Accordingly, as the temperature decreases, the linear rod decreases and the system works in the reverse order, opening a larger hole for gas access and increasing the temperature inside the oven.

Gas oven thermostat

The maximum temperature inside the oven is limited by a switch knob installed on the front panel of the gas stove.

How to check if the thermostat is working

Having figured out what a thermostat or temperature controller is in a gas stove, you need to make sure that this device is working properly.

Significant errors in the instrument readings can ruin any culinary masterpiece. In one case, the food will simply burn, in the other, it will remain raw. To check the thermostat, it is best to invite a specialist who, using precision instruments, will identify any deviations in temperature readings, up to 1 °C. If this is not possible, and a difference of 3-5 °C is not of great importance, you can check it yourself:

- Turn on the oven at 150°C;

- Place a mechanical thermometer inside the oven, designed to measure temperatures in the appropriate temperature range;

- Leave the oven on for 20-25 minutes until the temperature reaches the desired level;

- After 20 minutes, check the temperature readings on the thermometer and thermostat. If the difference in indicators exceeds 5-10 °C, the temperature controller needs to be repaired.

Important: to repair a gas stove, you must invite a specialist, since the problem may not only be a damaged thermostat, but also noticeable heat loss due to a loose door

How to use a propane torch

A propane gas torch will be simply necessary when carrying out roofing work, drying casting molds, removing old paint, crimping couplings, soldering copper pipes, etc. Before using the burner, two cylinders are purchased - with oxygen and propane - on which reduction gears are mounted. The latter provide optimal pressure.

When the reducers are connected to the gas burner using hoses, you can unscrew the valves and release the gas. Before igniting, the gases pass through an injector where they are mixed. The temperature of the emerging flame exceeds 2 thousand degrees.

To carry out work, first open the valve with flammable gas, then with oxygen. The mixture coming out of the nozzle must be set on fire. The pressure of the consumables is adjusted based on instrument readings or flame color. Afterwards, using a filler wire, a weld pool is formed, and the molten metal must be moved, forming a seam. When the work is completed, the filler wire is removed and the gas mixture is extinguished.

Principle of operation

The principle of operation of burners is to pre-mix fuel with air, ensure the supply of this mixture for combustion and ensure that the combustion products completely go through the combustion process.

The operation of this device is divided into three stages:

- Preparation . At this stage, the individual elements of the future combustible mixture are prepared. During the preparatory stage, air and fuel are given the necessary characteristics: direction, temperature, speed.

- Mixing . Air and the required amount of fuel are mixed, resulting in a flammable mixture.

- Burning . At the final stage of the burner operation, the combustion process occurs, or rather, the oxidation reaction of combustible elements with the help of oxygen occurs. Ultimately, the mixture ignites thanks to a nozzle that is placed at the end point of the tube.

Attention, even taking into account the simple design of the burners, if there are malfunctions, you should never attempt to fix them yourself.

Gas burners also contain additions that ensure safety and automation of the device’s operation.

These include:

- Automation automatically turns off devices as a result of detecting faults.

- Ignition is performed using a special piezoelectric element or electricity.

What gas can be used

Acetylene, hydrogen, and substitute gases (natural gas, propane-butane) can be used as combustible materials for a gas burner. Some designs operate on liquid flammable substances and waste oil.

gas burner cylinder marking

The combustible substance enters the acetylene burner from the generator apparatus, where calcium carbide decomposes into slaked lime and acetylene. The gas for the burner has a pressure of 100-150 mmHg. Nitrogen obtained from atmospheric air is used as a shielding gas, which prevents the formation of scale, and water is used as a catalyst for the decomposition of carbide.

The hydrogen torch is the most popular among similar equipment designed for gas-flame processing. It is important that when using it, only water vapor is released, so it is the safest. When an aqueous alkali solution decomposes, hydrogen burns, followed by the release of energy, which is needed to speed up welding. Hydrogen protects the weld from exposure to oxygen, thereby preventing oxidation of surfaces.

Many owners have an idea of how a liquid fuel gas burner works, since the operation of a kerosene stove is based on this principle. When heated in a special coil, the flammable liquid turns into gas and due to this, significant savings are achieved during subsequent combustion. As a rule, kerosene and Galosha gasoline are used as liquid fuel.

Knowing how to use a gas burner during mining, or a Babington burner, you can significantly save on consumables and reduce the cost of work. Such designs use motor, compressor, and any vegetable oil as fuel. The fuel enters a spherical part, from which it is blown off by a stream of compressed air. The resulting small droplets then ignite.

Features and history of creation

The first gas stove was invented back in the century before last, shortly after the general gasification in England. One of the gas factory workers named James Sharp was the first to think about using gas for cooking. It was he who, in 1825, designed the first analogue of a modern gas stove and installed it at home, significantly simplifying his life.

10 years later, factory production of such devices began, however, at first accidents often occurred, since people were not yet accustomed to the fact that gas must be handled very carefully

The period from 1837 to 1848 saw the evolution of the gas cooking appliance. The first models created by de Merle were not perfect enough. Afterwards they were improved by d'Elsner, who was an inventor. All these models still did not bear much resemblance to modern ones. But in 1857, the most advanced model of that time was invented by de Beauvoir, and it was this design that subsequently formed the basis for the creation of gas stoves for many years.

On the territory of Russia, stoves appeared only in the 30s of the last century, since mass gasification began after the revolution. However, the new devices were mainly used in apartments rather than private homes

Gas-powered units significantly saved housewives’ time, so they considered this feature a good compensation for the need for careful handling. Modern modified gas devices have a number of features

Among them there are both fairly new characteristics and those that were characteristic of all previous models.

- This unit only runs on gas. Therefore, it is necessary to either connect it to the general gas supply system, or supply fuel from a cylinder.

- A characteristic feature is the low cost of operation of this device. Even if you cook a lot, you won't have to pay a big utility bill because gas is cheap.

- A gas stove performs 3 main functions for cooking. It allows you to cook, fry and bake foods (if you have an oven).

- In most cases, the stove requires a hood, since sometimes the gas on which the device operates has a specific odor.

- A negative feature of the device is the need for extremely careful and attentive handling of it. Otherwise, there is a possibility of a gas leak, which could cause an explosion in the living space and tragic consequences.

- In the modern market of household appliances, gas stove models are presented in various embodiments.

Indicators related to the flame of the device

The burner flame power can be low (fuel consumption is 25-400 dm3/h), medium (400-2800 dm3/h) and high (2800-7000 dm3/h). Knowing the maximum and minimum power of a particular burner, you can calculate the fuel consumption and the amount of energy required to meet technological needs.

According to the number of flames, burners are single-flame and multi-flame. If the first type is used primarily for manual oxygen-acetylene welding, the second is widely used for mechanized flame soldering or heating.

Typology

The market offers a variety of gas cylinders for burners. The selection of a highly specialized or universal tool is determined by the requirements of the tasks:

- Activation time for one-time operations;

- The need to create a certain temperature;

- The amount of air involved in fuel combustion: diffusion, injection with full/partial mixing with air in front of the outlet;

- Control of the combustion process, temperature increase/decrease;

- Weight and dimensions of the complete device, grip;

- Volume and type of cylinders, connection method;

- Calorific value of the combustible mixture;

- The gas burner on the canister has piezo ignition and a clamp to keep the valve in working condition.

Tourist

The simplest device according to the requirements is a burner for cooking and heating a tent. The butane filler provides a temperature of 800–1000 C. There are 3 types of placement of the heating object:

- Installation directly on a cylinder with a wide base;

- Side connection;

- Removed via flexible hose.

Installation on a kerosene stove-type cylinder is compact, but the technical solution causes criticism:

- The load on the body is high;

- Instability of combustion, blowing out of fire by wind;

- Instability of the structure;

- Inadmissibility of installing wind protection;

- The case may overheat.

Important! Overheating of the cylinder body can lead to an explosion.

The stability of the structure allows installation on unprepared soil

Remote hose placement is fire safe. The fireplace can be protected with wind shields. The combustion intensity is adjusted using a gearbox.

Artificially pressurized lamp

Injection gas burners for a can with piezo ignition and additional air intake are suitable for melting, soldering with copper, refractory fluxes, and heat treatment. The variety of tools includes miniature ones for jewelers and decorators, solid ones for long-term use with high consumption of flammable substances.

Fundamental differences determine the caloric content of the fuel and the exit front of the pre-air-enriched mixture from the nozzle. A narrowed dagger torch is necessary for high-temperature soldering.

Expanded – replacement of the forge, hardening furnace.

The power of a gas blowtorch ranges from 1.5–3 kW. The conditional division into professional and amateur models is reflected in the cost. Filling the cylinder up to 0.5 liters with many hours of use.

Focused supply of thermal energy leads to fuel savings. The set includes several nozzles of different orientations and flame concentrations. Changing the nozzles turns the tool into a microcircuit soldering iron or micro-cutter.

Pencil-type burners have a built-in container that must be refilled from a standard cylinder. The hose extension will allow you to use a container from the retail chain.

Soldering iron

A gas soldering iron is less often equipped with a piezo ignition. The temperature balance is lower and the scope of application is narrower. But mastering technical skills is easier. In half of the cases, preliminary mixing of gaseous media is not provided.

The concentration of the torch core is not provided. Long-term heat treatment of large areas does not threaten the cylinder with overheating by the reflected heat flow due to the elongation of the gas supply tube and the dispersion of the flame.

Cutter

A gas torch is suitable as a substitute for a blowtorch if you expand and lengthen the torch. Soldering iron for refractory solders when focusing the core by installing a nozzle with a swirling flame.

Gas equipment

Fuel containers vary in configuration, size, filling volume, and composition of the combustible mixture. The main difference in the fastening method:

- Threaded, European standard - external thread, US standard - increased diameter.

- Collet.

- With internal valve.

- Pierceable.

Standardized thread is the preferred option. The burner or extension hose is screwed onto the neck. A fuel leak is unlikely. The connection is reliable.

The valve-type cartridge prevents gas loss. The connection with the burner or extension cord is made by forcefully pressing and then turning the lock until it stops.

Punctureable balloons are less common. The inconvenience is that before the cylinder is empty, disconnecting the burner is impossible without losing the contents.

Adapters allow you to universally use cylinders of any type and design for the purchased equipment. A pair of adapters will eliminate difficulties with selection and articulation.

Advantages and disadvantages of a gas torch for welding

The gas burner has the following positive qualities:

- a large number of types of devices;

- safety during operation;

- most models are compact and light weight;

- no lengthy preparation for use is required;

- does not leave soot or odor;

- the pressure of the fire can be adjusted;

- You can always find out what the device consists of and, if necessary, assemble a homemade burner.

Disadvantages of using a burner:

- at temperatures below -30°C, operation of the device becomes problematic;

- You cannot refill a flammable container yourself.

Rating of quality and properties

The list of the best gas burners for domestic needs is topped by the following models:

- Kovea TKB-8911 is a successful design solution.

- Providus FC300G – ease of maintenance and operation.

- Pathfinder Atom Energy – reasonable price.

Among the best series of torches for soldering and repair work are:

- Stayer 55584 Master is ideal in quality.

- Sturm 5015-KL-01 – functionality.

- FoxWeld VT-55 – efficiency.