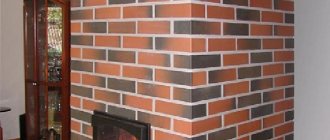

The combustion door in a brick oven is one of the most important elements that directly affects the durability and efficiency of the structure. With its help, fuel is supplied to the combustion chamber, the combustion process is regulated, and all this is done with great comfort. It would seem - what’s so complicated? In fact, unpleasant surprises are not uncommon - after several months, or even earlier, the door begins to hang, large targets appear around it and bricks crumble, which can lead to disastrous consequences. Let's look at how to secure the door to a brick furnace.

Disadvantages of metal cooking stoves and how to fix them

- The compact dimensions of metal stoves also have a drawback - the air heat exchange surface is too small.

- In addition, gaseous combustion products have a very high temperature - from +300° degrees or more. Therefore, you have to think about fire safety and thermally insulate the chimney.

- As is known, the efficiency of stoves is inversely proportional to the temperature of the exhaust combustion waste. To prepare food, cooking units do not use all the generated thermal energy.

- In addition, such stoves usually have short chimney ducts. Therefore, they also absorb some heat.

- Such heat losses are irrational from any point of view. There is a need to minimize them. One of the most common ways to reduce the energy losses of a furnace is to equip the unit with a heating panel yourself.

What is the device

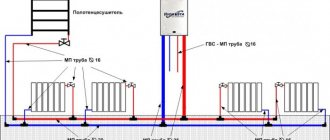

- The shield is a small brick wall attached to the stove, inside of which there is a developed chimney system.

- Such devices are almost never made with a firebox. The shield heats up thanks to the gases removed from the stove. Structurally, the wall is not capable of releasing much heat into the environment.

- There are more complex and convenient designs, the price of which is higher. They are equipped with their own small fireboxes. You can make them independent of the hob and attach them, for example, to stoves with a fireplace.

- Brick has good thermal conductivity, and most importantly, high heat capacity. Warming up when lighting the stove or cooking, it gives off heat to the room for several hours. This way you can get an analogue of a brick stove. Only simpler in design and for less money.

Glass materials and manufacturing

In order to create a glass oven door with your own hands, you will need the following materials:

- silicone sealant;

- about 4 window glasses suitable for the size of the screen;

- stones for decoration;

- metal mesh or grate;

- a metal box, the size of which will match the size of the screen.

The design of a glass screen for a fireplace is quite simple:

- Silicone sealant is applied to all 4 glasses along their edges.

- All glasses are fixed in such a way as to create a parallelepiped shape. It is important to maintain right angles.

- The planes of the elements are pressed tightly against each other and remain in this position until the sealant has completely hardened.

- The remaining substances that protrude beyond the plane must be cut off.

In this simple way you can make a fireplace screen.

Common mistakes

There are many nuances and difficulties in installing a stove.

This process is not as simple as it might seem at first glance. Everything must be done correctly so that there are no accidents during operation. In the bathhouse, the stove is heated very hot, and there are wooden elements and a high temperature, so for safety you need to observe the insulation as correctly as possible. All connections and installation must be done correctly and efficiently. This work is difficult, responsible and dangerous. Therefore, it is not easy to cope with such a matter alone.

When purchasing a stove in a store, they always offer installation, but some people want to do everything themselves, so they make many mistakes.

With a small area, some build baths close to other buildings, which makes a big mistake. To protect against accidents, the pipe at the bathhouse should be higher than all other buildings, and a grate should be installed on top to extinguish sparks.

Remember, repairs must be carried out in accordance with all safety regulations.

Glass structures

Glass equipment is characterized by the contemplation of a living flame.

In addition to being decorative, this feature helps monitor the efficiency of the main heating device.

The doors are made of a material that contains heat-resistant functions. It is usually based on transparent metal ceramics and heat-resistant quartz. Therefore, in addition to its aesthetic purpose, the product guarantees safe operation.

In addition to the advantages, there are some disadvantages of these products:

- Weak resistance to damage. Despite the fact that they are made of high-quality material with shock-resistant properties, they are often broken. Therefore, when removing soot from its surface, you have to be extremely careful.

- Rapid contamination. This is eliminated by the firing system, which is thought out during the installation of the fireplace or stove.

- Use only wood fuel. Coal is not acceptable for these structures.

Glass products are produced in three versions:

- Segmental form. 3 glasses thick.

- Flat shape. 1 glass thick.

- A circular shape that is used for free-standing fireplaces.

In addition, there are combined structures that are made of steel and equipped with glass.

In addition, casting or forging elements are used to decorate the finished product. Looks good with tinted and laminated glass, as well as mosaic finishing.

Doors also come in different types, with sliding and lifting mechanisms. Forging and casting elements, tinting and lamination, stained glass and mosaic finishing are also used. There are sliding and lifting doors.

DIY oven door with glass

Types of fire doors

Today, all doors used in ovens can be divided into several groups, which differ in certain ways. For example, such products are made from a variety of materials:

- One of the most common materials for fire doors is cast iron. Such products have been quite popular for many decades. However, they have such disadvantages as large mass, inconvenience of use, and a significant volume of products.

- The second group includes iron doors. Typically, such products are used when arranging stoves in baths. Iron doors are not used for home stoves because they have a relatively small number of positive characteristics.

- Furnace doors are also made of panoramic glass. Today, such models are most widespread. They are quite light and also provide a full overview of the combustion space.

The last option for the oven door is worth paying special attention to. Their advantages and disadvantages should be described, as well as the types of similar products should be highlighted.

Installation methods: choose any!

Check how easily the door opens and closes. If the part is new and tight, it needs to be developed before installation.

There are several ways to “embed” a part into the masonry: on a corner, using a stainless steel box, etc. Let's describe the most popular ones.

Installation of the combustion door on a wire

nichrome wire

You need to attach a wire to the frame of the combustion door, the diameter of which is 2-3 times less than the thickness of the joints in the brickwork. Usually the doors already have special holes for the wire, so this installation stage will not cause difficulties. But if there are no ready-made holes, it doesn’t matter. Drilling holes in a cast iron product is easy; with glass you will have to tinker more.

Installation on elements made of stainless steel sheets

Stainless steel mounting elements are either flanged plates or a solid shell.

Flanged plates hold the part, clinging to the brickwork. Moreover, these plates must be installed on self-tapping screws, and the holes must be drilled in advance.

The one-piece shell is placed on the combustion door frame. The thickness of the metal sheet in this case should be less than when using plates.

Installing the door with self-tapping screws or bolts

A rather dubious option in terms of reliability for installing cast iron, metal and glass parts for the firebox.

Do not place the product tightly in the masonry under any circumstances.

You should also avoid sealing cracks with a solution of clay and sand. The part heats up quickly and strongly, which means that when it expands it can cause cracking of the brick and destroy masonry joints.

For clarity, we have prepared a video that will help you understand how to correctly install this firebox element.

What it is?

Hidden under the name “furnace doors for stoves” is a well-known element of fireplace design. Do not forget that, first of all, it, of course, performs utilitarian functions, but the overall appearance of your fireplace, and with it the atmosphere in the room, also depends on it. Fire doors for furnaces simultaneously serve:

- a barrier so that the fire burns better;

- a guarantee of safety so that not a single spark penetrates into the room;

- decorating a stove or fireplace.

Therefore, the choice of such a door should be approached with special care. And in our store you will find everything you need for this, thanks to our wide catalog.

What types of doors are there?

It is necessary to distinguish between two types of doors, which are used in heating devices and are widely represented in our catalog.

- Doors for stoves - as a rule, are a cast iron plate, uniform or richly decorated with patterns, which reliably protects the space surrounding the stove from sparks and ash.

- Fireplace doors are a more complex and elegant device, created from a cast iron frame and a special type of glass that is resistant to temperature changes, through which you can clearly see everything that happens to the flame inside.

What is the best way to buy a door?

The most convenient way for any buyer will be to purchase a door for fireplaces in the “Stoves Here” store. Here you will find:

- qualified consultants who are always happy to help you with your choice;

- convenient terms of delivery and payment for goods;

- a simple order form, filling out which will not take you much time;

- favorable prices accessible to everyone;

- An excellent selection of products for stoves and fireplaces for every taste.

Despite their simplicity, stove doors contain several elements, each of which performs a specific task.

In the first place is the door itself, which is designed to open and close the oven, ensuring safety during operation. There are several versions of these parts, for which different materials are used.

The most popular is the design with heat-resistant glass, metal and cast iron. Depending on what material is taken as a basis, the product acquires certain properties and characteristics.

During the production of equipment, special attention is paid to the elements located on the front side of the furnace, because the operation of the main equipment, as well as the design of the room, depends on their configuration

Oven door functions

Its most important function is to prevent sparks from falling from the stove onto the floor. In addition, it helps eliminate drafts that occur when the firebox is open. A closed stove can be left unattended and walked away with full confidence that not a single ember will fall out. In addition, the door serves to suppress smoke in the house.

If it is made of heat-resistant glass, then due to the transparency of the material, you can observe the burning fire. What is very important is that the smell of burning does not enter the house. If the firebox is closed, the efficiency of burning wood increases, which leads to less wood consumption.

Thanks to modern technologies, oven doors can be made with an air-cooled frame, as well as with special non-heating fittings. In addition, a blowing system can be installed on the oven door.

Doors equipped with such options will help ensure that even small children are safe around the stove. If the handle is removable, this will help prevent a child from accidentally opening the firebox and getting burned.

Installing a cast iron cookstove

Absolutely all slabs are installed strictly according to the construction level. For installation, it is necessary to cut out a groove in the very top row that corresponds to the size of the slab and has a gap of 5 mm on each side. It is strictly forbidden to clamp any sides of the plate, since during heating the opposite side will change and become askew. You need to use a clay-asbestos solution. They also need to be rubbed over the entire top of the slab around the entire perimeter.

Independent construction of a home stove involves the use of special elements that make up this heating structure. Installing the combustion door of a brick oven is a critical step. Therefore, you need to know about possible ways to secure this stove device.

- cast iron;

- steel;

- with built-in glass.

The first option is most widespread because it best corresponds to such an indicator as price/quality. Stainless steel stove elements are mostly installed in rooms where there is contact with water, for example in baths. As for doors with glass, they can be recommended to those who like to watch the fire.

Before you begin installing the stove in the masonry, you need to check how easily it opens so that there are no problems after installation. There are situations when the door opens tightly even before installation, but during the operation of the heating structure it is developed. If we look at most of the stoves that are installed in village houses, then their door elements do not have asbestos gaskets. Today this material is used in industrial furnaces where it is needed for resistance to high temperatures.

Since we are talking about installing a stove in home ovens, the temperature in them is not so high, and the door frame itself is located away from direct fire. In this case, installation on asbestos may not be carried out. Some craftsmen, when constructing heating structures that use coal as fuel, do without asbestos and install the door using wire. To guarantee, you can drill holes in the frame of the stove closer to the edge. There are several ways to install a firebox door.

The third method is to fasten the furnace door with bolts or screws

Installing the fire door of a brick oven using self-tapping screws or bolts is considered the fastest and at the same time unreliable. The installation process involves screwing the door into prepared holes in the masonry. This method is not the best for either a cast iron appliance or a steel or glass one. You cannot install the door close to the masonry, since when the part is heated, the masonry will gradually collapse.

The listed methods for installing a stove appliance can be used not only when laying a stove from scratch, but also when repairing an old one. Which option you choose depends on personal preferences, available materials, and experience in the stove business. The best method would be one in which the door can be easily removed if necessary.

Regarding the choice of a furnace device, first of all, it should be taken into account that this part is not only protection against fire, i.e., it ensures safety, but also allows you to control the combustion process. In addition, it should look beautiful and be appropriate in a particular room. Only in this case will its installation provide warmth and comfort in the house.

How to fold a stove firebox with your own hands

The furnace firebox consists of a ashpit (ash pan) with a door, a grate and a combustion chamber (firebox) with a door.

Dimensions are determined based on the volume of firewood for simultaneous loading. The width of the combustion chamber is equal to its door or slightly wider on both sides.

The height of the firebox should facilitate complete combustion of fuel, which is achieved by having free space in the chamber after loading firewood. Recommended height 80-100 cm.

Reference. The depth of the furnace firebox must accommodate the length of the combustible material; there are no other restrictions.

The combustion chamber is connected to the ash pan via a grate. The latter is designed to supply air during combustion and collect ash. When installing the grate, it must be buried below the level of the fire door to prevent burning coals from falling onto the floor.

The firebox must have bevels in the direction of the grate to move the ash into the ash pit. The gap between the masonry and the grate must be at least 5 mm to prevent rupture of the brick as a result of the difference in expansion of the brick material and metal at high temperatures.

The choice of materials for masonry and flooring, how to process the structure

The structure is made of clay red brick with lining (lining) of fire-resistant material

When choosing a brick material, you need to pay attention to ensure that it is not burnt or cracked. High-quality brick, suitable for stove masonry, has smooth edges, sharp edges and a uniform color; when tapped, a clear, almost metallic sound is heard

Attention! Sand-lime brick is not suitable for the construction of the device. The following materials will be required:

The following materials will be required:

- red brick - for walls;

- refractory and wedge-shaped (fireclay) bricks - for lining and forming the ceiling;

Photo 1. Refractory brick used for laying the furnace firebox. Before using the material, you must ensure its integrity.

- clay, sand, water - for solution;

- cast iron grate;

- doors of the combustion chamber and ash pan;

- steel strips or wires - for fastening doors;

- asbestos sheet - for a fireproof gasket between the masonry and the doors.

To connect the stove masonry, you can buy a ready-made mixture or prepare the solution yourself. In high-temperature zones, compositions made exclusively of red clay, sand and clean water are used. The quality of the solution depends on the viscosity, plasticity and fat content of the clay. Sand for construction must be free of dirt and impurities.

Preparing tools

The necessary set of tools will allow you to make a structure with your own hands:

furnace hammer;

- trowel - for applying the solution;

- large container - for preparing the solution;

- building level - to control the correctness of the masonry;

- measuring instruments - ruler, tape measure, square;

- plumb lines - to determine the outer contour.

How to properly cover the firebox and make a roof for a brick oven

To build a firebox, the exact layout of the future furnace must be determined and a foundation with a layer of waterproofing must be laid.

Before laying on the mortar, you need to assemble the structure without it - to accurately adjust the bricks to size.

The phased construction looks like this:

- Prepare a solution.

- The first row is laid on the foundation without gaps and formed under the stoves.

- On the second row, the formation of the ash pan and the fastening of its door begin. To do this, mark the center of the future firebox and place the blower strictly under it. A flexible wire is passed through the holes in the door frame and its ends are twisted into a bundle. Wire bundles are fixed in the masonry layer.

- The contour of the blower and the location for laying the grate are formed.

- Secure the combustion door with wire. The door frame is insulated with a gasket made of non-combustible material.

- The walls of the firebox and the vault with a hole for connecting the chimney are formed.

- The combustion chamber is lined with refractory bricks.

Important! During construction, you cannot combine simple bricks and refractory bricks due to different expansion coefficients. When heated, such masonry will burst

Preparation, list of tools

Before starting work, you need to determine and mark the place that the new stove will occupy.

The chimney pipe should be no closer than 15 cm from the roof rafters.

If you are doing masonry for the first time, professional stove makers advise you to practice in advance by making a model of the future stove from prepared bricks. Naturally, without a solution. This minimizes possible risks during real masonry, allowing you to learn from your mistakes, which can still be corrected in the layout.

The stove foundation requires preliminary waterproofing; its area must exceed the area of the stove.

When laying a new row, you need to control the absolute verticality of the walls.

To build a brick kiln, the following tools are needed:

- plumb line;

- trowel;

- roulette;

- putty knife;

- Bulgarian;

- knitting wire;

- building level;

- metal strips, corners;

- containers for cement and clay mortar.

Major renovation

The work is carried out according to a pre-prepared set of design documentation. However, the following items are required:

- exact dimensions;

- load calculation;

- list of consumables.

Complete replacement of the lower part of the furnace

Corrections determined by the features of a particular design are acceptable. Typically this technology is performed according to the following scheme:

- dismantle both walls and lining;

- remove construction waste;

- reinstall the lining (the connection with the main part is not used).

At the final stage, the integrity of the base and walls is checked in accordance with the working drawings plan.

Complete disassembly and relocation of the oven

To destroy the old furnace, use steel wedges and a hammer drill

In order not to frequently repair an outdated structure, you can install modern heating equipment. For the bath, maintaining the optimal temperature will be ensured by a convenient electric heater. During seasonal operation of the dacha, an inexpensive fan heater will create comfortable conditions, and there will be more free space in the room. With the help of a new high-quality project, it is possible to significantly increase efficiency compared to the “classic” version.

In all of these situations, the need for disassembly is implied. The following recommendations will be useful when performing the relevant work steps:

- If you intend to install a gas boiler (other heating equipment), it is possible to preserve the chimney.

- In old wooden houses, the stove structure served as part of the load-bearing frame, so individual components cannot be removed without special reinforcement.

- It is necessary to prevent contamination of the interior, remove furniture, and cover individual surfaces with polymer film.

- To perform work operations, you need to prepare a respirator, gloves, and other personal protective equipment.

- The clay parts of the structure become pliable after abundant wetting with water.

- Cement seams are destroyed using steel wedges, and the process is accelerated using a hammer drill.

- Dismantling begins with the pipe and continues sequentially from top to bottom.

Changing the volumes and directions of chimneys

The technical parameters of this part of the project have a significant impact on functionality and safety. The developer’s special recommendations should be taken into account when creating a sauna stove, fireplace, or other modification. General rules:

- the inclination is created up to 30° per meter of channel length;

- the outlet is installed at a height of at least 50 cm from the level of the flat roof or ridge;

- the distance from the firebox to the top end of the pipe is from 500 cm.

Increasing the number of turns improves the efficiency of heat removal. However, this reduces traction.

Complete replacement of one or more furnace walls

When combining old and new masonry, bricks of the same type are used to prevent deformation from uneven thermal expansion

Taking into account the significant weight of these parts, when repairing a brick kiln, special attention is paid to the strength of the base. If necessary, the foundation is further strengthened

Work process

Installation of a high-quality combustion door. This process must be taken with all responsibility and seriousness. It is most exposed to thermal and thermal expansion. Therefore, it should be installed so that the space in the stove is overlapped as tightly as possible and the door is securely fastened to the masonry. This oven door is secured with clamps, which are made of steel.

Clamps are made of steel. All ears should protrude 10-12 cm beyond the door frame, and they are fastened with special rivets. The lower part of the door can be secured with a wire about 60 cm long. Before installing the door, you need to wrap the frame with asbestos. The material can be used in the form of cord, crumbs or sheets, moistening with water before use.

In the exact location of the door installation, it is necessary to apply a layer of clay composition to the masonry. When using wire, the ends are hidden in the seams. Be sure to check the horizontal position of the installation with a level and fix it using a wooden strip. One end of this strip is placed on the door frame, and the other on three bricks of the masonry, a brick is placed on top of it. Next, bricks are laid on the mortar, gradually laying the door in the stove mass. Each row starts from the door.

What to do if the door doesn't stay on

The reasons for the loosening of the door may lie in the incorrect composition of the sealing solution or in leaving loose rings when fastening with wire, including without ledges during hard twisting. When fixed with bolts, abrasion of bricks occurs. Shaking leads to the formation of gaps and carbon monoxide escaping through them.

Repair options:

- Replacing anchors with steel inserts. To do this, cuts are made in the opening into which a fastening steel angle is inserted.

- Cutting the wire and changing the mounting method to bolts or built-in frames.

- Clearing the openings between the frame and the body from mortar and installing a new seal. The vacated areas are filled with heat-resistant glue, asbestos or ceramic cord, and a mixture of clay and asbestos.

These approaches are applicable when the masonry stones have retained their integrity. If they are cracked, you need to disassemble and lay new fragments on a heat-resistant mixture.

Rules for grouting

To properly coat the stove with clay, you must follow these step-by-step instructions:

The surface, cleaned of plaster, is generously moistened with primer or water. Using a chisel, knock out the gaps between the bricks. The oven is warming up. Using a trowel, apply the clay mixture into the cracks and spread it over the entire surface in an even layer. If you don’t have a tool, you can do the smearing by hand. The mixture does not cause irritation or damage to the skin. When the surface is dry, another layer of the mixture is sprayed

Particular attention is paid to cracks - there should be a dense layer of mortar between the gaps. Using a damp wooden trowel, grout in a circular motion to remove any unevenness. The last step is plastering the stove.

The process of sealing with fire-resistant adhesive is carried out according to the same scheme, but includes an additional step. After filling the cracks with plastic material, the entire surface is treated with a hard type of glue so that the stove no longer smokes. It takes half an hour to dry, which can be spent on decorating

It is important to remember that the structure can be used after the solution has completely hardened.

To seal a brick oven, you can purchase a special grout. In stores there are various formulations that are produced specifically for these purposes. It’s worth noting right away that this option will cost you quite a lot, however, it is optimal for lining stoves and fireplaces.

• clay;

• sand;

• water;

• straw;

• salt.

The clay needs to be thoroughly kneaded, filled with water and set aside for 12 hours. After the specified time has passed, the required amount of sand should be added to the mixture. In the process of kneading the two components, finely chopped straw and salt are gradually added to them. Clay and sand are taken in a ratio of 4:1, with about 50 kg of straw and a pack of salt added for every 4 buckets of clay.

The resulting composition can withstand temperatures of more than 1000 degrees.