Here is part two about basic work at the dacha during vacation. This second part is devoted to the installation of the stove and chimney. For almost six months I studied reviews on the Internet about the installation of various types of stoves and chimneys in dachas and country houses. After much thought, I came to the conclusion that Breneran (Buleryan) 01 is suitable for me. I also finally decided that I would install a chimney exclusively of the “sandwich” type. The choice of model 01 was due to the fact that there are still uninsulated rooms in the house (non-residential for now), which means that more powerful heating will be required. Accordingly, I took it with a reserve of power (as, indeed, many recommend). The main thing was to find the most optimal place to locate the stove in the house. Such a place was found, and I began to calculate how exactly to route the chimney through the wall and how to generally choose the type of chimney. After some time, I decided (with the help of consultations on the Internet) that this installation of the stove and the outlet of the chimney outside would be the most acceptable for me: https://foto.rambler.ru/public/meresiga/_photos/buler0/buler0- web.jpg I decided to install the stove and chimney myself while on vacation. Luckily there will be enough time and beer too. I also doubted for a long time whether I could unload the stove from the car myself, bringing it to the dacha after purchase. After all, the stove weighs a little more than 100 kg. However, everything went fine. When I bought the stove, they loaded it into the trunk of my Chevrolet Niva (after folding the seats and laying down the cardboard from the packaging box from under the refrigerator). And once there, I alone calmly pulled her out of there, lowered her to the ground, carried her home and installed her in her place.

I just had to do my shopping in two steps. First, buy a stove and all the necessary components for the chimney and, as a first step, take it all to the dacha. On my second call, I bought a stand for the stove and bought what I didn’t buy on the first call (I forgot or bought it based on new needs that had arisen). I bought the stove with glass. From the chimney - I bought the pipes themselves, adapters, a tee, a wall outlet, thermal insulating filler - cotton wool, fasteners to the wall and a head. I bought all the pipes, angles, and adapters exclusively from stainless steel. I didn’t buy a metal reflector, because I considered it unreasonable foppery - spending a minimum of 500 rubles for a tiny sheet of stainless steel measuring 50 cm by 1 meter, and a maximum of 1 meter by 1 meter - 1000 rubles. At the construction market I bought 2 sheets of clean, new, shiny galvanized iron for 560 rubles per piece measuring 2 meters by 1 meter. There was enough for heat protection on the wall, on the floor under the stove, and there was still enough left to cover the roof near the well. As I said above, the main thing for me was to accurately bring the chimney through the wall and accurately position it vertically - so that it would not interfere with the two edges of the roofs and would not come too close to the window. All this had to be implemented using standard parts that are sold for the chimney (feeder, adapter, corner sandwich and tee with a glass). What place was chosen and what it looked like before can be seen in this photo: https://foto.rambler.ru/public/meresiga/_photos/faz3/faz3-web.jpg It is clearly visible that there is not too much room for maneuver, but still it is there. I calculated exactly down to the millimeter (!) - at what level and distance from the edges and from the ground (from the floor) the chimney would exit through the wall and set to work.

The most important part was making a support bracket for the chimney. Because it must be strong enough and rigid, since the chimney along with the tee and other parts will rest on it with all its weight. This support bracket is a very individual product and I had to make it locally myself. I used 30 mm and 50 mm steel angles. As well as bolts of the corresponding length M10 and M8. For manufacturing I used a grinder, a regular drill and metal drills. We first had to disassemble the wall and strengthen the seats for the bracket from inside the house in the wall with additional force supports in the form of strong corners, long bolts, etc. I assembled the bracket from the outside and attached two corners to it on top in the form of runners - to be able to move the tee back and forth (so that it would be possible to move the entire chimney away from the roof). After testing and installation - trying on this support bracket - I coated it with metal varnish, thereby protecting it from corrosion (from rust).

After that, I just secured the stainless steel passage box and began to make thermal insulation on the wall. I got 35 cm from the stove wall to the wall. Which is within the acceptable range if the wall is equipped with a heat-reflecting screen. The wall was sealed with 10 mm plywood and an asbestos sheet was secured to the plywood with screws over its entire area (I worked with asbestos while wearing a respiratory bandage). Because asbestos in open circulation is undesirable for health (asbestos dust is a carcinogen). And once the asbestos is embedded in the wall and well sealed, it does not pose a danger (there is nothing to collect dust).

On top of the asbestos, the entire wall was covered with a single sheet of galvanized metal measuring 2 meters by 1 m 20 cm. Having previously cut a square hole in this sheet for the passage box.

I secured everything with screws with different types of heads (flat or semicircular, depending on where I used them). The place under the stove itself near the wall was also well insulated from heat. First, I laid out the tiles on the floor and secured them with screws along the edges and corners.

After that, an asbestos sheet was spread on top

and spread a sheet of thin basalt wool on top of the asbestos sheet.

All this was covered with a sheet of galvanized iron of the appropriate size and secured well with screws of the appropriate size. I made a border along the edges of the sheet so that debris from the firewood would not spread throughout the room, but would remain on the galvanized sheet (from where it could be easily swept away with a broom). Thus, having prepared a place for the stove and chimney, I began to assemble the entire structure into a single whole. I drilled the required hole in the adapter from the oven to the sandwich, put on the adapter and, moving the oven, put a 50 cm long sandwich into the adapter.

Breneran stove: technical characteristics

The stoves created by the Breneran company are convenient and can be suitable not only for installation in the house, but also in the bathhouse. The stove is designed to heat not only private homes, but even small warehouses. Of course, like any other installation, this stove has its positive and negative qualities, so we should consider it in more detail.

The design of the stove is well thought out and completely ensures a really long burning time on one load of fuel.

The main technical characteristics include the following 6:

- Great indicator of heat and saving effect;

- Can be used autonomously, since the stove is independent of gas and oil;

- Capable of functioning equally on all solid fuel types;

- All the heat that the stove produces is distributed evenly throughout the room;

- Convenient dimensions and easy use;

- The efficiency is more than 80% and can be adjusted.

We can immediately say that one load of fuel into the Breneran furnace is enough to operate for 12 hours. The main disadvantage can be considered the fact that the stove has an open combustion chamber, which means that oxygen is quickly consumed from the room. In addition, condensation quickly settles in the pipes, which appears if the firewood smolders slowly.

How to convert Buleryan for testing

As already noted, Buleryan is not intended to work in detention. But if desired, it is possible to remake the Buleryan stove so that it works to burn waste oil. You can do this in two ways:

- A dropper is installed for testing - this method does not require large material costs. An oil container is installed. A hole for the tube is cut in the firebox, and a valve is installed to regulate the fuel supply. The main condition for operation is the presence of good draft and a low oil supply rate. The disadvantage of the solution is low heat transfer and design performance.

- A nozzle (burner device) is placed inside the firebox (usually on the door) for testing. Just a few years ago, the manufacture of a burner for converting the Buleryan stove to waste oil fell entirely on the shoulders of the local “Kulibins”, which often led to rapid failure of the stove, frequent need to clean the chimney and other troubles. Now you can purchase a ready-made burner device, ensuring the maximum percentage of oil combustion. A homemade waste oil burner for Buleryan is significantly inferior in its characteristics to factory products.

All risks associated with changes in the design of Buleryan are fully borne by the buyer of the unit. Claims and complaints after modification are not accepted by the manufacturer.

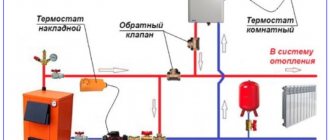

What kind of Breneran stove is there: diagram and device

As for the types of Breneran stoves, there are quite a lot of them. So, for example, Aquaten stoves of the Breneran brand can work to heat water and circulate it, which is carried out by convection. The consumer can even purchase special types created for dachas and houses, which differ in their fuel consumption and, as a result, efficiency. Many people often prefer fireplace stoves. This is a great option for a country house. And in the kitchen a model that includes a stove can be installed. However, one should take into account the fact that these options generally run on liquid fuel or gas.

Is it possible to install a Breneran stove with your own hands?

If you decide to install a unit such as Breneran with your own hands, you will need to purchase some building materials and tools. As for materials, their choice will depend on the room in which the installation will be carried out and what form of installation will be used.

The most common installation method requires purchasing:

- Metal sheets that will be used to cover the mill and the floor at the installation site;

- Materials for creating a chimney;

- Materials for covering the stove;

- Industrial type cement;

- Funds for creating a foundation;

- Pipes made of stainless steel for the construction of a chimney;

- Clay of fat or medium fat type.

Let us immediately note the fact that installing it yourself is not as easy as it might seem at first glance. Before starting installation, you need to think through everything in detail, especially the installation location, since the furnace emits harsh thermal radiation. In addition, the weight of such a unit is about 100 kg, which is also important to take into account during transportation and installation.

The stove does not need a large foundation; it is enough to raise it about 20 cm from the floor, but the heating elements should be protected, since the material heats up quickly.

Before installing the Breneran stove, be sure to read all the requirements set forth in the operating instructions, which include detailed photos.

Kindling technology

To use the stove, no specialized knowledge or skills are required. The boiler is easy to heat and maintain.

You can melt Buleryan as follows:

- Fuel is loaded into the firebox. First, firewood of small thickness is used. The fuel should be dry, this will minimize the amount of condensation that forms and allow the fire to start quickly.

- The wood is set on fire. The dampers that regulate the draft and the amount of air supplied are fully open.

- After hot coals have formed in the firebox, thicker firewood is loaded through the door. The dampers are installed in the desired position to ensure long-lasting combustion.

Positive and negative qualities of the Breneran stove

Let's pay attention to the positive qualities that this unit has. All of them are based on user reviews.

Today, many have already appreciated the Breneran brand stove as a first-class heating equipment

Positive qualities include:

- Acceptable pricing policy;

- High efficiency;

- Long service life, it is more than 50 years with proper care, plus the manufacturer provides a guarantee for the installation for several years;

- A stove can instantly heat a room;

- A small part of the fuel is consumed;

- The stoves do not require special care; it is enough to remove the ash every few months;

- The installation is compact and does not take up much space;

- Saves energy.

It is impossible not to take into account that the famous Canadian unit also has certain negative aspects. Here we can highlight that it is very difficult to achieve uniform combustion; this process will have to be controlled independently. Also, in the process of adding fuel, a certain amount of smoke may enter the room, which is not entirely pleasant. Also, if the stove is used in a sauna room, it will noticeably dry out the air, so you will have to add water more often.

How to remove condensation ↑

There is another known problem that is associated with the operation of Breneran. Its smoke pipe, as you know, is located on the wall of the stove at the back. A tee is mounted here - a chimney pipe is connected to it. At the bottom there is a glass plug for condensate. This design does not have the required tightness. And this is a problem, because condensation inevitably and steadily enters the air, which is not good. Some craftsmen adapt their own solutions, making sealed containers to collect condensate, while others remove it from the room using pipe devices. In short, we have to innovate as best we can, because the market, alas, does not offer ready-made solutions.

Breneran stove (video)

In conclusion, it should be said that those who have already purchased a Breneran stove recommend placing an order exclusively on the official website, since, according to reviews, it is there that you can save a large amount. This happens thanks to various promotions and discounts. In addition, you can protect yourself from counterfeiting, since all official products have been certified. However, which specific modification of the unit you need, and where to purchase it, you will decide individually.

The first Breneran stove appeared in Canada and was used mainly by lumberjacks to heat their homes.

Over time, it gradually gained popularity in other countries. In Russia it is known as the “stove from Canada”. It is characterized by a fairly simple design, so installing it yourself will not be difficult.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery throughout the Russian Federation and CIS countries.

Breneran furnace design

A type of long-burning stoves Breneran

The Breneran company's product range includes furnaces with a water circuit, which operate to heat and circulate a liquid that flows by convection by gravity. There are special bath models and options for the home, differing in the amount of fuel consumption and the quality of heat transfer (power and efficiency).

A fireplace stove can be an excellent option for a large house outside the city. A Breneran stove with a hob for cooking is ideal for the kitchen. In the assortment you can see both models intended only for cooking, and universal ones for cooking and heating. However, most often such modifications use gas or liquid fuel as fuel.

Breneran liquid fuel stoves are available to buyers: oil, diesel fuel, gasoline. The assortment includes gas models, gas generator models using coal or logs.

Pros and cons of ovens

The Breneran stove in its classic design is an all-metal structure that includes many pipes that create forced convection. This way the air is heated and distributed throughout the room.

The unique design allows the stove to draw air from under the floor, heat the air almost instantly, and then release it upward. The output temperature is about 150˚C.

Remember that how long the oven will operate on one bed depends on many nuances. This includes the quality of the logs, the overall height of the smoke exhaust ducts, the mode of operation, etc.

Let's say there are bath attendants who managed to heat the room with one bookmark for 12 hours. Although this will not allow you to get good heating. It’s better if the stove runs for about seven hours on one burner. It will be much more effective.

Operating rules

Despite the simplicity of execution, you need to heat the Buleryan stove using certain knowledge and rules:

- For ignition, it is necessary to use exclusively dry and solid fuel, wood chips, pressed cardboard, and small boards.

- Do not clean out the coal and ash formed after ignition; their layer will protect the metal bottom from burning out;

- The main fuel loading occurs after most of the ignition has burned out, namely 2/3 of the total initially loaded fuel;

- You should not use wet firewood and coniferous wood - they will cause plaque to form on the walls of the stove and chimney, reducing the efficiency of the heating system;

- Experts do not recommend using coke and coal, as they burn too quickly and do not allow the air to warm up enough;

- Maximum efficiency is achieved through a closed damper and blower: convection processes in this case begin to work more efficiently;

If all these operating rules are taken into account, the outer casing will not heat up to high temperatures, and the air leaving the pipes will reach its maximum temperature in less time. The heating system of the building using a long-term fuel combustion furnace, called Buleryan, involves saving fuel while providing high-quality heating of the air inside the building

Such stoves are very effective in country houses, garages, greenhouses and agricultural buildings. They are quite safe to use. But the main advantage of these heating systems can be considered that the manufacture of a Buleryan stove is possible at home, without the use of complex technologies and expensive materials

The heating system of the building using a long-term combustion furnace, called Buleryan, involves saving fuel while providing high-quality heating of the air inside the building. Such stoves are very effective in country houses, garages, greenhouses and agricultural buildings. They are quite safe to use. But the main advantage of these heating systems can be considered that the manufacture of a Buleryan stove is possible at home, without the use of complex technologies and expensive materials.

Installation of a Breneran gas generator stove and a chimney for it

It is possible to install the Breneran stove yourself. It is important to consider a number of factors. The stove, like other metal sources, emits harsh heat radiation. Thus, it is necessary to think about the placement of equipment to avoid negative consequences.

Breneran stove in the interior

The stove weighs about 105 kg, which is worth remembering during transportation and installation. A stand for the Breneran stove is not required, but it would not hurt to make it higher than the floor level to a maximum of 20 cm.

Tubular electric heaters must always have protection, because this is a hot material. For this stove, it is worth considering stainless steel pipes so that they serve longer and with better quality.

You can also make a chimney pipe for the Breneran stove by hand. To do this, you need to cut out the manhole cover and make a hole in it for the pipe. It is advisable to wrap the pipe with asbestos cardboard and attach it to a pre-made metal sheet. As a result, the ceiling will not heat up. The pipe outlet should be made based on the material of the cover. If it is made of metal, then you can cut a hole with a jigsaw.

Now you need to put on the sandwich pipes and do not forget to remove the metal inserts from them. The entire connection must be well lubricated with sealant. Experts also recommend putting on a casing and making a connecting manifold, after which piping can be carried out.

The casing can be made of thermal insulation, which is used for winding collectors on sports cars. It is clear that with a self-made pipe, kindling will be more difficult, because the air draft may not be so strong.

Variety of “Buleryan” models for dachas

Buleryan units are produced by industrial enterprises in different countries. They produce heating devices and sauna stoves, as well as heat accumulators that are compatible with certain models. Typically, manufacturers reflect the technical parameters of manufactured products in summary tables.

Heat accumulators are most often used in greenhouses, where there are almost no walls, which in standard buildings can accumulate heat. The hinged panels, made of painted steel plates, correspond to the shape of the Buleryan model; for this reason, a separate type of heat accumulator is produced for each of them.

This device is installed on the top of the heat exchange pipes and rests against their lower ends. It is filled with various heat-intensive materials, such as coarse crushed stone, broken brick, pebbles and others.

Breneran stove range

There are six main variations of Breneran stoves. When choosing suitable equipment, you should take note of its characteristics, which are indicated by the manufacturer in the technical documentation.

| Model | Characteristics |

| AOT 19 | The design has 8 pairs of convection pipes. Stove power 35 kW. The equipment copes with heating rooms with a volume of 1000 m³. The total weight of the fireplace without firewood is 240 kg. The combustion chamber can accommodate up to 200 kg of fuel. This is a Breneran wood-burning gas generator stove with long burning time, perfect for heating a home with several floors and rooms. |

| AOT 16 | This is another model that is suitable for heating rooms up to 600 m³. The weight of the equipment when the firebox is empty reaches 190 kg, so a foundation will be required during installation. AOT 16 is well suited for industrial purposes. Based on the model, air heating of several rooms isolated from each other is installed. |

| AOT 14 | There are two types of equipment here, which differ in the presence of a fireproof glass door. The model is necessary for installation under brickwork, with imitation under a fireplace or Russian stove. The productivity can be 18 kW, this is enough to properly warm up rooms with 180 m² or a volume of up to 400 m³. |

| AOT 11 | More suitable for domestic rather than industrial conditions. The compact dimensions of AOT 11 made it possible to reduce the weight to 100 kg, while maintaining a high efficiency of 11 kW. The stove is capable of heating one large room or hall with a volume of 200 m³. By creating an air duct system for certain rooms, a boiler of this modification is capable of heating the entire house with an area of about 100 m². |

| AOT 08 | Model AOT 08 is a compact but efficient stove; it is ideal for heating cold rooms: cottages, garages, greenhouses. Weighs only 70 kg when the firebox is empty. For efficient circulation of warm air, there are seven convection channels on the body. The range includes models with and without glass doors. The maximum productivity is 8 kW, the volume of the heated room is 140 m³. |

| AOT 06 | The Breneran AOT 06 stove is a long-burning household solid fuel air-heating boiler using wood. Designed for efficient and fast heating of rooms with a total volume of up to 100 m³. The model is successfully used for heating individual rooms. The furnace power is not enough to connect the air duct system. The series includes modifications with glass and all-metal doors. |

In conclusion, we suggest watching a video with a review of the Breneran stove.

Is it possible to install buleryan in a residential building?

The technology of the pyrolysis process and convection oven has found itself in low-rise individual construction. If all fire safety standards are observed and installed correctly, Buleryan is safe even for wooden cottages.

Similar systems have existed for a long time, but initially they were mainly used for heating non-residential premises. Modern manufacturers have implemented solutions suitable for use in residential buildings.

Buleryan copes well with heating a room in which there are no internal walls. Heat transfer rates are significantly superior to traditional stove heating. Prolonged combustion allows you to reduce the amount of fuel consumed. The efficiency is about 80%. This indicator is facilitated by the process of pyrolysis and convection heating.

The appearance of the stove is more consistent with an industrial hangar. A non-standard interior solution will help. In the hands of a skilled designer, such a stove can look very organic in a residential building:

Modern manufacturers offer boilers of different capacities. Minimum - easily heats up to 100 m3. There are systems for heating an apartment building.