The use of wood stoves for space heating is most often used to heat small spaces. The technology itself is based on the use of traditional cast iron or steel stoves with low efficiency. In addition to high fuel consumption, such stoves also require the constant presence of a person, because if you do not constantly add firewood, it will simply go out. Long-burning stoves are another matter, but alas, today they still have an unreasonably high price, so there is only one option left - to make such a potbelly stove yourself.

What is the difference between a long-burning stove and a wood-burning stove?

Fundamentally, the difference between a long-burning stove and a conventional potbelly stove is how the combustion process occurs. A conventional cast iron or steel stove with a grate and a straight chimney is characterized by rapid combustion of fuel. In fact, the name “potbelly stove” itself comes from the exorbitant appetites of the stove. The combustion process in the firebox occurs on a grate, with a large air flow, which, on the one hand, makes it possible to increase draft, and on the other hand, when burning wood, I burn with a large amount of soot and smoke. This state of affairs cannot indicate fuel economy; they simply have to be constantly added to maintain the temperature.

In a long-burning furnace, the process occurs differently. Depending on the design of the firebox and additional equipment, combustion can take the form of slow combustion (smoldering) or pyrolysis - combustion of gases emitted by the fuel.

When smoldering, it is possible to make the combustion process controlled by reducing or increasing the air flow into the firebox. The result is slow combustion of fuel and the combustion process increases in time. It is difficult to judge how economical such heating is, but it is a fact that the combustion time increases significantly.

During pyrolysis, solid fuel decomposes into simple substances under the influence of high temperature. As a result, it turns out that it is not wood that is burned in the firebox, but the gas emitted by the wood. Such long-burning stoves are much more economical and their installation quickly pays for itself.

But, in fairness, it is worth mentioning intermediate designs that combine the advantages of controlled smoldering furnaces and pyrolysis furnaces. These hybrids are basically the most commonly used DIY projects.

What types of fuel can be used

When it comes to the heating system for a temporary premises, such as a workshop or garage, two aspects are usually taken into account - economic feasibility and safety. In terms of economic feasibility, the most affordable type of fuel today is wood. Liquid fuel, such as diesel fuel or used engine oil, is used for heating mainly utility rooms; in residential areas, the use of this fuel is limited because it has a specific odor. Coal is usually not used for long-burning furnaces of handicraft production; it is intended for heating boilers and stationary brick furnaces.

Thus, the most acceptable type of fuel is firewood or pallets - fuel from wood processing waste. And here lies the whole secret of long-burning furnaces. The fact is that to get maximum effect you need to use only dry firewood. In ordinary, freshly cut firewood, the wood contains a large amount of moisture; during combustion, it turns out that two processes occur in parallel - burning of wood fibers and drying, releasing a large amount of water vapor. The result is a large amount of unburned fuel and combustion at a low temperature. These processes do not allow obtaining the maximum amount of heat.

It's a different matter with dry firewood. The moisture content in them is minimal, which means that when the temperature rises to 300 degrees, the process of decomposition of wood into simple substances begins. This allows you to significantly increase heat transfer, as a result of which the firewood burns completely with minimal formation of soot and ash.

Designing a long-burning potbelly stove

The starting point in the process of designing a long-burning potbelly stove is the need to ensure a comfortable temperature in the room with minimal expenditure of time and effort. The next stage is the search for the optimal design option. To heat a residential house, you can use a Burelyan or rocket stove circuit. But for a greenhouse, garage or industrial premises where there are no high requirements for cleanliness, you can use bubafonya - a stove with vertical fuel loading.

In practical terms, the following is taken into account:

- Location of heating devices;

- Purpose of the premises;

- Dimensions of the heated room;

- Availability of necessary materials and tools;

- Availability of skills to work with tools.

Each of these points is important in its own way and it is simply irrational to discard it during design. The installation location must ensure complete safety of the premises, both in terms of fire safety and safety during use. In addition, it is important to place the stove in such a way that it does not interfere, the chimneys do not take up much space, and the heat from it is evenly distributed over the entire area of the room.

To efficiently heat a room, you need to choose the right dimensions of the structure itself. In a garage or workshop, it is enough to construct a stove of standard sizes, but for a greenhouse you will need a stove from a 200 liter barrel.

The idea of building a long-burning stove with your own hands is often put off until later due to the lack of necessary materials or tools. But on the other hand, if there is no metal sheet 5 mm thick, this does not mean that the idea should be abandoned completely, because there are many successful stove designs created from old cylinders, channels, angles or thick-walled pipes.

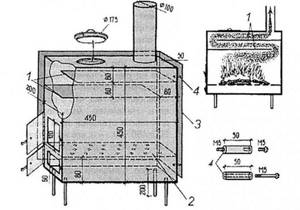

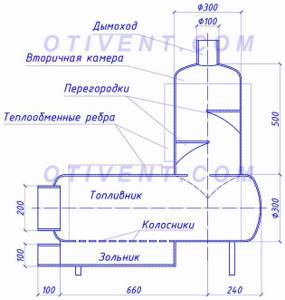

Do-it-yourself potbelly stove with a water circuit

A potbelly stove with a water circuit is made with your own hands in a few steps.

Furnace formation

First, a sketch is worked out, which indicates all the main dimensions of the future structure. To work you will need:

- hammer;

- Bulgarian;

- welding machine;

- pliers;

- workwear.

When drawing up a project, it is very important to take into account how thick the parts of the future product will be.

After cutting the metal, the bottom is connected to the walls, excluding the front side. Welding parts must be performed at 90 degrees.

In the free space formed between the firebox and the ash pit, a partition with holes is installed to remove ash.

The blower hole is made 3 centimeters smaller than the blower itself.

Openings are made on the front wall where the doors will be installed. The front part is equipped with canopies on which doors are installed.

The chimney pipe is welded to the top of the stove.

When the work is completed, the welds are checked. Defects are not allowed. If everything is in order, add a water circuit.

The main part of such a stove is the heat exchanger. It can be made from sheet steel or use hollow metal pipes. In addition, this “potbelly stove” includes:

System installation

To create free circulation of water, two holes are made on the upper surface of the stove. Through one the water is supplied, through the other it returns back.

You can use any leftover material to create a water tank. The tank usually takes up the most space. Before installing it behind the firebox, holes are made in it where the pipes will be connected. A metal sheet is installed between the firebox and the tank.

Then the piping is created. It can have several types:

It is very difficult to create collector wiring with your own hands.

After installing the wiring, all pipes are connected to the radiators installed in the house.

It is advisable to install batteries under a windowsill. This will help increase the thermal conductivity of the stove.

The created water circuit is thoroughly checked. There should be no leaks anywhere.

The supply line is equipped with an expansion tank. It will prevent cold water from entering the system. The dimensions of the tank are calculated according to the volume of water in the system. The tank capacity should exceed this value by 20%. If everything is installed correctly, the water in the heat exchanger will be evenly heated. The liquid will begin to move and enter the radiator. After cooling, it will return to the heat exchanger.

The created stove can be painted and, if desired, covered with brick. It all depends on the imagination of its owner.

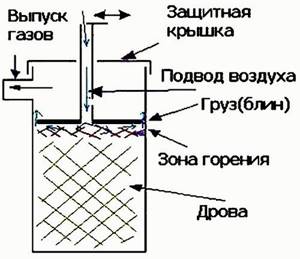

Bubafonya - the most popular long-burning potbelly stove design

The practicality of the Bubafonya stove is proven by its popularity. The fact that this is one of the most popular long-burning stoves is evidenced by the fact that it is used in almost all small greenhouse farms.

The great advantage of this stove is its practicality and ease of use - it is practically omnivorous; dry firewood, sawdust, pellets and briquettes made from straw or sunflower can be burned in the firebox. This stove also shows one of the highest results in terms of fuel combustion duration.

The basic concept of this heating device is that the fuel combustion process combines the process of burning conventional fuel with a controlled supply of oxygen and the process of pyrolysis. The design of the furnace is a metal body with an open top. For the body, a 200 liter thick-walled metal barrel is most often used. It contains a central rod, made of a thick-walled pipe, with a rigidly welded metal disk slightly smaller than the internal diameter of the barrel. The height of the pipe is 10-15 cm higher than the barrel. Ribs are welded on the bottom side of the disk so that there is a small space between the disk and the bottom of the barrel - this is necessary for oxygen access to the firebox. The third element of the design is a structure similar to a guide with a disk. The difference is that the diameter of the pipe is larger than the guide, and the disk itself has holes throughout its entire area. It is put on the internal guide and gradually moves down as the fuel burns. The lid is made of thick metal so that the hole allows the press to lower evenly as the fuel burns. The chimney is sealed in the upper part of the body at a distance of 5-7 cm from the top.

How bubafoni works

Before use, the central guide is inserted into the housing. The entire volume of the body is filled with fuel - firewood, briquettes, flights. The firewood is stacked vertically very tightly. The height of the bookmark should be 5-7 cm below the top cut of the barrel. After this, the upper press is installed on the guide and the cover is put on. Ignition is carried out from above. After the fuel combustion process begins, a process of gradual temperature rise occurs - oxygen enters through the pipes into the combustion chamber. When the temperature rises to 300 degrees, the process of gas formation begins. The gases rise upward and the flame moves into the space between the lid and the upper press. Thus, the process of combustion of gases begins. To regulate the burning speed, an adjustable damper is installed on the pipe of the upper press. When using such a stove, one load of firewood is enough for 48-72 hours of burning.

How to properly heat a potbelly stove?

Before you start melting, you need to take care of fire safety. If the house is made of wood, then several options are possible. For example, asbestos-cement tiles, or just a brick cabinet or metal sheet protection, must be laid on the floor.

Advice! By installing shielding elements, an obstacle is created to prevent coal or wood chips from accidentally flying out of the firebox.

Tips on how to properly heat a potbelly stove:

Cleaning the potbelly stove firebox

- Before starting stoker work, you need to clean the ash pan from combustion products and the grate from accidentally remaining unburned firebrands. Thanks to this, it will be possible to achieve normal air circulation, as a result of which the logs will burn much better and give off more heat.

- After completing the first stage of preparation, we move on to laying firewood. Laying firewood is a fairly simple process at first glance, but without knowledge of the combustion features of stoves and a little experience, it may not work the first time. It is necessary to stack the firewood in such a way that there is enough space for air exchange. If everything is done correctly, the fuel will burn out completely.

- Laying is done in a cellular or row manner.

- When laying firewood, you should maintain a distance of 1 cm from each other, and the height of the stack should be such that it does not reach the top of the chamber by about 10 cm.

- Following these recommendations will increase efficiency.

- After the firewood is stacked, you need to take care of the ignition. For these purposes you will need dry wood chips or paper. They need to be placed between the rows.

Attention! Never use flammable materials to light stoves. This can lead to serious consequences.

Properly stacked firewood burns evenly. Try to do this strictly in the center.

Coal

Is it possible to heat a potbelly stove with coal? It is worth remembering that coal may not be the main type of fuel in all cases. This is because the temperature generated during combustion is high, and not every stove can survive this. And now about the process of firing a potbelly stove.

Place paper and wood chips on the bottom and light it. After the wood chips have ignited, firewood is added and as soon as the logs burn out completely, coal is thrown in a layer of 10-15 cm. When the coal flares up sufficiently, the last portion is added. If necessary, you can add more, but only after the coal has completely burned out.

Firewood

How to heat a stove-stove with wood? A process that does not require special knowledge. As soon as you have finished lighting the potbelly stove with wood, all that remains is to monitor the temperature of the stove and add logs.

Attention! To avoid cracks, it is necessary to maintain the furnace in one temperature pore. If frequent changes from cold to hot occur, the oven may collapse.

Unfortunately, it is impossible to heat around the clock. You want to sleep at night, but winter is unlikely to provide such an opportunity, otherwise you will wake up in a cold room in the morning.

After several days of heating, a lot of waste accumulates in the ash pan and must be removed in a timely manner. The process is carried out using an iron scoop.

Other fuels

Heating with other types of fuel must be done in the same way as when heating with wood and coal. Pellets are placed in the firebox according to the principle of coal, in gradual portions, and briquettes, like firewood, leaving small gaps.

Advice! Don't forget about the blower door. It must be kept slightly open at all times, otherwise smoke may escape into the room.

Since pellets and briquettes appeared relatively recently, a universal combustion method was not invented for them.

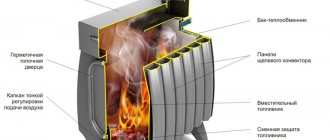

Improved potbelly stove

Like bubafoni, this project has many fans, and do-it-yourself assembly videos can be found in large quantities on the Internet. Unlike other potbelly stoves, its advantage is that, with its compact size, the duration of fuel combustion is 4-5 times longer than that of a simple potbelly stove.

The whole secret lies in the design of the firebox. More precisely, in the absence of a grate in the firebox and the presence of an adjustable damper. The duration of the combustion process is regulated by the supply of air to the combustion chamber.

To independently manufacture such a metal furnace, you must have not only accurate calculations, but also skills in working with a welding machine. The fact is that the moving parts of the housing must be very precisely adjusted to each other, otherwise there will be no controlled air access; it will simply penetrate into the firebox through loosely fitting doors and a gate valve.

The principle of operation of this version of a long-burning potbelly stove is as follows: after the combustion process begins, the gate valve is installed in the desired position so that a slow smoldering mode is maintained in the firebox. Due to the fact that the design does not have a grate or ash pan, air enters through a gate valve.

What to heat with?

The potbelly stove is efficient, small-sized, and unpretentious in operation. Its installation is not difficult, and kindling is a process that does not require special preparation. Firewood (or dry wood chips) is used as fuel.

Expert opinionPavel KruglovStoker with 25 years of experienceWhen using firewood, it is recommended to use logs whose length does not exceed half a meter and whose thickness is 8-10 centimeters. This will allow them to burn efficiently and evenly, avoiding sudden smoldering. You can also take a closer look at wood briquettes, which are no different in properties from firewood. At the same time, they are more capricious in storage and, if left for a long time in conditions of high humidity, disintegrate into sawdust.

Wood is one of the most popular types of fuel. But how to heat a potbelly stove other than wood?

What to use besides firewood?

You can take:

- Peat briquettes, like wood briquettes, do not tolerate direct wetness, but they are less critical of storage conditions. However, when they are burned, a lot of ash is formed. Peat does not like long-term combustion, releasing an unpleasant odor .

- Coal is no less popular for kindling than firewood. It burns longer and has higher efficiency. But due to the high combustion temperature of the stove, coal-fired stoves place special demands on the design of the chimney.

- Pellets are granules made from compressed waste from the woodworking industry. The economic benefit of such fuel lies in the fact that it is produced from real waste and does not require special processing - cutting, splitting.

What can't you heat?

You should not heat a potbelly stove with raw fuel; this leads to moisture being converted into steam during combustion. Steam, passing through the furnace channels, cools them and settles on the walls of the structure. Mixing with soot, the drops form condensation, which leads to damage to the metal components of the unit and the failure of the potbelly stove. So, firewood must dry out for at least a year before use.

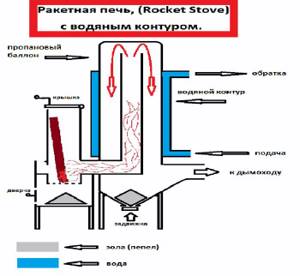

Rocket stove with a cylinder for combustion of exhaust gases

The conventional lightweight rocket stove is quite easy to recognize from photographs due to its unusual design. Three round or square pipes welded at one point and having a common internal space are perhaps the simplest design for a camp fireplace.

But, like an ordinary cast iron stove, the rocket has a very large appetite. On the other hand, the rocket furnace simply has enormous heat transfer from the fuel; it is not for nothing that this design is recognized as the most efficient compared to other projects.

It is this property of rocket-like emission of flame that is used in the design of long-burning potbelly stoves with a cylinder. The fact is that the flame coming out of the firebox is used ineffectively. The video of the operation of such a furnace shows that the flame comes out with great pressure. But along with the flame, a large amount of unburned gases also comes out. The idea of using this potential is to install a large cylinder after the rocket furnace, with the entrance window located on one side and the exit window on the other.

The flame with unburned combustion products, entering the cylinder, continues to burn until complete splitting. Thus, further combustion of flammable gases occurs in the cylinder itself, and smoke and other combustion products are removed through the outlet window.

Pros and cons of homemade long-burning potbelly stoves

Now that the basic designs of furnaces with an extended fuel combustion period are known, it is necessary to analyze the positive qualities and disadvantages of these devices.

The positive aspects include:

- Significant fuel savings;

- High heat transfer;

- Ability to work in “offline” mode for a long time;

- Possibility of use for most types of different fuels.

Alas, these designs also have disadvantages that cannot be called insignificant:

- The need for a hermetically sealed connection of all parts of the housing during assembly;

- High requirements for keeping chimneys clean;

- Despite the fact that the stoves are designed for a long period of operation, they must be looked after periodically;

- To use such devices, certain skills and abilities are required;

- To assemble such a stove yourself, you need to have fairly high skills in metalworking;

- To use, you need well-dried firewood.

Step-by-step instructions for assembling a potbelly stove with your own hands

The first stage is the preparation of the drawing and necessary materials. As for the drawing, it should reveal the design features and subtleties of all elements in as much detail as possible.

For experienced craftsmen, this stage can be skipped, but for those who are just starting the journey of constructing potbelly stoves, it is recommended to assemble a model from cardboard. Modeling, in this case, will cost much less than miscalculations immediately embodied in metal.

The next step is the selection of tools and materials. Here it is recommended to use ready-made components and housings produced industrially as much as possible. This way you can not only reduce the cost of work, but also find new, more effective technical solutions. Another piece of advice regarding this stage is proper organization of the workplace. When working with sheet metal, it is recommended to assemble a jig from wood so that the structures to be welded can be easily installed in the desired position.

During assembly, you need to remember that all connections must be as precise and strong as possible, especially for the body and supports of the potbelly stove. And of course, after assembly, it is necessary to make a test firebox to check the functionality of the assembled structure.

The main advantages of a potbelly stove

In terms of its design, this is the most primitive stove, which, at the same time, has long proven its ideal efficiency. It is for this reason that furnaces that operate during mining still remain in demand today. You can easily find a suitable drawing and make the design yourself.

Some manufacturers of modern heating equipment are still producing high-quality factory-built models, but despite this, potbelly stoves that burn wood or are often made with their own hands, based on a drawing. Moreover, their overall characteristics are sometimes much higher than those of standard factory options.

Below we will describe the main features of this heating device, which will help you decide what important details you need to pay special attention to if you decide to make a stove yourself.

- Among the main advantages of this furnace are the following positive factors:

- A potbelly stove is a relatively simple design that can be made by a simple craftsman without any problems using available tools and materials;

- As a result, this product is quite mobile, even when using a thick metal sheet or lining;

- Thanks to the presence of walls made of metal, the stove quickly heats the room - it is for this reason that this device is an ideal option for country houses and garages;

- Low cost of the furnace, as well as the fuel used, since very often such furnaces operate as waste.

Before you make a stove of this type, based on a drawing or photo, you should be aware of some disadvantages. Due to its small heat capacity, such a stove warms up the room when the firebox itself is fired. The wall of the device becomes very hot, so extreme caution is required when handling the oven.