Main characteristics of polystyrene foam blocks

Despite the fact that the first blocks of foamed polystyrene foam appeared back in the 70s in the USSR, developers only recently began to actively pay attention to this building material.

The production of polystyrene foam blocks is now established on an industrial scale at many domestic enterprises. Below are the main physical properties of the blocks, standardized by GOST:

- the density of blocks for a house should be from 150 to 800 kg/m³;

- have good resistance to frost (without loss of properties, the block will last from 30 to 150 cycles of freezing and thawing);

- the compressive strength indicator ranges from B0.35 to B2.5;

- thermal conductivity varies from 0.055 W/mºC to 0.145 W/mºC;

- vapor permeability coefficient is 0.05 mg;

- The material belongs to the low-flammability group, that is, it is fire resistant.

Application of material

The use of building materials is allowed for:

- construction of external walls of buildings;

- arrangement of interior partitions on the upper floors of the house, in which, due to the weakness of the slabs, the use of cinder blocks or other heavy materials is impossible;

- as an additional insulation or soundproofing layer in a building;

- when constructing premises that require maintaining a certain temperature level, for example, for the construction of a bathhouse or a pen for animals.

Advantages and disadvantages

Having analyzed these characteristics, we will consider the pros and cons of the material for building a house. Based on GOST standards, one can assume that all the characteristics of expanded polystyrene concrete are normal and it is quite possible to build large buildings from it, but this is not the case.

Advantages of expanded polystyrene concrete

For example, the compressive strength of blocks is not particularly high; therefore, experts strongly do not recommend building a house with a height of more than two floors from this building material.

A small coefficient of vapor permeability also has its pros and cons. The advantages are that the material does not absorb moisture, which means it resists frost well. But the disadvantages are that this same property does not allow the building material to “breathe”. As for the environmental properties of the blocks, everything here is also not clear.

You can definitely say something about environmental friendliness only after many years of living in a house built from expanded polystyrene. This is only possible by analyzing the air to detect styrene, but no one is doing this today.

Today, consumers have only one proof - certificates received by the manufacturer, the authenticity of which, unfortunately, cannot be determined.

The undoubted advantage is that expanded polystyrene concrete has a long service life. Considering these advantages, many developers today choose this material for the construction of one- and two-story houses.

Despite their large dimensions, polystyrene foam blocks are lightweight

If you believe the reviews of experts, the disadvantages of houses built from expanded polystyrene concrete include the possibility of destruction of the material from constant sunlight. In addition, according to data posted on construction forums, polystyrene foam is not recommended for use in internal insulation.

Despite all the disadvantages, the building material still has three main advantages:

- Excellent energy-saving properties, as a result of which the owner of the house does not need additional insulation of the building.

- Expanded polystyrene concrete does not need waterproofing.

- Plasticity of the material and precise dimensional geometry. As a result, installation is greatly simplified, which helps save mortar.

Polystyrene concrete blocks: disadvantages and advantages (video)

Dimensions and approximate cost

Today you can find blocks in many sizes on sale. The most popular sizes that are in demand among consumers are the following (based on width-height-length):

- 188x300x588;

- 300x380x588;

- 92x300x588;

- 138×300588;

- 80x300x600 (can only be used when building interior partitions).

Also on sale you can find high-density polystyrene foam blocks (about 600 kg/m³), which are lintels for doors or windows. Such blocks are reinforced and are intended for both load-bearing and heat-insulating structures.

Now regarding the cost. Of course, we cannot provide exact prices as they change from time to time. But the approximate price range is as follows: the price per cubic meter of polystyrene concrete blocks varies around 3,500 rubles (1,200 hryvnia). The cost of foam concrete material is approximately the same.

Structures of popular building blocks

When compared with aerated concrete, the latter costs about 3,800 rubles (1,300 hryvnia) per cubic meter, and wood concrete costs around 4,500 rubles (1,500 hryvnia).

Pros and cons of polystyrene concrete blocks

When thinking about building a country house, many owners consider polystyrene concrete blocks as a building material, the pros and cons of which are determined by the granular structure of the material. The advantages include:

- Economical. The material captivates with its cheapness.

- Low thermal conductivity. Good thermal insulation properties make it possible not to install additional wall insulation with mineral wool or polystyrene foam.

See also: Catalog of companies that specialize in insulating houses.

- Low density and mass (compared to classic concrete). The load on the foundation is reduced (it can be made less massive), as well as the costs of transportation and masonry.

- Low water absorption (water is absorbed only by the surface) and, accordingly, low thermal conductivity, even in conditions of high humidity.

- Decent sound insulation.

- Treatment. PSB blocks lend themselves well to mechanical processing (they can be sawed and grooved without effort), which is valuable when laying communications.

- Frost resistance. GOST sets a minimum rate of 25 freeze-thaw cycles for structural materials used in the construction of external walls. The frost resistance of thermal insulation material is not standardized. In regions with cold winters, walls can be protected by insulating or plastering them.

- Environmentally friendly. Polystyrene, used in the production of polystyrene concrete, is used to make decorative ceiling moldings, toys and well-known yogurt cups. Harmful additives can get into the material during garage production.

Like any material, polystyrene concrete also has disadvantages:

- Low compressive strength (used for the construction of buildings no more than two floors high). Windows and doors can become loose over time.

- Low vapor permeability. A wall made of polystyrene concrete will not breathe, which will inevitably affect the microclimate of the premises. To remove moisture, forced ventilation and air conditioning are needed.

- Flammability. The concrete frame of the blocks is not flammable, unlike the filler. Polystyrene decomposes when exposed to fire, which leads to a decrease in the strength and heat-shielding properties of the material.

- Fasteners In order for the swivel bracket (and with it the TV) to hold firmly in a wall made of polystyrene concrete blocks, anchors and dowels are needed that are specially designed for fastening into lightweight concrete.

What are foam blocks for construction?

This is a molded structure of two foam plates with internal bridges. Building foam blocks in industrial production are produced in the following sizes: length up to 200 cm, width up to 100 cm, and the thickness can be any, but a multiple of 10 mm.

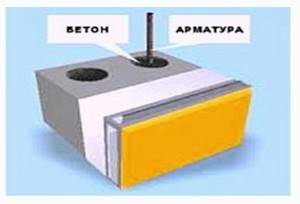

A house built using the latest technology, the walls of which are made of hollow foam blocks filled with heavy concrete, is also called a thermal house. Therefore, the resulting structure is called a thermoblock, where the foam is, in fact, a permanent formwork. In this case, the concrete, hardening, forms a monolithic frame of the building.

Fixed polystyrene foam formwork for house construction

Combining insulation with durable wall material and making the wall construction process quick and simple - that's why permanent formwork was developed.

Expanded polystyrene, as a fairly rigid and at the same time very warm material, is optimally suited for this. If we take into account the economic factor - the low cost of this polymer, then the high popularity of permanent formwork technology among developers becomes clear.

Standard permanent formwork made of expanded polystyrene consists of large-sized (1200x250x250 mm) lightweight blocks with through “windows”. Concrete is poured into these cavities and reinforcement is installed.

Round or rectangular protrusions and recesses are made on the upper and lower edges of the polystyrene foam blocks, with the help of which they fit tightly on top of each other. Anyone who has seen the “bricks” of a children’s Lego set will probably find a lot in common between them and permanent formwork.

There is another “collapsible” design of thermoblocks, when instead of one volumetric mold, two flat ones are used. Such a block consists of two sheets of foam plastic 50 mm thick, connected to each other by plastic jumpers.

The idea of permanent formwork technology is very simple: we assemble a warm wall row by row, filling it with concrete as it grows and inserting reinforcing bars to increase spatial rigidity. The result is a durable frame structure - a reinforced concrete lattice, the internal and external surfaces of which are reliably insulated with foam plastic.

Labor-intensive operations typical of conventional brickwork - laying out mortar, trimming and splitting bricks - are absent here. The blocks are quickly assembled into a single line, and workers can only fill them with fine-grained concrete in time.

The eternal problem of masons - masonry corners - has also been successfully solved. For this purpose, special corner foam blocks with perfectly precise geometry are used.

The main condition for high-quality construction of walls using permanent formwork technology is a level foundation. If it has differences in height, then it will be very difficult to accurately place the blocks on it without additional grouting with cement mortar.

Important note! Permanent formwork can be successfully used not only for the construction of warm walls, but also for pouring strip foundations.

Features of the technology

- At the stage of constructing the foundation, it is necessary to lay vertical rods in it to connect it with the wall made of permanent formwork.

- Reinforcement outlets from the foundation must be long enough to install the first three rows of polystyrene foam blocks.

- Waterproofing of the first row of formwork is necessary. Without it, moisture will flow freely into the concrete, reducing the thermal insulation of the wall. For this you need to use compounds that do not dissolve polystyrene foam.

- Horizontal reinforcing bars are laid inside each row to provide longitudinal rigidity to the frame.

- Pouring concrete is carried out after installing three rows of formwork blocks. After the concrete has set, the wall can be built up further.

- To cover window and door openings, you need to buy special lintels and plugs that are used to seal the ends of the formwork to prevent concrete leakage. Above the opening, the formwork is reinforced with two rows of horizontal reinforcement and supported from below to avoid deflection.

The outside of polystyrene foam permanent formwork is finished with special adhesive mixtures that have a high coefficient of adhesion to polymer surfaces. To protect the plaster or putty from cracking, a fine-mesh fiberglass mesh is glued to the blocks, which is then covered with a finishing mortar.

Other types of permanent formwork cladding are not particularly problematic, provided you make a suitable base for them in advance. For example, for siding, at the installation and concreting stage, you need to attach bars or a metal profile to the wall. To finish with decorative brick or stone, wire loops are placed in the concrete formwork to connect it to the masonry.

Sheet plasterboard or glass magnesite are optimally suited for interior wall decoration. It can be attached using regular starting putty. Ceramic tiles are also easily attached to the surface of polystyrene foam using special adhesive.

Pros and cons of permanent formwork

Speaking about the advantages of polystyrene foam blocks used as formwork structures, it is necessary to note the disadvantages of these products. Yesterday and today, the construction of houses using permanent formwork technology raises a number of discussions. The heated debates, if you read reviews on construction forums, revolve around the issue of environmental friendliness and durability of polystyrene foam.

Avoiding emotions and trusting laboratory tests and practice, let's say the following. The sanitary safety of this polymer is confirmed by the hygienic certificates that each manufacturer receives for permanent formwork. This is a fact that is difficult to ignore. Owners of houses built using this technology, having lived in them for quite a long time (3-5 or more years), do not notice discomfort or increasing health problems.

The fire safety of polystyrene foam blocks falls within the framework of current Russian norms and regulations. They belong to the category of low-flammability and low-flammability materials (G1 and B1). But their level of smoke formation is quite high - D3.

This is what we see in the hygienic certificate for polystyrene foam boards (analogous to blocks for permanent formwork).

In terms of the content of the most dangerous substances - styrene and formaldehyde, permanent formwork meets the standards.

But after studying the information on the scope of application, some questions arise.

The use of polystyrene foam as the middle layer of a wall structure is a requirement of Soviet GOST. Today, building facades are covered with this material everywhere.

But for indoor use (the blocks face one side into the room), high-quality foam insulation is required. That is, it is not enough to simply putty it and paint it. It is necessary to line the wall with fire-resistant plasterboard or glass-magnesite sheets (SML) and apply the finishing touches to them.

This polymer is not dangerous in operation, but in case of fire without proper protection it releases toxic gases. Fire-resistant drywall or plaster will allow people to leave the room before the gases from decomposing polystyrene foam fill it.

To be fair, it must be said that the use of polystyrene foam indoors, provided it is protected from direct contact with fire, is less dangerous than conventional household items - chipboard furniture and decoration (linoleum, curtains, wallpaper and other materials containing flammable polymers).

High-quality external finishing of permanent formwork is very important, since the direct action of ultraviolet radiation quickly destroys the polymer. Therefore, after finishing the construction of external walls, do not delay with plastering.

Approximate prices

When buying permanent formwork blocks, it is advisable to choose those made of denser polystyrene foam (25-35 kg/m3). They can better withstand the pressure of wet concrete.

The average cost of one block of permanent formwork (1500x250x250 mm, wall 25 mm) made of polystyrene foam with a density of 30 kg/m3 (M25) ranges from 150 to 170 rubles.

The cost of a one and a half meter collapsible block (wall thickness 25 mm) starts at 170 rubles. Its main advantage is the ability to adjust the width by installing jumpers of different lengths (150-250 mm).

For harsh climatic conditions, manufacturers produce permanent formwork with increased wall thickness (75 mm). The price of such blocks ranges from 190 to 210 rubles per 1 piece.

In addition to the standard length of 1.5 meters, ordinary meter blocks (1000x250x250 mm) are sold on the market. Their cost starts from 130 rubles per piece.

Video on the topic:

greensector.ru

Polystyrene concrete: getting to know the material

Polystyrene concrete is a composite (complex in composition) material belonging to the class of lightweight concrete. Lightweight concrete has a reduced density, which allows solving several construction problems:

- reduce the weight of the building;

- increase its thermal insulation characteristics;

- reduce the cost of construction (by reducing labor costs and increasing the productivity of builders).

For the production of polystyrene concrete the following is used:

- Portland cement (a type of cement);

- water;

- polystyrene, filler in the form of granules of various fractions with heat-insulating properties (polystyrene is a polymer with a wide range of uses);

- quartz sand;

- plasticizers - various additives (for example, resin) that improve the plasticity of the mixture; Thanks to this, the blocks do not crack during hardening and drying.

Polymer granules (very similar to foam balls) create the lightweight structure of polystyrene concrete. The low density of foam and aerated concrete is ensured by air pores resulting from a chemical reaction.

Polystyrene granules Source archidea.com.ua

Price of polystyrene concrete blocks and their advantages

The high performance characteristics of polystyrene concrete blocks are ensured by their special composition. For their manufacture, cement, additives to improve the properties of blocks and porous filler – polystyrene – are used. The latter component provides the blocks with the best thermal and sound insulation characteristics among almost all existing building materials. At the same time, the prices of polystyrene concrete blocks are only slightly higher than for blocks of other types, and almost half the price of brickwork of the same volume. Additional savings are provided due to the low weight of this building material, which reduces the costs of transportation, storage and installation.

What are the proportions of foam chips with cement

Screeding with cement mortar will entail a load on the covering slabs. This is very bad, so to significantly reduce it, you need to add foam chips to the cement mixture. An important aspect is to increase heat and sound insulation.

Before adding crumbs to cement, it must be treated with a special solution.

You can use something like this:

- crushed, obtained by grinding foam pieces;

- primary, specially produced for use in mortars.

The first type has a cheaper cost than the second.

What is the proportion of cement for foam chips for concrete mortar? It's quite simple:

- from 4 to 5 buckets of fine foam crumbs;

- 1 part of cement grade M 500;

- 2 parts coarse sand;

- 1 part water.

Use a concrete mixer to mix all components. This will take you no more than 5 minutes, and the result will be a slightly dry mixture, somewhat reminiscent of buckwheat in appearance.

Concrete with crumbs - negative aspects

As already mentioned, a mixture of mortar with light filler (foam chips) has a high level of sound insulation and thermal insulation. In addition, this material is not porous and does not absorb moisture.

But foam balls, interacting with cement mortar and sand, are not durable. The action of oxygen causes their destruction. They will completely collapse in about 20 years.

That is why concrete with the presence of foam chips must be plastered. In addition, such material as polystyrene foam is not absolutely harmless. Since foam balls, when combined with sand and cement, become non-flammable, when heated they simply melt and release toxic gas.

Instructions for preparing concrete with foam chips

First you need to load sand and cement into the concrete mixer. After this, add the crumbs. At this stage, you should mix the ingredients and only then add water. The proportions of foam chips with cement must be taken into account so that the mixture does not crumble later. After mixing all the components, add water and bring the solution to a homogeneous state.

The finished product will have the following characteristics that positively distinguish it from pure concrete:

- Reduced heat conductivity;

- Lightening the weight, with the ability to reduce the load on the foundation;

- Increased sound insulation;

- Significant cost reduction.

But, despite all the advantages, this product clearly lacks strength. In order for this indicator to be normal, it is necessary to maintain the ratio of foam crumbs and other components.

Pediments: a hint of status

Expanded polystyrene decorations on the pediment are mainly represented by decorative elements in the form of waves, bends and curls. They are an addition, a crown to the exterior of the house, decorated with columns, pilasters and other pompous elements. The monogram, located in the center of the composition, speaks of belonging to a famous or ancient rich family.

Even if you do not come from a noble family, who is stopping you from showing everyone that this is not so? Simply hang a framed monogram with your initials on the gable

Foam tiles

Foam garland

About the environmental friendliness of the material

Most people are sure that polystyrene foam, like any other “chemical”, is unsafe or even harmful to health. This fact has not yet been confirmed, but it has not been refuted either. It is worth noting that there are a number of requirements, in particular sanitary and GOST, to which the manufactured products fully comply.

But some people are difficult to convince even of obvious things, which is most likely due to a psychological factor. And even the fact that foam plastic is widely used in insulation and interior decoration, as well as in the manufacture of disposable tableware, for some reason is not a compelling argument in this case.

Analysis of advantages and disadvantages

Since we have reviewed the main properties and features of the technologies, it’s time to analyze the above data and find out what advantages and disadvantages the products and buildings built from them have.

So, polystyrene concrete blocks: pros and cons - which of the parties are superior in quantitative and qualitative indicators?

Strengths of products and buildings built from them

Positive qualities, of course, dominate.

Let's look at them:

- The first thing I would like to note is thermal conductivity. Expanded polystyrene deservedly occupies the first position among wall materials in this indicator.

- The frost resistance of products attracts with its high value.

- The strength characteristics cannot be called truly high, but they are quite sufficient.

- Environmental friendliness and fire resistance are a strong argument in favor of choosing this block.

- The speed of construction and ease of processing will make the task easier for the developer, especially if you decide to build the walls yourself.

- The price of the products pleasantly surprises many buyers. The cost of construction will be significantly reduced when using polystyrene concrete as a material for constructing walls. Compared to a brick building, such a house will cost about 15-20% less.

- The low weight of the block reduces the weight of the entire wall and, as a result, the load on the base. A lightweight foundation can also be erected if the building is one-story, light and compact.

- It is worth remembering the possibility of making products at home. The process is quite simple and can be implemented by almost any developer. Moreover, expensive equipment is not required.

- The scope of application of blocks is extremely wide. They can be used not only for the purpose of building a wall.

- The diversity and large selection of manufacturers contribute to high competition and, as a result, the opportunity to choose among the most worthy ones that meet high standard requirements. You will also be able to save on product delivery by searching for a nearby dealer or simple supplier.

- The ability to isolate noise will create favorable conditions for staying in the room, protecting it from extraneous sounds.

- The variability of finishing only attracts those interested. Almost any materials can be used. This fact indicates that almost every developer will be able to choose for himself the optimal method of cladding and interior decoration.

- The biological stability of polystyrene concrete does not allow fungus and mold to form on its surface.

Some pros

Negative aspects of polystyrene concrete

Disadvantages of products:

- Hygroscopicity. It may be small, but everything has its place. In this regard, the requirements for finishing techniques have been increased. This often means not only increased costs, but also a high risk of errors when doing the work yourself.

- Shrinkage of buildings constructed from polystyrene concrete is not uncommon. As a result, cracks may form on the surface, which will subsequently have to be corrected.

- Low adhesion. We can correct this fact, but additional costs cannot be avoided.

- The prevalence of small private industries, which do not always comply with all standards and technologies. This means increased risk when purchasing products.

- The need to plan attachment points to a polystyrene concrete wall if you want to fix heavy elements, for example, in the form of a heating radiator.

- The use of ordinary hardware is unacceptable; specialized ones should be purchased.

- The requirement for technical documentation regarding finishing is that it should not begin earlier than 28 days from the date of completion of construction work. This is due to shrinkage of the material.

- Planning ventilation systems is also mandatory.

- Polystyrene must be plastered to protect the material from external influences.

Polystyrene concrete blocks: disadvantages - poor adhesion to plaster

Some ways to optimize material deficiencies

It turns out that the material has a lot of shortcomings. However, there are certain methods and tricks with which some of them can be partially or completely eliminated.

Here are some tips:

- In order to avoid a decrease in the properties of the material due to exposure to moisture, it is worth familiarizing yourself in detail with the technical side of the finish. If done correctly, there will be no problems.

- Fastening problems can be avoided by planning the joints at the design stage. There is no need to rush to start construction work. Think over everything properly, taking into account the characteristics of the material.

- You can protect yourself from purchasing low-quality products by requiring and checking a quality certificate and other accompanying documentation. It is also recommended to give preference to proven, popular suppliers on the market. Too low cost of the material should alert you.

- Adhesion can be increased by priming the walls before finishing and using reinforcing mesh when plastering.

- As for the appearance of cracks, this is not always the result of shrinkage. This can happen for a number of reasons, such as: errors in foundation construction, excessive moisture in products, unfavorable conditions for construction (rain, high humidity), and so on.

By following the above rules, you will certainly be able to avoid the manifestation of at least some of the shortcomings of the material.

The video in this article: “Polystyrene concrete: pros and cons” contains useful information about methods for eliminating deficiencies.

Manufacturers of polystyrene concrete stones

There are several manufacturers of polystyrene concrete blocks on the Russian market:

- The concrete block plant is located in Crimea, in the city of Simferopol. Engaged in the sale and production of building materials of various sizes, there is delivery throughout the regions.

- Plastblock is a manufacturer from Yekaterinburg. It has been operating for more than 20 years, producing not only blocks, but also lintels and reinforced slabs from the specified material.

- Ermak is a plant from Chelyabinsk. It works according to standards, has all the certificates and expert opinions, the goods are distributed throughout the territory of the Customs Union.

- PromstroyPenoplast is a manufacturer from Moscow. Produces material and delivers it to surrounding areas. You can order large quantities for large-scale construction.

- Polystyrene concrete plant from the Sverdlovsk region. Products are manufactured according to certificates, fast delivery, 18 years of experience.

Almost every region of Russia has its own manufacturers of this material, so ordering it will not be difficult.

What do you need for work?

To make artificial bricks you will need sheets of dense polystyrene foam. We call it foam plastic in general, it can be:

- "Penoplex" used for insulation of buildings. The thinnest one will do - 20 mm.

- Styrofoam. It is better to take with high density (for example, PPS-35).

- PVC sandwich panels with expanded polystyrene, which are used for finishing slopes. This sandwich brick needs to be cut lengthwise into two parts. On one side there will be foam plastic, on the other there will be a PVC base.

In order to glue foam bricks to the wall, the following is suitable:

Glue “liquid nails” such as “Moment Installation” or “Titanium”. Liquid nails are needed when brickwork is laid out one element at a time, i.e. foam rectangles are glued 1 piece at a time.

Polyurethane foam . With its help, you can glue a whole sheet of foam plastic on which imitation masonry is made. For individual bricks this method will be inconvenient. The foam adheres well to strong, rough substrates: concrete, aerated concrete, plaster, drywall. The polyurethane foam comes off from smooth PVC panels. When purchasing, look at the mass of polyurethane in the cylinder; with the same volumes of foam, it may be less. A good option is “Macroflex” (MAKROFLEX).

Adhesive for insulation . This option is also for installing foam plastic sheets directly under the brick. The adhesive that is used for constructing wet facades is suitable: Ceresit CT 85, Unis Warm Adhesive, Weber.Therm S100, Knauf Sevener.

Glue gun . It is useful for gluing decorative bricks from sandwich panels, i.e. with a smooth PVC base.

Other advantages of polystyrene concrete blocks:

- convenience and ease of processing. If necessary, such blocks can be easily cut, for example, to make a short wall or corner. A regular hacksaw is suitable for sawing polystyrene blocks;

- high strength. Although the blocks are relatively light, they are characterized by very high strength. At the same time, not only individual blocks are strong, but also the structure as a whole, incl. through the use of special adhesive compositions for fastening elements. Masonry made of polystyrene concrete blocks can easily withstand the weight of floor slabs, which allows the construction of multi-story structures;

- the frost resistance of the blocks is one and a half times higher than the parameters of similar building materials;

- the blocks are superior in thermal conductivity and sound insulation even to gas silicate and foam concrete, and are practically not inferior to wooden structures;

- the blocks do not absorb moisture, making them resistant to mold and destruction from temperature changes;

- resistance to aggressive environments and substances: acids, alkalis, oils, gasoline, etc., which makes it permissible to use polystyrene concrete blocks in special facilities such as warehouses or chemical plants.

The company “Kirpich.ru” offers delivery of polystyrene concrete blocks using its own transport throughout Moscow and Moscow Region. You can place an order, request a calculation of the required volume of building materials, or ask questions by phone.

Warm blocks for walls (heat block) - what is the problem of application

Three-layer wall blocks, consisting of two layers of concrete and insulation between them, are a relatively new building material. According to the plan, they should simplify, speed up and reduce the cost of building three-layer walls. But did everything work out?

There are no building codes or regulations for these blocks. There are only recommendations for their use developed by one of the institutes. Designers who do not depend on the companies that produce these blocks try not to include them in house designs.

Such blocks are not difficult to produce. They are produced by many small manufacturers. (... which often fail to fulfill the stated characteristics). But also a number of large ones. The well-known brands are Teploblok, Polyblok, Kremnegranit, Telosten..... But the essence is the same - a three-layer heat-efficient wall block, characterized by increased heat conservation.

Why do experts try to do without warm blocks?

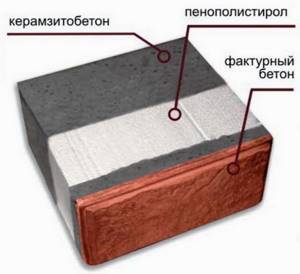

Heat block design

The usual dimensions of warm blocks (thermally efficient wall blocks) are shown in the figure. With a total width of 300 - 400 mm, the thickness of the layers can be different. The inner concrete layer is the widest, 120 - 200 mm, and has the greatest impact on the strength of the wall.

The outer layer is narrower, finishing, can be painted, and equipped with a relief, textured surface.

The insulation is most often foamed polystyrene foam (EPS), and the more expensive extruded polystyrene foam XPS is also less common. The thickness of the insulation varies between 100 - 160 mm.

To connect the layers, plastic anchors are most often used in addition to glue. Or the strength of the connection of the layers is increased due to the comb shape of the connection, which prevents tensile forces.

What are they releasing?

Blocks from small manufacturers with metal internal reinforcement are more likely to fall into the “reject” category due to increased thermal conductivity and reduced durability.

All block configurations necessary for the construction of walls are produced.

When purchasing, you need to purchase all the configurations necessary for masonry, use the order of the project, durable concrete products are not easy to cut.

The composition of concrete can vary greatly; various heavy durable fillers and expanded clay are used. And some manufacturers use both mineral wool and foam glass as insulation.

Technical characteristics of warm blocks

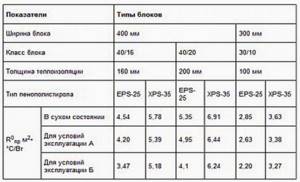

The dimensional error in the manufacture of blocks is often no more than 2 mm. This allows you to lay blocks on a thin layer of glue - 3 - 5 mm. If the dimensional accuracy of the blocks is more than 2 mm, then the masonry is made using ordinary cement-sand mortar with a joint thickness of 10 mm.

An important characteristic of heat blocks is the resistance to heat transfer of the finished wall. First of all, it will depend on the thickness of the insulation layer. And also from his appearance.

Polystyrene foam is “colder” than extruded polystyrene foam. In addition, the foam can be moistened. At the same time, it significantly increases its thermal conductivity. While extruded polystyrene foam does not absorb water and does not change its thermal conductivity when the wall is saturated with moisture.

Heat transfer resistance

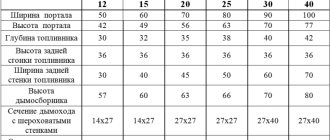

The table provides information about the heat transfer resistance of heat blocks depending on the insulation material, layer thickness, and humidity.

For blocks in the wall, the maximum humidity value should be taken.

Heat blocks, even with a small thickness of extruded polystyrene foam (XPS), have satisfactory heat transfer resistance for many regions according to SNiP.

Before choosing a heat block, you need to find out more precisely what heat transfer resistance should be at the walls of a house in a specific climate zone according to the standards.

The wall design itself practically does not increase thermal conductivity. The coefficient of thermal heterogeneity of a wall made of this material when laid on glue with thermal break of seams on foam plastic is 0.92. The thermal insulation characteristics of the wall will depend mainly on the correctness of the masonry; it is necessary to prevent cold bridges.

Strength of heat blocks and walls made from them

The strength characteristics of warm blocks are the most important. In a conventional three-layer wall, only the inner layer is the load-bearing layer. And the outer one creates façade finishing and protection for the insulation; it does not take the load from the overlying structures. How three-layer walls are insulated and finished

In a wall made of three-layer warm blocks (thermal block, polyblock, porcelain stoneware, thermal...) both the inner and outer layers are load-bearing.

Layer thickness in blocks

What thickness of concrete layers should be in a warm block to ensure the strength of the wall throughout its service life? It is known that experts recommend using heat blocks with an inner layer thickness of at least 180 mm for two- and three-story buildings.

For a one-story building with a non-residential attic, it is permissible to use blocks with an internal concrete layer thickness of 130 mm, but subject to mesh reinforcement of the masonry (every fourth layer), openings, as well as the creation of a reinforced concrete belt under the floors.

Compressive strength characterizes the entire block as a solid product - found in M35, M50, M75. When determining the characteristics, all layers are taken into account, even foam.

It is necessary to distinguish between the strength of the concrete from which the block is made and the strength of the block itself. The compressive strength of the concrete from which the block is made will be greater than the similar characteristic adopted for the entire block as a whole.

Increasing the width of the insulation leads to a thinning of the internal load-bearing layer of concrete. Ensuring strength, reliability and durability is the main criterion when choosing blocks. Therefore, it is impossible to reduce the thickness of concrete in pursuit of better heat conservation.

Features of application

The use of warm blocks is still experimental.

Research Institute "Teplosten", which are considered the developers of this technology, recommend using a spatial reinforced concrete building frame together with blocks. And the blocks themselves can have a total thickness of 300 mm (with reduced strength characteristics).

But the construction of a spatial reinforced concrete frame, although not so expensive, complicates the construction process; many construction organizations simply avoid such problems, preferring classic masonry.

Most manufacturers recommend using wider blocks. By making external and internal load-bearing connected walls from them, together with the ceiling, they form the load-bearing frame of the building (according to the project).

How to do masonry

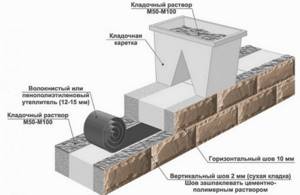

When laying, it is recommended to fill the vertical and horizontal seams between the concrete parts with glue (mortar). (any masonry adhesive can be used, for example under tiles). And the seams between the foam parts are made with ordinary polyurethane foam. When using a solution, flexible tape insulation can be placed on the foam.

Some manufacturers produce blocks with holes in the thick inner layer specifically for creating vertical reinforcement with steel rods, and a spatial reinforced frame directly in the blocks.

Question with seams

A special feature of the use of heat blocks is the absence of external plaster and the jointing of through joints in the masonry. In this case, it becomes necessary to very carefully and reliably rub all the seams between the blocks from the outside. Why use the same masonry adhesive, and on top of it façade primers or silicone sealant.

It is necessary to monitor the condition of these seams throughout the operation of the building. When the wall is soaked with sediment, water can get inside the wall through small cracks in the seams. Which threatens it with frost destruction, loss of thermal and strength properties, penetration of moisture into the house, and destruction of the polyurethane foam in the seams.

Walls made of this material with a relief surface on the outside are additionally painted with facade paints with any vapor permeability, usually in light colors, which creates additional protection for the structure.

The technology of protecting the wall from the outside by grouting through joints between load-bearing elements seems unreliable.

Unlike aerated concrete or porous ceramics, which are also laid with through seams, but for which an external protective finish of the wall is always provided, façade plaster is lightweight

Durability

The presence of the synthetic substance polystyrene foam between the mineral load-bearing layers also raises questions. Expanded polystyrene has a service life that is not as long as mineral substances. Presumably this insulation will gradually decompose, compact, crumble, etc. And here this layer is a binder and can take loads...

After all, the predicted service life of polystyrene foam insulation and mineral wool on a wall is only 35 years, after which it is necessary to carry out the next energy audit of the building and replace insulation materials that have become unusable. Even clinker brick cladding in a three-layer wall can be disassembled brick by brick to replace the insulation. But in this case... The durability (100 years or more) of walls made of thermal blocks is in doubt.

Blocks made entirely of mineral substances, where the insulation is foam glass, “eternal” and vapor barrier, are clearly the preferred option. But they are much more expensive.

The use of mineral wool in blocks, which not only has a short service life, but also absorbs water like a sponge, also raises many questions.

According to the project

Heat blocks (three-layer concrete blocks with a middle layer of insulation) can only be used in accordance with a design made specifically for this wall material.

Based on the calculations, the optimal design of the heating block will be selected, as well as the reinforcement and spatial frame formed by the walls and ceilings.

You should not use the services of drawing up specifications and orders for heating blocks based on any house design offered by manufacturers of this material.

Advantages and disadvantages

The pros and cons of heat blocks, as well as how walls are laid from this material, can be found in this film

Production technology

Let's briefly consider the manufacturing technology of building materials. To obtain the final product, manufacturers use the pressing method, which, in fact, is used to produce all blocks used in construction without exception.

More modernized production uses the method of vibratory pressing of blocks. According to experts, this makes it possible to improve the stability indicator and also increase the service life.

If you understand that insulating a concrete floor with polystyrene foam is a profitable business, then you can try to organize your own business at home. To organize production, you will need a concrete mixer, the material itself is polystyrene, cement, water and sand.

Liquid concrete mixture with polystyrene foam granules for pouring into molds

Naturally, the volumes of sand, cement and water must be quite large. At home, it is quite possible to make building materials with a density of D1200 and D350. To produce the first one you will need:

- 1.1 cubic meter of polystyrene foam;

- about 300 kg of cement;

- approximately 800 kg of sand.

When the mixture hardens, the result is a solid concrete material. The production stages are as follows:

- First you need to make the mixture. The elements described above must be mixed in a concrete mixer for about thirty minutes.

- Then the mixture is poured into formwork or pre-prepared forms.

- In the summer, it will take about three days for the mixture to harden; in the winter, at least a week, sometimes more. In any case, before removing the resulting polystyrene foam from the molds, it must harden.

- The next stage, at your discretion, is cutting the material.

Equipment for the production of polystyrene concrete and polystyrene concrete blocks

Installation of blocks

Work on the installation of expanded polystyrene concrete blocks is carried out in the following sequence:

- Installation. The very first row must be installed on the waterproofing layer of the foundation; reinforced rods must be inserted into it, which will play a connecting role. This stage is one of the main ones, since you should pay attention to the compliance of the planned dimensions and the resulting contours. Also consider the need to arrange outlets for internal partitions. All other rows are installed similarly to brickwork.

- The reinforcement is installed in each row of the formwork; two rods must be used. The blocks are pre-provided with holes for reinforcement. The rods should be overlapped and secured to each other, as well as to the pins that are laid in the foundation, using wire. Thanks to reinforcement, you can add strength to the structure of the future building, and this will also reduce the pressure of concrete on the formwork.

- The final stage is pouring concrete.

As you can see, the technology for installing blocks is not particularly complicated. We hope this material will help you.

Features of insulated wall blocks

Wall blocks, like insulation for walls inside a house, are a building material that can not only facilitate the construction of a private house, in comparison with the construction of brick walls, but also reduce the time and financial resources required to implement the project.

Wall block with insulation and siding

This article will consider wall blocks with insulation and cladding. You will find out what these products are made of and what structure they have, what their advantages and disadvantages are, and what the estimated cost of facade blocks with insulation from different materials is.

1 Advantages and disadvantages of wall blocks

Walls are one of the main structural elements of any home. It is the walls that, for the most part, determine how strong and reliable the building will be, and what thermal insulation characteristics will be inherent in it.

Almost any house built from classic building materials - brick or concrete, including the recently popular materials of foamed concrete, must be insulated, since only high-quality thermal insulation can provide housing that is comfortable for year-round living.

Foam insulation for wall insulation is necessary due to the fact that common building materials have relatively high thermal conductivity - for brick it is 0.46 W/mk, for concrete - 0.7 W/mk.

This indicator determines whether the walls of the house will effectively retain internal heat in the cold season and coolness in the summer. The lower this indicator, the better.

The technology for building a truly comfortable home involves thermal insulation of housing even at the stage of its construction, which entails additional financial costs for the insulation itself, vapor barrier and waterproofing, and facing materials for the facade.

Wall blocks with insulation and cladding are a relatively new building material that allows you to take all of the above tasks off your shoulders.

Wall blocks with insulation from the inside of wooden walls are multilayer products, the structure of which consists of three layers connected by fiberglass reinforcement: a load-bearing part - a material that guarantees the strength and reliability of the wall of the house, insulation - responsible for the thermal insulation characteristics of the walls (foam plastic, or penoplex), and facing part - making the facade of the house visually attractive.

Structure of an insulated wall block

A comparison of insulated wall blocks with currently common building materials demonstrates that such structures have the following advantages:

- Cost - the financial costs of constructing walls from insulated blocks are significantly lower than building a house made of bricks, and subsequent thermal insulation;

- Dimensions – wall blocks are an order of magnitude larger than bricks, which significantly speeds up the pace of wall laying. For example, laying brick walls of a medium-sized house usually takes about two weeks; if wall blocks are used, the construction time for walls is reduced by at least 2 times;

- Thermal insulation for insulating the walls of an apartment from the inside - the presence of an internal layer of insulation - a material with a thermal conductivity ranging from 0.29 to 0.035 W / mk, ensures that the walls of the house will not freeze even in the coldest season, as a result of which an optimal microclimate will be maintained in the house ;

- Sound insulation – high-quality insulation materials used in the production of wall blocks, in addition to thermal insulation properties, have the ability to reduce noise, which guarantees the acoustic comfort of housing;

- Aesthetics - the cladding of wall blocks with insulation is made from a variety of materials - you can choose blocks with a facade made of brick, wood, marble, or any type that suits you.

2 Structure and characteristics of the wall block

As already mentioned, insulated wall blocks consist of three layers: the first is load-bearing material, the second is insulation (foam), and the third is facing panels.

The standard size of a wall block with insulation is, as a rule, 400 mm in length and 200 mm in height. The width of the block can vary from 250 to 400 millimeters, in most cases it is 350 mm. The width of the material depends on the thickness of the insulation layer.

Wall blocks with insulation are significantly lighter than monolithic building materials, as a result of which their installation is much simpler.

Connection diagram of layers of insulated wall block

Installation of insulated wall blocks is similar to brickwork and insulation for protecting the walls of a house; it can be done either using cement mortar or using a special adhesive composition. The latter option is more preferable.

When laying blocks on cement mortar, in order to achieve the required strength characteristics of the wall, it is necessary to use at least a centimeter layer of mortar. When laying blocks with glue, similar structural strength is achieved with a 2-3 mm layer of glue.

A thick layer of mortar, firstly, is uneconomical, as the consumption of cement and sand increases greatly, and secondly, such a compound will significantly worsen the thermal insulation properties of the walls, since cement mortar has high thermal conductivity.

Cement joints will form cold bridges - elements in the wall structure that have greater thermal conductivity than the base material, through which the wall will freeze in the cold season.

This is not typical for adhesive mixtures used for laying wall blocks, since they contain special polymer impurities.

2.1 Load-bearing part of the wall block

There are a lot of materials used to make the load-bearing part of a wall block. It could be:

All of the materials listed above are characterized by low weight and low thermal conductivity compared to conventional reinforced concrete. However, such diversity can only be found in foreign countries, where insulated wall blocks have been used for building houses for decades.

The main materials of the load-bearing part of the blocks presented on the domestic market, as a rule, are expanded clay concrete and clay brick. Expanded clay concrete is made from a mixture of cement, sand and expanded clay - thermally treated clay.

The advantages of expanded clay concrete include its low thermal conductivity, compared to ordinary concrete, which is 0.5 W/μ. And brick is also inferior in this regard.

The material is also characterized by high mechanical strength, which is an order of magnitude higher than the similar characteristics of gas silicate products - foam concrete and aerated concrete.

Compared to other porous concretes, expanded clay concrete has better noise-reducing properties, which, together with the soundproofing characteristics of the insulation layer, ensures almost complete insulation of housing from all external sounds.

Varieties

Construction standards (according to GOST R51253-99) provide for polystyrene concrete products of the following categories:

- Structural, marking D450-600.

- Structural and thermal insulation, grades D350 to D450.

- Thermal insulation, D150-350.

Types of PSB products Source nauka-i-religia.ru

PSB building blocks are also classified by size and method of use:

- Polystyrene concrete blocks for mounting external walls (structural) have a density of D500-D600 (500-600 kg/m3). Products with parameters 188x300x588 and 300x380x588 mm are produced industrially.

- The blocks used for organizing internal partitions (thermal insulation) have a density of D400 and sizes 92x300x588 and 92x600x588 mm.

- Reinforced lintels (to protect openings) with a density of D400 can have a length from 1200 to 3000 mm and various sections (140x235, 140x295, 180x235, 180x295 mm).

- Facing (decorative) products have a molded front surface, density from D300 and various sizes. A façade lined with such blocks does not require additional finishing (it can be painted if desired).

Blocks with insulation and cladding are an economical and reliable building material

Any owner of a private house will agree that living in a poorly insulated house is very unpleasant, in addition, you need to make sure that the facade of the house is attractive in appearance - this is, after all, the pride of the homeowner. Therefore, you need to take care of the strength of the walls, the high quality of insulation, and the exterior finishing. For many developers, this is a whole headache, which can be solved by a material such as blocks with insulation and cladding.

This is a modern building material, which is manufactured in such a way that it combines a load-bearing module, a heat-insulating layer, and an external finishing layer. Until recently, such material was just a dream, but today you can quite easily purchase three-layer blocks. Since this is still a fairly new material, it costs a lot, but technologies tend to get cheaper, so it is likely that soon blocks with insulation and cladding will cost no more than conventional building materials.

Structure of blocks with insulation and cladding

As mentioned above, such blocks consist of 3 layers:

- load-bearing layer - made of expanded clay concrete, which has a large number of microscopic pores in its structure;

- insulation layer - polystyrene foam is most often used here, but there are variations with mineral wool insulation.

- outer layer - made of concrete with a textured pattern applied, which can be either abstract or repeat the surface of natural materials.

Qualitative characteristics of three-layer blocks

Blocks with insulation and cladding have a number of specific advantages:

- the most important thing is to reduce work costs, because main masonry, insulation and external finishing are carried out simultaneously;

- structural strength - all layers of the block are securely connected to each other by reinforcement;

- excellent thermal insulation properties - houses made of blocks with insulation and cladding do not require additional thermal insulation.

- high level of moisture insulation;

- immunity to fungal and putrefactive lesions;

- profitability - in terms of single-layer materials, construction from three-layer blocks is much more profitable.

Scope of application of three-layer blocks

Most often, blocks with insulation and cladding are used in the construction of low-rise buildings, because This is where the dilemma of balancing efficiency, simplicity and accessibility most often arises.

In the photo: laying blocks with cladding

However, such blocks can also be used for the construction of multi-story buildings. Of course, they should not be used for the construction of load-bearing structures, but this makes it possible to reduce the thickness of the load-bearing layer, which has a positive effect on the dimensions and cost of the blocks. If you decorate the interior of an apartment with such blocks, you will get a very nice and warm home.

Blocks with insulation and cladding are also effective in the construction of frame houses, when the main load falls on the frame, and the space between its elements is filled with one material or another. Brick or aerated concrete blocks are often used here. however, the use of three-layer blocks can significantly reduce the cost of time, effort and money. And due to the fact that a wall made of blocks can be much thinner than a brick wall with the same thermal insulation value, the internal area of the room is larger with the same external perimeter.

An important circumstance is that the use of blocks with insulation and cladding has passed all the necessary approval procedures and is fully approved by government authorities.

Wall blocks, like insulation for walls inside a house, are a building material that can not only facilitate the construction of a private house, in comparison with the construction of brick walls, but also reduce the time and financial resources required to implement the project.

Wall block with insulation and siding

This article will consider wall blocks with insulation and cladding. You will find out what these products are made of and what structure they have, what their advantages and disadvantages are, and what the estimated cost of facade blocks with insulation from different materials is.

Finishing features

After complete hardening of the concrete mass, it is necessary to finish the foam wall surface. Plastering of such walls is carried out in the following order:

- A reinforcing metal mesh is attached on top of the foam. It must be made of wire with a diameter of at least 1 mm. Fastening is carried out to the inner concrete layer using dowels.

- Coating the mesh with a special adhesive mass intended for polystyrene foam.

- Installation of beacons to control the thickness of the plaster layer, and the accuracy of their installation is checked by the building level.

- Application of cement-sand plaster mortar.

Foam walls can be finished with any facing material. Some polymer panels are glued directly to polystyrene foam. For siding or finishing panels, you will have to do cladding (read: correct installation of siding on a wooden house).

Important. It should be noted that the profiles should be attached not to the polymer, but to the inner concrete layer . With the help of cladding it is possible to provide a ventilated façade.

Ceiling stucco

Polystyrene foam is lightweight, which is why it is used for finishing suspended, suspended, and ordinary ceilings. The following parts are used:

- decorative panels - square tiles, approximately 50 by 50 cm in size, with which the ceiling is completely covered, usually have convex parts;

- ceiling sockets - they are used to decorate the bases of lamps mounted on the ceiling;

- caissons - available in the form of textured rectangular and square tiles;

- domes - have the shape of round concave tiles;

- ornaments, including corner ones - details of different sizes in the form of flowers, curls, diamonds, attached to both the ceiling and walls;

- ceiling plinths - mounted between the ceiling and the wall, sometimes decorated with lighting.

To order, some companies produce entire ceiling and wall panels, stylized as the Renaissance era or with an image that the client wants.

When decorating with interior stucco, the main thing is not to “overdo it” with the decor - too much of it looks tasteless.

A little about quality

There are no problems with building a house from polystyrene concrete blocks - this is a common building material. To determine the quality of products, you must remember:

- High-quality products are equipped with a certificate that lists the characteristics of the material.

- The choice of product brand depends on the type of structure (residential building or outbuilding). The standard size of a regular PSB block is 188x300x588, a large one is 380x300x588 mm.

Low-quality polystyrene concrete blocks break with one blow Source beton-house.com

- The durable PSB block can withstand a fall from a height of 3-4 m or several blows with a sledgehammer.

- The granules on the cut of the material are clearly distinguishable, have the same size and are evenly spaced, adjacent to each other.

- The material must not have voids.

Types of foam blocks with decorative coating

Facade decorative block with cladding comes in several types:

- Simple. A simple wall foam block with a finished facade has become widespread in the field of country and cottage construction. Its main advantage is that after the walls are erected there is no need to carry out facing work. The outer surfaces of the blocks are initially covered with a layer of high-quality finishing, making the façade look beautiful and respectable. The facing coating applied to the front side of each block not only gives the materials excellent aesthetic qualities, but also protects it from external influences (since it has a high degree of moisture resistance).

- Angular. Unlike a conventional facade block, this material has two adjacent decorative surfaces. It is used for arranging door and window openings and finishing corners.

- Thermoblock. Structurally, such blocks consist of several layers. On the front side of the material

There is a facing facade layer that gives the foam block an aesthetic appearance. Behind it is a thick layer of heat-insulating filler designed to reduce the thermal conductivity of the blocks. On the inside there is a load-bearing layer, which gives the building material sufficient strength and resistance to mechanical loads. Thermoblock is one of the best thermal insulating materials. Thus, a 0.4 m thick thermoblock wall is identical in thermal insulation quality to a 2.4 m brick or 4.6 m concrete wall. Therefore, it is often used to fill the walls of buildings that require effective thermal insulation.

Insulating the corners of a timber house

Shrinkage inevitably occurs even in structures made from the most thoroughly dried material; distortions between the crowns are the reason why cracks appear. Primary shrinkage occurs 1-1.5 years after the construction of the house. Then, within 1-2 years you may experience shrinkage. Finally, after 10 years, the previously selected seal wears out and requires replacement. Methods for insulating corners:

- Caulking joints inside and outside the building. The method is ancient, labor-intensive, but remains relevant to this day.

- Polymer sealing. Allows you to solve the problem once and for all, the only disadvantage is that the technology is expensive.

- Wind protection - facing - the facade with clapboard or block house.

Using Popsicle Sticks

This DIY fence can be made from identical rounded wooden ice cream sticks. They can be easily purchased in stores, and for working with children, they can be collected over the summer, when ice cream is eaten in large quantities. Making such a fence is simple. On a flat surface, lay out the sticks in a row and attach two horizontal ones on top of them. You can use either PVA or a glue gun.

It is better to make a fence from popsicle sticks in small sections, as in the photo in the article. Now you know how to make a fence for a craft, but that's not all. You need to install it in a vertical position, and this is much more difficult. One simple way is to cut two strips of green cardboard, install them at right angles to the surface of the base and glue them on both sides to the fence section. The upper edge is cut into strips, imitating grass. You can applique flowers to complement the composition.

If the fence for a garden craft is made especially strong, then it can be strengthened with gypsum mortar. For example, if the craft is a hut made of branches, then around it you can lay out a “sausage” made from a mixture of plaster and water. When the solution begins to set, insert the fence sections into it. After hardening, they will be firmly fixed. Subsequently, you can use gouache or acrylic paint to paint it green, as if it were a mound overgrown with grass.