Products by manufacturer All products A ... Z

Light-type industrial gas infrared emitters

Industrial gas infrared dark type emitters

Ceiling, wall (wall) infrared panels and strip infrared heating systems

Infrared heating control systems

Air curtains, thermal curtains, gas-air heaters, heat generators

Climatic ventilation units, air conditioning units

MANUFACTURERS OF EQUIPMENT FOR INDUSTRIAL HEATING:

| JSC "Schwank" | CARLIEUKLIMA Srl | MANDÍK, as | Tecnoclima SpA (Group Energia) TS Group Energia LLC | LLC "TEPLOWEY" |

Questionnaire for calculating gas-radiant heating of industrial premises >>

Questionnaire for calculating air heating (gas) of industrial premises >>

Why are industrial and outdoor infrared heaters needed?

Industrial and outdoor infrared heaters are needed to create a comfortable temperature in certain areas. The scope of application of outdoor infrared heaters is wide. They are in demand wherever it is necessary to provide comfort to people in closed, open and semi-open spaces.

Infrared heaters are used : in industrial premises, at dachas, summer cafes, traveling exhibitions, outdoor cinemas, for installing icing systems. An infrared heater heats objects, not air. Thanks to this, objects in industrial premises, gyms, chairs on the terrace and benches in the garden will always be warm. The devices have a reliable and simple design. Metal body coated with heat-resistant paint. Sealed flask with heating element, aluminum reflector.

Advantages of industrial and outdoor infrared heaters:

- Economical

- Efficient - sufficient power to quickly achieve results and minimize wasted working time

- Eco-friendly and safe - absence of factors harmful to humans and compliance with safety requirements in specific operating conditions

- Convenient installation

We offer to buy industrial and outdoor infrared heaters at a competitive price with prompt delivery throughout Moscow and the regions. For orders and consultation, please call.

Types of infrared heaters for industrial use

*

So, IR heaters are recognized as the most effective and appropriate for production conditions, since they do not use air as a transit medium (drafts are common in workshops) and therefore are suitable for working in open areas, have a high heat transfer rate and are effective for heating moving objects (conveyors , drying chambers, kilns).

But infrared radiation can be obtained by using various energy carriers, which determine the design of the heaters. Let's look at the most common types of infrared heaters produced for industrial needs.

Electric IR heaters for industry

Installation of such units is carried out on ceilings or walls, control is carried out mainly from wired wall-mounted devices, but for ease of use, some models provide remote wireless control and, in addition, the ability to connect to a thermostat.

The power of electrical units is in the range of 2-7.5 kW, which determines the consumed voltage - 220 or 380 V.

Manual heater remote control and signal switch location.

Structurally, industrial infrared electric heaters consist of a metal body, a reflector-reflector and an infrared wave emitter.

The body is covered with a heat-resistant protective paint and varnish composition, usually made by spraying. In order to increase the reflective area, the reflector is made corrugated.

As a radiator, industrial electric IR heaters use quartz or halogen lamps with a special coating on the bulb (carbon ones are not used due to their low power) or heating elements (tubular electric heaters).

Methods of mounting infrared industrial heaters are remote brackets and hanging devices.

Heating elements, in turn, can be of an open or closed arrangement.

*

With an open layout, the heater in the housing is visible and, although the unit is equipped with a protective grille, the heater is less safe, since its temperature after heating reaches 800 degrees. Heaters with heating elements of an open design are mounted in places inaccessible to personnel and are used in industrial premises with significant ceiling heights (10 m or more), in the absence of external thermal insulation, with drafts or the need for regular ventilation.

Infrared electric heaters with an open heating element.

In a closed position, the heating element is located behind a corrugated metal plate that does not contact it directly and therefore heats up only to 200 degrees, which increases the safety of the electric heater, but reduces the heating efficiency. Units with closed heating elements are used in non-ventilated rooms with external wall insulation.

To calculate the efficiency of an industrial heater in a specific room, a value called power density is used, measured in watts per square meter (W/m2) - the amount of power to provide the required temperature conditions over an area of 1 m2. The calculated values are tabulated taking into account the region, the degree of thermal protection of the enclosing structures and the recommended temperature threshold for a given production. For example, to maintain a room temperature of 19 degrees, you need to spend up to 100 W per 1 sq. meter of mercy.

Installation of wall and ceiling IR heaters for industrial use is carried out in accordance with GOST standards and manufacturer's recommendations, including location, orientation and installation height.

Gas industrial infrared heaters

The high power of industrial heaters causes increased energy consumption, so gas heaters are mainly designed for mains natural gas, but there are also models that consume propane (butane).

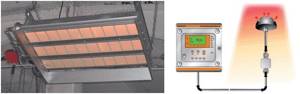

Gas infrared heater in action. It is possible to connect a thermostat controlled remotely.

*

Industrial infrared gas emitters are classified according to the temperature of the heat transfer plane - into “light” (800–1000°C) and “dark” (300–600°C) types.

Gas infrared heaters of the light type are designed for heating large areas with high ceilings - production workshops, warehouses, agricultural and zootechnical premises, equipped with canopies for open areas, etc.

Important! “Light” type IR heaters belong to gas equipment of group A1 - combustion products are not discharged anywhere and remain in the heated room, which must be equipped with a forced exhaust ventilation system.

Gas IR heaters of the “dark” type are structurally a pipe with a diameter of 75 to 120 mm, with a burner mounted at one end and a fan at the other.

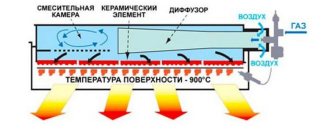

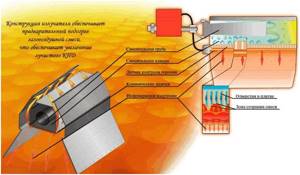

Device diagrams and operating principles of industrial gas infrared heaters of the “dark” type.

The pipe is made of a special heat-emitting alloy or coated with a heat-resistant coating with identical properties and placed on a steel sheet with a mirror surface.

Gas (natural or liquefied) is supplied to the burner, which, when burned, heats the pipe from the inside and initiates infrared radiation from it.

Most - 50-75% of the thermal energy is transferred to the surface of the pipe and is directed downwards in the form of infrared radiation - towards the floor, the middle and lower zones of the walls of the room, as well as equipment, which is facilitated by a mirror reflector located behind the pipe.

25-40% of the thermal energy from gas combustion goes to compensate for heat loss in the room through the roof, the upper zone of the walls, and only 5-10% of the heat goes into the atmosphere along with the gas combustion products discharged outside.

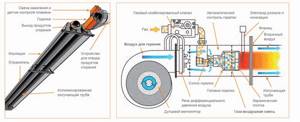

A real image of one of the models of a “dark” type gas infrared heater and its section.

*

Industrial gas heaters of the “dark” type are divided into the following types:

- modular - for local heating of limited areas or workplaces;

- strip (block) - designed for assembling heating systems of complex configurations that follow the geometry of the room.

Gas infrared heaters are attractive due to the low cost of the energy used, but it should be remembered that gas is a fuel of increased danger of use, and the operation of such equipment requires more attention than the use of electric heaters.

Liquid fuel infrared industrial heaters

The energy carrier consumed by these units is diesel fuel or aviation kerosene.

The principle of operation of the device is based on heating the emitter with fuel burning in the nozzle and then emitting infrared wavelengths from it. Therefore, unlike a liquid fuel heat gun, these units do not create directed air flows that raise dust.

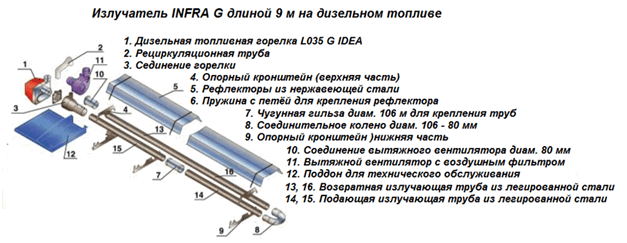

Liquid fuel IR heaters are produced for stationary (modular) and portable use. The design of stationary diesel IR heaters for industrial use resembles gas infrared units, but only at first glance - the difference in energy carrier determines a different design of components. The similarity of the systems can be seen using the example of the INFRA heater, which has proven itself well on the Russian market.

Diagram of the installation of an industrial infrared emitter using diesel fuel for stationary placement

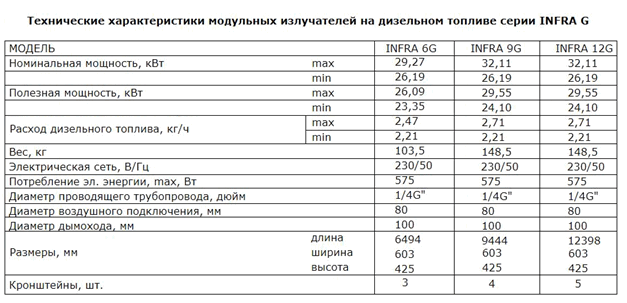

Modular diesel infrared emitters are used for heating medium and large areas of industrial premises, indoor agricultural facilities (poultry farms, farms, greenhouses), warehouse areas and sports facilities. When choosing a heater of the required power, it is convenient to use the following table of the range of models of these units:

Portable diesel infrared heaters, although not compact, are no less effective than modular ones. Their design, thanks to a carriage with wheels, with the dimensions of the unit being more than a meter in length, allows one worker to move the equipment to the desired location. The heat transfer power of such devices can reach 40 kW or more with a fuel consumption of 2-3 kg/hour, which allows heating rooms with an area of 300-400 square meters. But efficiency also determines the price - the cost of top models can exceed one hundred thousand rubles.

Important! The use of energy carriers not specified in the user manual in liquid fuel IR heaters is prohibited.

Water thermal panels

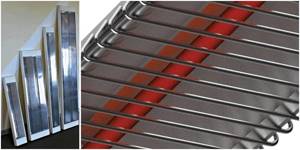

This emitting infrared device for industrial use is a system assembled from separate sections, which are a profiled steel or aluminum reflector sheet in which a system of tubes is mounted for the movement of coolant - hot water. The sections are connected using fittings.

Types of heating sections with hot water supply and their connection

Such devices, with their simple design, are reliable, durable, highly economical and efficient in use. Of no small importance is the factor of the absence of flammable energy in the system, which makes the device absolutely environmentally friendly and highly safe.

Infrared heaters with hot water supply are mounted on the ceiling or walls and are ideal for industrial, agricultural, warehouse and other premises. The base planned for the placement of the heating system is pre-equipped with thermal insulation to reduce heat loss through the supporting structure. The insignificant weight of the sections in most cases does not impose additional requirements on the load-bearing characteristics of the base, and compliance with the installation rules recommended by the manufacturer ensures reliable installation of the device.

Advantages

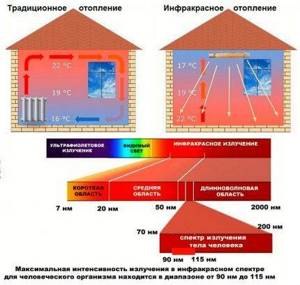

Industrial infrared ceiling heaters are based on radiant heat technologies, which have great advantages over traditional industrial heating systems.

- High energy saving rates.

- Possibility of heating local work areas.

- Creating an atmosphere of thermal comfort without a feeling of stuffiness - a healthy microclimate that is optimal for humans.

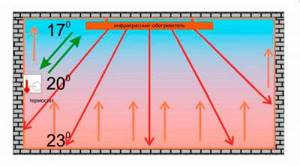

- There is no phenomenon of air stratification, in which heated air rises, and to heat the lower zones of the room it is necessary to increase the power of the equipment. Industrial infrared ceiling heaters give off heat directly to the surfaces of objects and people.

- Significant reduction in heat loss.

- Heat transfer is carried out using infrared rays, which eliminates air convection.

- The equipment does not make any sounds during operation.

- Heating of production facilities and warehouses takes place within a few minutes – even over very large areas.

Infrared heating systems system based on infrared emitters

The basis of an infrared heating system is infrared heaters. The principle of their operation is based on the fact that the energy of burned gas or electricity is converted into thermal radiation energy.

Advantages: the ability to target heat to the desired zone and heat individual local zones on a large scale.

Disadvantages: if it is necessary to warm up the entire volume of air in the room, the efficiency of the devices is greatly reduced; radiating surfaces heated to high temperatures are located directly in the heated room, which can lead to a fire; emitters running on natural gas require a complex and extensive gas supply system, which greatly increases the cost of the entire project; Gas-powered emitters burn oxygen from the room, which leads to the need for ventilation; emitters running on electricity consume a lot of electricity, which is uneconomical; Possible deterioration in the well-being of personnel exposed to direct radiation.

Emitters are effective only when in a large volume room it is necessary to heat up several local working areas in a targeted manner; the effectiveness of their use for heating the entire volume of the room as a whole is extremely low.

The main purpose of such technology

Industrial heaters differ from household devices primarily in power. If we consider that they are used on large objects (larger than a living room), this means that sufficient performance is needed to quickly warm up. Like any analogue of heating equipment, infrared units are capable of creating comfortable conditions for working on site. However, the significant difference is the ability to act locally without completely heating the entire air space of the room.

Let's watch the video, a little about infrared heating:

That is why, even at very large facilities, the prohibitively high power of such equipment is not always needed, since, first of all, industrial infrared heaters of various types act with heat on various surfaces, heating them. This includes the floor, walls, and nearby objects or furniture (but not too close due to the risk of fire).

If we compare it with convection equipment, then in this case the air environment warms up, and, as you know, warm air rises to the ceiling of the room. This leads to the need for regular heating, which does not happen when using infrared devices.

Types of heating devices

Today's realities show that infrared heating is in sufficient demand, so equipment manufacturers are trying to approach the manufacturing issue carefully. Depending on the purpose, the types of heating devices powered by infrared healing can be divided into the following types:

- heaters. Almost everyone is familiar with a device with a lamp, often equipped with an additional support. Such devices are good for gatherings on the terrace or in the gazebo. They can also be used to heat private buildings and even greenhouses;

- lamp devices. Lamps with IR radiation are not much different from heaters, except for the installation method. They are attached to the ceiling at a certain angle. Thus, large production premises and workshops are heated;

- panels. Panel equipment powered by infrared radiation is probably the most reasonable solution for heating a home. A beautiful smooth surface, sometimes with a chosen design, fits perfectly into the overall interior and does not create any special problems for residents;

- film. There is also a film type of device. This is an indispensable basis for obtaining heat in the house based on the “warm floor” technology. But when installing equipment, it is quite acceptable to place it on the walls of the room.

In general, infrared heating has a number of advantages. It operates silently, does not create dust or deposits on surfaces, and does not take up storage space.

Infrared heater

Types of infrared heaters: gas, electric 380V

Among the emitters of infrared heat flow, the following two types are distinguished, if we focus on the heating method:

- Gas heaters.

- Electric heaters.

Fuel consumption of gas equipment is reduced by 50-85% in contrast to electrical appliances . The payback of such installations is noted already in 1 or 2 seasons, subject to their constant operation. The operating principle of such devices is to use gas fuel mixed with oxygen inside a special device - a burner. Combustion temperature from 800 to 1000 degrees Celsius . Combustion products are discharged through a special channel.

Electric heat emitters are widely used in industries both inside and outside buildings. The space can be heated locally (spotwise) and be an addition to the main heating system. These installations can be used in areas where there is a high level of industrial dust, fire risks, and where paint and varnish products are stored . They are also used for industrial purposes - as equipment for drying something, heating metal, being used in anti-icing systems, floor heating, and more.

Gas heater for a summer house with a cylinder, main manufacturers

Currently, gas cylinder heaters are manufactured by many manufacturers in technically developed countries. The most famous are: Bartolini (Italy), Ballu (Russia), Timberk (Sweden), Alpine Air (Turkey), as well as Kovea (South Korea) and Result Group (Russia).

Bartolini gas heaters top the popularity rating among heating units operating with a cylinder. The model that ensured the primacy of the Italian brand is the Bartolini Pullover K heater, used for heating various buildings and structures. Main technical characteristics:

- Type – catalytic.

- Fuel – propane / butane.

- The capacity of the gas cylinder is 24.5/27 liters.

- The location of the cylinder is inside the housing under the protective casing.

- Automation devices - sensors (flame control, air condition), rollover protection.

- Piezo ignition.

- Power adjustment.

- Products of Timberk company (Sweden). Among the company's models, the most popular among users is the Timberk TGN 4200 SM1 - a mobile heater that uses infrared heat transfer. A 12-liter cylinder is located inside the heater body. The model is equipped with control of gas supply and combustion, as well as the removal of waste products. The heater has a tip-over protection function, as well as piezo ignition, and power adjustment is possible.

- Devices from the Alpine Air company (Turkey). In the company’s product line, in the gas heater segment, the Alpine Air NGS-20F model is popular. This is a wall-mounted gas converter. The model is equipped with a cast iron heat exchanger, which ensures long-term operation of the device (up to 50 years). The heater can operate on various types of gas (natural / liquefied), some modifications are equipped with a fan.

- Gas heater Vallu. The Ballu BOGH-14E model is an infrared outdoor heater that enjoys well-deserved popularity among owners of suburban real estate. The body is made of stainless steel and equipped with wheels, which makes the heater mobile. The device comes with a remote control that allows you to remotely configure the operating modes of the device.

- Heaters from Kovea. The South Korean company produces a large number of different models of heaters and other climate control equipment. Among the heating units that are especially in demand among hunters and fishermen, the main place is occupied by the portable Kovea Fire Ball model, which operates on infrared radiation. The reflector of the device has two placement positions in space - horizontal and inclined. The model is equipped with piezo ignition and a preheating system for the gas used.

How to choose an industrial heater?

When purchasing an industrial heating device, preference should, of course, be given to infrared models. They can be:

- wall-mounted;

- floor;

- ceiling

The first two options are quite effective, but their thermal comfort zone is insignificant. So, a device installed on the wall will heat the wall and objects opposite. Floor-standing models heat only up to a certain height. And in the case of devices located on the ceiling, this problem is solved by itself - the comfort zone expands, since a fairly large area is heated.

Objects and the floor heat up, releasing the resulting thermal energy to the air masses. At the same time, energy resources are consumed extremely economically.

Which option should you choose? From a design point of view, all IR devices are practically the same. They can differ only in wavelength and materials used in manufacturing. And if everything is more or less clear with the length, then with the materials things are different:

- quartz models are attractive due to their low cost;

- made of carbon - economical;

- made of metal - long service life;

- made of ceramics – excellent performance properties;

- from Incoloy – rust-resistant;

- film - special warmth, comfortable and soft.

There are even special programs that allow you to determine the power of the heating device after entering data about the industrial premises.

In addition, when purchasing, be sure to consider the following information:

- number of windows;

- type of lighting;

- number of workers on site;

- availability of electrical appliances.

The best option is film models.

What is an infrared heater for industrial premises?

An infrared heater for industrial premises uses gas, electricity or another type of fuel to create an initial source of energy and then convert it into infrared radiation.

The device has a simple but at the same time reliable design, the components of which are:

- metal body, the surface of which is coated with heat-resistant paint;

- sealed flask with a heating element inside;

- aluminum reflector.

By heating industrial workplaces with an infrared heater, you will save money. Traditional heating using radiators will cost more.

The room begins to feel warm a few minutes after turning on the device. Infrared radiation affects the surface of objects through heating. Excess thermal energy is transferred to the air through natural circulation.

IR heaters in production

Gas: dark, light emitters

Among gas equipment that emits heat in the infrared spectrum, heaters are divided into the following two types according to the intensity method:

- Light emitters. The main feature is the bright reddish-orange color of the heating devices when they are incandescent. Variations of this class are capable of heating their metal tubes (heating elements) to a bright, intense color-light, without overheating.

- Dark emitters. The main difference is the muted color of the hot heating devices - metal tubes. They do not become red hot, which is why they are conventionally called “dark” heaters.

Light infrared heating devices are used to heat space in a room with a height of at least 4 meters from floor to ceiling. Their performance is always higher than those with lower heating intensity. Installing such devices follows a simple calculation: for every 20 cubic meters. m. it is required to install one heater with a power of 1 kW. If we take into account large areas of premises, then for every 100 sq. m. of space you will need one device with a power of 5 kW.

Dark ones are designed to heat a space in a room with an installation height of 3-3.5 m. Gas is burned in this case at temperatures from 350 to 400 degrees Celsius. These units are significantly heavier in weight than light type equipment. Therefore, this factor should always be taken into account during installation. To select this or that equipment, you need to look at the height of the ceilings in the room, the type of activity of the enterprise and the current ventilation.

Dark emitters

The combustion process of a gas-air mixture in a low-intensity IR device occurs in a closed system in which a metal pipe serves as the radiating element. It works on the same principle as the light emitter, but at reduced temperatures of about 350-450 degrees. During operation, flue gases heat up the screen tube, which begins to emit infrared rays.

The gas IR heater received its name “dark” due to the fact that its radiant tube never becomes red hot.

The design of the device includes:

- gas burner;

- reflector;

- screen emitting tube;

- gas outlet

Screen tubes are available in linear and U-shaped. In the latter case, infrared radiation is distributed more evenly in space due to the location of the hot and cold segments in the structure opposite each other. When choosing a model with a linear screen tube, keep in mind that at its end the temperature will always be lower than at the burner side.

Dark gas infrared heaters are installed in rooms whose height is three meters or more. When installing heating devices in warehouses with high racks, it should be taken into account that flammable materials and explosive objects are not allowed to be placed at a distance of one and a half meters from the radiator.

It is prohibited to use dark emitters:

- in residential premises and offices;

- in workshops where the work process involves flammable substances.

Dark gas heaters are heavier and larger than light ones, so the costs associated with their installation will be more expensive. They do not take up useful space, as they are suspended from the ceiling. And they are used for both general and zone heating.

It is most beneficial to use dark emitters:

- in isolated large buildings with minimal air exchange;

- in narrow passages;

- in rooms with reduced heat requirements;

- in workshops with relatively low ceilings (3 meters), where the use of light-colored models of gas emitters is not allowed.

It should be noted that with high humidity conditions in the room, it is necessary to choose a device made of stainless steel.

Electrical: long wave, short wave

In addition to the numerous advantages of electric infrared heaters, they also have their disadvantages. The main disadvantage is the high cost. Cost reduction is carried out through the additional installation of auxiliary devices - thermostats, also of an industrial level.

Based on the type of radiation, IR can be divided into two groups:

- Long wave. They can be used where people work; these devices are not harmful to their health.

- Shortwave. Most often they are used for drying wood, but are not used in rooms where people are constantly present.

In addition to these types, there is also a gradation according to the type of installation - wall or ceiling heaters. Some modifications are provided for any type of fastening. In addition, there are stationary devices, and there are mobile (portable) ones. No flammable objects, furniture or animals should be placed near such installations.

Types of industrial IR heaters

Currently, gas and electric industrial infrared heaters are distinguished, which, in turn, are divided into several types, based on the type of fastener:

- wall;

- floor;

- ceiling

Wall-mounted models are designed for small-sized rooms; they are mounted on a wall at a height of 2.5-3 meters.

Ceiling heaters are used to heat large rooms. The power of such devices is high; they are mounted at great heights, on suspensions or torsos.

The IR heater is a floor-mounted one, which is rare; such a unit is a single stand with emitters attached to it. Scope of application: spot heating.

Gas

Such devices are highly economical. Provided they operate continuously, such devices fully pay for themselves in 1-2 heating seasons.

Industrial-type infrared ceiling heaters operating on gas can be divided into two categories:

- Light radiators are used to supply heat to industrial premises where the ceiling height starts from 4 meters and above. The models are considered one of the most effective. The operating principle is based on the combustion of a mixture of gas and air in a special burner at a temperature of 800-1000°C. Combustion products are removed through a drainage channel.

- Dark emitters - the gas combustion process is carried out at a temperature of 350-400°C. As a result, the metal tube, which acts as an emitter, does not glow red-hot, which contributed to the name of the device. When attaching dark-type heaters, you need to take into account that the emitters have a larger mass than light-colored heaters.

For industrial premises, heaters of either light or dark type are selected. The choice is influenced by the technical characteristics of the building itself (ceiling height, good air circulation), as well as the type of production activity.

Advantages of gas heaters:

- possibility of local heating of premises;

- reduction of heat loss;

- payback occurs very quickly;

- There is no need for any costs for maintaining boiler room personnel.

Electrical

Wall-mounted and floor-mounted units are used for local and general heating of premises inside and outside buildings. Depending on the principle of operation and design features, the following types of devices are distinguished:

- According to the type of mounting, electric infrared heaters can be ceiling, floor, wall or universal, which can work anywhere with equal efficiency. There are stationary and mobile installations, which are very popular among construction teams.

- According to the principle of operation, emitters are distinguished that emit short and long infrared waves. Short-wave heaters are actively used for drying wood and equipment for painting booths.

Short infrared waves have a negative impact on human health. Therefore, the installation of industrial electric short-wave infrared heaters in a room where people are constantly present is strictly prohibited.

Emitters that use long waves have a beneficial effect on people's health, so they can be installed in production shops without any problems. Long-wave heaters act as the main source of heat in winter.

TOP 3 electric infrared heaters

Short-wave electric IR heater Helios Titan EHT1-15 1500 W IP25 (white)

- Power – 1.5 kW.

- Heating area – 25 sq.m. maximum.

- Dimensions – 455x130x90 mm.

- Protection – not afraid of rain and moisture.

- Installation is possible both indoors and outdoors.

- Recommended installation height is 3.5-4 m.

- The wire for powering from the socket is 1.5 m.

- Kit - grille and fasteners.

- Cost – 15,225 rubles.

- Production - Italy.

Ceiling electric heater IK "Bilyuks" B1350, AOX 1300

- Power – 1.3 kW.

- Power supply – 220 V (50 Hz).

- Heating area – 26 sq.m.

- Dimensions – 1500x160x40 mm.

- Weight – 3.4 kg.

- Cost – 3300-3500 rubles.

- Production – Russia, Moscow.

High temperature IR heater Frico IR6000

- Power – 6 kW.

- Power supply – 380 V.

- Heating coverage area – 120 sq.m.

- The heating element is heated up to 700 degrees.

- Dimensions – 1800x358x83 mm.

- Weight – 14.1 kg.

- Cost – 42,100 rubles.

- Production - Sweden.

Advantages of gas emitters

Experience in using gas emitters has made it possible to discover several key advantages that set the equipment apart from its analogues:

- possibility of local heating of the room;

- reduction of heat consumption;

- payback in a short time;

- no costs for maintaining boiler house workers;

- the ability to turn off the device in winter and instantly warm up the unheated area if necessary.

The technical characteristics of industrial infrared heaters do not allow their use at home. The minimum ceiling height of the room required for safe use is from 3 to 4 meters.

Largest producers

The largest manufacturers of infrared heaters are the following companies:

- "EcoLine";

- "IcoLine";

- "Infra";

- "Peony";

- "Frico";

- "Mr. Hit";

- "Ballu"

- "Bilux";

- "Zilon"

- "Helios";

- "Starprogetti";

- "Hyundai".

If we rely on reviews from users or those companies that constantly use IR equipment for their production purposes, then “Peony” is considered the best among mobile installations. Each has its own advantages, the main thing is not to buy a fake device.

The essence of infrared radiation

Infrared radiation differs from ordinary and so familiar visible light. They are similar in the speed with which they spread and cross space. Both varieties are capable of refraction, reflection and bunching.

Unlike ordinary light radiation, which is electromagnetic waves, IR flux has both wave and quantum properties. That is, it transmits both light and heat.

Both ordinary light and infrared radiation are streams of electromagnetic waves. The difference is that in the first case the visible component predominates, in the second the visible component is combined with the thermal

The light supplied by infrared devices moves in waves. Electromagnetic light vibrations are in the spectrum segment from 760 nm (nanometers) to 540 μm (micrometers). The heat generated by IR emitters is a flux of quanta. Their energy ranges from 0.0125 to 1.25 eV (electron volts).

The heat and light fluxes emitted by infrared devices are interconnected. As light intensity increases, the quantum heat flux decreases. Depending on the temperature, infrared radiation may or may not be perceived by our eyes. Thermal radiation is not visually detectable.

This specificity of infrared radiation is used in industry to accelerate polymerization and hardening processes. The thermal part of infrared radiation makes it possible to determine the presence and location of a person or animal in dimly lit and unlit night periods.

Infrared heating devices emit light in combination with thermal energy, used to create a comfortable microclimate on parking lots, workshops, production halls, poultry farms, greenhouses and many other objects

The non-standard operation of IR devices that emit light in combination with heat became the basis for the development of night vision devices. It is used in flaw detection, in hidden alarm systems and in technical devices for photography in the dark.

Both components of infrared radiation are almost not scattered in the treated space; they seem to be focused on objects located in the zone of their influence. Heat penetrates into the body of the heated object, the depth of penetration depends on the properties, structure and material of the object. The depth varies from a tenth of a mm to several mm.

Infrared heaters are installed on the floor, attached to walls, or suspended from the ceiling. The devices are distinguished by flameless combustion, preservation of oxygen in the surrounding space, and do not raise columns of dust, unlike convectors

When used for industrial purposes, the wavelength from infrared emitters is selected based on the technical characteristics of the object or substance. IR rays pass freely through the air mass, so heating is carried out without noticeable losses. This circumstance is reasonably considered a significant advantage in production.

In addition to heating and illuminating the area treated by the device, infrared emitters are used to solve the following problems:

Where are they used?

Designers of construction projects today must take into account the presence of heating devices in the room for both additional and primary use. Such heaters cannot be used in domestic conditions - there is insufficient space, ventilation level and ceiling height. Infrared heaters are used in the following places:

- stock;

- shop;

- shop;

- hangar;

- trading platforms;

- medical institutions and others.

It should be installed so as to maximize coverage of the space to be heated. Also, you should not install such devices close to furniture, indoor plants, animal cages and other objects. There should be optimal free space around it.

How to make a gas infrared heater for a garage with your own hands

Not every user is ready to shell out their hard-earned money to purchase a small heater, which will greatly simplify the life of a car owner in his own garage during the cold season. Of course, after all, independent car maintenance, as well as its repair, require at least relative comfort.

In rare garages, heating was initially planned, which is why something has to be thought out later, closer to winter, as a rule.

Not every car enthusiast, as already mentioned, wants to spend money on an expensive device that will be used occasionally, and many car owners in our country are real “handicraftsmen”. Fortunately, in my own garage there are tools and some materials that are kept in it “just in case” - that is, they have hypothetical value.

So, there are handicraft “developments” for this case that allow you to solve this serious issue.

Before manufacturing such a device, you need to understand the principle of its operation, as well as become familiar with the production and assembly procedures.

The most necessary qualities of the device:

- Easy to activate.

- Sufficient power to quickly warm up the box.

- Simple design with minimal costs.

- Device security.

Whatever heating method is used in the garage, in most cases ventilation is necessary. This is necessary because with any heating either the amount of oxygen decreases or combustion products accumulate in the air, which is a risk to human health and life.

Preparation of materials and finished parts for the production of a garage heater comes down to what you need to prepare:

- You need to purchase (if not available) a burner with a valve.

- Sheet of tin.

- Scissors for cutting metal.

- Drill and set of drills.

- Rivets with a riveter.

- Fine mesh steel mesh to make a lattice. It can be replaced by an old mesh small-sized colander.

- Collet cylinders. Their convenience lies in the fact that the contents cannot be consumed all at once due to shut-off valves. As an option, it is not necessary to use cylinders for gas lighters, but a small country cylinder, for example.

Manufacturing itself:

- The heater must be fixed to the burner. To do this, you need to draw protruding ears on four sides, one of which will be twice as long as the other three.

- The blank is cut along the intended contour. Carefully cutting with metal scissors, excess material is put aside as unnecessary.

- The burner must be screwed to the workpiece using bolts.

- The ears are bent in the other direction and are used to secure the mesh.

- The strainer, already fixed, is initially made in the shape of a dome - this will allow the heat to be evenly distributed to the sides.

- To secure the second mesh, another sheet of tin is taken, and a circle of the same size with the same ears for attaching the mesh is cut out in it.

- Stepping back from the edge 5 mm. 10 holes are drilled in a circle - they will serve as a nozzle for the flame.

- A strip of length equal to the diameter of the already made tin blank is cut out of a piece of fine mesh.

- The ears are bent on all sides, using mesh strips to fix them, while the second workpiece is fixed on the opposite side.

- The round shaped ears of the blanks (already bent) are attached to the opposite ends of the strip by means of rivets using a rivet gun.

When already assembled, the structure is a kind of cylinder with walls made of mesh and ends made of tin.

The two mesh design is advantageous in that the heating surface is increased and has additional protection.

Now all that remains is to turn on this heater and test it in action. The heat will be enough to heat a garage or even a small room.

Infrared heaters - operating principle

Our natural luminary called the Sun does not warm the air at all, as it might seem at first glance - it warms up for completely different reasons. It delivers infrared radiation to the Earth's surface. This radiation, reaching the surface of the planet, landscape elements and artificial buildings, is absorbed by them and turns into heat. In principle, we can call infrared rays heat, although this is a little different.

We go further - objects located on the surface of the planet (including the surface of the earth with landscape elements) begin to give off heat. It is this heat that heats the air and the objects around us, buildings and much more. As altitude increases, the air cools, since it simply has nowhere to take heat from. Therefore, at the altitudes where planes fly, terrible cold reigns, reaching levels of -50-60 degrees and even lower.

Industrial heaters, which are based on sources of infrared radiation, work in a similar way. Here is their step-by-step operating principle:

IR heaters concentrate heat in the floor area, which allows people to be in the most comfortable environment.

- Infrared emitters are connected to the electrical network and begin to generate IR radiation (or generate it due to the combustion of natural or liquefied gas), and in very large quantities - you need to remember about the volume of production premises;

- IR rays penetrate surrounding objects (ceilings, walls, floors, machines, furniture, etc.), as a result of which they begin to give off heat. In other words, they become noticeably warm;

- Heat is transferred from heated objects into the air - as a result, the industrial premises become warm and comfortable.

Criteria for selecting contractors for the development of a heating system for industrial premises

The right choice of a contracting organization that can quickly and efficiently cope with such a difficult task as organizing optimal heating of production is 99% of success.

One of the fundamental criteria is formal – the Contractor’s membership in a specialized SRO (self-regulatory organization).

Such non-profit partnerships were created within the framework of legislation in 2009. Previously, the obligatory basis for carrying out work was the presence of an appropriate Rostechnadzor License.

Now such a criterion is membership in one of the SROs

If the Contractor is included in it, it means that he has the appropriate legislative framework, human, material resources and production base necessary to carry out contract work even on such a scale as heating factories professionally and on time. Often this factor is not given attention, and yet an organization that is not a member of the SRO does not have the right to take on such contracts

The second criterion can be called the company’s experience, both in the engineering market in general and in the segment under consideration in particular. Even the presence of all permits and qualified specialists does not guarantee high quality results.

As we have already written, this topic has many specific nuances. Inexperienced companies may simply not know about them or imagine them by hearsay, and have a superficial knowledge of the topic.

Everyone gets into trouble at some point... But you want them to be “hit” not on you, right?

Another important parameter is the number and structure of the company, as well as the qualifications of its employees. If the company is a member of the SRO, it meets the minimum requirements

But when we are talking about such an important and large-scale project as industrial heating, the minimum acceptable level is, as a rule, not enough. Therefore, it is advisable to familiarize yourself with the potential capabilities of the future Contractor in advance.

The next significant criterion is the presence of a clearly structured system for performing work and a model for managing it. Its influence on the result, it would seem, is less obvious than the parameters indicated above, but, nevertheless, many cases are known when experienced companies with competent technical workers, who approached the task quite conscientiously, “failed” the Object.

The main reason is the lack of a systematic approach to performing this work, insufficiently effective management of business processes, and the lack of a quality control system.

Finally, the level of business and personal contacts of the company with suppliers and subject knowledge of the equipment used are also important. It is no secret that, for example, heating factories is a very resource-intensive and expensive project, so the success of the result depends on how high-quality and appropriate the equipment is selected and supplied, how quickly it is delivered and installed. Overlays in this process are fraught with high costs.

In addition, the possibility of further service also plays an important role, which also depends on the level of the contractor’s relationship with suppliers and manufacturers of heating equipment.

The price level for equipment from a company with established business connections will always be lower than that of a newcomer to this business. This is due to the size of the discounts provided by manufacturers and distributors. Accordingly, a company with large discounts can offer better conditions to its Customers.

We, as a member of a specialized SRO, have been working in this area since 1999. Our structure has a powerful engineering staff, a qualified design department, as well as experienced installation teams. The staff of specialists is divided into those who work in the industrial segment and those who deal with the domestic segment - heating country houses.

Each Object is assigned an experienced manager-coordinator. The work is carried out through multi-stage control at all stages.

Our established direct contacts with manufacturers of equipment and materials allow us to complete Objects quickly and at attractive prices.

Are you looking for a reliable Contractor for heating industrial premises and workshops? We guarantee that our cooperation will be pleasant, free of headaches, and mutually beneficial!

Table - Comparative characteristics of parameters and costs of models

| KSK 3-8 Water heater Weight – 65 kilograms Capacity – 4000 cubic meters per hour 8200 rubles | TV 6 K Alvin Electric Weight – 8 kilograms Productivity – 300 cubic meters per hour 5700 rubles | Master B2 Era Electric Power – 2 kilowatts Power – 220 volts 3000 rubles |

| VIN-AR-3.0 Electric, infrared, on the ceiling Power – 3 kilowatts Weight – 4 kilograms 6830 rubles |

|

|

| OVE-4/380 Electric heater Weight – up to 20 kilograms Power – 1.8 kilowatts 3200 rubles |

| TPK 15 Heat fan Weight – 20.5 kilograms Power – up to 15 kilowatts 9970 rubles |

| Sunrain Electric, infrared, on the ceiling Weight - up to 10.5 kilograms Power - up to 3 kilowatts 3990 rubles | TV 9 K Alvin Electric heater Weight – 13 kilograms Power – 3+6 kilowatts 6600 rubles |

| TV 12 K Alvin Electric heater Weight – 14 kilograms Power – 9+3 kilowatts 7900 rubles |

|

|

| Frico EZ 336 Electric, infrared, three-panel ceiling Weight - 19.8 kilograms Power - 3.6 kilowatts 48,600 rubles | Master B22 Era Electric Power – 3 kilowatts Power – 220 volts 15,900 rubles | VIN-AR-4.0 Electric, infrared, on the ceiling Power - 4 kilowatts 7190 rubles |

| VIN-T-1.5 Electric, infrared, on the ceiling Power - 1.5 kilowatts 2500 rubles | VIN-T-6.0 Electric, infrared, on the ceiling Power - 6 kilowatts 7200 rubles | Ballu VNS-36W Thermal curtain Weight – 65 kilograms Power – 34.7 kilowatts 33,000 rubles |

What type of heating to choose for large industrial premises

Previously, we talked in more detail about what type of heating is best suited for large industrial premises, cited SNiP standards and did a comparative analysis, we advise you to read this information

Water heating of the workshop

The use of traditional water heating is relevant for small industries whose workshop area does not exceed 250 m². It is necessary to constantly maintain the air temperature at the optimal level throughout the entire volume of the room. Woodworking shops are often heated using water.

This is due to wood waste from production. For their disposal, a long-burning solid fuel boiler is installed. This scheme of work allows you to not only quickly but also effectively get rid of wood waste. They are subsequently used as fuel.

However, this heating organization scheme has a number of nuances:

- In order for the heating efficiency of the production workshop to be maximum, the area of the heating devices must be significantly increased. For this purpose, large diameter pipes are used, which are welded together into registers;

- Inertia. It takes quite a long time to heat the air in the workshop from the coolant;

- The inability to quickly change the water temperature in the pipes.

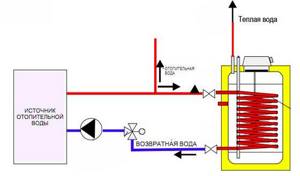

However, along with this, when installing water heating in a welding shop, a heated floor system can be used. This scheme will help reduce the required area of heating devices. At the same time, the inertia of the system will decrease - the air in the workshop will heat up faster. During heating design, it is possible to provide for the organization of hot water supply, which is important for many production processes. To do this, you need to purchase (or make) a heat exchange tank to heat the workshop with your own hands.

Indirect water heating tank

In it, the coolant energy will be transferred through the coil to the water. This will make it possible to use hot water not only for domestic needs, but also for production processes.

In addition to solid fuel boilers, you can install other types of heating equipment:

- Gas boilers . Economically effective if there is no cheap solid fuel;

- Electric heaters . It is preferable not to use them, since energy costs will be high;

- Boilers running on liquid fuel - diesel or waste machine oil. Installed if there are no gas lines. They are economical, but inconvenient because they require special containers for storing fuel.

To use water heating circuits for a workshop, you need to correctly calculate the power of the heating installation.

The standard ratio of 1 kW of released thermal energy per 10 m² of area is only relevant for a workshop whose ceiling height does not exceed 3 meters. If they are higher, then each additional meter is +10% to the boiler power.

How the heating system is built

The heating system should be made from infrared heaters in such a way as to take into account the parameters of the devices themselves. It is necessary to think over a whole network of such devices. For example, in what quantity should they be used for a particular room, at what height from the floor should they be mounted, at what distance from each other should they be placed, and what should they be powered with. Gas installations serve well both with bottled and main fuel supply. It’s easier with electrics - heat emitters are connected to the electrical network with a preliminary calculation of the load on it.

During work, people who are indoors under the influence of thermal infrared heating can receive heat not only from directly operating devices, but also from heated objects. The temperature of reflected radiation from heated surfaces will be felt by a person to be 1-2 degrees higher than from the heater itself . This suggests that for workers to feel comfortable, it is possible to reduce the power of the main heating device to +15 degrees.

Advantages and disadvantages

Industrial air heaters are the best option for supplying heat to large rooms. They heat them evenly and are not a hindrance, because... They are most often located under the ceiling or on special stands.

Infrared radiation is distributed over fairly large distances, so it easily reaches surrounding objects. Such devices have a large number of advantages, which we note:

- first of all, they work absolutely silently;

- high heating efficiency - heating of industrial premises allows you to deliver heat directly to consumers;

- another important advantage is the high speed of operation, the room warms up in the shortest possible time;

- the devices are adapted to work in rooms with large ceilings - industrial IR heaters heat the room from top to bottom;

- do not require maintenance;

- characterized by efficiency, using such equipment you will save approximately 15% on costs

- for heating and energy;

- thermal energy is distributed evenly.

Despite the large number of advantages, there are also a number of disadvantages:

- If the heater is placed incorrectly, people in the room may experience discomfort and headaches. Therefore, it is very important to strictly observe the height of the device;

- Electric models consume a lot of electricity. Therefore, if you are not ready for such waste, you can always purchase a unit that runs on gas;

- If you accidentally touch a heated heater, you can get burned. In this regard, it is important to be very careful.

You can read more about gas IR heaters here.

Electrical infrared heating systems

There is also a type of heaters that operate not on gas, but on electricity. They are suitable for heating a large area of a room, as well as for local use. There are several types of such devices and each of them has its own special approach and individual design characteristics.

Types of electrical IR systems

To begin with, let's say that they can be classified according to the following characteristics:

- Type of fixation. There is the possibility of installation on the ceiling, walls, and there are also universal models. There are also options for installing a stationary or mobile installation. Such heater options are very popular among work teams.

- By type of work. There are different purposes for industrial infrared heaters, one of them is wood drying. For this purpose, systems with short radiation waves are specially purchased. But the downside is that these waves are quite dangerous for humans. For this reason, if the device is turned on in the room, work should not be done near it! But emitters with long waves, on the contrary, are useful for humans. Therefore, they are often purchased for construction sites. They are often used as the main source of heating.

Pros and cons of electric emitters

Quite a large number of buyers want to purchase this particular option for a number of the following reasons, or rather advantages:

- Perfect for working in dusty places. In general, they easily tolerate any location with difficult conditions.

- They are used as the main source of heating, as well as an additional one. It happens that they heat part of the desired area.

- There is an option to heat it pointwise, very locally. Usually used to heat the material before work.

- It can often be found in circulation in medical schools.

The only downside is that it consumes a large amount of electricity, which means it is a rather expensive device.

Industrial heating

Industrial heating is a system of measures aimed at creating favorable conditions for production activities. The main task of industrial heating is to maintain a comfortable temperature in the workplace, which, as a rule, helps to increase labor productivity. Maintaining an optimal temperature is also necessary to protect equipment from sudden changes in heat, which can lead to failure of machines and equipment, which leads to unnecessary financial costs for their repair or replacement. The management, which has set the task of organizing industrial heating, faces complex issues that need to be resolved in the most optimal way. The problem immediately arises of how to achieve this goal while spending a minimum amount of money. First of all, the entrepreneur must take into account the climatic features of the area where industrial heating is required. For the regions of Moscow or St. Petersburg, these will be the same conditions with the typical climate for this area; for Tyumen or Yakutia, completely different conditions due to severe frosts and winds in winter. All these features are taken into account in the questionnaire for calculating heat losses of production presented on the website.

Heating systems production

Industrial heating systems are technical means that make it possible to create acceptable climatic conditions in workplaces for production activities. The most common heating systems today are infrared, air and water. The last two belong to central systems that provide heat from heating plants. With an air-based industrial heating system in a workshop area, air ducts are installed through which warm air is supplied from a heat generator located outside the production facility. The efficiency factor (COP) of this heating method reaches about 50%. Water, unlike air, has its advantages and disadvantages. Since the heat capacity of water is much higher than the heat capacity of air, its consumption for heating the same room will be much less, and therefore the coolant delivery system is much less than that of air. At the same time, the water heating system has great inertia due to the fact that heating water takes much longer than air. This significantly increases the time required to heat production premises to the required temperature. The main disadvantage of these industrial heating systems for enterprises is the presence of a significant amount of additional equipment (heat generators), bulky supply systems that ensure the delivery of heat to the heated object, large heat losses along the route, and low efficiency.

Infrared heating systems do not have all the disadvantages inherent in the above methods. There is an opportunity to significantly free up the workspace from unnecessary bulky heat management of production areas that take up a lot of space and to deploy on it the production of additional products manufactured by the enterprise. At the same time, the efficiency of this heating system is about 70 - 90%, depending on the method of using infrared heating, which also provides serious savings in money and ultimately allows you to reduce the cost of the final product. The absence of expensive supply systems and heat losses along the route also reduces operating costs for industrial heating, which in turn makes it possible to additionally provide heat to new jobs. The customer, as a rule, chooses which industrial heating system to use at a given enterprise. But at the same time, it is necessary to take into account all the features inherent in one or another method of coolant delivery and its efficiency, depending on the current conditions and prices on the market.