Air conditioner refill methods

It is recommended to refill air conditioners with freon at least once every 1.5-2 years. During this time, a natural leakage of a significant part of the refrigerant occurs, which must be replenished. Operating coolers without refilling for 2 years or more can lead to failure of the device due to overheating and wear of parts, as well as oil leakage.

Refueling of air conditioning devices is carried out by specialized services. However, if you have the necessary tools, you can carry out this procedure yourself.

A beginner can do this procedure in two ways:

- By pressure. To find out the amount of freon, you need to look at the air conditioner instructions - the pressure level in the system will be indicated there. Then you need to attach a manifold to the device - it will show the real pressure level in the cooler. By subtracting the resulting value from the parameters specified in the documents, it is easy to find out the required amount of substance for refueling.

- By weight. When the air conditioner is fully charged, you can find out the required volume by weight. To do this, you also need to refer to the documentation. When filling the device with freon, the cylinder with refrigerant for the air conditioner is placed on an accurate scale. During the pumping process, you need to carefully monitor the weight of the cylinder and, when replenishing the lack of substance, immediately turn off the system.

Refilling the air conditioner: algorithm of actions

Before filling the air conditioning system with freon, you need to select the necessary tools and materials. To do this, you will need a pressure gauge, a cylinder with freon, a vacuum pump, as well as scales, which will be used to determine the volume of refrigerant in the air conditioner.

Algorithm of actions when refilling the air conditioner:

First you need to disconnect the cooler from electricity and determine the amount of freon required for refilling by weight or pressure in the system. You also need to “purge” the tubes with nitrogen to remove excess impurities from the system and make sure the system is tight

This is important to do if there is a suspected refrigerant leak due to system damage. Then you need to close the three-way valve clockwise. To determine the pressure level and refuel, you need to attach a pressure manifold to the fitting. After this, the three-way valve opens again, a refrigerant cylinder is connected to the manifold and pumped into the system.

Refrigerant Comparison Chart

Previously, ammonia was used as a refrigerant in the production of refrigeration units. However, this substance has a detrimental effect on the environment and destroys the ozone layer, and in large quantities can create health problems for people. Therefore, scientists and manufacturers began to develop other types of coolants.

Modern types of refrigerants are safe for the environment and people. They are different types of freons. Freon is a substance that contains fluorine and saturated hydrocarbons, which is responsible for heat transfer. Today there are more than forty types of such substances.

Freons are actively used in household and industrial appliances that cool air and liquids:

- As a refrigerant in a refrigerator.

- For cooling the freezer compartment.

- As refrigerants for cooler bags.

- To cool the air in an air conditioner.

The properties table allows you to select the optimal type of refrigerant. It reflects the basic properties of freons: boiling point, heat of vaporization, density.

When refilling the air conditioner, you may also need comparative tables of freons. They identify substances that can replace a particular refrigerant if it cannot be found on sale. Below is a simplified version of such a table with the most common types of coolers.

CFCs - chlorofluorocarbons, HCFCs - hydrochlorofluorocarbons, HFCs - hydrofluorocarbons

Preparing for refueling

You need to start preparing to refill the air conditioner by cleaning it. This will allow you to achieve optimal performance of all system components and, accordingly, eliminate measurement errors associated with deviations of operating modes from optimal ones.

The filters of the indoor unit of the split system and its outdoor unit need cleaning.

The latter is serviced in the following sequence:

It is advisable to carry out mechanical cleaning

- De-energize the equipment.

- Carry out mechanical cleaning:

- remove dirt and dust from the outside of the casing;

- dismantle it;

- remove accumulated debris from inside the housing.

- Perform flushing. For this:

- cover the electronic unit with polyethylene to prevent water from entering;

- Use a damp sponge to remove dust and dirt from the fan blades and structural elements;

- clean the capacitor in the same way;

- Use a hand-held vacuum cleaner to remove dust in hard-to-reach places.

- Clean the radiator. To do this, use special brushes, rinse the cells with water under pressure or use a steam cleaner.

- Install the casing and leave until the moisture dries completely.

To avoid damaging the electronic unit, the user should not clean it themselves. This work should only be carried out by specialists with the appropriate level of qualification!

The next stage of preparation is to check the system for leaks. If the refrigerant leak rate exceeds the permissible rate (the same 8% during the season), most likely there are problems with the sealing of the connections. You can find the location of a serious leak by visually inspecting the lines and connections.

If it was not possible to find the problem area by simple inspection, other methods will help using:

Ultraviolet dye

Soap solution . Works well if the suspected location of the leak is known.

- Halogen finder . Uses the effect of changing the color of the flame when interacting with chlorine vapor. Can only be used on equipment with chlorine-containing freons.

- Water . Requires preliminary injection of nitrogen into the circuit and immersion of system parts in water, which is not always convenient.

- Ultraviolet dye . A UV dye is added to the gas pumped into the system, which indicates the location of the leak. Finding it is easy with ultraviolet illumination.

Expert opinion

Starostin Konstantin Adreevich

Air conditioner installation and maintenance specialist

If there is a suspicion of a leak due to leaks in connections or system components, the refrigerant should be removed from the system, filled with nitrogen, searched for problem areas, troubleshooted, and pressure tested and evacuated the system.

Pressure testing of the system involves pumping the circuit with nitrogen through a pressure gauge manifold. Injection is carried out according to the permissible pressure in the circuit (indicated in the technical documentation and on the device nameplate).

Once the pressure is reached, the nitrogen supply to the system is stopped. In a sealed system, the pressure will remain constant; if leaks persist, nitrogen will continue to be released. In this case, the procedure for searching for problem areas and crimping should be repeated.

Vacuuming

After the tightness has been restored (the system has been pressurized), vacuuming is performed:

- A vacuum pump is connected to the pressure manifold.

- Start the pump and open the gas valve.

- I control the pressure in the system using the pressure gauge.

- When the minimum is reached, the pump is turned off.

- Close the gas valve.

During operation, a vacuum pump with a check valve is used, which will prevent oil from entering the freon circulation circuit. After pressure testing and evacuation, the collector is not turned off to prevent air from entering the system.

Air conditioner not cooling? How to refuel? Freon pressure table

To operate any air conditioner, a refrigerant is required, also called freon. Freon is fluorine and chlorine-containing derivatives of hydrocarbon compounds that are used as refrigerants in modern refrigeration units. Today, there are more than 40 types of stable compounds with various individual properties. In household air conditioners, two types of refrigerant are most often used: freon R22 and freon R410a. The letter R stands for Refrigerant - cooler, refrigerant. It is possible to buy refrigerant yourself and refill it, but only if you have specialized expensive tools, so it will be much cheaper and better to invite a specialist! You can see the refrigerant pressure in the system using a pressure gauge station.

During system operation there is no cooling, the blue (low pressure) pressure gauge measures the pressure at the inlet of the main circuit to the external unit - the refrigerant suction side (in front of the condensing unit), the red (high pressure) pressure gauge measures the pressure at the outlet of the main circuit from the external unit - discharge side (after the compressor-condensing unit).

The maximum low and high pressure values for each type of system, for any type of refrigerant, are usually indicated on the housing in the manufacturer's plate:

Discharge side - the discharge side, that is, high pressure, the refrigerant (freon) is in a liquid state, after the compression process by the compressor in the outdoor unit;

Suction side - suction side, that is, low pressure, the refrigerant (freon) is in a gaseous state after the evaporation process in the indoor unit of the air conditioner.

In domestic air conditioners operating in cooling mode during the warm season, it is necessary to measure the low pressure on the suction side of the refrigerant, that is, using a blue pressure gauge. The pressure gauge station is connected using a specialized hose to the service valve, which is located at the point where the thick (gas) tube is connected to the external unit. You need to let the system run (with the compressor on) in cooling mode for 10 - 15 minutes, and then look at the pressure gauge readings. Be sure to carry out the measurement only while the compressor is running.

But in order to refuel, you need to know what pressure should be in this air conditioner. For this, a table of freon pressure is used. Below you will find tables with pressure parameters for different types of freons and the most common air conditioner capacities. For high-quality pressure measurements and making a correct assessment, I recommend measuring the air temperature indoors and outdoors. You should also take into account that the data presented in these tables may differ slightly from what is measured in your specific conditions.

Installation of equipment on R410a

When installing equipment on R410A, you must adhere to the following basic recommendations (similar to R407C):

- prevent contamination from entering the hydraulic circuit;

- when soldering pipelines, they must be filled with an inert or weakly interacting gas, for example, nitrogen with a low moisture content;

- perform evacuation especially carefully;

- Refill refrigerant only in the liquid phase.

Here are some recommendations for performing evacuation aimed at completely removing air and moisture from the circuit. In order to transfer water from liquid to gaseous state without heating, you will need to reduce the pressure in the circuit. The lower the temperature of the circuit (outside air), the lower the pressure at which water evaporation will begin.

Evaporation pressure of water at different air temperatures:

| Temperature, °C | Pressure, Mbar |

| 15 | 9 |

| 10 | 12 |

| 15 | 17 |

| 20 | 23 |

| 25 | 42 |

Therefore, during evacuation, the residual pressure in the circuit must be such that the evaporation temperature for this pressure is lower than the outside air temperature

Particular attention should be paid to the choice of tool. The vacuum pump can be either one- or two-stage, but its productivity must be at least 4–8 m3/h for systems with a cooling capacity of up to 11 kW and 8–15 m3/h for more powerful systems

The advantage of two-stage pumps is that they can achieve lower residual pressures. To prevent mineral oil from entering the refrigeration circuit from the pump, it must be equipped with a special valve. The manifold must be designed for R410A, i.e. have a pressure/temperature scale corresponding to this refrigerant, as well as increased diameters of ports for connecting flexible hoses (due to significant differences in the thermodynamic characteristics of R410A and R22, R407C).

It is very important that measuring the vacuum depth using a low pressure gauge (up to 17 bar) on the manifold is unacceptable, since it does not provide sufficient accuracy. A special pressure gauge is required to measure vacuum; only with its help can you correctly measure the residual pressure and ensure that there is no moisture in the circuit

In general, if you follow these simple recommendations and work with a professional tool, using it for its intended purpose, then installing and servicing equipment on R410A will not cause difficulties, and users will be able to appreciate the reliability and high energy efficiency of new air conditioning systems.

Do-it-yourself pressure level diagnostics

What should be the pressure in a car air conditioner and how to check this parameter? The diagnostic procedure involves the use of a pressure gauge station with all the necessary pipes and hoses. To connect to the air conditioning system, you will also need to additionally purchase adapters, which can be one of two types - for pushing or for firmware. The first option, judging by the reviews of experts, is more relevant, since such adapters are characterized by higher reliability and quality.

Before purchasing the correct adapter, it is important to understand exactly what fluid is used in the system. For example, in cars that were manufactured before 1992, R-12 freon is used in most cases

If we are talking about cars manufactured between 1992 and 1994, then such cars can use R-12 or R-134 standard fluids. This period is considered controversial because car manufacturers could not unanimously decide which standard was best to use. Cars that were produced after 1994 use a working fluid of the R-134 type (the author of the video is the Avtomatika channel - car air conditioners from A to Z).

To find out exactly what kind of freon is used in your car, we recommend that you read the service manual or the table, which is usually located on the back of the hood. Once all the tools and instruments necessary to complete the task are ready, diagnostics can begin. Opening the hood, you can see the lines of the air conditioning system; they are usually located to the left of the power unit. As a rule, these are two pipes - high and low pressure; to perform the test you will only need the latter.

Reduced pressure hoses are larger in diameter:

- First, you need to unscrew the plug on the line and instead install an adapter with a connected hose from the pressure gauge station. Before installation, clean the area around the plug to prevent possible contamination from entering the lines.

- Then, on the pressure gauge installation, you will need to unscrew one tap, but you do not need to touch the second. If you accidentally open it, it will cause freon to leak.

- After this, you need to start the car engine - diagnostics can only be performed when the unit is running. The best option is for the pressure in the car air conditioner to correspond to a value of 250-290 kPa.

If the resulting parameter is less than the specified range, this indicates the need to refuel the unit. If the pressure value is more than 290 kPa, then there is no longer a need to refuel the system, since this may cause a malfunction of the compressor device. This unit is not designed to work under high pressure conditions, so due to the increased pressure it may simply jam (video author - vassilij pavliuk).

Questions and answers

When charging by superheat, is the refrigerant pumped in a continuous flow or in portions?

It is recommended to do this in small portions, waiting for the readings on the instruments to be established. This increases the accuracy of calculations.

After refueling and turning on the air conditioner, the taps freeze. What is the reason?

Freezing of taps most often indicates an insufficient amount of freon in the system. Refueling must be done. If the situation does not change, you need to look for the location of the refrigerant leak.

How much refrigerant is in an air conditioner?

The amount of freon depends on the model of the air conditioner (primarily its power) and the length of the routes. So, a device with a power of about 7 kW with a minimum length of lines contains 750-800 g of freon. In powerful systems this figure can exceed 1.5 kg.

I want to top up the air conditioner by weight. How to find out how much freon is left in the system?

Calculating the mass of refrigerant remaining in the system is a very difficult task; even most service centers cannot solve it. You should choose a different refueling method or release all the freon and perform a full refueling.

Why do experts advise pumping in less freon than is necessary according to calculations and characteristics?

An insufficient amount of refrigerant will only affect the performance of the unit - it will increase temperature more slowly or not reach the limit values. Excess freon leads to equipment failure.

You can charge or top up your home air conditioner with freon yourself. The operation is not so complicated, but requires the use of special tools and some skills. In addition, if a serious error occurs, the equipment may be completely damaged. Accordingly, it is better not to chase savings of 2-3 thousand rubles, but to entrust the work to the service center specialists.

Signs of a freon leak

Freon refrigerant in air conditioners is susceptible to leakage during operation. Over the course of a year of use, the amount of freon decreases by 4–7% naturally. However, if the air conditioner malfunctions or the indoor unit is damaged, a leak may occur in a new device.

It is important to determine it at the initial stage and refill the device with refrigerant in time

The main signs of a freon leak:

- Poor room cooling.

- The appearance of frost on the parts of the indoor and outdoor units.

- Oil leaks under taps.

- Increased noise and vibration of the device during operation.

- An unpleasant odor appears when the air conditioner is operating.

If the leak occurs as a result of prolonged use, the air conditioner can be restored to function by refilling it with refrigerant. If parts and freon tubes through which the cycle moves are damaged, not only refueling will be required, but also the intervention of cooler repair specialists.

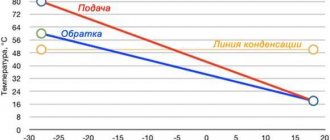

Relationship between working pressure and temperature conditions

Car air conditioner malfunctions. 7 main car air conditioning problems

Thus, if external temperature conditions are slightly increased, then the operating pressure will increase proportionally. So, for example, if we consider refrigerant 410, then in this case, under conditions of an increase in the temperature within the room or outside it by five degrees, the operating pressure of freon in the air conditioning system will also increase. The value will be increased by 0.5 bar. Another dependence is observed for such a type of freon as R22, but here it differs depending on the street temperature, or this indicator within the room. In order to obtain updated figures, you should refer to specialized tables, everything should be indicated there.

What is the pressure in the air conditioner?

The pressure may depend on the ambient temperature, the type of freon and the operating mode.

At a temperature of 24 degrees in R410A freezing and cold operation:

- suction operating pressure approx. 8 bar.

- operating discharge pressure is approximately 20-25 bar or more.

- non-operating pressure approximately 15 bar.

“Working suction pressure” is the pressure shown by the pressure gauge station on the suction side (gas pipe) when the air conditioning compressor is turned on.

“Operating discharge pressure” is the pressure shown by the pressure gauge station on the liquid pipe when the air conditioning compressor is turned on.

“Non-operating pressure” is the pressure shown by the pressure gauge station on the suction side (gas pipe) when the air conditioning compressor is turned off.

The operating suction pressure and the operating discharge pressure for some models are indicated on the air conditioner nameplate.

1 4 · Good answer

Will the air conditioner fail if it operates in a room with the windows wide open?

This is a fairly common misconception. One of the conditions for trouble-free operation of the air conditioner is compliance with the temperature conditions specified in the documentation

It is important to note that it is indicated for both the external unit (outdoor temperature) and the indoor unit (indoor temperature). And it can be different for different operating modes of the air conditioner: heating, cooling, air drying, cleaning, etc.

Thus, when operating in the temperature conditions provided by the manufacturer, open windows do not threaten your air conditioner, but are avoided only for economic reasons. However, personally, I would advise opening the windows sometimes, since contrary to another misconception, the air conditioner does not take air from the street and does not replace the necessary ventilation of the premises.

The heat mode on the air conditioner does not turn on. What reasons?

Try removing and reinserting the batteries in the air conditioner remote control. Some manufacturers specifically make sure that the Heat program does not interfere with the summer. When reinstalling, it’s as if another split operating program is launched.

2 8 · Good answer

Is it possible to pump freon into the refrigerator instead of r12? r600a without changing the compressor?

Even if you are a good specialist, it is better not to do this. There is a widespread belief that any freon is extremely dangerous to health, especially those of the old generation. In your case - R12. But it is worth considering that in the volumes available in household refrigerators, a refrigerant leak cannot cause harm to health or lead to an explosion or fire hazard.

So why not? Gas is not a liquid. And you won’t be able to deal with it just like that without special skill. Of course, for such manipulations it is worth calling a specialist. In addition, it is also not so easy to get R600a for free sale. And you need to be sure that it is really him and of good quality. Do you have a place and equipment where you can check this?

Source

Freon pressure table

Freon R410a pressure parameters on the suction side

Freon R22 pressure parameters on the suction side

Indoor temperature readings are for dry/wet bulb

But remember that high-quality diagnostics can only be carried out by a specialist who can not only connect a pressure gauge station to the required valve, but also has a good understanding of the structure and specifics of the refrigeration cycle. Many people, without possessing these skills and knowledge, as well as additional tools, such as a clamp tester, draw conclusions about the lack of freon only by the pressure in the system. Very often (especially in cold weather) this leads to the appearance of excess pressure and, subsequently, the death of the compressor.

All household split systems are supplied with refrigerant already pumped into them. If it suddenly turns out that there is a leak, then before refueling, you must find the cause of the leak, eliminate it, and only then refuel. Otherwise, the work will be done in vain and everything will happen again.

Freon R22 - consists of one component, therefore it is easier to use for refilling air conditioners in case of leakage. It can be pumped into the system without the use of electronic scales, using only a pressure gauge station and an electronic thermometer. Since freon R22 is recognized as harmful to the environment and the ozone layer, its use is gradually being phased out. In the European Union countries, this type of refrigerant has been banned since 2010. At the moment, household air conditioners are supplied to the Russian Federation only using the safer and more modern R410A freon, and in the near future equipment will begin to be supplied using the new R32 freon.

Attention: systems operating on R410 freon can be refueled only in very rare cases, and only a competent specialist can determine this. Mostly, refilling with R410a freon occurs when the length of the freon line is increased during installation, and is done by adding refrigerant strictly by weight for each meter of line that exceeds the standard, the weight is indicated in the installation instructions for the system

In cases of R410a freon leakage, air conditioners should be refilled by weight, having first removed all old freon from the system. This is due to the fact that R410a consists of two components, and in the event of a leak, one component, having a higher density, squeezes out the other, disturbing the proportion of the components, as a result of which the refrigerant loses its thermodynamic properties.

Refilling process with freon R410a.

If the “air conditioner” simply “threw” a pressure gauge unit onto the service valve and started filling the air conditioner with R410a freon without electronic scales, you should know that the result will be a call to another technician, and possibly a failure of the system.

Refilling the air conditioner is a very responsible procedure that can only be entrusted to a qualified specialist!

If you want to carry out professional diagnostics and refueling of your air conditioner, I recommend contacting our partner, who kindly provides a 15% discount on all work and materials to any buyer of our store*

*Affiliate discount is provided based on the purchase invoice

freon pressure table r22; freon pressure table r410; freon pressure table R407; freon pressure table R32

Source

Conclusions:

Having compared all the information provided, weighing the pros and cons, we can give the following recommendations:

— If the equipment is designed for 22 freon, you should use it as long as it is possible to purchase it at a reasonable price, and there is no final ban on its use.

— When purchasing new refrigeration units, designing refrigeration production or storage, it is necessary to make a thorough technical and economic calculation. Take into account the required modes and cooling capacity, the cost of equipment and its operation. Also take into account the proximity of 2021 with a complete ban on chlorine-containing refrigerants.

And only after a complete analysis of all factors can we draw a conclusion about the use of equipment designed for a particular freon.

Related Posts

- Do-it-yourself air conditioner dismantling

- Caspian (road)

- Why does the air conditioner gurgle when not working when there is wind?

- How to treat pressure drops in a heating system; norms for operating deviations

- Air-to-air heat pump and its prices

- How to set up a water pressure sensor in a water supply system

- At what temperature of the coolant is the heating system turned off and turned on in an apartment building according to GOST

- Recharging the air conditioner in a car

- Hydraulic accumulator selection and principle of operation

- How to properly connect and use a winter air conditioner kit

- How to check the compressor of a split system air conditioner: diagnostic nuances + tips in case of breakdown

- Disadvantages of polypropylene pipes in home heating

- Water pressure in the apartment's water supply

- Copper pipes and their use in air conditioners

- Homemade Russian stove on the street under a canopy

- Aermec nrb

- Choosing dowels for drywall

- How to choose the right pumping station for a private home

- Online calculation of the capacity of round and rectangular profile pipes

- What to do if cold air enters the room from the air conditioner in winter

- Installing an air conditioner yourself

- Technologies, secrets, recipes

- Freon r134a

- LPG gas reducer

- Pumping station for increasing water pressure: features of selection and installation in an apartment and house

Read with this

- Do-it-yourself air conditioner dismantling

- Caspian (road)

- Why does the air conditioner gurgle when not working when there is wind?

- How to treat pressure drops in a heating system; norms for operating deviations

- Air-to-air heat pump and its prices

- How to set up a water pressure sensor in a water supply system

- At what temperature of the coolant is the heating system turned off and turned on in an apartment building according to GOST

- Recharging the air conditioner in a car

- Hydraulic accumulator selection and principle of operation

- How to properly connect and use a winter air conditioner kit

Advantages and disadvantages of freon R 410a

- The high level of specific cooling capacity does not require the installation of a powerful compressor.

- In the event of a leak, the gas quantity is easily replenished without loss of refrigerant quality.

- Ample opportunities arise in terms of reducing equipment energy consumption.

- Cooling performance is 50% higher than R22 and 407c systems.

- Good thermal conductivity and low viscosity have a positive effect on the efficiency of the system. Heat is transferred faster and with less cost to move.

- High operating pressure in the system, which negatively affects the compressor, leads to rapid wear of the bearings.

- The pressure difference between the suction and discharge sides of the refrigerant reduces the compressor efficiency.

- The requirements for circuit tightness are increasing. The wall thickness of the main copper pipes must be greater than for R22. Minimum value 0.8 mm. A significant amount of copper increases the cost of the system.

- The refrigerant is not compatible with HVAC components made from elastomers sensitive to diphthomethane and pentafluoroethane.

- Polyester oil used in conditioner is more expensive than mineral oil.

Differences between R22 and R410a

Compared to freon r22, refrigerant r410a has a number of advantages and disadvantages. They are due to its technical characteristics, physical properties and complexity of production.

Freon r22:

- Has low cost;

- Should be phased out by countries that have ratified the Montreal Protocol by 2021;

- It is single-component; in case of a leak, refilling is possible regardless of the amount of refrigerant lost;

- It is not difficult to produce, thanks to which there are many manufacturers around the world.

Freon r410a:

- More expensive than R-22 refrigerant;

- Non-toxic, fireproof;

- Two-component, if a large amount leaks from the system, it must be cleaned of residues and refilled;

- Does not destroy the ozone layer;

- Has higher operating pressures, equipment must be more durable. It is expensive, but reliable.

It is worth mentioning separately about the effect on the wig effect. The global warming potential of r410a refrigerant is 32.3% greater than that of r22. But if all equipment switches completely to it, an interesting effect will result.

Since the cooling performance of r410a freon is better, less of it is needed. It was calculated that when the system was transferred from 22nd refrigerant to 410th, its impact on the greenhouse effect decreased by an average of 11-13%. From an environmental point of view, R22 loses.

In terms of energy efficiency, 410a refrigerant is better than 22a. A study published in the International Journal of Engineering Research & Technology showed that the difference is about 5-10% (see figure).

Results of a study on the energy efficiency of refrigerants r410a, r22 and r404a

Region I - supply of liquid freon.

Region I conventionally lies 2 bars above the freon condensation line. It is precisely these suction conditions that high-pressure pump manufacturers often require.

Both liquid pumps and booster compressors and Haskel pump compressors can operate in this area.

The operation of liquid pumps is most efficient, since freon does not undergo phase transitions during pumping, but is strictly in the liquid phase - otherwise the pump will not pump.

Booster compressors and pump-compressors strive to transfer the liquid into the gas phase during the suction cycle, and transfer it back to the liquid phase during the discharge cycle. As a result, compressors supply multiphase media, which significantly reduces efficiency.

Features of application

- centrifugal compressors;

- flooded evaporators;

- pump refrigeration units.

The new freon has found application in air conditioning systems and household heat pump units. The azeotropic mixture is suitable for equipment with direct expansion and flooded heat exchangers. Due to its high density, refrigerant is used in domestic and industrial installations:

- transport cooling systems;

- air conditioning installations in offices, public buildings, industrial facilities;

- household refrigerators;

- commercial and food refrigeration equipment.

Synthetic (polyester) oil is used together with freon 410a. The disadvantage of the product is its high hygroscopicity. When refueling, avoid contact with wet surfaces. It is recommended to use PLANETELF ACD 32, 46, 68, 100, Biltzer BSE 42, Mobil EAL Arctic products. Mineral oils are not compatible with refrigerant; their use will damage the compressor.

Source

Why was there a need to replace R-502 and R-22 freons?

The Montreal Protocol of 1989 included freons R502 and R22 on the list of non-ecological ones due to their high ozone depletion potential.

The ozone depletion potential of R-404a refrigerant is zero, but it has a critical global warming potential. Although this figure is 15.6% lower than that of R-502 and R-22, there is a high probability that it will soon be banned by environmentalists.

R-404a refrigerant is used in low- and medium-temperature refrigeration equipment: in domestic and commercial refrigeration and freezing units, as well as in vending machines and in refrigerators transporting products that require refrigeration.

FOR REFERENCE

R-404a is sold under the following brands: SUVA HP62, FX70, Genetron 404a, Forane 404a; Solkane 404a, HFC-404A, HFC-404.

Technical characteristics of refrigerant r410a

| Parameter | Unit change | Meaning |

| Molecular mass, | g/mol | 72,58 |

| Boiling point at 1 atm | °C | -51,58 |

| Freezing point | °C | — |

| Critical temperature | °C | 72,1 |

| Critical pressure | MPa | 4,92 |

| Critical density, | kg/cub.m | 488,9 |

| Liquid density at 25 °C | kg/cub.m | 1062 |

| Specific heat capacity of liquid at 25 °C | kJ/kg | 1842,192 |

| Specific heat capacity of vapor at 1 atm | kJ/kg | 711,756 |

| Heat of vaporization at boiling point | kJ/kg | 264,3 |

| Saturated vapor density at -25 °C | kg/cub.m | 18,5 |

| Saturated vapor density at -51.58 °C | kg/cub.m | 4 |

| Steam pressure at 25 °C | MPa | 0,1653 |

| Flammability limit in air | % volume | No |

| Self-ignition temperature, 0C | °C | — |

| Flammability class | A1 | |

| Ozone Depletion Potential ODP | ||

| Global Warming Potential HGPW | 0,45 | |

| Global Warming Potential GWP | 1890 | |

| MPC at the workplace, ppm | 1000 |

Thermodynamic properties of R-12 refrigerant

R12-TD-5.pdf – Table of thermodynamic properties of R-12 refrigerant. Temperature range: -100 to +112 degrees Celsius in 5 °C increments. The SI system is used. The table shows:

- Temperature, °C;

- Absolute specific pressure (bar);

- Specific density (cub.m./kg);

- Specific enthalpy of liquid and steam in kJ/kg;

- Specific entropy of liquid and steam in kJ/(kg*K).

R12-TDF-10.pdf – Table of the thermodynamic characteristics of the R-12 refrigerant in the imperial (English) system of measures. Temperature range -130 to +230 degrees Fahrenheit. Step - 10 degrees (-130, -120, -110, etc.). The table shows:

- Temperature, °F;

- Pressure (absolute), psi (psi);

- Specific volume, cubic feet/lb;

- Internal energy, Btu/lb;

- Enthalpy, Btu/lb;

- Entropy, Btu/(lb*R).

Features of application

- centrifugal compressors;

- flooded evaporators;

- pump refrigeration units.

The new freon has found application in air conditioning systems and household heat pump units. The azeotropic mixture is suitable for equipment with direct expansion and flooded heat exchangers. Due to its high density, refrigerant is used in domestic and industrial installations:

- transport cooling systems;

- air conditioning installations in offices, public buildings, industrial facilities;

- household refrigerators;

- commercial and food refrigeration equipment.

Synthetic (polyester) oil is used together with freon 410a. The disadvantage of the product is its high hygroscopicity. When refueling, avoid contact with wet surfaces. It is recommended to use PLANETELF ACD 32, 46, 68, 100, Biltzer BSE 42, Mobil EAL Arctic products. Mineral oils are not compatible with refrigerant; their use will damage the compressor.

Source

What should be the freon pressure in home and car air conditioning?

Due to the evaporation and condensation of the refrigerant in a closed circuit, the thermal energy of the air is selected and released into the environment. This is the operating principle of any refrigeration machine. The physical state and other parameters of the working substance are constantly changing. But most ordinary users are interested in only one characteristic - freon pressure in the air conditioner.

The rationale is clear: many owners of private houses and apartments want to service the split system themselves, filling the refrigerant in the simplest way found on the Internet. We will reveal the essence of the method in 3 stages - the theoretical part, diagnostics and instructions for refueling.

Refilling and refilling the air conditioner with freon

refilling tool kit

How is air conditioning refilled with freon, and how does it differ from refueling?

Refilling is a partial replenishment of the lost volume of refrigerant. It may be needed in case of a leak or during preventative refueling. It is also carried out when the route is enlarged during installation. On average, the factory volume of refrigerant pumped is designed for 5 meters of route. If its length increases, then the air conditioner must be refilled with freon at the rate of 30 grams per meter of line.

For household air conditioners with R-22 freon and the like, the refueling method is used, and for systems with R-410a freon, only the full refueling method is used. This gas consists of a mixture of chemical substances with varying degrees of volatility, which evaporate completely unevenly, therefore, the composition of the remaining substance varies greatly.

A full charge is the replenishment of the entire volume of gas in the refrigeration device. It is necessary when refilling household air conditioners with freon after moving, when all the refrigerant has previously been drained, or when replenishing the volume of freon, which has a complex composition.

Release of freon from the air conditioner

Before pumping freon into the air conditioner when it is fully charged, the remaining gas must be released from it. How to properly drain freon from an air conditioner, and what tools are needed for this?

Some technicians don’t see anything wrong with simply loosening the nuts on the external unit and venting everything into the atmosphere, considering a small amount of refrigerant safe for the environment. In its pure form it is actually harmless, but you shouldn’t do it that way. To release it from the air conditioner, you must have a freon collection station, which cuts into the air conditioning system using a special fitting and pumps out all the gas from it.

Next, a vacuum is carried out, and only after that a cylinder with freon is connected and it is pumped into the air conditioner at the required rate.

How much freon do you need?

Different refrigeration systems contain different amounts of refrigerant. How much freon can be in the air conditioner depends on the cooling capacity of the unit. On average, its volume in standard splits ranges from 700-800 grams, and in powerful installations for commercial or industrial use more than a kilogram.

The required volume is indicated by the manufacturer on a nameplate, which is a metal plate on the internal body of the split. It helps determine how much freon should be in the air conditioner. Using a pressure gauge, the technician determines the pressure in the cooling housing and looks at this plate.

Air conditioner refill methods

filling by weight

Recharging the air conditioner can be done in several ways, but the simplest and most commonly used are:

- refilling by weight (by scale) - you will need expensive scales to weigh the refrigerant cylinder;

- filling by pressure - at values below 3-3.5 atm, gas replenishment is required;

- by current - you will need a current clamp applied to the phase of the power wire of a working external unit.

There are two more methods: refueling by hypothermia and by overheating. But in reality, they are used only when checking industrial compressor-condensing units, since household splits do not have a device that regulates freon consumption. Its role is played by a capillary tube.

Only experienced installers know all the safe ways to drain freon in an air conditioner and how to make up for its shortage. You should not try to carry out such actions yourself, which can lead to burns of the skin or eyes, as well as completely disable the refrigeration machine.

Refueling based on pressure and overheating temperature

We would like to warn you right away that this method of adding freon is considered unreliable, although many refrigerators fill freon “by eye”, focusing only on pressure.

The best and most correct charging method is to completely replace the refrigerant by draining the system and filling it by weight, as described in our manual. In addition to the thermometer and gauge manifold, you will need:

- hex and open-end wrenches;

- electronic scales (kitchen scales will do);

- freon of the required brand (indicated on the plate of the external unit).

First of all, make sure there are no leaks, otherwise you risk wasting time and effort. When refueling, follow the instructions:

- Connect the hose from the LP gauge to the service port and the yellow middle tube to the gas cylinder according to the diagram below.

- Open the cylinder valve and purge the air from the hoses by briefly opening the high pressure tap (on the right side of the manifold).

- Place the container with the refrigerant on the scales and reset the readings to zero. When filling with R410a freon, the cylinder is placed upside down.

- Turn on the air conditioner for cooling and open the service valve, having first unscrewed the protective cap.

- When opening the LP tap (on the left at the pressure gauge station), release the freon into the circuit in small portions, literally 30 grams each. Use electronic scales as a guide.

- After pouring each portion, turn off the tap and measure the temperature of the gas pipe for 1-2 minutes. Serve next portion as needed. The task is to reduce overheating to normal 5-8 °C.

- Upon completion of refueling, close the valves of the manifold, service pipe and cylinder one by one.

Example. If previously the temperature of the gas main at a pressure of 5.4 Bar was +17 °C, the overheating reached 17 - 8 = 9 degrees (freon R22). This means that the tube needs to be cooled to + 14 °C in order to meet the standard.

The technology for refueling a split system based on overheating and pressure is described in detail in the video:

Characteristics of R410a on the saturation line

| Temperature, C | Saturated liquid | Saturated steam | |||||||

| Saturation pressure, 105 Pa | Density, kg/m3 | Specific enthalpy, kJ/kg | Specific entropy, kJ/(kg*K) | Saturation pressure, 105 Pa | Density, kg/m3 | Specific enthalpy, kJ/kg | Specific entropy, kJ/(kg*K) | Specific heat of vaporization, kJ/kg | |

| -50 | 1,123 | 1339,761 | 131,4 | 0,726 | 1,122 | 4,526 | 401,5 | 1,936 | 270,1 |

| -45 | 1,417 | 1325,036 | 137,8 | 0,754 | 1,415 | 5,616 | 404,6 | 1,924 | 266,8 |

| -40 | 1,770 | 1309,941 | 144,2 | 0,782 | 1,767 | 6,909 | 407,5 | 1,913 | 263,4 |

| -35 | 2,191 | 1294,45 | 150,7 | 0,809 | 2,187 | 8,435 | 410,5 | 1,902 | 259,8 |

| -30 | 2,689 | 1278,534 | 157,3 | 0,837 | 2,683 | 10,224 | 413,3 | 1,891 | 256,0 |

| -25 | 3,273 | 1262,162 | 164,0 | 0,864 | 3,265 | 12,312 | 416,1 | 1,882 | 252,0 |

| -20 | 3,954 | 1245,297 | 170,9 | 0,891 | 3,944 | 14,738 | 418,8 | 1,872 | 247,8 |

| -15 | 4,743 | 1227,897 | 177,9 | 0,918 | 4,730 | 17,546 | 421,3 | 1,863 | 243,4 |

| -10 | 5,651 | 1209,914 | 185,1 | 0,945 | 5,635 | 20,785 | 423,8 | 1,854 | 238,7 |

| -5 | 6,690 | 1191,292 | 192,5 | 0,973 | 6,670 | 24,511 | 426,1 | 1,846 | 233,6 |

| 7,872 | 1171,968 | 200,0 | 1,000 | 7,849 | 28,79 | 428,3 | 1,837 | 228,3 | |

| 5 | 9,211 | 1151,863 | 207,7 | 1,028 | 9,184 | 33,696 | 430,2 | 1,829 | 222,5 |

| 10 | 10,719 | 1130,887 | 215,7 | 1,055 | 10,688 | 39,317 | 432,0 | 1,821 | 216,3 |

| 15 | 12,410 | 1108,928 | 223,9 | 1,084 | 12,375 | 45,759 | 433,6 | 1,812 | 209,6 |

| 20 | 14,299 | 1085,849 | 232,5 | 1,112 | 14,260 | 53,149 | 434,8 | 1,803 | 202,4 |

| 25 | 16,399 | 1061,481 | 241,3 | 1,141 | 16,357 | 61,643 | 435,8 | 1,794 | 194,5 |

| 30 | 18,725 | 1035,603 | 250,5 | 1,171 | 18,681 | 71,44 | 436,4 | 1,785 | 185,9 |

| 35 | 21,293 | 1007,926 | 260,2 | 1,202 | 21,247 | 82,798 | 436,6 | 1,774 | 176,4 |

| 40 | 24,116 | 978,057 | 270,4 | 1,233 | 24,070 | 96,062 | 436,2 | 1,763 | 165,9 |

| 45 | 27,211 | 945,435 | 281,2 | 1,266 | 27,165 | 111,722 | 435,2 | 1,750 | 154,0 |

| 50 | 30,592 | 909,218 | 292,8 | 1,301 | 30,549 | 130,504 | 433,4 | 1,736 | 140,6 |

Danger to humans

R32 refrigerant is considered a fire hazard. But it belongs to class A2L. In this abbreviation, the first letter “A” means that the gas has low toxicity. And the designation “2L” means that it belongs to substances of medium fire hazard. Class A2L substances have the following characteristics:

- Concentration in air for combustion is more than 0.3 kg/m3;

- Burning rate 400 ppm.

If there is a leak, R32 refrigerant may catch fire. But this requires special conditions. An ordinary spark will not be able to set it on fire. For freon to ignite, energy of at least 15 megajoules is needed. In addition, it will burn if its concentration in the air is from 13.3% to 29.3% (according to studies published by the Consortium of European Historical Libraries).

If freon R32 is exposed to high temperatures in other concentrations, it decomposes. In this case, fluorides are formed. Some of them pose a health hazard.

R23 refrigerant is almost 2 times heavier than air. When there is a leak, it accumulates at the bottom. Accordingly, it is very difficult to breathe in them. This freon actually poses no threat to humans.

Source

Features of refrigerant r404a

Freon R404a is three-component - a mixture of three other refrigerants. In mass ratio, its composition looks like this:

- 44%: R125 – C2F5H (pentafluoroethane);

- 52%: R143a – CH3CF3 (trifluoroethane);

- 4%: R134a – CH2FCF3 (tetrafluoroethane).

Unlike some other ternary mixtures, this refrigerant is close to azeotropic. This means that all three gases have similar characteristics. Accordingly, when there is a leak, they come out equally.

Due to this feature, the percentage of components does not change when it leaks. Accordingly, there is no need to completely change the refrigerant in the system in the event of an accident. It can be refueled.

According to the ASHRAE classification, freon r404a corresponds to class A1/A1. The first value means that it has a very low fire hazard and toxicity. The second is that its individual components are also extremely fireproof and harmless to humans.

Standard cylinder of Chinese freon R404a, net 10.9 kg.

Technical characteristics of freon R410a

| Characteristic | Meaning |

| Molecular weight (g/mol) | 72.58 |

| Boiling point at atm. pressure (°C) | -51.58 |

| Mass fraction of R125 | 0.5 |

| Mass fraction of R32 | 0.5 |

| Liquid density at 25 °C, (kg/m3) | 1062 |

| Saturated vapor density at 25 °C, (kg/m3) | 18.5 |

| Critical temperature (°C) | 72.1 |

| Critical pressure, kPa (abs.) | 5166 |

| Critical density of liquid, kg/m3 | 488.9 |

| Steam pressure at 25 °C, kPa (abs.) | 173.5 |

| Heat of vaporization at normal boiling point, kJ/kg | 264.3 |

| Flammability limit in air (0.1 MPa), vol.% | No |

| ODP (ozone depletion potential) | |

| HGWP (Global Warming Potential) | 0.45 |

| GWP (100-year global warming potential) | 1890 |

| MAC (maximum permissible inhalation concentration), ppm | 1000 |

| Net weight in standard metal cylinder (kg) | 11.3 |

| Saturated vapor density at boiling point, kg/m3 | 4 |

| Latent heat of vaporization at boiling point BTU/pound | 116.7 |

| Specific heat capacity of liquid at 25°C BTU/pound °F | 0.44 |

| Specific heat capacity of vapor at 1 atm. BTU/pound °F | 0.17 |