The bathroom should always be warm. After a shower, human skin is especially sensitive to temperature, and even short-term hypothermia can cause colds. In addition to the obvious discomfort and danger to human health, the cold in the bathroom can cause damage to finishing materials. They dry out too slowly, which leads to constant dampness, the appearance of fungus and mold. How to insulate a bathroom in a private house and do without connecting additional heating?

Why is it cold in the bathroom?

Of the heating appliances in the bathroom, usually only a heated towel rail is installed. If the owner built his house himself, then there may be a radiator in the bathroom, but it is installed only in cases where the area of the room is large enough. A room may be cold simply because it is not heated well enough. There are other reasons for low temperature:

- Powerful hood. There is high humidity in the bathroom, so you have to take care of normal ventilation. Together with air and condensate, heat also evaporates through the hood. If a room is poorly insulated but well ventilated, it will be cool.

- Slots in the windows. Many private houses have wooden frames. Over time, they dry out and cracks appear. Insulating the frames alone will not be enough, because... Air circulation through the cracks continues.

- Gaps in walls, floors, ceilings. The building may shrink. The result is the appearance of cracks and crevices in building structures. If they are not insulated, the rooms may be cool even when the heating system is operating normally.

Why is it so important to insulate the ceiling in a house?

School knowledge of physics can still be useful in life. So, due to convection, when cold air goes down and hot air goes up, all the heat accumulated in the room will penetrate through the uninsulated ceiling into the unheated attic. Because of this, you have to increase the boiler power and, as a result, incur additional heating costs.

For the same reason, ceiling insulation requires a more serious approach than wall insulation - due to air flows, heat loss from a wooden ceiling can reach 3 W/m2/K. For brick or concrete floors the figure is even higher. At the same time, there is no need to insulate the ceilings between living spaces if the temperature in them is the same. It is enough to take care of sound insulation and save money on thermal insulation of the attic and roof.

In summer, it is also better to have an insulated ceiling - the roof heated by the sun transfers heat into the room, negating the operation of air conditioners. Having spent once on thermal insulation, you can enjoy a comfortable microclimate in your home for many years.

How to insulate - from the inside or outside

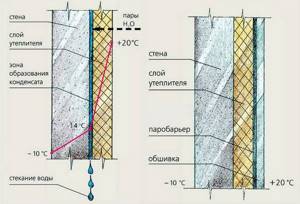

If in apartments the layout is such that the bathroom does not border on external walls, then in private houses it is difficult to arrange it this way. Often the bathroom turns out to be a corner room, and it is almost always cold in it. It is advisable to make high-quality insulation of the walls in the bathroom from the inside and outside.

External thermal insulation of walls is usually carried out before finishing the facades, and materials are selected to insulate the entire house as a whole. But the inside of the bathroom should be insulated separately. It is necessary to minimize heat loss through the floor, ceiling and walls. For each design, insulators are selected taking into account the materials from which they are made.

What to look for when choosing insulation?

First of all, you need to decide where to install the insulation - inside or outside the living rooms. The first option is extremely undesirable for several reasons:

- ceiling height decreases;

- it is impossible to use bulk insulation;

- the cooling point moves closer to the inside of the ceilings;

- inevitable repairs due to dismantling the old ceiling.

Attic insulation is devoid of all these negative features. But if an attic is not provided, or the project includes an attic floor, the roof must be insulated immediately.

Choosing materials for insulation with your own hands

Polystyrene foam or EPS, as well as mineral wool and its analogs are suitable for insulation from the inside and outside. Such materials are laid between beams or in a specially constructed frame and covered with plasterboard, OSB boards or clapboard.

But if there is a sauna in the house, then it is better not to insulate the ceiling above it with polystyrene foam - due to high temperatures, it can begin to release substances harmful to humans.

Aerated concrete slabs are also excellent for internal insulation due to their low weight and ease of installation. Their thickness of up to 10 cm will not “eat up” very much height, and additional cladding will not be required. Polystyrene board adhesive is applied to the boards with a notched trowel and pressed against the ceiling.

The insulation is puttied and painted.

Bulk insulation materials such as shavings, ecowool or expanded clay are quite economical. True, having high hygroscopicity, they require good waterproofing. Such insulation is poured between the beams on the attic side in a layer of about 15 cm, and for ease of movement in the attic it is covered with OSB boards.

True, having high hygroscopicity, they require good waterproofing.

What kind of insulation is not chewed by mice?

Mice chew any insulation. But not as food, but to expand their moves. You may hear claims that mice eat styrofoam. This is not entirely true - they gnaw through it and build nests in it. But the same fate will befall mineral wool, albeit a little later.

Due to its flowability, ecowool can help a little - but rodents will simply endure it until they can settle and move normally in the insulation. The most rodent-resistant expanded clay is strong “pebbles”, large enough so that mice and even rats cannot carry them away, and at the same time small enough to fill their passages.

But there is a catch here - mice will arrange “beds” there. Therefore, the only way to protect the insulation is to prevent rodents from entering it in principle. Everything else is only a temporary and very unreliable solution.

Materials for thermal insulation of walls and ceilings

The most popular materials for thermal insulation of bathroom walls and ceilings:

- polyurethane foam;

- cork agglomerate;

- Styrofoam;

- mineral wool;

- warm plasters.

All insulators have their advantages and disadvantages. Before purchasing, you should soberly evaluate them, because some insulation materials lose their properties when they become damp. If this happens, the money spent on protective measures will be thrown away.

Whatever material the home owner chooses, he will have to take care of preparing the surfaces. It is necessary to remove the old finish and treat the structures with an antiseptic composition. This is necessary to destroy the fungus and prevent its occurrence in the future.

It is best to level the walls, but for the installation of most insulation, perfectly smooth surfaces are not necessary. Minor defects will not affect the quality of the insulation in any way. The main thing is that large cracks, distortions and differences are eliminated in advance.

Option #1: mineral wool mats

Mineral wool absorbs water, and many experts do not recommend using it at all for those home owners who are not ready to invest money in high-quality hydro- and vapor barrier.

Under the influence of moisture, the thermal insulation properties of the material are reduced, so it must be reliably protected from drops of water and condensation. On the other hand, mineral wool does not interfere with micro-air circulation, and this is important for rooms that need good ventilation.

Advice. If mineral wool is chosen as insulation, be careful when installing hydro- and vapor barrier layers. It is necessary that the joints between the strips of materials are absolutely sealed. This largely depends on the quality of the insulators themselves and the installation. Savings will only result in additional costs.

It is better to give preference not to roll insulation, but to rigid mineral wool mats. They are mounted on a special frame made of wooden slats or galvanized profiles. The second option is preferable. The metal frame lasts longer and does not deform. Thanks to this and the design of the mats themselves, the insulation will not slide off the walls or bunch up downwards.

When installing an insulating layer of mineral wool, the areas where heating devices are installed should be shielded. Aluminum foil is used for this. If the heat insulator is properly installed and reliably protected from moisture, it can serve for decades without changing its technical and operational characteristics.

Option #2: foam

To insulate the bathroom from the inside, you can use polystyrene foam. It is often used for external thermal insulation. The material has good performance properties, but has a number of disadvantages. The main one is low vapor permeability.

When installing foam plastic, you need to carefully seal the joints. If even small gaps remain, condensation will accumulate under the insulation. Over time, this will lead to the appearance of fungus, which will be extremely difficult to get rid of: you will have to dismantle and replace the insulation.

Selection of tools and materials

In addition to insulation, you will need to select other materials necessary to create thermal insulation for the ceiling and acquire a certain set of tools. For high-quality thermal insulation of the upper part of the building you will need:

To insulate the ceiling with mineral wool, it is important to prepare all the necessary materials and equipment

- plywood sheets 10 mm thick, designed to support mineral mats;

- a vapor barrier membrane that protects the insulation from moisture from the room;

- wooden blocks measuring 5x5 cm, used to fasten the counter-lattice from the outer part of the ceiling;

- waterproofing film that protects the insulating layer in the event of a roof leak;

- polyurethane adhesive designed for sealing joints between sheets of thermal insulation;

- tongue and groove board for flooring;

- fire-bioprotective impregnation for wood, increasing fire safety and protecting wooden elements from bio-corrosion.

To tighten the screws you will need a screwdriver. To secure moisture-proof films, you will need a construction stapler. To cut plywood you will need a small one-handed saw.

In addition, you will need a standard set of plumbing tools that any owner of a private home has.

How and with what can you insulate a bathroom floor?

As thermal insulators, you can choose polyurethane foam, mineral wool, regular or extruded polystyrene foam. Some home owners opt for the cheapest option - polystyrene foam. However, you should always remember that the insulation is installed under the screed, and fragile foam sheets do not always successfully cope with the loads. They burst, and moisture penetrates into the cracks. The result is dampness and fungus.

The best choice for insulating the bathroom floor is polyurethane foam. If your budget is limited, you can buy extruded polystyrene foam. It is rigid, tolerates loads well, has high thermal insulation properties, and is vapor permeable.

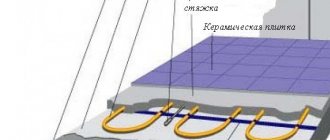

For high-quality insulation, it is necessary to install a thick layer of extruded polystyrene foam, which means raising the floor level. A reinforcing mesh is placed under the concrete screed. The material needs good waterproofing. To do this, use a waterproofing film or penetrating compounds.

Waterproofing and insulation of floors under tiles

One of the ways to waterproof a floor when laying tiles

This option is suitable for thermal insulation of a bathroom on the first floor in the presence of durable wooden floors. This method involves insulating the lower part of the floor structure at the location of the beams.

- All wooden elements are treated with an antiseptic. Next, waterproofing of the base is carried out. To do this, a waterproofing film is spread on the joists, and then insulation boards are laid in the spaces between the beams. A layer of vapor barrier is laid on top and a counter-lattice is installed on which the boards are laid.

- Dust and dirt are removed from the subfloor. This is necessary to ensure good adhesion of the material to the wood.

- Next, internal waterproofing is carried out using a self-adhesive bitumen-polymer film. First, a concrete primer, which is a water-soluble emulsion, is applied with a roller to the entire surface of the floor. It is also necessary to grab the lower part of the wall to a height of approximately 20 cm.

- The composition dries very quickly, at room temperature it takes no more than half an hour. Waterproofing should be done immediately after the primer has dried.

- A piece of the required length is cut from the roll, rolled, and placed on the floor. Carefully removing the protective film, unwind the material in the opposite direction, gluing it to the base and immediately removing any air bubbles that have formed with a brush.

- The next canvas is laid with an overlap, the joints are coated with bitumen emulsion.

- After laying the waterproofing on the floor, the material is applied to the pre-treated wall. It is necessary to cut strips 30 cm wide, of which 20 cm go to the wall, and 10 cm are glued to the floor, previously lubricated with mastic.

- A reinforced concrete screed is poured over the film, and then, after the solution has completely dried, ceramic floor tiles are laid on waterproof glue.

Video tutorial: thermal insulation of walls in a wooden house

There are many materials for insulating walls in a bathroom from the inside. Each home owner can find a heat insulator that is best suited for a particular room. The main thing is to take into account all the operating features. This will help avoid troubles in the future. Remember, consulting a specialist is never superfluous. If you are not confident in your abilities, do not hesitate to ask for help.

Describe your question in as much detail as possible and our expert will answer it

When you're renovating a bathroom, it's worth thinking about not only its design, but also its insulation. The material required for insulation must match the color of the walls and ceiling, and at the same time have maximum characteristics. The walls and ceiling in the bathroom must “breathe” and be highly resistant to any moisture.

A common problem is that the bathroom is not warm but has high humidity. To eliminate this problem, it is necessary to plan in advance the procedure for insulating this room. Questions arise: how to insulate a bathroom in a private house? And how to insulate a bathroom in an apartment?

What is the best way to insulate the ceiling in a house + video?

Most owners of private houses only insulate the walls of the building, but a large amount of heat is lost through the roof of the house. This happens because warm air is lighter than cold air and rises to the top. Therefore, when insulating a house, you need to take care of the ceiling so that the heat does not escape outside. Let's figure out the best way to insulate the ceiling in a house.

Typically, ceiling insulation is performed in conjunction with insulation of the entire room.

If you carefully examine the roof of your house in winter, you will notice that the snow and ice melts faster there than around it. And this happens due to the heat coming out of the room. In order to reduce heat loss, you need to insulate the ceiling. As a result, you will save on electricity and the house will not need to be heated for a long time.

Materials for ceiling insulation

Thanks to an insulated ceiling, you can retain a significant amount of heat in the house. That is why it is necessary to carefully select materials. To work you will need the following:

To make slats of the appropriate size, you will need to take an electric jigsaw and a hacksaw. A regular knife is suitable for cutting foam sheets.

We insulate the roof using polystyrene foam

Before you start insulating the ceiling, you must insulate the roof. Almost all residential buildings have a gable roof. Such roofs need to be insulated from the inside, and after construction is completed.

Here is another option for insulating the roof of a building:

- First, cover the roof cladding with a thick layer of waterproofing;

- install a wooden sheathing;

- Carefully place the insulation boards between the slats of this sheathing;

- Fill cracks and gaps that inevitably remain with foam;

- At the end of the work, nail the boards - they will fix the insulation.

It is important to leave a small space between the insulation layer and the waterproofing film - ventilation will occur through it. Otherwise, the air will not carry water vapor out of the room, the humidity will increase, and as a result, condensation will appear.

Ceiling insulation with mineral wool

If you have your own private home, it is easier to insulate the ceiling from the attic side. In addition, this method will not reduce the living space. It is very convenient to insulate the ceiling with mineral wool.

First, prepare the surface of the attic floor for insulation. To do this, cover the floor with a vapor-proof film and attach wooden slats. The distance between them should accommodate blocks of mineral wool. In case of very large heat loss, lay the insulation in several layers. The last layer must be placed so that it covers the beams, otherwise heat will leave the house through the wood.

Fill the gaps with polystyrene foam or seal with foam.

Next, in the same spirit, install the second layer of vapor barrier film.

Moisture insulation is necessary because mineral wool, when it gets into a humid environment, loses its thermal insulation properties. When spreading the moisture-proofing film, it is better to leave a small margin. For ease of use, the edges of such a film can be attached to the side beams or wall using a stapler.

This way the ceiling is insulated with mineral wool. After all the work done to insulate the attic, you can arrange living quarters or utility rooms.

But if you want to frequently use the attic space, then you should lay another board floor on top of the insulation. And if the attic will be practically not used, then you can nail several boards in the form of paths so that you can move along them if necessary.

Ceiling insulation using expanded clay

If for some reason you are not satisfied with mineral wool, then to insulate the ceiling you can use a lightweight porous material - expanded clay.

It has a lot of advantages:

- expanded clay is not damaged by rodents;

- thermal insulation based on it is very long-term;

- Since expanded clay is a bulk insulation material, it can easily fill absolutely any space, even the narrowest and most inaccessible.

However, this material also has disadvantages. And the main thing is its relatively low thermal insulation properties. Having carried out all the necessary calculations for insulating the ceiling with expanded clay, you may find that you will need a very impressive amount of such insulation. This means that due to the mass, the pressure on the floors of the building will increase.

Expanded clay is used to insulate the ceiling when heat loss is not very significant and it is quite possible to get by with a small amount of such insulation. Its big advantage is that expanded clay is not affected by a humid environment, which means it does not require additional protection with waterproofing material.

Ceiling insulation with foam plastic

Recently, polystyrene foam has been in great demand in construction because it is environmentally friendly and non-toxic.

It is produced in the form of slabs. Bulk foam is also suitable for insulation. When thinking about what material is best to insulate the ceiling, many people choose foam plastic. And all because:

- polystyrene foam has a low mass, which means the pressure on the floors will be minimal;

- slabs of this material are easily cut for joining inside the sheathing with an ordinary knife;

- installation of foam boards is easy to do yourself;

- polystyrene foam is a cheap material;

- If previously the big disadvantage of polystyrene foam was its flammability, then modern polystyrene foam does not burn.

How to insulate a ceiling with polystyrene foam?

First, cover the ceiling with waterproofing; you can use glassine for this purpose. To do this, we cut the material into strips so that it fits easily between the beams. Leave 5 cm on the side of the beams so that you can then attach the material to the ends with wooden slats.

Cut the foam boards to a size that will fit between the joists. Carefully fill all cracks with construction foam.

Place a second layer of glassine on top of the entire resulting structure.

How much insulation to use depends on the heat loss of your home. In some cases, it is advisable to lay several layers of mineral wool on the foam layer. Such an insulating structure must be mounted so that the upper edges of the beams are covered with insulation. After all the work, you can start laying the floor.

Conclusion

Before starting work on ceiling insulation, you must determine:

- what material will you use to insulate the ceiling;

- how much of it you will need;

- what tools should you have with you.

The process of insulating a room

Many people have felt discomfort while in the bathroom, as cold air flows into the room through the ventilation.

In order to get rid of this feeling, it is necessary to use only high-quality materials for thermal insulation:

- First you need to insulate the floor (this will be written below). If you want to cover the floor with tiles, you must remember that you should not slip on wet tiles. Or lay down some kind of rug.

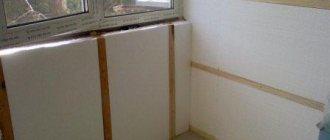

- Then the procedure of thermal insulation of the walls is carried out. The insulating material in this case should be polystyrene foam (foam), because it is not exposed to water. Mineral wool will not be very suitable for this particular room, because this material absorbs moisture well. As a result, its thermal insulation characteristics will deteriorate. It is also worth remembering that insulating the walls in the bathroom will reduce the total space in it.

Algorithm for insulating a bathroom:

- At the very beginning, the walls must be completely cleaned.

- Then they need to be coated with a specially designed preparation that will protect the surface from fungus.

- Extruded polystyrene foam is glued to the wall.

- Immediately after installing this material, moisture-resistant plasterboard sheets are applied on top.

- Ceramic tiles must be laid on top of the plasterboard sheets.

This was the first method of insulation, there is another:

- Thermal insulation material must be laid in two layers.

- On top of the insulation it is necessary to install a system of materials that solve problems associated with waterproofing and vapor barrier (isospan).

- Again, moisture-resistant plasterboard sheets are glued to the top.

- We complete all the work by finishing the surfaces.

- Thermal insulation is also necessary for the ceiling. The best option is installation work with a suspended plasterboard ceiling. The distance that remains between the plasterboard sheets and the ceiling must be insulated using foam boards.

- It is important to take care of the correct ventilation system. Ventilation must effectively remove all vapors that form in the room. How to achieve this? A specially designed grille must be installed on the ventilation. The grille includes a fan. The fan will draw out any vapors that form. But outside air will not be allowed through.

- The sewer shaft will also need to be insulated. For what? The sewer shaft is the main source of drafts, and it also draws out all the heat, so the bathroom cannot heat up.

Materials for thermal insulation

An experienced craftsman has a wide selection of materials with which to insulate thin-walled steel bathtubs with his own hands. They differ in thermal conductivity coefficient, price and method of application. If the thermal insulation of the washing container is carried out before installation, you can use almost any material that suits you in terms of price and quality ratio. The most popular means of insulating steel products are:

- Polyurethane foam sealant. A sealant based on polyurethane foam, popularly known as polyurethane foam, is the optimal material for thermal insulation of a bathtub. It has a low thermal conductivity coefficient and high resistance to moisture, is easy to apply and dries quickly. Many craftsmen choose polyurethane foam for insulating bathtubs because of its affordable price.

- Sheet foil polyurethane foam. Another material that effectively maintains the temperature of water in steel containers is polyurethane foam in the form of self-adhesive sheets. The layer of foil with which the polyurethane foam is supplied additionally reflects heat into the bowl. This material is used to cover the outer surface of the bathtub using a self-adhesive layer or glue.

Insulation of walls using plaster materials

“Warm plaster” is excellent for thermal insulation. A distinctive feature of this material is that it has a high level of vapor permeability, as well as a low level of thermal conductivity. A high level of vapor permeability is formed due to the cement base. A low level of thermal conductivity is achieved thanks to certain additives in the overall composition.

Plaster materials are divided into several types:

- vermiculite;

- sawdust;

- polystyrene foam.

The main advantage of “warm” plasters is that you can get a uniform coating that will not allow the cold air ceiling to pass through. There is no need to level the surface of the bathroom walls. Also, thanks to excellent adhesion, plaster materials can be safely applied to absolutely any surface. The main disadvantage of this material is that it applies a thick layer to the surface of the walls, which can visually significantly reduce the area of the bathroom.

Before applying “warm” plaster materials to the walls, the surface must be primed.

It is necessary to pay attention to the sealing of seams in the bathroom. To seal the seams, you need to use foam. Seams and joints should be sealed correctly. Be careful when sealing.

Purchasing material

Before starting repairs and going to the construction market, you must take the measurements responsibly. This will help to make the highest quality ceiling insulation.

First, determine the ceiling area by multiplying the length by the width. The resulting figure will be the required area.

Please note that in the case of foam plastic, its thickness should be no higher than 5–6 mm, and its density should be from PSBS-15 to PSBS-35. Also, do not forget to purchase dowels with a wide head for fixing the material and glue. All this will help you to independently insulate the ceilings in your living space without any problems.

Warm floor system

How to insulate a bathroom floor? A floor covered with ceramic tiles is itself cold. Therefore, electric mats are often installed under this facing material. They heat the surface of the flooring and maintain a constant surface temperature.

The entire overall system, together with electric heating mats, is called a “warm house”. On the construction market, this material is sold in different sizes.

In addition to mats, hot water is used for thermal insulation of the floor. But since the total area of the bathroom is small, and the water has low purification quality in plumbing systems, insulating the bathroom floor using this method is a difficult task. Therefore, floor insulation is best done using heating elements.

The work intended to create a “warm floor” system is divided into several actions:

- The floor surface must be strong and dry, and there must also be an intermediate layer of cement (screed).

- Then you need to correctly install the heating elements.

- Before you begin installation work, you need to remember that each electric heating mat has exactly two wires, each four meters long. The voltage of all systems is 220 Volts.

- Proper installation will ensure reliable thermal insulation of your bathroom floor.

Electric mats are already programmed to a regular temperature. Hot water heating has significant differences from electric heating:

- Low price of installation work.

- The "warm floor" system is completely independent of central heating.

- Huge service life.

- High level of reliability.

- The thickness increases slightly. Heating with hot water raises the surface of the flooring by several centimeters.

Although the installation work is quite simple, floor insulation must be carried out carefully and certain safety rules must be followed.

Proper insulation of the bathroom from the inside will allow you to create unique comfort and coziness in this room. You will be able to freely take water treatments, because cool air in the bathroom can be detrimental to your health.

Laying heating cable in the bathroom

Before you go buy a heating cable, check two points for yourself:

-what are you going to use it for? If it will play the role of a central heating system, then it is better to choose a more powerful cable. And if just as a source of additional heat, then in this case a cable of regular power will do. This cable should be laid before the façade is insulated.

-measure the surface area that it will cover, measure only the surface where there is no equipment or furniture.

If you have not yet decided on the type of flooring, then it is better to choose mats as a heater. These are special heating type mats. For such mats, it is better to choose stone or tile as a covering. They fit perfectly under mats. The mats are directly installed on the finished concrete screed. This will greatly facilitate the installation process.

What is a heating cable?

This is a cable that has a fixed length, and for connecting to the network it is equipped with mounting ends. In order to begin installing the heating cable, you will also need:

-thermal insulating substrate;

- thermostat;

-necessary materials for installation;

- leveler.

Thermal insulation of the bathroom from the outside

External wall cladding helps to achieve excellent results in insulating the room. For this purpose, various thermal insulation materials with great energy-saving potential are used:

- mineral wool . The outer structure with mineral wool is fireproof, heavy and has fairly low thermal conductivity, while allowing the building to breathe;

- expanded polystyrene. A relatively lightweight material with low vapor permeability, which, in addition to thermal insulation, protects the building from the appearance of fungus.

The process of insulating a façade involves attaching heat-insulating material to the external walls and then finishing it with a decorative waterproof layer.

Materials for thermal insulation of rooms with high humidity

Laying mineral wool on a metal frame

First of all, let's focus on the choice of materials.

Since the bathroom is a room with high humidity, the materials for cladding must have certain technical characteristics:

- Low water permeability;

- Strength and durability;

- The finish should be easy to clean with any, even aggressive detergents;

- The vapor permeability of the finish should ensure free circulation of air under the skin;

- The lining in the bathrooms, as required by the instructions, is made from materials that are not susceptible to fungus and mold.

Bathroom insulation

Thermal insulation of walls with polyurethane foam

Internal bathroom insulation work

If for some reason it is impossible to insulate the facade of a private house or the bathroom does not have contact with the street, thermal insulation work is carried out indoors. To insulate the internal walls of the bathroom, the following insulation materials are used:

- Mineral wool thermal plates. The material has increased rigidity, so it is suitable for insulating both bathroom walls and ceilings. To secure it, a supporting frame made of a metal profile is equipped, which is resistant to corrosion and mechanical deformation. Mineral wool is characterized by high hygroscopicity, which allows the surface to breathe.

To preserve the properties of mineral wool when performing thermal insulation work, the material is carefully sealed with a waterproofing layer, and in places of contact with heating elements - with aluminum foil.

- Styrofoam . The material has high heat and moisture insulation properties, but rather low vapor permeability. In this regard, there is a possibility of condensation accumulation under the thermal insulation layer and mold formation. Before installing the foam plastic, the surface must be primed several times with antiseptic primer.

To ensure the integrity of the coating and avoid moisture accumulation, the joints are carefully sealed, and then 2 layers of finishing putty are applied to the surface. The putty surface is finished with moisture-resistant decorative materials.

Photo gallery: thermal insulation materials for bathroom insulation

- Cork insulation. To insulate a bathroom, the material must be treated with wax impregnation. The cork thermal insulator is attached to the surface with a special glue for cork.

- Polyurethane foam. This liquid insulation is ideal as a thermal insulation material for bathrooms. It has moisture resistance, fire resistance, vapor permeability, and high heat and sound insulation properties. The material is sprayed onto any surface of the walls and ceiling in a thin layer.

Monolithic biologically resistant polyurethane foam coating completely eliminates the accumulation of condensation and mold formation.

- "Warm" plaster. The cement base of the material ensures high vapor permeability, and special additives provide low thermal conductivity. Applying plaster does not require preliminary leveling of the walls and ceiling; it is enough to prime the surface.

Insulation of a private house

Providing a good level of thermal insulation has another positive effect: as a result, we get an additional level of protection from external noise. There are two main types of thermal insulation work: external and internal.

Experts insist on insulating the walls of the house from the outside, and finishing from the inside should be done in some cases. However, not everyone understands why. The first reason is saving internal space. The second is a load-bearing wall; with thermal insulation from the inside it does not become warmer, sometimes even quite the opposite, it begins to freeze. Third, the wall should be concrete, brick or stone. They conduct water poorly and conduct heat easily.

Why is it not beneficial to insulate a house from the inside?

When decorating the inside of a house, unpleasant consequences arise. Namely: - the room will be significantly reduced;

- the room will be temporarily inconvenient to use, or even impossible;

— it is necessary to think about ventilation, otherwise over time the insulation may fail and lose its positive properties;

How to insulate a floor

A cold floor always creates inconvenience, especially a bathroom floor on which you have to walk barefoot. Therefore, its insulation is very important for the overall thermal insulation of the room. This can be done by laying a thermal insulation layer or installing a heated floor system.

The base of the floor must be lined with waterproofing material or covered with liquid rubber.

Extruded polystyrene foam, which is characterized by rigidity and vapor permeability, can be used as a thermal insulation material. It should be noted that to ensure proper thermal insulation, the layer of this insulation must be over 5 cm. A more practical material is polyurethane foam, the thermal insulation properties of which make it possible to reduce the layer to 2 cm.

The heated floor system uses electrical elements, the distance between which is filled with special mixtures. Such a heating system has a high heating capacity even at a relatively low heating temperature.

Thus, by carefully considering the insulation system for a bathroom in a private house, you can independently make the room comfortable for your stay.

Selecting a thermal insulator

To insulate the bathroom ceiling, non-hygroscopic, moisture-repellent materials should be used.

To insulate the bathroom ceiling, non-hygroscopic, moisture-repellent materials should be used. See tips for choosing thermal insulation materials here. The insulation must be safe for human health and maintain its thermal insulation properties in conditions of high humidity and significant temperature changes.

To insulate the bathroom ceiling, it is not recommended to use cotton wool insulators due to their high hygroscopicity and the need to additionally install a supporting frame. It is best to give preference to extruded polystyrene foam, polystyrene foam or polyurethane foam.