The main reasons for the failure of Baxi heating equipment:

Twenty years ago, a boiler was considered a simple device whose main purpose was to generate heat. Today, the requirements for heating equipment have changed dramatically. Now the boiler unit must be able to maintain a comfortable temperature automatically, prepare hot water in the required quantity, be energy efficient, environmentally friendly and safe. Baksi gas boilers not only meet all modern conditions, but also, in some respects, exceed them. For example, boiler units of the Baxi Luna–3

,

NUVOLA

,

ECO

have a built-in self-diagnosis system and many integrated safety devices and sensors that ensure maximum reliable and safe operation. And yet, during the operation of the boiler, it becomes less productive, and its reliability decreases.

This happens due to the influence of 4 main factors:

- natural gradual wear of parts;

- contamination of surfaces with salt deposits and carbon deposits;

- features of the operation of heating equipment in our country - our heating season lasts longer, so the load on the equipment is higher;

- low quality engineering systems.

Noticing and eliminating all problems as early as possible means saving yourself from breakdown of boiler equipment and expensive repairs of the baxi boiler. During regular service inspections, our engineers not only carry out all the measures prescribed by the manufacturer, but are also ready to eliminate all shortcomings and errors made during installation of equipment by third parties and carry out a complete modernization of the heating system.

Certified service is the key to efficient operation of equipment for many years:

Many years of experience of specialists from the authorized E-Tech service center have shown that it is the non-compliance of operating conditions with established standards, as well as the requirements of equipment manufacturers, that is the most common cause of failure of even the most advanced equipment. For example, according to statistics, one of the most common causes of breakdowns of Baxi Main

is poorly prepared water and low-quality fuel;

Baxi AMPTEC

- power surges that disable automation. Baksi specialists tried to neutralize some of the negative factors in advance by equipping all models of boiler units with a reliable safety control system and adapting them to work in Russian conditions. However, identifying most defects in the boiler piping and their neutralization falls on the shoulders of specialists providing service.

Our engineers are ready to undertake the entire range of servicing of the heating system based on the Baxi boiler. Before starting direct maintenance work (cleaning work surfaces, replacing spare parts for baxi boilers, etc.), E-Tech center specialists will conduct comprehensive diagnostics and determine the entire range of factors that negatively affect the operation of heating equipment. During the service, the automation will be calibrated, allowing you to set the most effective operating mode. After carrying out the maintenance, our specialists will draw up a Certificate of Completion of Work, which will indicate faults that require separate repairs, and will also record recommendations for operating the boiler. Modern technical support and our own spare parts warehouses allow us to carry out work of any complexity and level of responsibility in a short time and with maximum efficiency.

Today, a gas autonomous heating system is quite popular; it is used not only by owners of country houses, but also of apartments located in multi-storey buildings. This can be explained by the positive qualities of modern devices, ease of installation and operation, which is confirmed by many reviews from experienced specialists and consumers.

Spare parts for BAXI boilers

Home \ Spare parts for boilers, burners, boilers \ BAXI spare partsTo correctly select spare parts for the BAXI boiler, we may need a photo of the nameplate (stickers, tags, plates) on which are indicated, incl. Matr.No. and equipment model name. This sticker tag can be pasted both on the boiler itself and on the service book (see example above). You can send a photo to us either by e-mail or WatsApp.

| GSM module | 3 way valves | Anodes | Expansion tanks | Tanks for boilers | Fans | Air vents | |||

| Remote control panels | Gas-air mixers | Gas valves | Hydrogroups | Burner tubes and burners | Flow sensors | Temperature sensors | |||

| Traction sensors | Outdoor temperature sensors | Hall sensors | Chimneys | Injectors (nozzles) | Interface boards | Clips, staples, retainers | |||

| Room thermostats | Pressure gauges | Micro switches | 3-way valve motors | Pumps | Neutralization of condensate | Hull panels | |||

| Control panels | Pneumatic relay | Circuit breakers | Safety valves | Wires, cables | Gaskets | Piezo ignition | |||

| Relay min. water pressure | Thermal insulation | Main heat exchangers | DHW heat exchangers (secondary) | Cast iron heat exchangers | Thermometers | Thermocouple | |||

| Overheating thermostats | Tubes | heating elements | Venturi devices | Ignition devices | Filters | Electrodes | |||

| Electronic boards | B | Surge Protectors | B | Spare parts catalogs | B | Installation and operating instructions | B | B | B |

Sort by: Name Price Reset

1 …

Spare parts for BAXI boilers (warehouse program) with shipment throughout Moscow, Moscow Region and Russia. If you cannot independently determine which BAXI spare part you need (and this happens in the vast majority of cases), then upon your request by phone. or we can help you find it. You are required to provide the full name of the BAXI boiler model and the preliminary/approximate name of the BAXI spare part that you need. Our specialists are sufficiently qualified to select the Baxi spare part you need in the shortest possible time, based on the information received from you.

The warehouse we have created of original spare parts and accessories for the entire range of Italian BAXI boilers allows us to ship to your address within one day from the date of order.

Discounts are provided for service centers and specialized organizations performing repairs and maintenance of baxi boilers.

When purchasing spare parts, it is important to know that the warranty on purchased spare parts for the boiler is 6 months from the date of sale, provided that the spare parts are installed by a specialist certified by the boiler manufacturer.

In case of failure of volatile parts of the boiler (electronic control boards, fans, circulation pumps, etc.), we recommend that you purchase a specialized voltage stabilizer for the Baksi boiler, which provides high-quality and reliable power supply to the heating system.

If the heat exchangers fail, we recommend purchasing water treatment for the heating system that includes the Baksi boiler.

Practical recommendations

You can eliminate the appearance of “random” errors (and they are regularly displayed as a result of instability of the power supply) by connecting the gas Baxi to the network via a UPS. Various modifications of blocks are available for sale, designed to work together with household boilers.

The stabilizer and UPS are connected to the Baxi boiler

Unlike a stabilizer, this device will supply voltage to the heating unit even in the event of power line breaks and a malfunction of the backup generator. The autonomy of the UPS is ensured by built-in (or attached external) batteries. Users note that after its installation at the site, the number of Baxi boiler errors that appear is sharply reduced.

Do-it-yourself Baxi boiler repair - Video tutorial

Burner flame does not reach maximum power

The cause of the malfunction may be incorrect pressure setting in the heating system, a malfunction of the gas valve modulator, or a breakdown of the diode bridge.

Remedy: adjust the system parameters using the boiler operating instructions.

The boiler starts and immediately stops working

The reason is low gas pressure in the gas pipeline.

Remedy: reduce the incoming gas pressure to five mbar (standard - twenty-five mbar).

Weak heating in the hot water supply system

The reason for this is the incomplete opening of the three-way valve or its breakdown. To confirm a valve malfunction, you should allow the system to cool, close the shut-off valves of the heating system, then turn on the boiler in hot water supply mode. If the valve is faulty, then heating in the heating system will occur simultaneously with the DHW.

8450a73603b914af9982af52fad3309c.jpe

When igniting a “popping” sound is heard in the boiler

This noise appears due to: insufficient gas combustion (minimum pressure adjustment is necessary); changes in the distance from the gas supply to the igniter during careless transportation of the Baxi boiler (the gap should be adjusted by setting it to 4-5 mm); excessive draft (use a damper to reduce the draft in the boiler).

How to adjust the gap between the burner and the igniter

Open the front panel and completely remove it from the boiler. Remove the damper from the inspection hole. Behind it is an igniter

To change the gap size, you need to unscrew the screw that secures the igniter electrode, then remove it and carefully bend the electrode. Then we install it in place and close the hole flap

A sharp decrease in coolant temperature in the circuit

The reason for this is: clogged filters (they need to be cleaned or replaced); damage to pipes, radiators, their clogging or freezing (the malfunction must be identified and replaced or the defective section of the pipeline must be cleaned).

How to clean the primary heat exchanger with your own hands (video)

We drain the water by unscrewing the tap on the boiler on the right. If possible, drain the water from the heating system. For cleaning we use a device called Jelly. We connect the pipes of the device to the heating pipes of the baxi. Unscrew the cap on the device and fill in cleaning liquid. We turn on Zhel in the electrical network. Over the course of a couple of hours, use the knob on the device to switch the direction of the washing liquid “forward - backward”. After two hours, turn off the device and unscrew the tap to drain water from the baxi boiler. We remove the hoses, making sure that the washing liquid flows back into the device. We connect the boiler to the system and fill it with coolant. Cleaning the boiler will remove scale from its parts and prevent clogging and breakdowns.

Cleaning the secondary heat exchanger (heating circuit)

We use the washing device again. We connect it to the boiler and turn it on. The gas tap should be closed and the hot water tap should be opened. And after that, turn off the cleaning device. Thus, the liquid will be driven along a short circuit of the system.

Before installing the boiler, operating it or repairing it, be sure to consult a specialist. Despite all the positive qualities of baxi boilers, they, like all equipment, have their own margin of safety and service life. In this article, we looked at the main types of breakdowns, and also saw how to repair Baxi boilers with your own hands. We wish you and your boilers success.

Clocking of a Baxi double-circuit gas boiler in DHW hot water supply mode

The operating manual for the Baxi double-circuit gas boiler states that with the factory settings for a maximum power of 24 kW, the boiler provides water heating for a temperature difference of dT = 35 °C, with a maximum hot water flow of 9.8 l /min.

In a house with a boiler connected to the central water supply, the following results of measuring the maximum hot water flow were obtained: through the bath mixer horn 6 l/min, in the washbasin 4 l/min, in the kitchen sink 5 l/min.

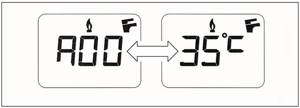

You can find out the maximum flow of hot water in the taps yourself if you use the information menu of the Baxi Main Four boiler. Open the hot water taps one by one and observe the flow rate in the information menu, Line A08 : current value (l/min x 10) of domestic hot water flow.

Usually, in order to save money, users do not open the water taps to full flow.

Products for the garden, garden and vegetable garden

⇆

Obviously, the difference between the factory settings for the maximum boiler power in DHW mode, designed to heat 9.8 liters per minute, and the power required to heat the actual flow rate at the tap, will be significant.

This leads to cyclical (clocking) heating of hot water. The boiler burner in DHW mode periodically turns on and goes off. Accordingly, either cold or hot water comes out of the tap.

For comfortable use of hot water, it is necessary to adjust the boiler power in DHW mode . This can be done through the service menu. Line F09 - maximum useful power of the DHW system (0-100%). Line F16 - minimum useful power of the DHW system (0-100%).

Read more: Either cold or hot water comes from the boiler

System errors

When a malfunction occurs in the Baksi double-circuit wall-mounted gas boiler, an error code is displayed on its electronic display, which can mean one of two things: either blocking the operation of the heating device or turning on the standby mode.

In the first case, you need to manually restart the boiler. The device can be blocked when problems are detected affecting the main parts of the system, which can cause harm not only to the equipment, but also to the health of its owner. Such errors include excessive heating of the boiler, insufficient or reverse draft, as well as its absence. If gas does not flow into the storage tank, the equipment also becomes blocked. Sometimes this problem resolves itself, and then the device turns on automatic startup mode.

Code E01 - burner sensor

Code E01 appears on the display when the sensor monitoring the burner operation reacts. This error can be caused by a number of reasons:

- gas stopped supplying to the burner;

- there is no correspondence between zero and phase;

- sensor is disabled;

- the sensor needs cleaning or repair;

- malfunction in the ignition device;

- the gas supply valve has failed;

- the electronic board does not work;

- there is not enough air to maintain the flame;

- There is not enough gas pressure for combustion.

If the sensor is triggered involuntarily, the boiler will continue to operate as usual. If the error repeats, it is better to ask for advice from a gas equipment repair specialist. This fault code indicates problems in the chips, and trying to fix the problem yourself may lead to undesirable results.

E10 - water cycle indicator

Code E10 relates to sensors that monitor the operation of pumps and regulate the water cycle in the system. Such a cipher can diagnose the presence of the following problems:

- pressure decreased;

- the conductivity between the relay and the board is broken;

- the pressure switch does not function properly;

- malfunction of the pump sensor;

- the pump itself needs repairing;

- the heat exchanger is dirty.

E96−98 - electronic board problems

The remaining Codes E96, E97, E98 indicate problems in the operation of the electronic board. If they appear on the display, the owner should not take any action and immediately call a repairman, because only an experienced specialist can deal with them without outside help.

Fixing problems with household appliances is a kind of treatment. There are simple diseases that a person can get rid of on their own, but for complex diagnoses it is better to consult a doctor. But both can be prevented with timely prevention. This also works in the case of preventing malfunctions of the Baksi wall-mounted double-circuit gas boiler.

26982f2c5b2b24607a10bb10cc545ead.jpe 9faf437d16aaf8e34bdda6d0dfe78f19.jpe

Regular service and maintenance of Baxi boilers at E-tech:

Modern heating units are distinguished by high reliability, which is due to the use of the latest technical solutions and materials, as well as the increasingly widespread use of control and protective automation. However, relying only on the quality of the equipment is wrong. Any manufacturer will say that only regular service will help your boiler maintain excellent operating parameters and operational safety for many years. In addition, it is the service agreement with a certified organization that is the main requirement for maintaining the warranty on the equipment installed at your facility.

The persistent reminders about the need for regular maintenance of boiler equipment are not at all accidental - every boiler is a potential source of danger. You should not wait until the Baxi boiler itself signals the need for service, because if events develop favorably, this will simply trigger the automatic warning system (for example, Baxi Main

has electronic protection against scale formation, which gives a signal when it is necessary to clean the heat exchanger); in the worst case, the heating unit will fail.

Positive Features

Malfunctions of the Baksi boiler, of course, sometimes occur, but it still has more positive features - automated operation, environmental friendliness, reasonable cost, ease of operation, and maximum adaptability to difficult conditions. The last feature is relevant for Russia.

Because the equipment is automated, it can operate for a long time according to a specific program. This is convenient for country cottages in which the owners do not live permanently, but from time to time. When such boilers operate, carbon dioxide is released into the air, which is absorbed by plants. This indicates the environmental friendliness of such devices. The manufacturer has made sure that the buyer repairs Baxi boilers as rarely as possible. The main faults and solutions are described below.

During the manufacturing process, equipment is equipped with protective chips that are capable of leveling out voltage fluctuations in the network.

What is a gas boiler error?

During the operation of the equipment, a situation may arise when the automatic protective equipment is triggered. That is, the gas boiler detects that something is not working correctly and is blocked. To facilitate finding the cause of a malfunction, most gas boilers are equipped with a fault display system for initial diagnosis. In some cases this may be a combination of LED signals, in some cases an error code is displayed on the display, in some cases the display shows the specific cause of the malfunction (some premium boilers). The malfunction itself can be critical (emergency), or minor - requiring simple user actions. Also, in some cases, the operation of the boiler is blocked until the error is reset (for example, lack of water pressure in the boiler), and in other cases, the error must be reset by the user (for example, problems with igniting the burner).

Most often, the procedure for dealing with errors is described in the user manual, which is supplied with the gas boiler. It also indicates how the error is reset.

Malfunctions and error codes of the Baxi gas boiler

The microprocessor control and monitoring system of a modern gas boiler detects a malfunction and displays an error code indicating a particular malfunction in the operation of the boiler components and assemblies.

Error code on the display of the BAXI gas boiler. The display backlight flashes synchronously with the displayed fault code.

The boiler control system reacts differently to the occurrence of a malfunction. Depending on the possible consequences of the malfunction:

- The operation of the boiler is immediately blocked in an emergency. The boiler turns off. Error codes: E01, E02, E04, E07, E25, E27, E40, E41, E42, E43, E50, E62, E65. It is necessary to eliminate the malfunction and restart the boiler using the “R” button (keep pressed for at least 2 seconds).

- The boiler operation stops abnormally, but is not blocked. After the problem is resolved, the boiler will automatically continue to operate with the previous user settings.

- There are errors - warnings that do not require immediate intervention, in which the boiler operation does not stop.

MORA boiler and EFD-503 control units

Case from practice. Several EFD-503 units came in for repair. Such blocks are installed directly on the gas fittings and are used in boilers MORA, BERETTA, PROTHERM and others. So, specifically in this modification of the block, the error reset occurs through the closure of two contacts on the block itself, and the switching is displayed on the control panel with a button. The client says I change the blocks regularly once a year. Tired of replacing it (the price of 1 unit is approximately 10 thousand, and there are two of them in the boiler), he turned to us for repairs. In fact, faults were identified and corrected on the units provided - the units were sent back. Installation result: 1 unit works, two worked for 20 seconds, went into error and no longer work.

The probability that the control unit only worked for 20 seconds after repair is very small (even more so if there are two units at once). A more suitable description of the malfunction is “phasing error” - non-compliance with the polarity of the connection. I ask - what actions does the boiler perform before the error appears? The answer is none, just a mistake and that’s all. Let me explain that the error should be reset, maybe you have a bad contact on Reset. No, about the theory of contact - we know that the blocks are faulty. Okay, send it. The client sends two blocks after repair and two additional blocks from the “faulty” collection. We first install the blocks that were repaired on the stand. Blocks are in error. We reset the error - ignition is in progress, the valve opens, the unit sees the flame - it is working! We deliberately create an error on the block, reset it again - there is ignition, the board works according to logic. We check all four blocks in the same way - everything is in error, after a reset everything works. We provide information to the client about which contacts are closed on the block to reset the error, he takes the “faulty” block from the collection and voila! - works. All questions have been resolved.

And this case is not the only one. This happens often, and on different boilers.

“Baksi” is the name given to the line of gas boilers from the Italian company. If you are faced with the task of ensuring a comfortable microclimate in the room, then Baksi boilers are the best solution. The installations of this manufacturer have many advantages. The most important thing is that Baxi boilers are economical. In addition, they can be used for a long time and do not make noise during operation. These units perform well during use and are also easy to use. The reasonable price of this equipment makes it accessible to most consumers.

Troubleshooting

If the flame is not powerful due to incorrect operation of the gas valve, the pressure in the system must be adjusted. This must be done in accordance with the requirements of the instructions. The diode bridge often fails. Then what is required is not repair, but complete replacement.

"Baksi" fee

If the coolant is not heating well, check the pressure at the outlet of the gas valve. Change the position of the regulator and try to start the boiler again. That's all the repairs.

If there are deviations in the sensor readings, they need to be changed.

When the temperature in the DHW is unsatisfactory, check the functionality of the three-way valve. Wait until the water has cooled completely, then close the heating taps, and then turn the heater back on to hot water supply mode. If the heating starts heating up, the valve is faulty. It needs to be replaced.

When strong pops are heard at the moment of ignition, the reasons for what is happening are as follows:

- Gas supply pressure too low.

- Increased distance from the nozzle to the igniter (due to improper transportation).

In such cases, the gap needs to be adjusted. It should be within 4-5 mm. Open the front panel, unscrew the screw securing the electrode, remove the electrode, bend it a little and put it in place.

Error codes and causes of malfunctions of Baxi wall-mounted gas boilers

Summary list of fault indications for Baxi wall-mounted gas boilers equipped with a liquid crystal (LCD) display, models Eco Compact, Four Tech, Eco Four, Main Four, Main 5.

E01 (01E) - flame control sensor. Boiler blocking after three unsuccessful ignition attempts:

- There is no gas, the gas valve is closed, low pressure in the gas pipe.

- The phase and neutral wires of the electrical network for phase-dependent boiler models are mixed up.

- The ionization flame control electrode is faulty or dirty.

- The ignition unit or electrodes are faulty.

- The gas valve is faulty or incorrectly adjusted.

- Lack of air for gas combustion in the boiler burner

E02 (02E) - heating circuit temperature sensor. Overheating of the coolant in the heating circuit:

- Temperature sensor malfunction.

- Insufficient heat transfer to the sensor - it is recommended to apply thermal paste where the sensor body adheres to the adjacent part of the boiler.

- Insufficient coolant circulation through the heat exchanger due to pump malfunction or air in the system

E03 (03E) - draft sensor (thermostat in boilers with an open or pneumatic relay in boilers with a closed combustion chamber). Insufficient draft in the chimney or flue system:

- Traction sensor malfunction.

- Fan malfunction.

- Reducing the cross-section of a chimney or chimney.

Only for boilers with an open combustion chamber. As a result of the draft failure, the flue gas thermostat overheated and, as a result, an emergency shutdown of the boiler occurred. Check the chimney and whether it has the required draft.

Troubleshooting tips:

Check the chimney for the tightness of the seams and connectors, for compliance with the manufacturer’s recommendations for length and diameter, for the absence of obstacles in the smoke channel (clogging, icing), for blowing and backing of draft by the wind (for the location of the chimney head relative to the roof)

Check the free flow of air into the room where the boiler is installed. There must be an inlet from the street or from an adjacent room with windows.

For a boiler with an open combustion chamber, if the air comes directly from the street, then a supply ventilation opening of 8 cm2 per 1 kW of boiler power is sufficient, but not less than 200 cm2. If the air supply comes from an adjacent room of the building, then the minimum size of the supply ventilation opening should be determined at the rate of 30 cm2 per 1 kW of boiler power. The supply valve in the room with the boiler is installed at a height of no more than 30 cm from the floor. This could be a ventilation grille in the wall or door, or just a gap under the door.

Note: Electric hoods are prohibited in the boiler room.

Check the functionality of the flue gas thermostat.

E04 (04E) - flame control sensor. Frequent, more than six times, loss of flame on the burner:

- The reasons listed in E01 and E42 are

- Exhaust gases entering the boiler supply air duct.

E05 (05E) - heating circuit temperature sensor. No signal from the sensor:

- Malfunction of the heating circuit temperature sensor or open circuit with the electronic board.

E06 (06E) - DHW circuit temperature sensor. No signal from the sensor:

- Malfunction of the DHW circuit temperature sensor or open circuit with the electronic board.

E07 (07E) - NTC flue gas temperature sensor. No signal from the sensor:

- Faulty flue gas temperature sensor or open circuit with the electronic board.

E08 (08E) - electronic board. Error in flame control circuit:

- There is no grounding of the electronic board, there is no contact in the circuit between the board (connector X4) and the power supply box.

- Malfunction of the electronic control board.

E09 (09E) - electronic board. Gas valve safety circuit error:

- Faulty electronic control board.

E10 (10E) - minimum pressure switch for the heating circuit. Insufficient coolant pressure in the heating circuit:

- Check the pressure gauge readings and, if necessary, add water to the heating circuit.

- Minimum pressure switch faulty.

E12 (12E) - differential hydraulic pressure switch. There is no signal from the pressure switch:

- The circulation pump does not work.

- The heating system is contaminated.

- Insufficient coolant circulation (filter clogged, hydraulic resistance of the heating system is high).

- Malfunction of the pressure switch (membrane, microswitch, impulse tube)

E13 (13E) - differential hydraulic pressure switch. False signal from the pressure switch: stuck contacts of the pressure switch microswitch.

E22 (22E) - electronic board. Boiler shutdown due to low voltage in the electrical network, less than 162 V:

- The voltage in the electrical network does not meet the standard.

- The electronic board is faulty.

E25 (25E) - heating circuit temperature sensor. The rate of temperature increase in the heating circuit is more than 1 oC/sec:

- The circulation pump does not work.

- The heating system is contaminated.

- Insufficient coolant circulation (filter clogged, hydraulic resistance of the heating system is high).

- The heating circuit temperature sensor is faulty.

E26 (26E) - heating circuit temperature sensor. Exceeding the coolant temperature by more than 20 °C from the set one:

- The circulation pump does not work.

- The heating system is contaminated.

- Insufficient coolant circulation (filter clogged, hydraulic resistance of the heating system is high).

- The heating circuit temperature sensor is faulty.

E27 (27E) - DHW circuit temperature sensor. Incorrect sensor position:

- The DHW circuit temperature sensor is installed incorrectly.

- The DHW circuit temperature sensor is faulty.

E32 (32E) - temperature sensors for the DHW and heating circuits. Exceeding the heating temperature above 95 ° C twice in a row. Reducing the water temperature in the DHW circuit by 3 °C:

- Presence of scale in the bithermic heat exchanger.

- Malfunction of the NTC temperature sensor of the DHW circuit.

E35 (35E) - flame control sensor. Flame presence signal after the burner is turned off:

- The gas valve is faulty and does not completely shut off the gas supply.

- Moisture on the electronic board of the boiler.

- Interference coming from the electrical network. It is necessary to install a voltage stabilizer with galvanic isolation from the electrical network, and check the proper grounding of the boiler.

E36 (36E) - flue gas temperature sensor. The flue gas NTC sensor is faulty.

E40 (40E) – flue gas temperature sensor. GDC does not pass cyclic flue gas temperature tests:

- The flue gas NTC sensor is faulty.

- Obstruction of the chimney or air supply channel.

E41 (41E) - gas valve. GDC does not pass cyclic tests for ionization current:

- There is no gas, the gas valve is closed.

- The flame control electrode is faulty or dirty.

- Gas valve is faulty.

- Gas valve not calibrated.

E42 (42E) - fan. GDC fails initial tests. Boiler blocking after three unsuccessful attempts:

- The fan is faulty.

- Obstruction of the air supply channel.

E43 (43E) - electronic board. Blockage due to possible blockage of the air supply or too low gas pressure:

- Reasons described in E40 and E41.

- Inconsistency of the quality of supply electricity with the requirements of the standard (low voltage, interference)

E50 (50E) – NTC flue gas temperature sensor. Blockage due to flue gas temperature rising above 180 °C:

- Insufficient coolant circulation.

- The flue gas NTC temperature sensor is faulty.

E55 (55E) - gas valve. Gas valve not calibrated. It is necessary to perform calibration (parameters F45 and F48 of the service menu).

E62 (62E) - flame control electrode. Triggering of safety devices in the absence of stabilization of the flame signal or flue gas temperature:

- The flame control electrode is faulty or dirty.

- The NTC flue gas temperature sensor is faulty.

E65 (65E) - electronic board. Triggering of safety devices due to frequent, 10 times within 10 minutes, clogging of the air supply channel: reasons described in E40 and E41.

E96 (96E) - electronic board. Low voltage in the power supply network.

E97 (97E) - electronic board. The voltage frequency in the electrical network differs from 50 Hz.

E98 (98E) - electronic board. Internal error on the electronic board. Incorrect board parameter configuration:

- The parameters have not been configured depending on the boiler type.

- Parameters F03 and F12 of the service menu are set incorrectly.

- Electronic board malfunction.

E99 (99E) - electronic board. An internal error on the electronic board, which accumulates as a result of interference from the power supply network and leads to an independent reboot of the boiler.

The “exclamation mark within a triangle” icon flashes on the display . The boiler is operating at minimum power. The chimney/air duct is clogged or the gas inlet pressure is too low. To reset the fault, temporarily turn off the request for heat production from the heating or DHW system. If the problem persists, contact an authorized service center.

The “radiator” and “faucet” icons flash alternately on the display Scale has formed or the DHW temperature sensor is incorrectly positioned. Attach the clamp of the DHW temperature sensor to the pipe and check the contact with the temperature-sensitive element. Check the DHW temperature sensor (*). Check the primary heat exchanger for scale (when drawing water from the DHW circuit, the temperature of the domestic water leaving the boiler does not increase, while the temperature of the heating water supply to the heating circuit rises rapidly; in addition, the water flow is too low due to partial blockage heat exchanger).

DHW temperature sensor and heating supply temperature sensor: resistance value is about 10 kΩ at 25 °C (resistance decreases with increasing temperature). Flue gas temperature sensor: resistance value is approximately 49 kΩ at 25 °C (resistance decreases with increasing temperature).

More articles on this topic:

⇒ How to reduce the high gas consumption of a boiler for heating a house ⇒ DHW boiler for a double-circuit boiler or water heater ⇒ Setting the pressure in a heating system with a membrane expansion tank

More articles on this topic

- Do you need heated floors in a private home?

- Bearing capacity of soils at the base of the foundations of a private house

- Attic floor on wooden beams

- Installing a boiler in a private house in the attic

- Should I build a house on one floor or two?

- Insulated, thermally insulated foundation is the best for a home

- There is formaldehyde in the house, the source is chipboard, OSB, plywood, mineral wool

- How to remove the smell of hydrogen sulfide from water in a well, boiler, well

Maintenance and cleaning

If the system is heavily clogged, the temperature drops and the efficiency of the boiler sharply decreases, which leads to a deterioration in the microclimate in the house and excessive gas consumption. To extend the life of a Baxi Main boiler or another model, as well as to maintain high efficiency, it is necessary to periodically clean the heat exchanger using a special device and cleaning fluid.

Video: flushing the Baxi Main boiler

Repair and maintenance of boilers when error codes e01, e03, e10 appear can be done with your own hands. More complex faults that involve complex adjustments or replacement of elements require calling a gas equipment specialist. In addition, it is better to contact a service center if the boiler is under warranty, since independent repairs will void it.

Errors and their codes

Error codes that may occur during the operation of Baksi gas boilers can be divided into two groups:

- complete blocking of equipment operation;

- switching the device to standby mode.

If the installation is completely blocked, you will need to restart the boiler manually. The blocking is activated if serious problems occur in the boiler operation, which can pose a serious danger to human health. Failures that cause the boiler to block include overheating of the equipment, and in addition, lack of draft. Blocking also occurs if there is no gas supply. The error resolves itself in rare cases. If this happens, the device starts in automatic mode.

Error E01

This error is the most common. When the flame control sensor is triggered, this code is displayed. Several reasons can lead to its appearance:

- no gas supply;

- there is no correspondence between phase and zero; this reason is relevant for phase-dependent models;

- no contact with flame sensor;

- the sensor is dirty or faulty;

- there are malfunctions in the ignition system;

- the gas valve is faulty or the electronic board is faulty;

- air access is insufficient for normal combustion;

- The gas pressure in the system is insufficient.

If this code appears on the display, then the first thing to do is check whether the sensor is connected correctly. It is also worth checking the gas supply. If everything is normal, then in this case you can press R. It should be held for 3 seconds.

If accidentally triggered, the equipment will continue to operate normally. If the error continues to appear, then in this case you should contact a specialist. Note that the occurrence of this error is associated with problems in the electronics. If you try to solve the problem on your own, then everything can end disastrously for gas equipment.

Error E10

Another common mistake is E10. The main reason for its occurrence is sensors that monitor the operation of pumps and monitor water circulation. This error may appear on the unit display in the following cases:

- the coolant pressure in the system has decreased;

- there is no contact between the board and the pressure switch;

- pressure switch is faulty;

- the pump operation sensor has become faulty;

- there are malfunctions in the pump;

- heat exchanger clogged.

If this error occurs, you should not try to fix it yourself. Self-repair is acceptable if the pump needs to be replaced. Carrying out this event will not be difficult. You can also clean the filters without assistance. All other work related to the repair of the Baksi boiler should be performed by an experienced specialist.

Errors E96, E97, E98

Urgent repairs by a qualified specialist are required if the gas boiler display shows errors E96, E97, E98. If they occur, it is unacceptable for the owner of the equipment to interfere with the operation of the boiler. The prohibition on intervention in the event of these errors is due to the fact that these three codes appear when the electronic board has become faulty.

Menu for displaying information about the operation of the Baxi boiler

To display a menu of information about the operation of the boiler on the display located on the front panel of the boiler, press the “i” button for at least 6 seconds.

The “INFO” function is activated and the designation of the first line of the information menu “A00” appears on the display, which is replaced by the display of the temperature parameter.

To move through the lines of the information menu, press the buttons (tap +/-).

BAXI Main Four |Baxi Eco Four | BAXI Four Tech:

Line A00 : effective value (ºС) of the domestic hot water temperature (DHW system);

Line A01 : value (ºС) of the outside temperature (with an outside temperature sensor connected);

Line A02 : Instantaneous value (%) of the gas valve control signal;

Line A03 : value (%) of power (MAX R);

Line A04 : set value (ºС) of the supply temperature to the heating system;

Line A05 : effective value (ºС) of the water supply temperature to the heating system;

Line A06 : set value (ºС) of domestic hot water temperature;

Line A07 : value of % flame level (0 - 100%);

Line A08 : current value (l/min x 10) of domestic hot water consumption;

Line A09 : last error detected in the boiler operation.

BAXI Main 5:

A00 : current value of the heating water supply temperature (°C);

A01 : current value of domestic hot water temperature (°C);

A02 : current outside temperature value, in °C (with an outside temperature sensor connected);

A03 : current value of flue gas temperature (°C);

—>

A04 : Gas valve control signal instantaneous value (%);

A05 : power indicator, in % (MAX CH);

A06 : heating water temperature setpoint (°C);

A07 : Domestic hot water temperature set point (°C);

A08 : last malfunction in the boiler;

A09 : not used; A10 : not used.

The “INFO” function remains active for 3 minutes. To exit this mode before this time, press the “i” button for at least 5 seconds or turn off the power supply to the boiler.

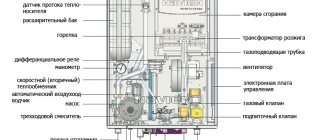

Design and operating principle

The best option for apartments is a wall-mounted double-circuit boiler. Such models are produced in several series, differing in power, smoke removal system and type of gas burner. For apartments, it is recommended to choose a device with forced exhaust. Calculating the power is simple - divide the square footage of the living space by 10. You will get the required boiler power in kW.

Small boilers of the Main series with a bithermic heat exchanger, to the tubes of which copper plates are spot welded. This increases efficiency. The design includes an expansion tank and a circulation pump. Filtration of incoming water is provided. The heat exchanger is installed on top of the firebox.

The combustion chambers of Baksi boilers are made of metal and covered on the outside with a heat insulator.

The system operates in the same way as all gas boilers. The signal from the thermostat goes to the pump, which creates a vacuum in the return. Water under low pressure (less than 0.45 bar) enters the heating system. Ignition occurs automatically.

The output power increases smoothly with increasing temperature. When it reaches the set value, the operating mode will switch from heating to modulation. When the temperature drops, the thermostat will command the inlet valve to open and the water will be heated again.

If the burner shuts down due to excess power immediately after startup, then restarting is allowed after three minutes.

Baksi device

Hot water supply works like this. Water is supplied through a three-way valve that shuts off the heating main and enters the secondary circuit. There it is heated and supplied to the taps for personal use.

But no matter how problem-free the Baksi is, it also sometimes breaks down.

Heat exchanger clogged (reduced throughput)

Often the fouling of the internal walls of the heat exchanger with scale or mud deposits is the cause of problems with hot water. If tap water does not undergo pre-filtration (rough cleaning) and the temperature of the hot water is too high, the walls of the heat exchanger become overgrown with scale and dirt over time, reducing their thermal conductivity and flow area. Each time the user increases the DHW temperature on the boiler more and more in order to obtain the desired result on the mixer. As the temperature rises, scale forms even faster and, as a result, the temperature of the boiler's hot water supply is at its maximum, and the water does not heat up enough. This process has a particularly negative effect on a boiler with a bithermic heat exchanger. Plate heat exchangers are easy to clean.

Main components and principle of operation

The Baxi line of gas boilers includes a number of models that differ in volume, type of installation, and functionality. However, the principle of their operation is generally similar.

The most popular boiler models:

- Baxi Luna (Baxi Luna);

- Baxi Slim (Baxi Slim);

- Baxi Main four (Baxi Main for);

- Baxi Main 24 fi (Baxi Main 24 fi);

- Baxi Nuvola (Baxi Nuvola);

- Baxi EKO four (Baxi Eco for, Baxi Ecofor).

According to the type of installation, gas boilers are divided into wall-mounted and floor-mounted.

The wall heater is fixed using special brackets in any convenient place, which makes wall-mounted models very popular. Chambers with a closed combustion chamber, for example, Baxi Main 24 fi, have increased efficiency and environmental friendliness in a small size.

The volume of coolant in the heat exchanger depends on the model, in the most powerful it reaches 80 liters. In terms of functionality, models can be single-circuit - for heating, or double-circuit - in addition to the heating system, they also supply the hot water circuit.

They can operate both on natural main gas and on liquefied gas from cylinders, making it possible to install them in non-gasified areas. The boilers are completely volatile and require connection to an alternating voltage network.

Operating principle of gas heating equipment:

- Sensors analyze the temperature in the room, and when the minimum value is reached, they send a signal to turn on the circulation pump.

- The pump turns on, creating a vacuum in the return pipe, and the heated water enters the heating system.

- The microprocessor sends a signal to ignite the burner at low power, it gradually increases, and the coolant is heated to a temperature specified by the user.

- Then the boiler operates in modulation mode - it maintains the temperature within the specified limits, turning on when it drops.

At any of these stages, a malfunction may occur, which the boiler notifies using coded errors.

Possible malfunctions of the Baxi Main for, Baxi Main 24 fi, Baxi Eco for boiler:

- the burner goes out immediately after switching on or during the heating process (error codes e01, e04);

- ignition of the boiler is impossible;

- overheating occurs (error code e02);

- The water pressure in the system drops (error code e10);

- extraneous noise is heard during operation;

- there is popping noise in the combustion chamber;

- the coolant does not heat up to the set temperature;

- One of the sensors fails (different error codes may appear).

The most common causes of certain malfunctions, according to service center specialists, may be:

- improper installation of the heating system;

- errors when connecting the boiler to the electrical network;

- water getting into the circuit board, burner or electrical part of the boiler;

- low quality of network water or other coolant;

- sudden drop in gas pressure;

- The network voltage drops or increases unacceptably.

The resulting malfunctions can be easily eliminated by adjusting the boiler, but sometimes it is necessary to call a specialist to replace boiler parts.

If you are not confident in your skills in setting up gas equipment, it is better to contact a service center. Incorrectly performed repairs can lead to complete failure of the boiler!

BAXI gas boiler service menu commands

In the service menu lines you can change some settings for the operating mode parameters of the Baxi gas boiler.

BAXI Main Four | BAXI Eco Four | BAXI Four Tech:

Line F06 - setting the maximum temperature (°C) of the heating system: 00 = 76°C (burner switches off at 80°C); 01 = 45°C. Factory setting = 00.

Line F08 - maximum net power of the heating system (0-100%): 80 - natural gas; 100 - liquefied gas. Factory setting = 80.

Line F09 - maximum useful power of the hot water supply system (0-100%): 80 - natural gas; 100 - liquefied gas. Factory setting = 80.

Line F10 - minimum useful power of the heating system (0-100%): 20 - natural gas; 00 - liquefied gas. Factory setting = 20.

Line F11 - burner waiting time between two starts (01-10 min): 00=10 sec. Factory setting = 03.

Only BAXI Main Four:

Line F14 - test to check the correct position of the hot water sensor: 00 - off; 01 - always on. Factory setting = 01.

Line F16 - minimum useful power of the hot water supply system (0-100%): 20 - natural gas; 00 - liquefied gas. Factory setting = 20.

BAXI Main 5:

Line F06 - Setting the maximum supply water temperature to the heating circuit (°C) 000=76 °C (burner shutdown at 81 °C) 001=45 °C (burner shutdown at 50 °C). Factory setting =000.

Line F08 - Max. power in heating mode (0-100%). Factory setting for boiler model 24F =055; for model 18F =100; for model 14F =050.

Line F09 - Max. power in DHW mode (0-100%). Factory setting =100.

Line F10 - Min. power in heating and hot water mode (0-100%). Factory setting =100.

Line F11 - Waiting time before turning on again in heating mode 000=10 seconds - 001...010 = 1...10 minutes. Factory setting =003.

Line F14 - Checking the correct position of the DHW sensor: 000=Disabled; 001=Always on. Factory setting =001.

Line F18 - Unlocking parameters for SERVICE. Factory setting =000.

I recommend recording all settings changes you make in the menu lines. Attach the notes to the instructions for the boiler.