The latest generation boiler equipment has smart automation that turns off the device if a problem occurs, and also informs the consumer about possible malfunctions. For this purpose, the manufacturer supplies heating equipment with displays, with the help of which the user receives information about the main error codes.

It should be noted that one of the promising areas in the development of engineering communications is the use of gas for heating apartments and houses. Manufacturers offer their products in a wide range, which allows you to choose the right device for any room. As an example, we can consider the Baksi boiler, the E10 error on the display of which is a fairly common occurrence. This equipment can be installed in any room; it is suitable not only for residential buildings, but also for industrial organizations. The premises where the device is installed must comply with certain standards. For example, a boiler room should have a volume of 15 m3, and the ceiling height should not be less than 2.2 m. With the help of good ventilation, it will be possible to guarantee intensive air exchange, which is necessary for the operation of heating equipment.

Troubleshooting instructions

If you purchased a Baxi boiler, error E10 may become a reality for you. Therefore, before starting to operate such equipment, it is necessary to understand the main types of problems. They are indicated by codes that can be divided into two groups, namely: the equipment goes into standby mode or completely blocks the operation of the device.

In the latter case, the problem can be solved by simply rebooting the unit. Such an error indicates that serious problems have arisen that can create dangerous situations for human life and health. That is why such a failure should be treated with special attention. Among them, the lack of traction, lack of fuel supply, and overheating of the device should be highlighted. If you purchased a Baxi boiler, error E10 can resolve itself. However, without human intervention such an outcome is unlikely. But if this happens, then it can be argued that the automation turned on the device on its own.

Description of error E10

The most common problem is error code E10, which you can see on the display under some circumstances. The reason may be caused by incorrect operation of the sensor, which monitors the circulation of coolant in the system and the functioning of the pumping equipment.

Automation can work in cases where the coolant pressure is reduced to a critical level. This can also be caused by a lack of contact between the pressure switch and the board. In some cases, consumers who use a Baxi boiler experience error E10 for this very reason. It can also be caused by a malfunction of the pressure switch or incorrect operation of the pumping equipment sensor. This code may also indicate a malfunction of the pump itself. Sometimes this problem is caused by a clogged heat exchanger or filter system located in the heating circuit.

Decoding

Error E10 is generated by the electronic unit of the Baxi boiler when the OB pressure switch is triggered . Occurs when the pressure in the heating circuit drops below a critical value (0.5 bar) . The relay contacts open, and the automatic protection system stops the unit upon an emergency signal. Knowing this, it is not difficult to understand the method for eliminating error e10.

p, blockquote 2,0,1,0,0 —>

Procedure

Step 1

Check the readings of the control device

If the boiler pressure gauge needle leaves the green sector (turns to red), bring the coolant volume to normal . The feed tap of any version of Baksi is located at the bottom of the heating installation, next to the connection pipe for the cold water pipe. It opens counterclockwise until the characteristic noise of incoming liquid appears. At the same time, the pressure is monitored using the Baksi boiler pressure gauge. When the arrow moves to the green zone (˃1 bar), error e10 will disappear , the tap must be closed: the unit will start on its own.

p, blockquote 3,0,0,0,0 —>

Check the pressure gauge on the Baxi boiler

On a note! The pressure in the “cold” system when filled from cold water should be 0.5 bar less than in the expansion tank.

Master's advice

Step 2

Loop Condition Assessment

Pressure drop in a closed system , error E10 is caused by a leak. By inspecting the facility, it is easy to identify the problem area of the highway by wet spots on the floor. Particular attention should be paid to the joints. With regular hydraulic shocks, this is where the depressurization of the circuit occurs. Pipes, radiators, and equipment included in the heating circuit are subject to inspection.

p, blockquote 5,1,0,0,0 —>

A pipe is leaking in the heating system

Leakage in areas of shut-off valves (taps, valves, plugs)

If error e10 of the Baksi boiler appears infrequently (once every few months), but regularly, the leak is insignificant. A difficult case - a microcrack cannot be detected by inspection. Small droplets of liquid flowing from it do not have time to fall to the floor - they evaporate. To determine the location of the defect, you need to wait until the pipes and radiators cool down. After some time, a stain will appear under the damaged area.

p, blockquote 6,0,0,0,0 —>

![Keep an eye on the connections in the heating system [always]](https://azbremonta.ru/wp-content/uploads/sledite-za-soedineniyami-v-sisteme-otopleniya-vsegda.jpg)

Keep an eye on the connections in the heating system [always]

Step 3

Pressure switch testing

If filling the system does not remove the E10 error, then its probable cause is the pressure switch . The sensor in Baksi boilers is initially set to 0.45 bar. When the pressure in the heating circuit increases, its contacts close and the board receives a switch-on permission signal. Accordingly, a drop in pressure leads to a break in the circuit, and error E10 is issued, blocking the operation of the boiler in emergency mode.

p, blockquote 7,0,0,0,0 —>

Pressure switch in gas boiler baxi

On a note! On thematic forums there are recommendations from “experts” regarding the elimination of error E10: bypass the pressure sensor. The code will disappear, but there is no need to talk about the safe operation of Baksi after such a “repair”. A pressure switch excluded from the protection circuit will not react if the coolant volume critically decreases. As a result, overheating, failure of the heat exchanger and other structural parts. The cost of the device is about 20% of the price of the boiler. There is little benefit, since the problem is not completely solved. But the consequences are unpredictable, including significant material costs to eliminate them.

p, blockquote 8,0,0,1,0 —>

Step 4

Checking the expansion tank

Users forget about it, but it is this special tank that often causes error e10. The cavity of the tank is divided into 2 compartments, one is filled with nitrogen or air under pressure in the range of 0.8–1.2 bar. Non-compliance with this value is reflected in the correct operation of the system, as a result, error e10 is displayed: possibly due to a crack in the body, rupture of rubber goods or its adhesion to the wall of the vessel (if the tank has not been used for a long time). The defect can be determined by examining the “pear” by removing it from the tank. Membrane models RB cannot be repaired - only replaced. If the air pressure in the tank compartment is low, bring it to normal using a car pump.

p, blockquote 9,0,0,0,0 —>

Step 5

Board diagnostics

This is the last probable reason for the appearance of error e10 in the Baksi boiler. You cannot do it on your own, no matter what home-grown experts say. This is the case when you need to contact a service center. On-site repair consists of replacing the module and does not require much time. Full electronics testing is carried out on a bench in the workshop.

p, blockquote 10,0,0,0,0 —>

Solution to error E10

If the error mentioned above appears on the display of your boiler, it is not always advisable to fix the problem yourself. If the pump fails, then the only correct solution to the problem is to replace it; a home handyman will not have to call in specialists for this task. If you have a Baksi gas boiler installed in your house, error E10 may appear on the display when a failure of the above-described nature has occurred in the system. To solve the problem, you can also clean the filter system yourself. If you notice that the problems are related to other equipment components, then it is best to entrust the adjustment to professionals.

Error E01

A fairly common error code is the designation E01 on the display. It can be output by the equipment when the sensor that controls the flame is triggered. This error may occur when:

- lack of gas supply;

- lack of contact with the sensor;

- lack of correspondence between zero and phase in phase-dependent models;

- sensor contamination or malfunction;

- when the gas valve fails;

- when the electronic board fails.

Sometimes error E01 is caused by a malfunction in the ignition system or insufficient access of air, which must flow for normal combustion. If error E01 appears on the boiler display, this may also indicate insufficient fuel pressure in the system.

How to fix error E10 on a Baxi gas boiler: instructions, common problems

Gas boilers from the Baxi company have a well-thought-out automation system that allows you to turn off the device in emergency situations and informs the owner about problems. To do this, error codes appear on the screen. In order for the equipment to work properly, you need to know what this or that designation says and what should be done if it appears, for example, how to correct the E10 error on the Baksi boiler. The instructions will solve the problem in a short time.

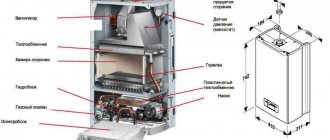

Main characteristics

Baxi equipment can be installed in buildings of any purpose. It is perfect for both city apartments and large private houses. However, the room in which the device will be installed must meet several criteria:

- Its area must be at least 15 cubic meters.

- The ceiling height is at least 2.2 meters.

- Availability of high-quality ventilation.

These parameters can be ignored if the choice was made in favor of a boiler with a closed combustion chamber. Such a device is a real mini-boiler room that meets all the necessary criteria and does not harm the environment.

The Baksi company produces many models of heating equipment and can offer units of various capacities. In Russia, the following boiler models are in great demand: Main Four 240 °F (Main For 240f), Eco Four (Ecofor), Luna (Moon).

Installation features

Baksi devices use gas as a coolant, and despite all its undeniable advantages, it is dangerous. Gas boilers require a professional approach. The slightest error in installation can lead to very negative consequences. Installation of the device should only be carried out by highly qualified specialists. List of problems that DIY work can lead to:

- Freezing of the device in the winter season.

- The occurrence of an explosion.

- Fire.

- Penetration of carbon monoxide into residential areas.

Of course, modern gas devices have a high-quality protection system, but even “smart” automation is not always able to cope with problems that arose due to unprofessional intervention. If we talk about a less serious outcome of the matter, the most common problem with self-installation is the incorrect operation of the equipment. For example, the device may not turn on and display error codes, despite the fact that the device is fully operational.

Baksi boilers are energy-dependent units. They are not able to function without being connected to the mains. The connection rules are quite simple and are no different from the requirements for installing a standard electrical device. The device is connected to a 220 V network; grounding is required.

Of course, if there is no grounding, the boiler will not turn on with a “bang” sound, but this may negatively affect the operation of the equipment. Quite often, the boiler displays error codes due to simple connection errors. If at the moment it is not possible to ground, you should purchase a stabilizer with galvanic isolation.

In addition to the need for grounding, there are other features when installing equipment. It is very important to follow these recommendations:

- In order for the boiler to function properly, the pressure must be 170-250 V. At a lower voltage, the equipment will turn off, and at a higher voltage, the varistor will burn out.

- The sinusoid should flow without disturbances. Such devices react very negatively to voltage surges. Professionals advise installing additional voltage stabilizers. When installing gas boilers, there is no need to use UPS devices.

- The connection must be made through a separate machine.

- If the model is phase-dependent, it is necessary to maintain the correspondence of phase and zero.

There is a whole system for classifying faults. However, all error codes can be classified into two categories:

- Complete device locking.

- The device goes into standby mode.

In cases of complete blocking of the equipment, a manual restart of the device is necessary, since this mode starts in case of serious problems that pose a danger to life and health. Such problems include: overheating, lack of necessary draft and coolant supply. In exceptional cases, the breakdown can be corrected on its own and the automation will turn on the device.

In order to correct the problem in a timely manner, you should study the instructions for errors on the Baksi boiler. Very often, automation displays codes e001, e03 and e10.

If error 01 appears on a Baxi gas boiler, there may be several reasons for this. The most common problems encountered are:

- No coolant supply.

- Zero-phase mismatch in a phase-dependent device.

- There is no contact with the flame control sensor.

- The flame sensor itself is dirty or damaged.

- Problems in the ignition system.

- Damage to the electronic board or gas valve.

- Lack of air for continuous combustion.

- Lack of gas pressure in the boiler.

Before eliminating error E01 on the Baksi boiler, you should check whether the sensor is connected correctly and whether there is a gas supply (sometimes its lack can be associated with trivial problems, for example, the gas tap is turned off). If everything is in order, you should press the R key and hold it for a few seconds. If the automation works by mistake, the device will start working normally. If the problem persists, it is best to contact a professional. Error e01 may be due to an electronic malfunction.

The e03 designation may appear on its own from time to time and then also disappear. If this error occurs on Baksi boilers, the instructions will be as follows: you need to thoroughly clean the blades, since a large amount of dust could accumulate on them. Sometimes the grease of the radiator bushing and axles wears out (they are located on the back side of the engine). This may be due to the fan starting to move slowly. If after cleaning the situation does not improve, you should contact a service center for help. In addition, you need to check the device settings.

Error E10 is another common problem. It occurs if there is a problem with the water sensor or pump.

Automation begins to notify about a breakdown in the following cases:

- Energy carrier pressure is reduced.

- There is no contact between the pressure switch and the board.

- Damage to the pressure switch.

- Pump sensor is broken.

- The pump is faulty.

- The filters in the heating circuit are clogged.

- Heat exchanger clogged.

It doesn’t always make sense to fix the E10 problem yourself. If the pump is faulty, it should be replaced. The replacement is quite easy to do yourself. You can also clean the filter system. All other actions are best left to a specialist.

Other problems

In addition, other problems may occur. List of problems and their possible solutions:

- E22. The voltage in the network has dropped below 160 V. The equipment turns off or is constantly rebooted. We need to find out why the voltage is low.

- E25. The problem may occur due to improper water circulation in the boiler. This happens if the heat exchanger is clogged or the pump is jammed. In addition, the cause of this error may be a broken temperature sensor.

- E26. You should check whether the temperature sensor is securely fastened, as well as its contacts. The sensor clamp may have become loose from the pipe.

- E35. This problem indicates a false flame signal. This may occur due to a lack of board grounding. You need to check the location of the flame sensor.

- E40 and E41. These codes may appear on the display if the gas pressure is insufficient (it must be at least 9 mbar) or there is a blockage in the chimney pipe. You should check whether the gas pressure is adjusted correctly, as well as the integrity of the cable between the gas channel modulator and the board. In addition, the flame electrode may be faulty.

- E42. Most often, this problem occurs in turbocharged equipment with a closed combustion system, since this error is related to the functioning of the turbine (fan). There could be a voltage drop below 180V or a clogged chimney that needs to be cleaned.

- E50. The error indicates that the temperature of the exhaust gases is above 180 degrees. In addition, the heat exchanger could be clogged with scale.

- E55. The code is displayed when the equipment is configured incorrectly. This often happens, for example, after replacing the device board.

- E62. If the flame and flue gas sensor is broken, the device reports an intermittent signal. These sensors should be checked and replaced if necessary. There may also be problems with the electronic board.

- E65. The chimney is checked regularly for blockages. This can happen due to excessively low gas pressure or malfunction of the exhaust gas and flame sensors. It is necessary to check whether the chimney is clogged, and also look at the burner operating settings.

- E96, E97 and E98. Errors appear if the electronic board is faulty. In this case, you cannot do anything on your own. You should immediately contact a specialist.

- E99. The problem is also related to the electronic board (most often a problem with the gas valve relay contact). The board will need to be replaced. However, in some cases the code may be displayed due to network interference. In this case, the boiler will restart and the error will correct itself.

The appearance of a special error code is necessary in order to notice even the smallest malfunctions in the operation of the heating system. Repairing a gas boiler is a “treatment”, and it is easier to get rid of any disease if it is diagnosed in time.

Source: https://pikucha.ru/otoplenie/kotly/e10-na-kotle-baksi.html

Recommendations for eliminating error E01

If, during operation of the equipment, error E10 appeared on the display on the Baxi boiler, you could find out how to eliminate it by reading the information above. However, this code is far from the only one that may indicate a hardware malfunction. For example, if the device displays error code E01, then the consumer needs to check whether the sensor is connected correctly. Experts recommend checking the fuel supply; sometimes it happens that the gas supply is stopped, and the reason is simply a closed gas valve.

If you are sure that all elements are normal, it is recommended to press the “R” button and hold it for 3 seconds. If the operation occurs accidentally, the operation of the device should return to normal. Sometimes the operation occurs repeatedly, in this case it is recommended to contact the service center specialists. Sometimes code E01 is indicated by problems with electronics, and interfering with it can be detrimental to the boiler.

Additional error codes

If you purchased a Baxi Mine Four boiler, error E10 is not the only code, which is one of the most common when operating such equipment. You should also pay attention to the fact that additional error codes that are found in the operation of such devices are: E03, 25, 26 and 35. Each of these errors will also indicate that the operation of the boiler has been blocked.

Installation features

Baksi devices use gas as a coolant, and despite all its undeniable advantages, it is dangerous. Gas boilers require a professional approach. The slightest error in installation can lead to very negative consequences. Installation of the device should only be carried out by highly qualified specialists. List of problems that DIY work can lead to:

- Freezing of the device in the winter season.

- The occurrence of an explosion.

- Fire.

- Penetration of carbon monoxide into residential areas.

Of course, modern gas devices have a high-quality protection system, but even “smart” automation is not always able to cope with problems that arose due to unprofessional intervention. If we talk about a less serious outcome of the matter, the most common problem with self-installation is the incorrect operation of the equipment. For example, the device may not turn on and display error codes, despite the fact that the device is fully operational.

Baksi boilers are energy-dependent units. They are not able to function without being connected to the mains. The connection rules are quite simple and are no different from the requirements for installing a standard electrical device. The device is connected to a 220 V network; grounding is required.

Of course, if there is no grounding, the boiler will not turn on with a “bang” sound, but this may negatively affect the operation of the equipment. Quite often, the boiler displays error codes due to simple connection errors. If at the moment it is not possible to ground, you should purchase a stabilizer with galvanic isolation.

In addition to the need for grounding, there are other features when installing equipment. It is very important to follow these recommendations:

- In order for the boiler to function properly, the pressure must be 170-250 V. At a lower voltage, the equipment will turn off, and at a higher voltage, the varistor will burn out.

- The sinusoid should flow without disturbances. Such devices react very negatively to voltage surges. Professionals advise installing additional voltage stabilizers. When installing gas boilers, there is no need to use UPS devices.

- The connection must be made through a separate machine.

- If the model is phase-dependent, it is necessary to maintain the correspondence of phase and zero.

Error 03

This error code may appear after quite a long time when the user is actively operating the boiler. Some consumers note that these symbols appear on the display from time to time, and then disappear by themselves.

To correct this situation, it is necessary to thoroughly clean the blades, because a lot of dust can simply collect on them. Sometimes the grease on the bushing wears out, as do the radiator spindles, which are located at the rear of the engine. This causes the fan to slow down. If even after cleaning it was not possible to correct the situation, in this case you need to contact a specialist. Don’t worry ahead of time if error E03 appears on the display; first you need to check all the equipment settings.

Error code E35

A fairly common heating equipment recently is the Baksi gas boiler. Error E10 (how to fix it was mentioned above) is not the only malfunction that sometimes accompanies the operation of such devices. If you encounter error code E35, then the problem may be expressed in the flame control sensor. This unit is necessary to signal the presence of flame before opening the valves.

The reasons why the control sensor did not work can be very diverse, but the most likely of them is moisture and condensation on the electronic board; the problem may also be a stray flame. If we are talking about an electronic board, then you need to look for it in the boiler itself. But if these assumptions are not confirmed, then the reason should be sought in the persistent flame that remains after the equipment is turned off. The manufacturer emphasizes that this problem may be due to insufficient valve tightness. But most often this error resolves itself; to do this, you just need to try to reboot the boiler.

Characteristics of Baksi boilers

The equipment of this manufacturer can be used both in a small apartment and in a spacious country house. But the space in which the heating system will be installed must meet certain criteria:

- The size of the room should not be less than 15 m³.

- Ceiling height: minimum 2.2 m.

- Good ventilation that can withstand heavy loads is necessary.

When operating a system with a closed combustion chamber, this list of rules may not be given much importance. Such equipment itself resembles a miniature boiler room and does not emit harmful substances into the atmosphere.

This is important: Baxi boiler maintenance.

In this video you will learn how to flush the heat exchanger:

Advantages and disadvantages

The Baksi company occupies a leading position in the heating equipment market.

The boiler is very easy to operate and maintain

The following advantages of this manufacturer’s equipment can be highlighted:

- environmental friendliness and safety;

- ease of operation and flexible adjustable settings;

- reliable protection against freezing;

- automatic diagnostic function;

- efficiency;

- a wide range of models, the ability to select a unit to suit any requirements;

- stylish, thoughtful design.

Of course, any equipment has its drawbacks, and Baxi products are no exception. The disadvantages are:

- Sensitivity of equipment to voltage changes. For the device to work reliably, you need to connect it through a stabilizer.

- Installation is quite complicated, so it is best to entrust it to a professional.

- High price compared to models from other manufacturers.

In this video you will learn about the main malfunctions of Baksi boilers:

Types of models

The company has a large range of wall and floor heating systems. Wall-mounted boilers are ideal for private homes. They are available in three series: Luna, Prime and Eco3.

You will certainly find your own version of the boiler on the market.

Models from the Luna line have a built-in automatic diagnostics and electronic modulation system. Such units are distinguished by the presence of two temperature regulators, which is very convenient. These are dual-circuit devices with an acceptable cost.

Equipment from the Prime line are high-quality and reliable economy-class boilers. They have a closed combustion chamber and are made of special composite materials. The devices operate almost silently. Models in this series are condensing and have a biothermal heat exchanger. Thanks to this they operate very economically.

Eco3 systems are no less reliable and convenient. These devices can operate even with high pressure drops. Equipped with an automatic water temperature regulator.

The Luna-3 Comfort and Eco Four models are very popular on the Russian market. Both systems can be presented with either an open or a closed combustion chamber. Eco Four has a performance of 14-24 kilowatts. It can be connected to a thermostat or timer. This boiler is equipped with high-quality sensors and reliable protection against temperature changes. Among all Baksi devices, it has the least power.

In addition, models from the Main line are in great demand. The most famous on the Russian market was the Main Four 240, which ceased production in 2021. It was replaced by Main Five, made using new technology. This system is similar to the previous one, but it has additions, such as a draft system in the chimney.

How to repair a gas boiler control board:

Errors E25 and 26

In some cases, the Baksi boiler displays an E10 error, but if you notice a code on the display that is different from this one, then you need to consider the causes of the problem more seriously. For example, error E25 may be indicated by exceeding the maximum temperature. The manufacturer himself says this. In this case, you need to pay attention to the heating circuit temperature sensor. But first you should check the pump, as well as the cleanliness of the filters, clogging of which in the heating system can lead to insufficient coolant circulation.

If error E25 occurs, the pumping equipment may simply be blocked. But there is also the possibility that the heating system is partially or completely aired. The last action, when all of the above assumptions are excluded, is to check the temperature sensor. It may fail. If you also chose the Baksi boiler, error E10 (what to do to eliminate it was described above), of course, may occur. However, not only this code indicates some problems in the operation of the device. Sometimes error E26 also occurs. True, it is much less common compared to all the others. This code is associated with a temperature sensor failure. If the device produces this designation, then you can be sure that the temperature has risen above 20 °C.

Error classification

Baksi gas boilers have energy-dependent automation. For convenience, special error codes are displayed on the control display.

Conventionally, all problems can be divided into two types:

- complete blocking of the heating system;

- transition of the equipment to standby mode.

Very often, if the gas system is completely blocked, a manual restart of the unit is necessary, since the boiler stops functioning only during serious breakdowns that can lead to a threat to life and health.

The display shows the temperature as well as an error code in case of breakdown

Such problems include:

- stopping the fuel supply;

- system overheating;

- lack of traction.

Sometimes breakdowns occur that the system can handle on its own. In this case, the device restarts and continues to function. However, this happens very rarely.

Troubleshooting:

- Code E01 appears on the display only when the flame sensor is triggered. In some cases this may happen accidentally. You need to make sure that the gas supply is normal and the sensor is connected correctly. After this, press the R key and hold it for 2-3 seconds.

- Problem E02 is related to the thermostat. The system can issue such a code if the water is overheated or the sensor transmits an incorrect signal. Signal disruption is possible if contact is broken or the sensor is broken. Overheating also occurs due to improper circulation of the heat exchanger. This happens if there is a lot of scale in the equipment, the heating circuit filter is clogged, the pump is broken, or the unit is air-filled. The thermostat may break down or the contact between it and the control board may be broken.

- If error E3 occurs in an open gas boiler, there is most likely a draft problem. This can happen if installed incorrectly. In addition, the thermostat sensor could be broken or the contact could be lost. In a closed system, the same problems are possible, as well as a faulty control relay or a broken fan. You can clean the fan yourself and lubricate the radiator bushing and axis.

- Code E4 appears when there is no flame control. This usually happens due to a clogged chimney or other chimney problem or bad wiring. The error may warn of instability of the network voltage or failure of the electronic board.

Opening the boiler in case of breakdown:

One of the most common problems is error E10 on a Baxi gas boiler. This problem is associated with the sensor responsible for water circulation and pump operation. The Baxi E10 code appears if:

- gas pressure is reduced;

- there is a fault in the board contact;

- problem with the pressure switch;

- pump sensor failure;

- The filter in the heating zone is clogged.

When an E 10 error appears on a Baxi boiler, it is not always possible to fix the problem yourself. If the pump breaks, it should be replaced. You can also clean the filters yourself. Sometimes this is enough to fix the problem. More serious repairs should be carried out by a professional.

The name of the buttons and their functions on the Baxi boiler

Error a00

If this error code is displayed on the screen, this does not mean that the boiler is faulty. This code may appear on the display when the “Info” mode is activated. “Error” a00 rhythmically changes to numbers that display the current temperature at the inlet pipe of the heating circuit.

Error e00

This malfunction is very serious, since it indicates that the electronic control board of the boiler has failed. Error e00 can only be resolved with the help of a service center representative, and under no circumstances should you attempt to resolve this error on your own.

Error e03

This error can occur in a situation where, for some reason, the pneumatic relay does not work correctly. Also, an error code e03 may appear if the traction sensor is faulty. Also, this malfunction can occur in a situation where, for some reason, there is difficulty in removing combustion products. This may be due to:

- improper installation of the chimney;

- chimney blockage;

- failure of the exhaust turbine;

- complete failure of the pneumatic relay.

The Venturi tube, which is used to measure the draft force in the smoke exhaust duct, may also be faulty. When the turbine starts, the pressure in the chimney changes, and this change is captured by the Venturi tube. The tube is connected to a pressure switch in which the membrane is located. The membrane reacts to pressure changes, and its movement closes or opens the contacts of the microswitch of the pressure sensor. Incorrect operation of these elements can cause error e03 to appear.

You also need to check the turbine itself. First of all, the presence of free rotation of the shaft is determined, and then the fan itself is checked. The presence of voltage at the terminals of the wire that comes from the electronic board is also checked. The windings of the turbine electric motor are also checked. Their resistance should be in the range from 38 to 48 ohms. If the resistance does not meet these parameters, the fan should be replaced.

We recommend: Korean gas boilers: detailed review and recommendations for choosing wall-mounted and floor-mounted, single-circuit and double-circuit models, reviews from owners, comparison of their characteristics and costs

Along with the turbine, you need to check the condition of the chimney and the correctness of its installation. The air relay must also be carefully checked for operation. You can use a pressure gauge to check.

Also, the cause of error E03 in Baksi gas boilers may be poor contact on the connectors that connect the electronic board to the turbine and relay. Poor contact can be caused by oxidation, which can occur when moisture gets into the connector.

Code E02 – thermostat-fuse against overheating

The manifestation of this error, displayed on the display as “E02” or “02E”, can also be accompanied by various variations of defects.

An example of the appearance of code 02E (E02) on the display of the Caldera Baxi Roca Victoria boiler model. Meanwhile, this kind of failure is also typical for other models.

In particular, the following defects may appear:

- the temperature of the main circuit water is exceeded;

- the circuit temperature sensor is faulty;

- no contact on the heating circuit temperature sensor;

- the coolant circulation in the primary heat exchanger circuit is insufficient;

- clogging of the filter, heat exchanger, presence of air in the system;

- circulation pump defect;

- fault on the electronics board.

The same errors are typical for boiler models that do not have a display. They are determined by the presence of a glowing indicator with a temperature marker.

Code E01 and E04 – flame control sensor

A situation typical for most models is related to the functionality of blocking the boiler ignition system. The classic error code for such cases is “E01” or “01E” (and also “E04” or “04E”), displayed on the information display.

If the design does not provide for a display, the same error is identified by the corresponding LED indicator.

Instability of the gas supply, malfunction of the flame control sensor and other technical malfunctions of Baxi equipment are the result of the appearance of code E01 (01E)

Relationship between error and possible situations:

- no gas supply;

- the contact on the flame sensor is broken;

- the flame control sensor is dirty;

- malfunction of the ignition system;

- on the power line, phase and zero do not correspond;

- malfunction of the gas tap, electronics, coaxial chimney.

Accordingly, based on possible malfunctions, you should check all of the specified components (elements) to ensure correct operation, and if not, carry out repair measures.

Error e05

A malfunction with this code indicates that the temperature sensor of the heating circuit is not measuring the temperature correctly. This can be caused either by a failure of the sensor itself or by a failure of the electronic board. In rare cases, it happens that contact between the electronic control unit and the temperature sensor simply disappears. In this situation, you need to carefully check the connectors that connect the temperature sensors to the electronic board.

Error e06

An error with this code also indicates a malfunction of the temperature sensor, but not of the heating circuit, but of the DHW circuit. This error can be triggered by the same reasons that are described in the previous section.

Codes E12 and E13 – DGP malfunction

The appearance of code “E12” (“12E”) or “E13” (“13E”) on the boiler display clearly indicates malfunctions associated with the operation of the differential hydraulic pressure switch.

Usually, during testing, a signal from the device is not detected, or there is a signal, but does not correspond to the specified characteristic (false signal)

The reasons for the appearance of the marked code may be:

- stopping the pump;

- presence of air in the hot water system;

- low circulation rate;

- there is no contact on the TIR or a “stuck” contact;

- membrane damage or filter clogging;

- Impulse tubes are clogged.

Accordingly, a technical check should be carried out to determine the malfunction of a specific element.

And in order to eliminate the problem, it is necessary to replace the faulty element or carry out preventive restoration work.

Error e10

Malfunction e010 occurs when the signal from the hydraulic pressure switch disappears. An error with this code may be caused by the operation of a sensor that monitors water pressure. There have been cases where an error with such a code occurred when the contact between the relay and the electronic control board was lost.

There are four main causes of error e10:

- Leaks in the heating system.

- Failure of the expansion tank, or lack of air in it.

- Failure of the water pressure sensor in the heating circuit.

- Clogged “oblique” filter on the return line.

Codes E21-22 and E97-99 – electrical and electronics

Both codes - "E21" and "E22" - indicate faults associated with the electronic board. Code “E22” may appear if the supply voltage drops below the control value (162V).

The same code is displayed on the display if the quality of energy supplied to the boiler does not meet the stated standards.

For code “E21”, a characteristic point is the scattering of controller parameters and disruption of normal gas combustion. If you lack experience and relevant knowledge, it is better to entrust board repair to a specialist.

Errors “E97”, “E98”, “E99” - all three codes are usually associated with defects in the electronics - electronic board.

Code “E97” indicates the frequency of the supply voltage does not comply with the standard. The code “E98” indicates defects that are present specifically on the electronic board.

The same thing is indicated by the code “E99”. True, the “99E” error can also be caused by too low gas pressure, as well as a malfunction of the flame sensor

The simplest defect is loss of electrical contact on the gas valve relay. In other cases, the board usually needs to be replaced.

Codes E25-27 and E32 – temperature defects

The appearance of any of these codes - “E25”, “E26”, “E27”, “E32” - is usually preceded by temperature changes in the heating circuit, occurring at a faster rate than set by the control system.

For example, if the temperature of the heating circuit (HC) increases by more than 1 degree per second, the code “E25” (“25E”) is displayed on the boiler display. For code “E26” (“26E”) to appear, the temperature exceeding the set temperature by 20 °C is usually sufficient.

We recommend: Ventilation for a gas boiler in a private house: requirements for the system, its types, power calculation and installation

Malfunctions or failures marked on the display with code E26 (26E) are a reaction to temperature deviations. Due to temperature failures, other codes of the same group may appear

Reasons that traditionally cause such codes:

- blocking the circulation pump;

- filter clogging;

- air inside the system;

- defective temperature sensor KO;

- electronics malfunctions;

- Incorrect installation of the DHW sensor.

To eliminate it, it is necessary to carry out preventive measures aimed at checking and testing DHW and CO units. Air in the system is removed using standard plumbing practices.

The performance of the circulation pump is checked by electrical and mechanical parts.

Codes E50 and E62 – NTC sensor and flame control

The automation of Baksi boilers is adjusted to certain parameters of combustion stability, as well as to a certain temperature range of flue gases.

Error E62 – burner flame control sensor

If any of the two parameters (or both at once) goes beyond the settings, the automation is activated, and the code “E62” (“62E”) appears on the control display screen.

Traditional reasons:

- faulty or dirty flame control sensor;

- faulty NTC sensor;

- electronic board defects.

Sensors are tested by replacing them with known good ones, and electronics are tested with instruments designed for such purposes.

Error E50 – NTC temperature sensor

The occurrence of the “E50” error is typical for boilers of the ECO-5 and Main 5 models. The “E50” code is usually displayed on the control display due to the detection by the flue gas heating temperature sensor above 180 °C.

Another sensor present in the design of the Baxi boiler, a defect of which leads to the appearance of code E50 (50E) on the control display

In turn, a rise in temperature above the set limit may be due to:

- low coolant circulation rate;

- clogged filters;

- the appearance of hydraulic resistance in the system;

- low concentration of antifreeze;

- circulation pump defects;

- system contamination or air ingress.

Also, the fault code “E50” (“50E”) is displayed on the display when the NTC sensor breaks down, due to electronic malfunctions, due to incorrect settings of the gas supply valve.

Accordingly, elimination is ensured by consistent testing of the designated units and carrying out the necessary work.

Error e25

This error in Baksi boilers can also be caused by a large amount of air that has accumulated in the heating circuit. The airiness of the heating system contributes to the rapid heating of the coolant, and it is to this rapid heating that the electronics of the gas boiler reacts - it turns off the heating device, displaying error E25 on the screen. Also, the occurrence of this malfunction can be caused by a breakdown of the circulation pump, or failure of the temperature sensor. Most rarely, this error appears due to incorrect operation of the electronic control board, or lack of reliable contact between the circulation pump and the electronic control unit.

E26

The set temperature is exceeded by more than 20 degrees. Error e26 occurs for the same reasons as e25, and similar methods of elimination.

E27

Incorrect location of the temperature sensor in double-circuit boilers. Error E27 is caused by a sensor failure or incorrect installation. How to fix this failure is to check the operation of the sensor and its position.

E32

Error E32 signals the formation of a large amount of scale in the heat exchanger. To eliminate this, you need to clean the heat exchanger from scale. To clean it with a reagent, you need to remove the heat exchanger, first draining the water from it and turning off the water and gas supply valve.

E35

A parasitic flame appears before the flame sensor sends the gas valve open. Error E35 appears when water appears on the electronic board, the gas valve is depressurized, the parameters in the electrical network do not meet the requirements of the instructions for the unit, or the board has failed. Most often, installing a stabilizer and grounding helps in this situation.

Heating boiler board

E40

Blocked chimney or too low gas supply pressure. There can be many reasons for the E40 error, the main ones are a lack of gas supply, a violation of draft in the chimney, insufficient air, incorrect operation of ionization sensors, exhaust gases, failure of the gas valve, and the board does not work. You can check the chimney yourself; it is better to entrust the rest of the diagnostics to a specialist.

E41

Error e41 has the same causes and solutions as e40.

E42

Indicates loss of flame. Error E42 occurs when the chimney is clogged, there is no contact between the board and the fan, the fan is faulty, or the rules for installing the chimney are violated. You can check the draft in the chimney with your own hands; for everything else, it’s better to call a specialist.

E96

Error E96 lights up on the Baxi Main Four display when the mains voltage drops. In this case, restarting the unit may help. If the situation repeats, invite a specialist from the service company. On a Baxi SLIM device, this code occurs if there is a malfunction in the control panel. Only calling a specialist can help here.

Boiler Baxi Main Four

E97

If the frequency setting of the signal supplied to the board does not match, error e97 lights up. To resolve this, change the frequency.

The rarest error

On the positive side, the Baksi boiler has proven itself among consumers. Error E10 (how to fix it was mentioned above), unfortunately, sometimes occurs. It is one of the most common. In contrast, we can give an example of error code E00, which you may not encounter during the entire life of the equipment.

This code occurs when the stabilizer breaks down. The simplest way out of this situation is to replace this unit. Some consumers, however, note that this alphanumeric designation is indicated by a failed board. The manufacturer himself denies this claim.