A situation may arise when the boiler stops heating water, that is, cold water flows from the tap when turned on. Most likely, the problem lies in a malfunction of the turbine, which does not transmit a signal to the sensor, then the flame does not ignite and, as a result, the liquid does not heat up.

The turbine cannot be repaired and needs to be replaced. To prevent a similar situation from happening again with a newly installed turbine, we recommend purchasing and installing a high-quality fluid filter.

In this article we will look at the Oasis gas boiler of the NZR series (available in 4 modifications). The number after the abbreviation “NZR” indicates the power of this boiler. For example, the Oasis NZR 13 model has a thermal power of 13 kW.

Since all modifications have similar characteristics, we will denote their numerical expression in a range.

We have a certain residential or administrative area, which has its own dimensions. Managers of household appliance showrooms guide buyers towards them when choosing a boiler. But at the same time, the features of the building or apartment are absolutely not taken into account:

- What material is the building made of? For example, private houses made of profiled timber are considered warm, and concrete “Khrushchev” buildings in this regard cause a lot of criticism;

- how is it insulated? After all, even in city apartments there are differences. Someone does, for example, internal insulation, glazing of a loggia or balcony;

- year of construction (applies to apartment buildings). You need to understand that in different periods there were significant differences in construction technology, and the service life reduces the quality of thermal insulation of premises. Consequently, a more powerful boiler is needed;

- location of the house. It can either be “open” to all winds, or, conversely, blocked by other houses, a forest belt, a hill, and the like. The climate in the area must also be taken into account.

The approximate power that the boiler should have is determined at the rate of 10 kW per 100 m 2 of room (ceilings of standard height). But if any mechanism is “driven” to the limit, then it will not work for long. That is why the power calculated in this way is increased by a third (the required reserve).

If a multi-storey building is built using modern technologies, and a private one is well insulated, then you can be guided by the ratio (5 - 7) kW per 100 m2. For old or poorly insulated buildings (“Khrushchev-era buildings”), the “formula” (15 – 20) per 100 m2 is used.

How the Oasis boiler works

The devices of this manufacturer are dual-circuit. This means that the water heater can provide not only hot water at the tap, but also heating in the room. The heating temperature is from 35 to 60 degrees, the average productivity is 10 liters per minute.

The boiler is equipped with two heat exchangers. One of them is responsible for providing water for heating batteries, the other for hot water supply (DHW). Accordingly, fuel consumption and heating waiting time in the summer are reduced.

Combustion products are removed forcibly. Closed chamber and ensure automatic and safe operation. Flame, gas supply, and flow sensors are installed for monitoring. There is also a safety valve that is activated when the pressure rises.

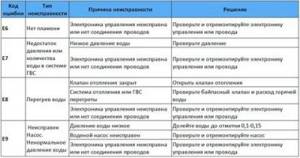

It can't do without troubleshooting. The equipment is equipped with a self-diagnosis system. In the event of a malfunction, an error is displayed on the display, the meaning of which is indicated in the instructions.

Oasis gas boiler errors, faults, do-it-yourself repairs

Do you have an Oasis gas boiler installed? Then it will be useful for you to familiarize yourself with the typical malfunctions of this equipment. During operation, device components may fail. We will tell you how to recognize the problem and fix it yourself.

How the Oasis boiler works

The devices of this manufacturer are dual-circuit. This means that the water heater can provide not only hot water at the tap, but also heating in the room. The heating temperature is from 35 to 60 degrees, the average productivity is 10 liters per minute.

Oasis equipment runs on natural gas, so it can be installed in houses connected to the mains.

The boiler is equipped with two heat exchangers. One of them is responsible for providing water for heating batteries, the other for hot water supply (DHW). Accordingly, fuel consumption and heating waiting time in the summer are reduced.

Combustion products are removed forcibly. The closed chamber and coaxial chimney ensure automatic and safe operation. Flame, gas supply, and flow sensors are installed for monitoring. There is also a safety valve that is activated when the pressure rises.

It can't do without troubleshooting. The equipment is equipped with a self-diagnosis system. In the event of a malfunction, an error is displayed on the display, the meaning of which is indicated in the instructions.

Basic faults

What to do if an error appears on the display? How to fix the situation? First you need to decipher the meaning of the symbols on the screen, and only after that start looking for a breakdown.

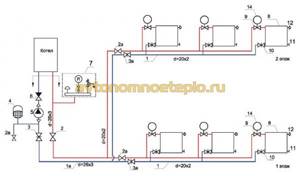

Installation and connection

The Oasis boiler is a wall-mounted model. Unlike floor-standing devices, it does not require boiler room equipment; it can be installed even in small rooms.

Fastening is done either with anchors or large screws, since the weight of the boilers is comparable to the weight of a regular gas water heater, and the dimensions are approximately the same.

The described gas boilers are produced with a closed combustion chamber. What does this mean? To ensure the combustion process, an air flow is required. A device with a closed chamber in this regard is isolated from the room in which it is mounted. Air is supplied from outside using a fan equipped with the boiler.

Therefore, before purchasing the Oasis product, you need to think about installing a special coaxial chimney. For private houses this is not a problem, but installation in an apartment will require specialist advice. Although such models are considered safer and more environmentally friendly.

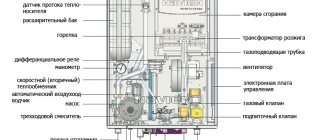

Internal structure of Oasis boilers

One of the characteristic features of the modifications is the presence of a closed combustion chamber. Air intake is carried out from the street, using a coaxial chimney. Combustion products are also removed through the pipe. This makes the operation of boilers as safe as possible. In addition, due to the closed firebox, gas consumption is significantly reduced.

Separately, we can note the presence of two heat exchangers. This solution increases the speed of heating water for domestic hot water, and also allows the device to be started in summer mode, which increases its efficiency.

All Oasis wall-mounted double-circuit gas heating boilers have a high degree of autonomy, achieved thanks to an internal structure that includes:

- Burner - a pressurized type device is used. The connected burner is controlled automatically. Electric ignition is provided. Photo sensors are installed on the burner to monitor the presence of gas. After a power outage, the gas supply to the burner is blocked. The boiler uses a coaxial chimney. It simultaneously takes in air and removes combustion products. Not included in the basic package.

- Safety group - 2-circuit mounted gas heating boiler Oasis has multi-level protection that prevents spontaneous combustion and the occurrence of explosive situations. Provided: water flow sensor - monitors the pressure of the water supply and heating system, blocks operation if it drops to critical levels. Relief valves are installed to help in case of overheating of the coolant. When the room temperature drops, the antifreeze system is activated, maintaining minimal heating of the heating system.

Oasis boilers have been certified and received permission to operate by Rostechnadzor. This made it possible to operate equipment from a Chinese manufacturer throughout the Russian Federation.

What to focus on in operation

Boiler piping - the internal structure of the boiler contains a circulation pump and an expansion tank. During installation, you will need to additionally install a filtration system. The automation is sensitive to voltage drops, which is one of the main disadvantages of the Oasis boiler. To eliminate possible failure of the control board, you need to connect a UPS. Lots of noise – the forced-air burner is noisy. The noise level requires installation of the boiler in a separate room. The technical characteristics declared by the manufacturer in this regard are somewhat different from what actually happens

It is especially noisy when the DHW is turned on.

Coaxial chimney - it is extremely important to comply with the installation requirements, strictly adhere to the maximum height, angle of inclination and other parameters. Productivity and efficiency ultimately depend on a quality installation.

Chinese doesn't mean bad

All components from the closed combustion chamber to the temperature sensor are checked for quality and compliance with standards. The only condition for trouble-free operation is the installation and operation of the boiler in accordance with all the rules and in accordance with the manufacturer’s recommendations.

The Oasis gas boiler can only operate on natural gas; conversion to liquefied gas is excluded; accordingly, it can be installed in rooms connected to the central gas main.

These devices are double-circuit, designed to heat a room and supply it with hot water for domestic needs. The heating temperature of the liquid ranges from 35-60 degrees, the hot water supply capacity is 10 liters per minute.

Equipped with a closed combustion chamber, which significantly reduces gas consumption. The operation of the burner is controlled automatically; there are photo sensors on it that monitor the presence of gas. A coaxial chimney is used for smoke removal; the air required for the combustion process comes from the street.

The design provides two heat exchangers, one for the heating circuit, the second for heating the DHW liquid. Thanks to this, the heating time of the liquid is reduced, and it is also possible to use the boiler in the summer.

It is possible to connect to a room thermostat, which is not included in the package; it must be purchased separately. For safe operation, there are relief valves that are activated if the coolant temperature exceeds the permissible limits. Also, for safe operation, there are flow sensors that monitor the pressure in the heating circuit; in case of non-compliance with the standards, the operation of the system is blocked.

Design and operating principle of Oasis boilers

A gas boiler

The

Oasis company will operate exclusively on natural gas; conversion to liquefied gas is excluded; therefore, it can be installed in premises connected to the central gas main

. Such devices have two circuits and are designed to heat a room and supply it with hot water for domestic needs. The heating temperature of the liquid can fluctuate between 35-60 degrees, the hot water supply capacity is 10 liters in 60 seconds.

It is equipped with a closed firebox, which greatly reduces gas consumption. The operation of the burner is controlled automatically; there are photo sensors on it that monitor the presence of gas. A coaxial type chimney is used for smoke removal; the air required for the combustion process comes from the street.

The design includes two heat exchangers, one for the heating circuit, the second for heating the DHW liquid. Due to this, the heating time of the liquid is reduced, and it is still possible to use a boiler

in summer.

Room thermostat with monitor

It is possible to connect to a room thermostatic valve, which is not included in the kit and must be purchased separately. For non-hazardous work, there are relief valves that are activated if the temperature of the coolant exceeds possible limits. Also, for non-hazardous work, there are flow sensors that monitor the pressure in the heating circuit; in case of non-compliance with the standards, the operation of the system is blocked.

Basic faults

What to do if an error appears on the display? How to fix the situation? First you need to decipher the meaning of the symbols on the screen, and only after that start looking for a breakdown.

Error codes and solutions

Let's look at what the symbols that the boiler shows mean.

E1

— problems with ignition, no ignition. What could be the reason:

- No fuel supply

. Turn the shut-off valve; it may not be fully open. If there is high or low pressure in the gas line, you should contact the repair service; - The contacts are loose and clogged

. Check the connections from the control module to the ignition unit. Tighten the wiring. If the contacts are oxidized, clean them and reconnect; - The control board is faulty

. It is better to entrust diagnosis and replacement to a specialist. But you can inspect the part yourself, look for burns and damage.

The ignition electrode does not work. This happens if the part has moved and is located far from the burner. Remove the casing, inspect the elements and return the electrode to its place. Additionally, clean it with a wire brush. If the burner does not light after this, install a new electrode.

E2

— the fan has been running for 8 seconds, but the pressure switch does not close. What does it mean:

No traction. The pipe or chimney is clogged. To check, light a match and hold it to the inspection window. The flame deviates to the side - there is draft, it burns evenly - no. You can hold a sheet of paper to the ventilation hole. With normal traction, it will tighten, and if the passage is clogged, the leaf will fall.

In this case, you need to clean the chimney on your own side, and call utility workers from the street to clean it. Open the combustion chamber. You will see that there are two tubes connected to the manostat (pressure regulator), which also need to be cleaned;

- The air relay is broken

. You can verify that a part is faulty using a tester;

The fan does not work

. The part is inspected for damage. There are tubes connected to it that may have melted and need to be replaced. Then start the boiler and close the manostat contacts. If the burner lights up, the manostat is broken; if not, the main unit is broken.

E3 -

The DHW input temperature sensor has failed. Diagnose the sensor and wiring. Replace faulty parts.

E4 -

The DHW output sensor is broken. Proceed in the same way as in case of E3.

E5 -

The heating sensor does not work. Similar actions.

E6

- there is no flame. What to do:

- Restart

. To do this, open and close the mixer several times until ignition occurs. Air has probably accumulated inside, which interferes with normal ignition; - Pull the contacts to the connectors

, make sure the insulation is intact.

E7

- low pressure in the line. What could be causing the problem:

- Too little water

. Perhaps one of the connections has started to leak. Apply a dry cloth to the joints to check for leaks. Seal the connection, tighten the nuts tighter and eliminate the leak; - The pressure in the distribution tank is incorrect.

It is necessary to adjust the settings as indicated in the instructions for the specific model. When heated, the liquid expands, causing the pressure to increase. Because of this, the safety valve is activated and releases excess water.

E8 -

the water overheats. What is the reason:

- The heating valve is closed

, you need to open it; - DHW or heating systems overheat

. Diagnose the operation of the bypass valve, as well as the degree of hot liquid flow.

E9 -

The pressure in the system is not normal. The pump is broken, so the burner may not light.

- The pressure in the line

must be at least 0.1–0.15 Bar; - Remove the pump.

Clean its parts from blockages and rinse under running water. Inspect the components for damage, especially the blades.

Thermal sensor is faulty. Diagnostics and replacement are carried out.

We have examined all the errors characteristic of Oasis gas boilers. In addition, users are faced with a malfunction such as lack of heating: when opening the mixer, there is no hot flow. This indicates a turbine failure. It cannot be repaired; it is better to install a new one.

Before starting work on equipment, turn off the gas and water supplies. If the error code does not disappear from the screen after all the efforts, contact a specialist. You should not carry out independent work on the gas line - this is dangerous and can lead to an accident.

conclusions

Let's summarize all of the above:

- The Oasis gas boiler is perfect for any city apartment or small private house connected to the gas main. It is also advisable to use it for small industrial or administrative buildings;

- Provides both heat and hot water;

- “Oasis” can be installed even in a small, non-separate room;

- Installation of a coaxial type chimney is required. When connected to a common house smoke exhaust system, the boiler must be provided with a separate air flow.

It should be added that the manufacturer provides a 2-year warranty on its products.

Boilers have relatively recently appeared on the heating equipment market. Positioning itself as a large international corporation created by German investors, Forte occupied a niche in the production and sale of bimetallic radiators. In order to expand the sales market, a step was taken to produce.

Currently, the model range is represented by one type of gas equipment - the Oasis NZR boiler. In order to increase the number of potential buyers, 4 main modifications of this boiler were made.

The Oasis NZR double-circuit gas boiler is designed to heat the coolant in the heating system and provide hot running water. Its general characteristics allow it to be used as the main heating device both in private homes and in small office buildings.

4 boiler models have been developed, which differ in rated power - from 13 to 24 kW. The company's marketing strategy allowed boilers with low power to confidently occupy their market segment. The relative shortage of inexpensive and low-power boilers has become a niche that allows Forte to continue its successful advancement in the market.

Specifications

All models of Oasis boilers are wall-mounted and have the technical characteristics presented in the table:

Technical characteristics of Oasis NZR boilers

Like every type of heating equipment, these boilers have some characteristic design features:

- Closed combustion chamber. The flow of air to maintain the combustion process occurs using a fan. To implement this process, a coaxial chimney is provided, consisting of two air ducts - a pipe in a pipe. One (external) provides air flow from the street, and the second (internal) removes gas combustion products to the street.

- The heat exchanger is made of copper, which increases its functional properties.

- Convenient controls. The process of adjusting and monitoring water temperature, both in the heating system and in hot water supply, is carried out using an electronic panel.

- Power modulation with electronic system.

- Extended boiler operation protection system for the following cases:

- Overheating of water.

- Critical decrease (increase) in pressure in the water supply system.

- Automatic restart when water stagnation occurs.

- Protection of electronic components when electrical voltage drops.

- Preventing water from freezing in 2 systems.

- The presence of a draft sensor to monitor the process of removing combustion products.

Ionization control of the burner flame.

But the main criterion for our citizens remains cost. It is thanks to a well-thought-out pricing policy that sales of these boilers are growing every year.

However, it is worth noting that in addition to the positive factors, there is some negative, which can be characterized by the phrase - not a very good quality. Of course, this does not apply to all products.

For a modern person, one of the main criteria for choosing a product is customer reviews.

There are several important points that must be taken into account when choosing heating equipment for your apartment or private home. A gas boiler must meet the requirements - to be reliable, efficient, have economical fuel consumption, easy to operate and convenient to use. The Oasis gas wall-mounted boiler fully meets all consumer expectations.

How should I eliminate the E3 error on the Oasis boiler?

The Oasis gas boiler can only operate on natural gas; conversion to liquefied gas is excluded; accordingly, it can be installed in rooms connected to the central gas main.

These devices are double-circuit, designed to heat a room and supply it with hot water for domestic needs. The heating temperature of the liquid ranges from 35-60 degrees, the hot water supply capacity is 10 liters per minute.

Equipped with a closed combustion chamber, which significantly reduces gas consumption. The operation of the burner is controlled automatically; there are photo sensors on it that monitor the presence of gas. A coaxial chimney is used for smoke removal; the air required for the combustion process comes from the street.

The design provides two heat exchangers, one for the heating circuit, the second for heating the DHW liquid. Thanks to this, the heating time of the liquid is reduced, and it is also possible to use the boiler in the summer.

Room thermostat with display

It is possible to connect to a room thermostat, which is not included in the package; it must be purchased separately. For safe operation, there are relief valves that are activated if the coolant temperature exceeds the permissible limits. Also, for safe operation, there are flow sensors that monitor the pressure in the heating circuit; in case of non-compliance with the standards, the operation of the system is blocked.

Design and principle of operation of Oasis boilers

The Oasis gas boiler can only operate on natural gas; conversion to liquefied gas is excluded; accordingly, it can be installed in rooms connected to the central gas main.

These devices are double-circuit, designed to heat a room and supply it with hot water for domestic needs. The heating temperature of the liquid ranges from 35-60 degrees, the hot water supply capacity is 10 liters per minute.

Equipped with a closed combustion chamber, which significantly reduces gas consumption. The operation of the burner is controlled automatically; there are photo sensors on it that monitor the presence of gas. A coaxial chimney is used for smoke removal; the air required for the combustion process comes from the street.

The design provides two heat exchangers, one for the heating circuit, the second for heating the DHW liquid. Thanks to this, the heating time of the liquid is reduced, and it is also possible to use the boiler in the summer.

Room thermostat with display

It is possible to connect to a room thermostat, which is not included in the package; it must be purchased separately. For safe operation, there are relief valves that are activated if the coolant temperature exceeds the permissible limits. Also, for safe operation, there are flow sensors that monitor the pressure in the heating circuit; in case of non-compliance with the standards, the operation of the system is blocked.

Characteristics of Oasis boilers

The Oasis boiler is a gas boiler, but it cannot operate on liquefied gas. All models are designed only for natural gas - conversion to liquefied gas is not provided and is impossible. Due to this, the boiler can only be used in buildings connected to the gas supply system.

In relation to the “average” structure, the Oasis boiler of various modifications is capable of heating the area (m2):

- NZR 13 – up to 100;

- NZR 16 – up to 120;

- NZR 20 – up to 160 – 180;

- NZR 24 – up to 200 – 220.

The volume of the membrane (expansion) tank of the gas “Oasis” is 6 liters. This must be taken into account if the boiler is selected for a private home. You may have to install an additional tank (if there is a large volume of coolant).

The boiler heat exchanger is made of copper and can withstand large hydraulic shocks, which is important for apartment buildings where the heating system is pressure tested before each season.

All Oasis gas boilers are double-circuit, so in addition to heating they also provide hot water supply. Depending on the automation settings, the water temperature can be from 36 to 60 0 C. The productivity of the DHW circuit is 10 l/min (for the NZR 24 model - 12 l/min) - quite sufficient to satisfy all the domestic needs of a family of 5 - 7 people.

Basic error codes

Let's try to look in more detail at the error codes of Oasis boilers and the possible reasons for their appearance.

Error e1. Indicates an ignition malfunction, possible causes:

- There is no gas supply to the device. Check if the gas valve is open, if not, open it. There may also be insufficient or, on the contrary, excessive gas pressure; to eliminate this, you must contact the gas service.

- The contact connection is broken or missing. Check for opens and shorts using a multimeter. They may have oxidized, in this case, strip and insulate the wires...

- The board has failed. It is necessary to test it and, in case of malfunction, replace it with a new one; this type of repair requires the necessary qualifications.

Boiler control board

Error e2. Lights up if the air pressure switch does not close 8 seconds after turning on the fan.

The reasons may be:

- Clogged pipe or chimney. Check for draft and clean the chimney. It would also be a good idea to open the combustion chamber, there are two pipes connected to the monostat, remove them and blow them out.

- The relay that controls the air pressure has failed. Test it for serviceability and replace if necessary.

- The fan has failed. Check its serviceability, examine it carefully, there are tubes in it, check their integrity, whether they are melted. Next, you need to turn on the boiler and after the fan starts working, short-circuit the two wires going to the monostat.

Oasis boiler fan If the boiler lights up, it means the monostat is broken and needs to be replaced, and if not, then the problem is in the control board.

Error e6. Indicates that there is no flame. What to do if a similar problem arises?

The following must be excluded:

- Presence of stray flame. There may be an accumulation of air in the system. Try restarting again.

- The connection in the wires is broken. Check for correctness and integrity.

Wire connection methods

Error e7. Low pressure or insufficient amount of liquid in the hot water supply system.

- There is not enough water in the system; the cause may be a leak in any of the system elements; this can be done with a dry cloth. Check everything carefully and if a leak is found, fix it. This can be done using special sealants, tightening the joints, use high-quality seals.

- The pressure level in the expansion tank is not adjusted. Since the liquid expands when heated, the pressure in it increases and the liquid is discharged using the valve. It is necessary to strictly follow the characteristics of a particular model and adjust the required level of pressure in the system.

Expansion tank in the heating system

Error e9. Indicates that the pump has failed, or that the pressure in the system is unacceptable.

- The level of optimal fluid pressure in the system varies from 0.1 to 0.15 atm.

- Check the serviceability of the water pump by first removing it. If necessary, clean the pump, rinse, check the integrity of the blades.

- The control board is broken. Needs replacement.

- You also need to pay attention to whether the temperature sensor is working properly.

Error codes for Oasis gas boilers: meaning and what to do

The Oasis gas boiler can only operate on natural gas; conversion to liquefied gas is excluded; accordingly, it can be installed in rooms connected to the central gas main.

These devices are double-circuit, designed to heat a room and supply it with hot water for domestic needs. The heating temperature of the liquid ranges from 35-60 degrees, the hot water supply capacity is 10 liters per minute.

Equipped with a closed combustion chamber, which significantly reduces gas consumption. The operation of the burner is controlled automatically; there are photo sensors on it that monitor the presence of gas. A coaxial chimney is used for smoke removal; the air required for the combustion process comes from the street.

The design provides two heat exchangers, one for the heating circuit, the second for heating the DHW liquid. Thanks to this, the heating time of the liquid is reduced, and it is also possible to use the boiler in the summer.

Room thermostat with display

It is possible to connect to a room thermostat, which is not included in the package; it must be purchased separately. For safe operation, there are relief valves that are activated if the coolant temperature exceeds the permissible limits. Also, for safe operation, there are flow sensors that monitor the pressure in the heating circuit; in case of non-compliance with the standards, the operation of the system is blocked.

Basic error codes

Let's try to look in more detail at the error codes of Oasis boilers and the possible reasons for their appearance.

e1

Error e1. Indicates an ignition malfunction, possible causes:

- There is no gas supply to the device. Check if the gas valve is open, if not, open it. There may also be insufficient or, on the contrary, excessive gas pressure; to eliminate this, you must contact the gas service.

- The contact connection is broken or missing. Check for opens and shorts using a multimeter. They may have oxidized, in this case, strip and insulate the wires...

- The board has failed. It is necessary to test it and, in case of malfunction, replace it with a new one; this type of repair requires the necessary qualifications. Boiler control board

- The control ignition electrode is broken. First, clean it using a wire brush and visually check for damage to its body. If you find a defect in it or its wire, replace it.

- The plug is not inserted correctly into the socket, replace it with the other side

e2

Error e2. Lights up if the air pressure switch does not close 8 seconds after turning on the fan.

- Clogged pipe or chimney. Check for draft and clean the chimney. It would also be a good idea to open the combustion chamber, there are two pipes connected to the monostat, remove them and blow them out.

- The relay that controls the air pressure has failed. Test it for serviceability and replace if necessary.

- The fan has failed. Check its serviceability, examine it carefully, there are tubes in it, check their integrity, whether they are melted. Next, you need to turn on the boiler and after the fan starts working, short-circuit the two wires going to the monostat. Oasis boiler fan If the boiler lights up, then the monostat is broken and needs to be replaced, and if not, then the problem is in the control board.

- The electronic part of the device is faulty, or a wire is coming off somewhere. Perform a visual inspection of all connections of the device and the integrity of the wires. If the board is faulty, then it is better to contact specialists to repair and diagnose it.

Errors in gas boilers Arderia (Arderia) and methods for eliminating them

Any gas boiler needs regular maintenance and preventive measures. It happens that the causes of problems are external factors: low pressure in the line, voltage drops, etc.

We recommend: Is it possible to paint hot radiators and how to do it correctly?

Malfunctions of Arderia gas double-circuit wall-mounted boilers are detected in the form of codes on the screen. Their decoding is available in the operating instructions.

- pump failure;

- 3-way valve failure;

- failure of the DHW flow sensor.

All heating system shut-off valves may be closed

Open shut-off valves.

Check the functionality of the three-way valve and the DHW flow sensor.

Replace broken items

- lack of fluid in the heating system;

- air jams;

- malfunction of the circulation pump or flow sensor

The speed of the circulation pump impeller should be adjusted.

Replace faulty elements

- low gas pressure;

- malfunctions of the gas valve or transformer;

- blocking of the gas duct

- shut-off valves are closed;

- filters are clogged;

- There is a problem with the circulation pump or three-way valve.

Check the functionality of the pump and three-way valve

Replacing a faulty element

Models of gas boilers Arderia B10, B14, B16 have different error codes. Let's look at what they mean and how to troubleshoot.

E0 – antifreeze mode. This code is displayed on the screen if the coolant temperature drops below +1°C. It is necessary to check the integrity of the system in which the liquid circulates. The error disappears if the coolant is heated. If it still hasn't disappeared, call a professional.

Code E1 indicates an ionization sensor error. This occurs when there is no expected flame. Appears as a result of unsuccessful ignition of the unit or after the flame fails during operation.

E2 – pressure sensor error. Appears as a result of weak draft, which is caused by malfunctions of the sensor or fan. The unit will attempt to return to normal operation for 15 minutes. Check the chimney and the presence of draft in it. If the error does not disappear after 15 minutes, contact the service center technician.

E3 – overheating thermostat error. Occurs when there is no coolant or its movement in the heating system. The circulation pump may be faulty. You should also check all valves and lines of the system. You can remove the lock using the MODE button. If this does not help, contact customer service.

E4 – overheating of temperature sensors. Appears on the screen due to the lack of fluid in the system or its circulation. Check the valves and heating pipe. The lock is released using the MODE button.

E5 – temperature sensor error. Appears when the cold water sensor is faulty. Turn off the hot water and wait. The lock can be released by pressing the MODE button. Code E6 – DHW sensor error. Appears when the DHW sensor is faulty. Close the hot water taps to normalize the heating system. The lock is released using the MODE button.

E7 – problem with the temperature sensor. Displayed when the heating circuit temperature sensor fails. Typically, this code appears when communication with the sensor is lost. When it gets better, the problem disappears.

E8 – indicates the presence of residual fire (ionization sensor error). Occurs if there is still fire in the combustion chamber or as a result of a sensor error. Unlock using the MODE button. If the error occurs again, contact customer service. E9 means pressure sensor error. Appears when fluid pressure is low or absent. You should check the system for leaks or adjust the speed at which the pump pumps coolant. It is necessary to eliminate any identified leaks or adjust the pump operation.

The fan starts working, but the flame does not appear

The air pressure switch does not work. Blocking the chimney. Leak in the combustion products exhaust system. The combustion chamber is not sealed. Power supply voltage is below 170 V. Install a voltage stabilizer

Incorrect combustion: flame color yellow or red

The burner is dirty. Incorrect functioning of the chimney. Incorrect gas valve setting.

Long waiting time for hot water

Since in the absence of water supply the water in the DHW pipe cools down, some time must pass before hot water appears from the tap.

The Arderia boiler often turns off: due to excessive temperature (error A4) or low pressure in the heating system (error A5).

Insufficient pressure, leaks or circulation problems in the heating system. It is necessary to check that the pressure in the heating system is within 1-1.2 bar, and that there are no leaks in the system. Checking the circulation in the heating system must be carried out by authorized personnel.

Presence of air in the heating system. Remove air.

Insufficient air pressure in the boiler expansion tank. Raise the air pressure in the tank to 1.0 bar - at zero pressure in the heating system.

The boiler pump shaft is blocked. The boiler pump is faulty. You need to call an authorized specialist.

Frequent spontaneous shutdowns of the boiler in DHW mode

Insufficient cold water pressure at the boiler inlet.

Ensure that the cold sanitary water inlet pressure is at least 1.5 bar. When using an individual water supply system with a hydraulic accumulator and uneven pressure, it is recommended that the pump turn on pressure be at least 2.0 bar.

Hot water flow too low. Do not set the water flow below 2 l/min, as this will trigger the DHW flow sensor and subsequently turn off the water heating. Random opening and closing of water taps respectively starts and stops the water heating process, which can lead to an increase in waiting time for hot water.

Fluctuations in hot water temperature

The simultaneous use of several hot water consumption points makes water consumption unstable. To reduce temperature fluctuations, do not use more than one hot water tap at a time.

The boiler burner does not turn on (error A6)

The power cord is not connected - connect the power cord. No gas supply - open the gas supply valve. The water temperature is set too low - set the temperature to a higher temperature using the regulator.

The appearance of strange sounds during boiler operation

There is air left in the pipes - bleed the air. Repeat filling the boiler with water. All shut-off valves are closed - open the shut-off valves. The Arderia boiler is not attached to the wall correctly - secure the boiler correctly. If the noise does not disappear, call a specialist from the service center.

The room does not warm up to a comfortable temperature

The boiler is operating in DHW mode - turn on the heating mode. The coolant temperature is set too low - set a higher temperature using the regulator. The shut-off valve in the heating circuit is closed - locate and open the valve. One or more taps in the heating circuit are not fully open - check all taps. Open partially closed ones. The boiler filter is clogged - clean the filter. There is air left in the pipes - bleed the air. Repeat filling the boiler with water.

No DHW

Clean the filter. The DHW stop tap is closed - open the DHW tap. The filter is clogged - clean the filter.

The boiler is overheating

Shut-off valves in the heating system are closed - check all valves. Open if they are closed.

Oasis gas boiler error codes

Error with code E1 Failure to ignite the Oasis gas boiler. There is no supply of gas fuel to the gas burner unit. The shut-off valve on the gas supply line is closed. You will need to open the shut-off valve. Vent the piping line when the unit is first started up. Measure the gas pressure supplied to the gas unit. Nominal pressure parameters are specified in the operating instructions. In turn, it is recommended to adjust the pressure of the gas mixture at the nozzle (minimum / maximum). The gas valve is inoperative. The gas valve must be replaced if malfunctions are detected. Poor functioning of the ignition electrode or its breakdown. Check and restore the gap between the ionization electrode and the burner block. If you notice a large amount of dust on the electrode, clean it. Malfunction of gas equipment elements, including shorted or broken contacts of the gas valve coil. If these violations are detected, replace the gas valve. Gas valve stem stuck. There is a fitting on the front of the valve. Attach a rubber tube to it and remove excess pressure. The ignition power of the Oasis boiler is insufficient. Enter the service menu of the device and adjust the required power. The control board is faulty or its functions are impaired. If the ignition transformer stops working, the unit should be rebooted. If error E1 occurs again, repair or replace the printed circuit board. After this, the grounding is checked. Do not allow potential on the cladding. The device may sometimes stop working due to a significant amount of condensation. The ionization electrode, furnace and gas burner mechanism must be thoroughly cleaned of moisture. The electrode that controls the flame is defective. There is no flame on the burner block, although it is detected by the electronic module. The connections are broken or the cable from the ignition electrode to the control module is shorted. Test the electrical circuit and correct the problems. Error E9 Pressure drop in the system. The Oasis boiler displays error code E9 if there is a lack of liquid in the heating circuit. Damage to connections from the pressure switch to the electronics board. Pressostat malfunction. Initially, check what pressure is determined on the pressure gauge. If the pressure drops, replenish the main circuit with liquid. To fill the coolant, a make-up tap is installed on the unit. When error E9 appears again, you need to inspect the system to detect a possible leak. Leaks may be present in the circulation pump, the safety group valve, the main heat exchanger, and also in worn gaskets and seals. Error with code E3 Overheating of the Oasis gas boiler. The heating temperature of the protective thermostat is 103C. Error E3 is not displayed when the ignition signal is not received at this time. When the temperature in the heating system increases, the burner goes out, but the heating of the heat exchanger is not interrupted. When the temperature of the emergency overheating sensor rises to 103 C, after 20 seconds the operation of the device will be interrupted due to the activation of the automation unit. When the thermostat detects a temperature of more than 100 C in heating mode, the electronics waits for an expected temperature drop for approximately 25 seconds. If the temperature of the thermostat and NTC heating sensors does not decrease within the designated period of time, the Oasis boiler displays error code E3. Blocking during the ignition stage of the burner device. When the temperature of the safety thermostat in the phase when a flame is formed is above 103 degrees, the control automation displays a malfunction with a pause of ten seconds. Activation of the overheating safety thermostat or heating temperature sensor, which blocks the unit. When the fluid temperature reaches 103 degrees, the overheat thermostat turns on. After the unit has cooled down, reset it to zero using the reset key. The overheating sensor is damaged or does not respond correctly. You will need to change it. The circulation of the coolant in the heating circuit is unsatisfactory. If, when measuring the pressure of a cooled heating system, it is determined that it is low, pour liquid into the device. There is air in the heating pipe. Use an air vent to remove air from the lines. There is no circulation process. For uninterrupted circulation of liquid, the shut-off valves on the pipelines must be fully opened. The combustion products temperature control relay overheats. Restart the unit when the thermostat sensor has cooled down. Code E7 The circulation water pump began to function abnormally. Pump speed too low. There is no stable voltage in the electrical network. In case of recurring complications with electricity, the device must be connected to the electrical network through a stabilizer. The circulation pump motor is damaged or the stator winding has short-circuited. Insignificant pressure, although the circulation pump is functioning satisfactorily. Obviously, the blades are broken, therefore the hydraulic pump should be replaced. The coolant flows to the hydraulic pump continuously, but it does not rotate. The pump must be checked for possible defects in the rotor shaft. The plug is unscrewed, then we turn the rotor shaft of the electric motor by hand. There is no signal from the control module to the circulation pump, which indicates a malfunction of the control module. If the current fault occurs again after resetting the device, replace the electronics board. Error code E2 Weak traction. The Oasis gas boiler functions reliably and stably when there is good draft in the chimney pipe. The automation monitors that flue gases do not enter the room, and when malfunctions are detected, the traction sensor-relay turns off the unit with error code E2. Here are a few reasons why cravings may be absent or poor. The chimney has a small hole diameter or defects during its installation. Presence of blockage or ice on the inside of the walls. Exceeding the maximum length of the smoke exhaust duct. Please review the relevant codes and regulations in the installation manual. The traction relay is damaged. It needs to be tested and, if necessary, replaced. The connections from the pressure switch to the control module are broken. Diagnose the electrical circuit and correct any problems. There is condensation, and in addition, the tubes are incorrectly connected to the sensor. Clean out the moisture and properly connect the tubes to the traction control pneumatic relay. The fan is damaged. The fan blades are dirty. The fan speed has decreased due to lack of lubrication on its shaft. The connections from the fan to the electronic board are damaged. Error code E5 The temperature sensor in the heating circuit is faulty. The Oasis boiler shows error E5 when the set temperature increases, or if the temperature sensor of the heating circuit is broken. The heating temperature sensor circuit is damaged. If the signal between the temperature sensor and the control module is interrupted, this malfunction occurs. Resumption of normal operation of the device after an accident will occur within a few seconds if the malfunction was accidental. If during the inspection it is discovered that there is no moisture on the sensor connector and the control board contacts, install a new sensor. The contacts of the electrical circuit of the temperature sensor are closed or the coolant is at an excessively high temperature. Check the temperature sensor first. If the resistance does not meet the standards, the sensor should be replaced. If you installed a new sensor, but error E5 is still displayed, repair or replace the automation board. Error code E4 Problems with the hot water temperature sensor. The Oasis gas boiler automation system reports error E4 when the hot water temperature sensor has broken down or the temperature required for trouble-free operation has significantly increased. If a defect in the hot water supply temperature sensor is detected, it must be replaced. There is a fault in the contacts between the hot water supply temperature sensor and the control module. Diagnose electrical connections and find defects. If the electrical contacts between the sensor and the control module are normal, the temperature sensor itself is without defects, but error E4 is somehow issued, then we can claim that the control unit is faulty. Error code E6 Failure of the burner device during ignition. Error E6 indicates that ignition does not occur as a result of the flame of the burner device dying out. Check the electrical contacts from the flame electrode to the ignition unit or from the gas valve to the control module. Restore the contacts of the electrical circuit if damage is detected. In addition, insufficient draft can cause malfunctions that cause flame breakout. Check the chimney for blockages.

_______________________________________________________________________________

_______________________________________________________________________________

- Bosch boiler - Typical problems and their repair

- Malfunctions in geysers Electrolux 275 - Repair and adjustments

- Problems with Celtic gas boilers - Diagnostics and adjustment

- Italtherm boiler error codes

- Causes of malfunctions in the gas wall-mounted boiler Arderia

- Diagnostics and repair of gas boilers Ariston Egis Plus

- Possible breakdowns and repairs of the Immergas Eolo Star boiler

- Malfunctions of Kentatsu gas boilers - Causes and solutions

- Error codes for Saunier Duval gas boilers

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers Koreastar Buran - Typical breakdowns and their elimination

- Causes of the main problems in gas boilers Baxi Eco 5 Compact

- Problems with the operation of Siberia boilers

- How to fix a breakdown of Bosch WR geysers

- Roc boilers - Diagnosis of possible problems

- Main errors of the Kentatsu gas boiler

- Baxi Eco 4S boiler breakdowns - Possible causes and solutions

- Malfunctions of the Ariston Next Evo geyser - Diagnostics and repair

- Methods for troubleshooting boilers Baxi Nuvola 3 Comfort

- Problems when operating gas boilers Baltgaz

- Error codes for Vaillant Turbotec gas boilers

- How to troubleshoot a Gaslux Standard boiler

- Problems during the operation of gas boilers Neva Lux 7224

- Diagnostics of breakdowns in Beretta Novella gas floor-standing boilers

- Problems during operation of Ferroli Diva gas boilers

- Error codes for gas boiler Baxi Ecofor

- Malfunctions during operation of the Ariston Genus boiler

- Bosch 4000 boiler errors

- Hyundai gas water heater - Causes of major breakdowns

- Malfunctions during operation of Protherm KLOM boilers

- Breakdowns in the Baxi Luna Platinum boiler - Causes and repair methods

- The main mistakes of Proterm Medved boilers

- How to fix a breakdown in a wall-mounted gas boiler Baxi Luna 3 Comfort

- Problems during the operation of the Nobel gas boiler and their elimination

- Troubleshooting methods for Ferroli Fortuna boilers

- Diagnostics of breakdowns of gas boilers Immergas Eolo Mythos

- Breakdowns during operation of the gas boiler Neva Lux 8224

- Error codes for Thermona gas boilers

- Boiler Protherm Gepard MOV - Causes of possible malfunctions

- Causes of problems with Fondital Antea gas boilers

- Gas water heaters Vector - Troubleshooting

- Problems with Baxi Slim boilers - Causes and solutions

- Troubleshooting methods for the Proterm Jaguar boiler

- Leberg gas boiler errors

- Basic problems and settings of the AEG geyser

- Mora boiler error codes

- Basic breakdowns and adjustments of Alpenhof gas boilers

- Causes of the main problems with Baksi Ecofor gas boilers

- Possible breakdowns and repairs of Haier gas boilers

- Malfunctions in the Protherm Panther KTV boiler - Causes and solutions

- Error codes for gas boilers Proterm Leopard

- Troubleshooting Thermex boilers

- Vaillant Atmotec gas boilers - Basic problems and troubleshooting

Other faults

A situation may arise when the boiler stops heating water, that is, cold water flows from the tap when turned on. Most likely, the problem lies in a malfunction of the turbine, which does not transmit a signal to the sensor, then the flame does not ignite and, as a result, the liquid does not heat up.

The turbine cannot be repaired and needs to be replaced. To prevent a similar situation from happening again with a newly installed turbine, we recommend purchasing and installing a high-quality fluid filter.

Sources:

https://mr-build. ru/newteplo/gazovyj-kotel-oazis-otzyvy. html

https://climaveneta-rus. ru/truby/gazovyj-kotel-oazis-oshibka-e10.html