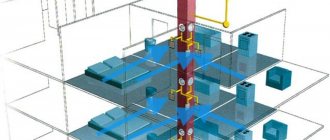

High-quality ventilation in the kitchen allows you to avoid breathing fumes that inevitably accompany the cooking process and ensures the safety of the furniture. The hood is mounted directly above the stove, and the ventilation shaft may be located at some distance. To connect them, special pipes are used - air ducts. Let's find out how to choose, assemble and disguise a plastic air duct for a kitchen hood.

Plastic pipes have a long service life and ease of installation. In addition, PVC products are safe in terms of environmental friendliness and hygiene.

Materials for choosing boxes for the kitchen, advantages and disadvantages

Decorative boxes that hide the elements of the ventilation system not only perform a decorative function, but also reduce the noise of the hood electric motor

It is important what material the box is made of

It must be resistant to moisture, temperature changes, and not subject to chemical and mechanical stress during cooking.

A box made of any material must be regularly cleaned of dust, grease and dirt. The materials from which boxes are made have their pros and cons.

Therefore, when purchasing or making your own, you need to take this into account. The structures are made from the following materials: plastic, metal, wood and plasterboard.

Plastic construction

Plastic is polyvinyl chloride. Plastic boxes have a round and rectangular shape. The rectangular box is more organic and looks good with the kitchen cabinets.

Quick and easy to assemble. The material has great sound insulation, is durable and has a long service life, and is not subject to corrosion. Easy to cut and adjust to fit. It is very light in weight.

The disadvantages of plastic include the fact that the white color becomes yellow, matte, or gray over time. Forms dents under the weight of objects or from mechanical impact.

After some time, its surface becomes porous, where dust and dirt penetrate, which is difficult to remove. When assembling connections of plastic elements, you must follow the sequence.

To ensure tightness, so that dirty air does not fall on the surface of the box and penetrate into the room, silicone should be applied to the joints. There are many different connecting parts available for sale.

With their help, channels are connected in any direction and at any angle. The fasteners of the structure must be placed often along the entire length at a distance of at least a meter, and also strengthened at the junction of parts with each other.

Metal construction

A metal box or hood is a more reliable design. Stainless steel is the ideal starting material. Ordinary metal is coated with powder-based paint.

Stainless steel is easy to clean, does not absorb dirt, is strong and durable. Features a stylish modern design. There are no visible scratches on it. The material is not subject to corrosion.

The disadvantages include the high price and the presence of a monotonous range of colors. Complexity of assembly, the need to maintain accurate measurements. The design is heavy and requires reliable fastening.

A box made of this material does not protect against noise, and fingerprints remain on the surface, which are difficult to erase. It does not always fit into the interior of the furniture and looks bulky.

When assembling a metal frame, welding is used and cut with a grinder. If the metal sheet is thin, replace welding with metal glue. The sheets are overlapped.

Plasterboard structures

A cheap, lightweight material - drywall is easy to assemble in any configuration and shape. It is necessary to install metal profiles for installation.

Allows you to assemble a box to hide the air duct in a short time

When working with drywall, care must be taken as the material is quite fragile.

The material is convenient and easy to process, so the box can be made and assembled by yourself, without unnecessary expenses or the involvement of a craftsman. The finished box can be processed, puttied and finished with tiles, wallpaper, mosaics and other decorative materials.

With proper use and pre-treatment against impacts, it will last a long time.

Decorative wood box

A wooden box looks harmonious with a kitchen set made of the same material. Possessing the same properties, it will be part of the kitchen, complementing the design of a certain style, and also fulfilling a functional purpose.

Wood is an environmentally friendly, reliable, good material that requires little maintenance. The disadvantage is the heaviness of the finished structure.

Features of the practical use of boxes

One of the most interesting solutions can be called a rotating elbow with a variable angle. Often, air flows in a ventilation system do not always have to be turned at right angles. Sometimes two plastic boxes need to be joined at an angle of 30o or 60o. It is almost impossible to make a docking station without “changes”.

You can buy boxes in three different sizes on the market - 35 cm, 50 cm and 100 cm. Each section of a plastic box is a finished product, at one end of which there is a landing belt, at the other - an extension. By inserting the belt of one section into the extension of the second, you can easily assemble an air duct for a ventilation system of any complexity.

The main thing here is not to get confused; when assembling a ventilation system, the receiving unit is first assembled, this could be the exit from the hood or the entrance window in the shower stall. There must be a seating collar on the receiving unit fitting. We put the first section of the box as an extension onto the girdle of the receiving unit. It turns out that all subsequent plastic sections will be placed in the direction of the flow. The joining with any shaped elements is carried out in a similar way.

Some manufacturers even put arrows on the surface of the box to make it easier to navigate during assembly. Why is this being done? Most ventilation systems are assembled without the use of rubber seals or gaskets at the joints. If the box is installed correctly, the air flow will suck air from the room through the leaks. The air pressure in the flow is always lower than outside the box.

If you assemble the ventilation system incorrectly, then due to dynamic pressure, polluted air will leak through the cracks at the joints of the ducts.

Often, craftsmen resort to an interesting way to check the correct assembly of the ventilation system. Instead of inspecting each plastic box, looking for marks and arrows, a stream of smoke is directed into the hood and an electric fan is turned on. If the ventilation system is assembled incorrectly, then wisps of smoke will be visible at the joints of the plastic boxes.

For long-distance ventilation systems, as a rule, plastic boxes with rubber gaskets at the joints are used. The most problematic places through which air siphons are located at the outlet of the rotary elbows. Leaks can be easily detected by dirty spots on the plastic surface around the joint line.

Used as a decorative element

The principle of the method is decoration. This applies not only to the ventilation duct itself, but also to the adjacent part of the wall (in some cases). You need to make sure that the box becomes a stylish accessory to the interior of the room. The following techniques are used for this:

- Fixing the mirror will not only have a functional purpose, but can also visually expand the space.

- Sticker of wallpaper, photo wallpaper, panels. Any of the options suits the style of the room.

- Continue finishing the work apron. It could be tiles, porcelain tiles, mosaics, melamine surfaces or something else. The goal is to blend the ventilation duct with the rest of the kitchen.

- Assembling a frame from gypsum board allows you to change the configuration of the box and give it the desired shape.

- A similar situation applies to cladding with PVC and MDF panels. The sub-cladding system covers visible imperfections.

- Organization of the slate board. Simple and tasteful, it will be possible to leave messages and wishes for household members, and write down important reminders.

- Decoration with artistic painting is suitable for rooms that already have such decorative techniques. You can emphasize the decorative significance of the ventilation duct by highlighting it with lighting. The ideal option would be spotlights recessed into the ceiling or a diode strip located there.

An example of the correct layout of a kitchen space Source stosastudio.ru

Extremely inconvenient location of the ventilation shaft Source esen.ucoz.net

Why hide pipes?

There are two types of kitchen hoods.

Circulating hoods that purify the air using a filter and return it back to the room. They do not require connection to the ventilation shaft of the building; therefore, they do not require an air duct and do not need to mask anything.

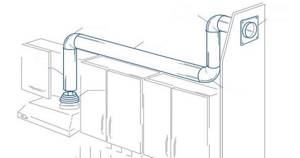

Flow hoods that remove polluted air from the kitchen. They clean much more effectively, but require connection to the ventilation system through a corrugated hose, which has an unattractive appearance that does not decorate the interior of the kitchen. In addition, if the ventilation shaft is located on the other side of the kitchen, the length of the air duct can be several meters. Therefore, the question of hiding the exhaust pipe arises simultaneously with the process of installing the entire system.

Selection of material

Once the dimensions have been calculated, you need to decide on the material for the hood decorator. You should not save on purchasing high-quality material, since this box is designed to last for several years. It will be exposed to various influences: sunlight, temperature changes, chemical treatments, shocks, etc. It’s worth taking care of this in advance; you’ll spend less nerves, effort and money.

The material for decorating the exhaust system, as a rule, matches the material of the installed kitchen unit. The most commonly used materials are plastic, wood, plasterboard, and metal.

Due to its flexibility, a PVC box product can be manufactured in any shape (round, square, triangular, rectangular). It can be easily combined with a stretch ceiling or decorative wallpaper. The negative side of a plastic box is its high price.

A wooden box is not durable in use and causes difficulties in cleaning. The settling dust must be removed more often, otherwise it will penetrate into the top layer of the tree. When impacted, a wooden product is quite durable, but is not always resistant to chemical reactions. In addition, wood is not a flexible material, so the design will be either square or rectangular.

Since this material is readily available, you can use an old wardrobe or bedside table as structural parts. This will significantly reduce your costs.

- A plasterboard box is used very often, as this material has many advantages. For example: low cost on the market; You can use used material; easy to assemble and install; small weight category. The material is durable, strong, and relatively flexible. With its help, you can elegantly hide the shortcomings of a corrugated air duct.

- Metal decor for hoods has its positive and negative sides. The box, made of stainless steel (steel, aluminum), is very strong and durable, which allows it to be used for many years. The metal is coated with a special polymer composition, or paint, which allows you to care for it without much effort. This is a flexible material that will allow the kitchen owner to fantasize and experiment endlessly.

Negative aspects - the iron box is difficult to install; it does not absorb noise, but amplifies it; expensive in price and heavy in weight. As a rule, metal structures are used in industrial and specialized kitchen areas.

7 photos

Review of air ducts for kitchen hoods

To connect the exhaust outlet pipe to the opening of the vertical shaft, 3 types of boxes are used:

- flexible aluminum corrugation of the Aluvent type;

- PVC plastic channels of round and rectangular cross-section;

- metal boxes of various shapes.

Now we will analyze each group of kitchen exhaust ducts separately - we will list the characteristics, pros and cons of the products.

Aluminum corrugated pipes

The flexible channel is a frame made of soft wire, covered with thin aluminum foil. A layer of polyester is applied on top for better sealing. The pipeline is transported and sold in a compressed state, after unpacking it is stretched to the required length (maximum 5 times).

Air duct technical characteristics:

- wall thickness – up to 100 microns, cross-section – round;

- maximum operating temperature – 250 °C;

- permissible bending radius is 0.7D (D – diameter);

- range of diameters: 80, 100, 110, 120, 125, 130, 140, 150 mm.

The main advantage of aluminum hoses is their reasonable price; 1 meter of air duct Ø100 mm in stretched form costs approximately 50 rubles. (0.9 cu). Thanks to a rich range of standard sizes, the ventilation duct can be easily matched to the outlet diameter of the hood opening and ventilation grille.

The corrugated exhaust duct is installed quickly and easily. The pipe is stretched to the required length, one end is put on the fitting of the exhaust unit, the other - on the grille. Then the corrugation is fixed with ordinary clamps, and the installation ends here.

The flexible corrugated pipe can be installed in literally 5 minutes; just secure the ends with clamps

Disadvantages of flexible channels:

- The appearance of aluminum corrugation does not meet modern interior design requirements. The box is suitable for a hood in a country house, in a summer kitchen or in an apartment undergoing regular renovation. In other cases, the pipe must be hidden behind a decorative casing or plasterboard sheathing.

- The wavy structure of the walls creates increased resistance to air flow. Fan efficiency decreases.

- For the same reason, more fat deposits are retained inside the canal. It is impossible to clean the corrugation; it is easier to replace it.

- Aluminum foil is easily damaged by any sharp object.

The last negative point is that when the hood is operating, the corrugated pipe makes a lot of noise. The reason is the vibration of thin flexible walls plus a wavy profile that provides air resistance.

In short sections, corrugated pipes look satisfactory; in longer channels, all beauty is lost

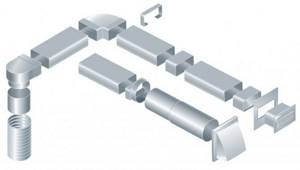

Plastic ventilation ducts

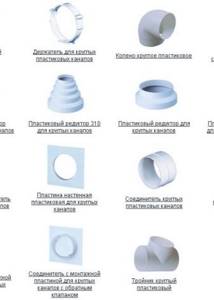

White polyvinyl chloride (PVC) is used to make air ducts. The pipeline does not bend, so sections of the ventilation network are connected using shaped elements - couplings, nipples, elbows, tees and various adapters. Characteristics of plastic boxes:

- maximum temperature of the transported medium – 200 degrees;

- cross-sectional shape – round, rectangular (flat);

- Diameters of round ducts suitable for hoods are 100, 125, 150 mm;

- “running” dimensions of flat boxes – 55x110, 60x112, 60x204, 90x220 mm;

- the length of the standard section is from 35 cm to 2 m.

Plastic air ducts are connected to fittings in two ways:

- The round section is put on the outside of the mating part of the mounting element - bend, tee or nipple.

- Rectangular pipes, on the contrary, are inserted inside the fittings. Couplings are used to connect straight sections.

On the left in the diagram the nipple connection of a round PVC air duct is shown; on the right, rectangular sections of ventilation ducts are inserted into the tee couplings

In both cases, the joint is carefully sealed with silicone compound. The cross-sectional shape of the ventilation duct can be changed at any point - install a straight or angled adapter, use a tee with different terminals.

The price of plastic is noticeably higher than corrugations of the same diameter. A meter of pipe Ø100 mm will cost about 180 rubles. (3.15 cu), rectangular box of equivalent section 110 x 55 mm - 185 rub. (3.3 USD). Here we also need to add the cost of the shaped parts involved in the scheme.

Other disadvantages of plastic ventilation ducts:

- the color range is limited to light shades, black pipes are impossible to find;

- Accordingly, dust and other pollutants are clearly visible on the air duct;

- plastic is afraid of overheating above 200 °C and is capable of burning on its own;

- over the years, polyvinyl chloride turns yellow and loses its appearance;

- the walls of flat boxes bend at the joints, a gap 1-4 mm wide is formed, as shown in the photo.

Which way is better

The most rational camouflage option will be the one that best suits the interior of your kitchen.

The simplest way is to replace the corrugation with a plastic air duct. But we must take into account that it is effective only when the hood is located close to the ventilation hole. In addition, the plastic box must fit into the color design of the kitchen. Otherwise, it will have to be painted or covered with suitable wallpaper.

If the sleeve is long and extends across the entire room, then the best option would be a suspended ceiling that allows you to completely hide the exhaust pipe.

Plastic box ↑

There are round, square and rectangular plastic boxes for hoods. The choice of design largely depends on the shape of the ventilation hole, but it should be noted that flat boxes, which are so easily hidden behind furniture or in the corner of a room, are usually designed for low-power appliances. But pipes with a round and square cross-section can handle a large volume of air, but they are no easier to disguise than flexible corrugation (although in any case, the plastic structure looks more aesthetically pleasing).

A plastic hood can serve as both an air duct and a decoration. It looks good without additional finishing due to its laconic appearance, but if necessary, it can be painted to match the color of the walls or furniture. The rectangular structure can be laid directly on top of the kitchen unit, without resorting to special disguise tricks.

The flat plastic box hides easily on furniture

Advantages of plastic boxes:

- Low noise level - the low conductivity of the material significantly reduces the sound effect from a working hood. The box practically does not resonate with air flows also due to its fairly rigid design.

- Long service life - this material does not corrode, tolerates moisture well and prevents the accumulation of condensation.

- Hygiene - virtually no vapors of fats and other suspended particles, which are quite abundant in the exhaust air, are deposited on the inner surface of the plastic. This means that you won’t have to try on the role of a “chimney sweep” very often.

- Quick installation - thanks to its low weight, plastic is easy to work with.

- Easy care - just periodically wipe the plastic from dust with a damp cloth.

The main disadvantages of plastic are mainly aesthetic: over time, a white box can turn yellow or gray, and a colored box can fade when exposed to sunlight. But if the air duct is installed correctly and hidden behind the canopy of the furniture, this does not matter much.

A plastic box for a kitchen hood is easy to assemble with your own hands. It is mounted according to the “socket-pipe” principle. A large assortment of connecting connections and elements of various lengths allows you to install the structure even in a room where there are many corners and other obstacles. If necessary, fitting the pipes can be done manually - the plastic can be easily sawed with a regular hacksaw.

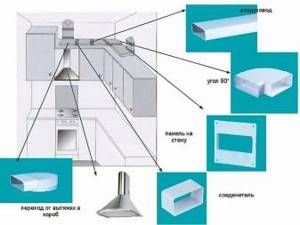

Elements of a plastic box

To assemble plastic boxes for kitchen hoods, you can buy the following auxiliary elements in addition to the main pipes:

- “Elbow” is a rectangular or round part for bending the air duct. With its help, you can rotate the box 45 or 90 degrees.

- Adapters - allow you to create combined structures in which both round and rectangular pipes are used simultaneously (for example, a more powerful air duct from a pipe with a round cross-section emerges from the hood, which turns into a laconic rectangular duct near the wall or ceiling).

- Connectors - if the length of one pipe is not enough to connect to the ventilation hole, you have to extend the air duct using another piece of pipe and an adapter. Of course, the connector must match the cross-section and shape of the parts.

- Anti-return valve - ensures air movement only towards the outlet. If a reverse draft is triggered in the ventilation duct (for example, during strong winds or when a powerful hood is running in a neighboring apartment), the valve closes the entrance to the shaft and blocks the penetration of unpleasant odors.

- The grille is fixed at the very entrance to the shaft and provides a hole of the required cross-section where the ventilation duct for the kitchen hood is inserted

Using these elements, you can assemble a structure of any length. The main thing is to fasten the connections sequentially, not forgetting that the air through the hood should only move in one direction.

Example of a plastic box design

How to choose?

The choice of hood box depends on the following criteria:

- operating features - temperature, humidity, dustiness of the room, mechanical influences;

- maximum permissible load on supporting structures;

- ventilation equipment capacity;

- requirements for vibration and noise insulation.

When choosing an air duct, you must follow the following recommendations:

- the number of joints should be minimal;

- you should reduce the number of structural elements when creating a wiring plan and at the same time maintain the system parameters;

- To reduce the number of blockages, flow resistance, noise and vibrations, channel turns should be kept to a minimum.

Kitchen hood box

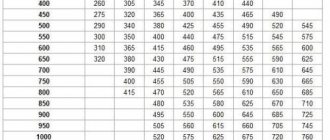

Rules for choosing the duct cross-section

The cross-section of the air ducts is selected depending on the exhaust power, maximum air throughput, regulatory requirements for installation and operation. Usually the size is taken equal to the area of the hood inlet pipe or slightly larger. If ventilation is rarely used, the cross-section relative to the pipe may be reduced.

The cross-sectional area Sc (cm2) is calculated using the formula:

S_c=L×k/V,

where L is air flow in m3/hour;

V is the speed of air movement in the ventilation system m/sec;

k is the coefficient of dimensional coordination; in these units of measurement it is equal to 2.778.

The actual cross-section S (cm2) of a circular shape can be determined as follows:

S=(π·D^2)/400,

where D is the pipe diameter in cm2.

For rectangular air ducts, the actual cross-section is determined by the following formula:

S=(A B)/100,

where A is the channel width in mm, and B is the length, mm.

Manufacturers and models of ready-made solutions: ratings and prices

The rating of exhaust systems is as follows:

- in the budget class worth up to 10 thousand rubles: Siarko, Faber, Korting, Kuppersberg;

- in the middle class up to 50 thousand rubles: Miele, Siemens, Smeg, Teka;

- in the elite class from 50 thousand rubles: Electrolux, Falmec, Bauknecht.

TOP 5 manufacturers of hoods: Hansa, Gorenje, Samsung, Elikor, Bosh.

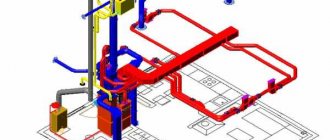

Features of installing an air duct for a kitchen hood

The task of a kitchen hood is to create an outflow of exhaust air without disrupting natural ventilation. Before installing plastic air ducts, the unit must be secured to the wall or ceiling.

For kitchen exhaust ducts, 2 types of products are used:

- PVC pipe;

- household corrugation made of aluminum.

Shaped elements and fastening to walls and ceilings

The most common segments on sale are 0.5-1 m long. When installing a plastic air duct for a kitchen hood, they are connected along the length using couplings.

To narrow them, adapters are used, but it is not recommended to change the cross-section unless necessary. Pressure losses increase and noise increases several times.

To change direction, use your knees. A sharp 90° turn can be rounded by connecting two plastic 45° exhaust elbows.

Communication will look much neater if you convert the round plastic ventilation duct into a flat one. This is done using a special adapter. Then you can run the channel close to the wall.

To maintain natural ventilation in the kitchen, a grille with 2 holes is installed on the shaft - one for connecting the air duct, the other for passing air into the exhaust shaft. Such products have an injector - a special partition to cut off the reverse flow.

To attach round and flat plastic air ducts to a wall or ceiling, manufacturers produce special holders that match the standard sizes of the ducts. The product is inserted into the fastener and snapped into place. Aluminum hangers, which are used for mounting drywall, clamps with a pin and a rubber gasket, and metal mounting tape, are also suitable.

Assembly Features

The easiest way to install aluminum corrugation. For assembly you will need two clamps and a grille for the ventilation shaft.

One end of the flexible air duct is placed on the adapter flange of the hood, the other is attached to the grille. The joints are secured with clamps, and that’s it - the corrugation is installed.

Typical hoods are usually equipped with a decorative casing. Before installation, it is removed and then installed in place.

Plastic parts are easy to cut. They are cut after measuring the size of the ventilation branch, using a hacksaw. The elements are connected in series into a spatial structure. During assembly, the joints are coated with silicone sealant.

When connecting a plastic hood in the kitchen, you can install a return valve at the end of the air duct, which prevents the reverse flow of air.

If you plan to install a suspended or suspended ceiling in the kitchen, and the hood will be attached to the ceiling, pre-install the embedded parts. Tension the canvas only after installing and connecting the duct to the ventilation shaft.

Plastic air ducts are used in everyday life and in production. For high-quality air exchange, you need to choose the right cross-section. In the kitchen, it is optimal to use plastic ventilation pipes for hoods with smooth walls. They make less noise, do not accumulate dust, and do not interfere with air flow.

Connection rules and errors when installing air ducts for a kitchen hood on video:

262

TOP 5 options for masking the exhaust pipe

When installing a flow-through hood, you should definitely provide several options for how exactly you will hide the air vent so that the aluminum pipe or corrugation does not spoil the impression of the overall style of the kitchen space. The sleeve can be decorated using all kinds of materials and technologies.

There are a number of requirements for camouflage designs:

- Presentable appearance and aesthetics.

- Temperature resistance.

- Moisture resistant.

- Resistance to chemical influences, as well as to ultraviolet rays.

- Easy to maintain and maintain.

When working on the task of how exactly to hide the corrugation of the hood from prying eyes in the kitchen, you should definitely take into account the fact that masking elements are also needed in order to reduce the noise from the electric motor of the direct equipment.

Plastic box

The easiest way would be to hide the air vent in the kitchen using a box made of plastic, especially if the distance between the entrance to the ventilation shaft and the hood is no more than 3 meters. You can see for yourself that there is an incredibly large range of current products on the specialized market, and the cost will vary in the affordable segment. The structure will be easily hidden - plastic boxes are produced ready-made, and there will be no need to spend precious time assembling the structure.

Plasterboard box

This solution is ideal for almost every type of interior and will attract attention with its variety of designs. The plasterboard box is usually placed strictly vertically with fastening to the wall surface or a horizontal type structure is created in the space between the upper perimeter of the kitchen unit and the ceiling surface. To ensure that the unity of the style in the interior is not disrupted, the surface of the box is even finished with the same materials as the kitchen.

Built-in headset

To be able to hide the unsightly corrugation from the hood inside the kitchen unit, the design of the furniture composition must include hanging cabinets with special openings for communications. The sleeve will take up very little space inside the module, and the main space will be used for its intended purpose as part of a storage system for kitchen utensils.

Decoration

A very inexpensive way to disguise a chimney is to paint it. To do this, you should choose colors in the style palette of the kitchen space. Decorating the air duct using coloring compounds will be a priority for those people who do not want to spend a lot on consumables for arranging exhaust equipment.

Stretch ceiling

Systems with suspended and suspended ceilings are also quite in demand as structures that hide the exhaust pipe in the kitchen space. Panel and tile solutions will be relatively inexpensive, and most often all the work can be done without the help of specialists. If it is necessary to carry out repair work for communications and scheduled maintenance inside the suspension system, it will be necessary to dismantle the selected sector of the surface, and after all the measures have been carried out, it will be possible to insert the panels back into place. To install a stretch ceiling, you need professional equipment, and this can significantly affect the final cost of the work. Moreover, to access the air duct, which will be securely hidden from everyone under the stretch ceiling system, you will need to remove the covering, which also entails additional costs.

Methods for masking a ventilation duct

Using simple methods, the ventilation will be reliably masked. One way would be to hide it behind pieces of furniture. After installing the cabinets, it will be impossible to guess its presence.

The design of a kitchen with a ventilation duct requires a special approach and a non-standard solution to the problem of an unsuccessful layout.

In a wide kitchen, when there is a corner protruding element, the option of purchasing a furniture set made in the letter G will help. If the protruding support is slight, the box located above the kitchen set will enhance the camouflage.

Functional box cover

There are various ways to transform a ventilation element into a functional item. Make compact shelves on a flat box. They will perform useful tasks: suitable for storing various containers and shallow dishes.

It is better not to disguise, but to increase functionality.

By attaching the bracket to a structure running along the walls, it will serve as a support for the plasma monitor.

A bar counter and an imitation fireplace will make it possible to decorate the kitchen space in an original way. Such a design will simultaneously act as a camouflage and bring comfort, beautifying the house.

You can turn the box into a TV stand.

Ventilation duct as decoration

The protruding part of the ventilation does not have to be hidden; it can be successfully decorated. In this case, you will need ordinary materials. First of all, you need to decide on the desired style. Possible finishing of the box.

Hang a drawing board. To achieve an unusual atmosphere, the box is coated with special slate paint. You will have a plane for writing reminders to your family members.

There is space on it to create a menu.

- Mirror surfaces - cover the box with mirrors and special reflective panels. This will help visually expand the space.

- Mosaic - a finishing material suitable for creating a country, Provence style. You can lay out the entire structure, in the middle, with a metal mosaic, which will create a style for high-tech lovers. A combination of various abstract designs and colorful patterns will add some zest to the setting.

- Modeling an interior that resembles finishing natural stone - covering the surface with tiles that look like brickwork. It is attached using adhesive. If desired, the tiles are laid out along the entire perimeter of the wall, separately on the box. The coating with cement mortar with the effect of unevenness looks original.

- Tile - placing the box flush with the kitchen apron will allow you to cover it with tiles of the same shade, diluted with a color palette. The burgundy shade will add playfulness. It is suitable to use tiles of a uniform style with different image application.

- The column of authenticity is a bold decorative design that allows you to create a Mediterranean style in your apartment.

Textured plaster or stone finishing will help increase the effect.

Kinds

Air ducts designed for proper operation of the hood are different. They are made from various materials, which always affects their performance characteristics and final cost. Let us consider in detail what types of such units exist, and by what parameters they are divided.

All types of air ducts are mainly divided into rigid and flexible types.

Flexible air ducts can be positioned at a variety of angles. If required, they can be stretched or compressed (of course, within the limits of what is possible). However, it must be taken into account that a weakly elongated air outlet has a stronger resistance to air flow. This does not have the best effect on the overall efficiency of the system as a whole. In most cases, such models are made of aluminum. The main disadvantage of such systems is that it is not recommended to make the corrugated box longer than 3 m, since any extra centimeter in this situation will reduce productivity by about 5-10%.

And also all air ducts are divided according to their immediate shape. There are several options for such systems.

Let us consider in detail what types of air ducts for hoods are.

Rectangular and square. These types of air ducts are recognized as one of the most popular and occur with enviable regularity. Many owners choose them precisely because of their shape, which allows them to be placed directly behind kitchen cabinets. Thanks to this feature, it is possible to lay almost any path from the exhaust equipment to the ventilation shaft. Rectangular specimens will be an excellent solution for kitchens with any ceilings (meaning any height parameter). In addition, these models boast a good appearance.

- Flat. These duct options are one of the varieties of rectangular models. They are very modest in size and seem completely invisible.

- Rounded. Such varieties are more demanding - they can only be installed in rooms with high ceilings. This requirement is due to the large dimensions of the equipment. If the outlet has a rectangular structure, then it will be necessary to additionally use rectangular adapters with the appropriate cross-section for round models.

- Oval. These specimens have the same strengths and weaknesses as the rounded specimens.

Of the listed options for air ducts, flat rectangular models should be highlighted.

They are represented by products with the following parameters:

- 110x55 mm - such options are required for hoods with a capacity of no more than 300 m3/h;

- 120x60 mm – suitable for equipping hoods whose performance level does not exceed 350 m3/h;

- 204x60 mm - ideal for operation in conjunction with high-performance units - up to 1000 m3/h.

Construction result

As we have already noticed, repairing ventilation is not an easy task and it will take a couple of days to complete a high-quality repair, especially if it’s not in the same room. Having the electrical tools needed for repairs will make the task much easier. To visually understand what each repair step looks like, it’s a good idea to watch the corresponding videos on the Internet.

WATCH THE VIDEO

In terms of attracting specialists to repair, do not expect to cope with the repair cheaply: although companies offer to solve this problem quickly and without monumental investments, the final amount is rather large. Therefore, it is better to do this work yourself, because there is nothing super complex here that an ordinary person cannot do.

Related Posts

- How to close the pipes in the toilet

- What should be the diameter and length of the exhaust duct?

- How to calculate the cross-section and diameter of an air duct?

- How to attach air ducts to the wall yourself

- Correct installation of a hood in the kitchen with your own hands

- The best plastic boxes for electrical wiring: how to choose the size and type of box for wiring installation

- Carbon filter for hood: device, principle of operation and replacement technology

- Pipe box

- Plastic ventilation pipes for hoods: types, their characteristics, application

- How to assemble a ceiling box from plasterboard?

- Decorative overlay for a heating pipe: what is better to choose to make it look beautiful?

- Corrugated air ducts for ventilation: corrugated hoses and corrugated pipes

- Dimensions and types of plastic air ducts for ventilation

- Soundproofing ventilation: device features and installation methods

- Features of the box for the LED strip and its installation yourself

- Calculation of the area of air ducts and fittings, aerodynamic and other indicators

- How to install a hood in the kitchen with your own hands

- Choosing a corner hood for the kitchen

- How to clean the ventilation in an apartment yourself

- Ventilation in a suspended ceiling

- Ventilation grille with non-return valve

- Features and installation of galvanized air ducts for ventilation

- How to glue fiberglass correctly?

- How to choose a hood over a gas stove: what criteria to consider when choosing a suitable model

- Fum tape technical characteristics, how and how much to wind on the thread

Read with this

- How to close the pipes in the toilet

- What should be the diameter and length of the exhaust duct?

- How to calculate the cross-section and diameter of an air duct?

- How to attach air ducts to the wall yourself

- Correct installation of a hood in the kitchen with your own hands

- The best plastic boxes for electrical wiring: how to choose the size and type of box for wiring installation

- Carbon filter for hood: device, principle of operation and replacement technology

- Pipe box

- Plastic ventilation pipes for hoods: types, their characteristics, application

- How to assemble a ceiling box from plasterboard?

Price for suspended ceilings with ventilation and hood for the kitchen

If you have already decided to install a ceiling in the kitchen with ventilation and exhaust hood, then to resolve this issue you can contact the specialists, who provide their clients with the best prices for certified work.

In order to find out what the price will be for suspended ceilings with ventilation and hood for the kitchen with installation, just contact the managers of our company and discuss all the nuances. The price is calculated individually, taking into account the total ceiling area, the complexity of the work and additional services that are ordered at the request of the client.

Get detailed information and place an order by calling 8 or using the feedback form. The company manager calls back within 1 minute.

Sign up for a free measurement using the form below.