Modern insulation materials can reduce the cost of heating rooms and additionally help protect them from adverse atmospheric influences. Effective polystyrene foam and Penoplex are often used for this. You just need to know their characteristics and understand that it is better to use polystyrene foam or Penoplex for your purpose. The quality of insulation of any building directly depends on the material used. Inexperienced developers often confuse their features when choosing insulation.

Why is thermal insulation needed?

The relevance of thermal insulation is as follows:

- Keeps you warm in winter and cool in summer.

Heat loss through the walls of a typical multi-storey residential building is 30-40% . To reduce heat loss, special thermal insulation materials are needed. The use of electric heaters in winter contributes to additional energy costs. It is more profitable to compensate for these costs by using high-quality thermal insulation material, which ensures heat retention in winter and coolness in the summer heat. At the same time, the cost of cooling the room with air conditioning will also be minimized.

- Increasing the durability of building structures.

In the case of industrial buildings using a metal frame, insulation helps protect the metal surface from corrosion, which is the most detrimental defect for this type of structure. And the service life of a brick building is determined by the number of freeze/thaw cycles. The impact of these cycles is perceived by the insulation, because the dew point is located in the thermal insulation material, and not in the wall material.

Such insulation allows you to increase the service life of the building many times.

Protection against increasing noise levels is achieved by using such noise-absorbing materials (thick mattresses, sound-reflecting wall panels).

- Increasing the usable area of buildings.

The use of a thermal insulation system makes it possible to reduce the thickness of external walls, while increasing the internal area of the building.

How to choose the right insulation?

When choosing insulation, you need to pay attention to: affordability, scope of application, expert opinion and technical characteristics, which are the most important criterion.

Basic requirements for thermal insulation materials:

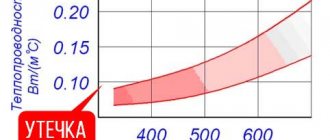

- Thermal conductivity.

Thermal conductivity refers to the ability of a material to transfer heat. This property is characterized by the coefficient of thermal conductivity, on the basis of which the required thickness of the insulation is taken. Thermal insulation material with low thermal conductivity is the best choice.

Also, thermal conductivity is closely related to the concepts of density and thickness of insulation, so when choosing, you need to pay attention to these factors. The thermal conductivity of the same material can vary depending on density.

Density insulation material. Based on density, materials are divided into: extra light, light, medium, dense (hard). Lightweight materials include porous materials suitable for insulating walls, partitions, and ceilings. Thick insulation materials are better suited for insulating the outside.

The lower the density of the insulation, the lower the weight, and the higher the thermal conductivity. This is an indicator of the quality of insulation. And the low weight makes installation and installation easy. In the course of experimental studies, it was found that insulation with a density of 8 to 35 kg/m³ best retains heat and is suitable for insulating vertical structures indoors.

How does thermal conductivity depend on thickness ? There is a misconception that thick insulation will better retain heat indoors. This leads to unnecessary expenses. Too much insulation thickness can lead to disruption of natural ventilation and the room will be too stuffy.

And insufficient thickness of the insulation leads to the fact that the cold will penetrate through the thickness of the wall and condensation will form on the wall plane, the wall will inevitably become damp, and mold and mildew will appear.

If the calculation is ignored, a number of problems may arise, the solution of which will require large additional costs!

Who is the warmest in the world?

The purpose of such a thorough study of insulation is one - to find out which one is the best. However, this is a double-edged sword, as materials with high thermal insulation may have other undesirable characteristics.

Polyurethane foam or extruded polystyrene foam

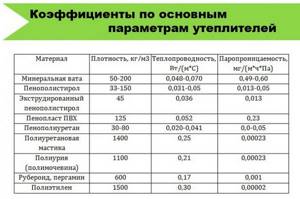

It is easy to determine from the table that the champion in thermal insulation is polyurethane foam .

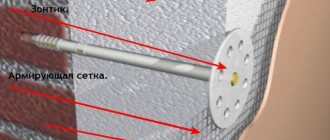

But its price is much higher than that of polystyrene or polystyrene. This is because it has two of the most sought-after qualities in construction: non-flammability and water-repellent properties. It is difficult to set fire to, so the fire safety of such insulation is high, and it is not afraid of getting wet. But polyurethane foam has a real alternative - extruded polystyrene foam. Essentially, this is the same foam plastic, but it has undergone additional processing - extrusion, which has improved it. This is a material with a uniform structure and closed cells, which is presented in the form of sheets of different thicknesses. It is distinguished from conventional polystyrene foam by its enhanced strength and ability to withstand mechanical pressure. That is why it can be called a worthy competitor to polyurethane foam. The only drawback to installing individual slabs is the seams, which can be successfully sealed with polyurethane foam.

As for what is more convenient for you to use – liquid insulation from a can or slabs – it’s up to you to choose. But remember that these materials do not “breathe” and can create the effect of fogged windows, so that all the insulation can leave the window during ventilation. Therefore, it is necessary to insulate with such materials wisely.

Mineral wool or polystyrene foam

If we compare mineral wool and polystyrene foam, their thermal conductivity is at the same level ≈ 0.5. Therefore, when choosing between these materials, it would be nice to evaluate other qualities, such as water permeability. Thus, installing wool in places with possible wetness is undesirable, since it loses its thermal insulation properties by 50% when wet by 20%. On the other hand, cotton wool “breathes” and allows steam to pass through, so condensation will not form . In a house that is insulated with basalt fiber wool, windows will not fog up. And cotton wool, unlike polystyrene foam, does not burn.

Other insulation materials

Eco-friendly materials such as sawdust, which are mixed with clay and used for walls, are very popular now. However, such an affordable material as sawdust has many disadvantages: it burns, gets wet and rots. Not to mention the fact that when sawdust gains moisture, it loses its thermal insulation properties.

Cheap and environmentally friendly foam glass is also gaining popularity, which can only be used without loads, since it is very fragile.

Table of thermal conductivity of materials

| Material | Thermal conductivity of materials, W/m*⸰С | Density, kg/m³ |

| Polyurethane foam | 0,020 | 30 |

| 0,029 | 40 | |

| 0,035 | 60 | |

| 0,041 | 80 | |

| Expanded polystyrene | 0,037 | 10-11 |

| 0,035 | 15-16 | |

| 0,037 | 16-17 | |

| 0,033 | 25-27 | |

| 0,041 | 35-37 | |

| Expanded polystyrene (extruded) | 0,028-0,034 | 28-45 |

| Basalt wool | 0,039 | 30-35 |

| 0,036 | 34-38 | |

| 0,035 | 38-45 | |

| 0,035 | 40-50 | |

| 0,036 | 80-90 | |

| 0,038 | 145 | |

| 0,038 | 120-190 | |

| Ecowool | 0,032 | 35 |

| 0,038 | 50 | |

| 0,04 | 65 | |

| 0,041 | 70 | |

| Izolon | 0,031 | 33 |

| 0,033 | 50 | |

| 0,036 | 66 | |

| 0,039 | 100 | |

| Penofol | 0,037-0,051 | 45 |

| 0,038-0,052 | 54 | |

| 0,038-0,052 | 74 |

This factor is significant, especially in the case of insulating a residential building, since many materials emit formaldehyde, which affects the growth of cancerous tumors. Therefore, it is necessary to make a choice towards non-toxic and biologically neutral materials. From an environmental point of view, stone wool is considered the best thermal insulation material.

- Fire safety.

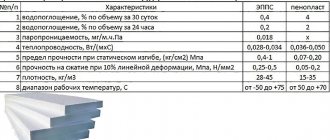

Extruded polystyrene foam

Conventional insulation of this type is marked with the letters EPS. The second type of material, extruded polystyrene foam, is designated by the letters XPS . Such slabs differ from ordinary ones, first of all, in their cell structure. They have it not open, but closed. Therefore, extruded polystyrene foam absorbs moisture much less than ordinary foam. That is, it is able to fully retain its thermal insulation qualities even under the influence of the most unfavorable environmental factors. The thermal conductivity coefficient of extruded polystyrene foam, depending on the brand, can be 0.027-0.033 W/mK.

Advantages and disadvantages of insulation

- Polyurethane foam is by far the most effective insulation material.

Advantages: seamless foam installation, durability, better heat and water insulation.

Disadvantages: high cost of material, instability to UV radiation.

- Expanded polystyrene (foam) – in demand for use as insulation for various types of premises.

Advantages: low thermal conductivity, low cost, ease of installation, water resistance.

Disadvantages: fragility, easy flammability, condensation.

- Extruded polystyrene foam – durable and comfortable material, if necessary, elements of the required size can be easily cut with a knife.

Advantages: very low thermal conductivity, water resistance, compressive strength, ease of installation, absence of mold and rot, ability to operate from -50⸰С to +75⸰С .

Disadvantages: much more expensive than polystyrene foam, susceptibility to organic solvents, condensation formation.

- Basalt (stone) wool – mineral wool made on a basalt base.

Advantages: resistance to the formation of fungi, sound insulation, mechanical strength, fire resistance, non-flammability.

Disadvantages: higher cost compared to analogues.

- Ecowool – insulation made from natural materials (wood fibers and minerals). Today it is used quite often.

Advantages: sound insulation, environmental friendliness, moisture resistance, affordable cost.

Disadvantages: thermal conductivity increases during operation, the need for special equipment for installation, and the possibility of shrinkage.

- Izolon – modern insulation made by foaming polyethylene. It is one of the most popular.

Advantages: low thermal conductivity, low vapor permeability, high noise insulation, ease of cutting and installation, environmental friendliness, flexibility, light weight.

Disadvantages: low strength, need for a ventilation gap.

- Penofol - insulation that meets many requirements for the quality of insulation and insulation of various premises, as well as structures, etc.

Advantages: environmental friendliness, high ability to reflect heat, high noise insulation, moisture resistance, non-flammability, ease of transportation and installation, reflection of radiation exposure.

Disadvantages: low rigidity, difficulty in fastening the material; penofol alone is not enough as thermal insulation.

What is the thermal conductivity of polystyrene foam? Properties and characteristics

The slabs, provided with tongues and grooves along the side edges, are laid on top of the roof frame. The tightness of the connection, hydrophobicity and the included fire retardant will protect the wood from moisture. Types Roofing The side faces are L-shaped, provided with tongues and grooves. Depending on the quality of the wood and the method of constructing the walls, the equivalent of a 5 cm thick PSB can be a log house up to 23 cm wide.

It is much more logical to compare styrene not with mineral wool, brick or wood, but to consider closer materials - polystyrene foam and Penoplex. Both of them are classified as foamed polystyrene and are even made from the same granules. The reason is that styrene beads for the production of Penoplex with the introduction of blowing agents are simultaneously processed under pressure and high temperature.

As a result, the plastic mass acquires greater homogeneity and strength, and air bubbles are evenly distributed in the body of the slab. Polystyrene foam is simply steamed in a mold like popcorn, so the bonds between the expanded granules are weaker.

However, the complexity of production also increases the cost of XPS, so you should not count on savings. By the way, there is one curious nuance here: usually extruded polystyrene foam loses a little in efficiency as the density increases.

But when graphite is added to Penoplex, this dependence practically disappears. However, if the issue of high strength is not on the agenda, and you just need good insulation, it is easier and cheaper to actually buy polystyrene foam. In comparison with materials such as mineral wool, wood and ceramic brick, it is certainly good.

The main thing is not to use it in fire hazardous areas and always try to insulate the outside of buildings. Modern standards for thermal insulation of building structures imply the use of energy-efficient insulation materials, especially Contents: What is thermal conductivity?

Penoplex is produced by the company of the same name. It creates insulating material using a special technology: extruded polystyrene is foamed under high pressure. The same applies to the technology for creating Technoplex, according to open sources.

Characteristics of different brands of polystyrene foam Comparison with other materials and prices Definition Thermal conductivity is a value indicating the amount of heat energy passing per hour through 1 m of any body at a certain temperature difference on one side and the other.

And if the main wall, according to its characteristics, does not reach this value, the difference should be covered by mineral wool insulation or the same polystyrene foam. While foam plastic does not exceed the corresponding characteristics in the same positions. That is why high-quality insulation of the exterior of a house, as well as the protection of other external structures, requires the use of Penoplex.

As for performance indicators, there are no particular differences in the technical descriptions. Both materials cope well with insulation, since their main characteristics are largely determined by their low density.

That is, objectively, extruded sheets are warmer. However, the fire hazard of these insulation materials forced manufacturers to use special fire retardants in their production, thanks to which polystyrenes acquired the ability to self-extinguish.

Manufacturing Features

However, high smoke production, as well as a critical amount of toxins released into the air during combustion, remain a weak point for both types of thermal insulation. And if we compare the cost of both types of styrene from our review, it turns out that only in this parameter does foam plastic win. However, the overall score still remains not in his favor. And if you are deciding what is best to use for insulating a house, without being too interested in the price of the issue, the answer will be clear: Penoplex slabs.

If the protected structure will experience mechanical loads, such as the weight of the decoration on the walls or people walking on the surface, it is better to buy Penoplex. The point is not that it is warmer - it’s just that its high rigidity in this case turns out to be most in demand. But the lack of pressure, say, on the walls will force you to choose more affordable foam plastic. Also, extruded polystyrene foam is unrivaled when it is necessary to simultaneously perform high-quality thermal and waterproofing of objects.

That is, in the case of the basement of a house or a damp basement, the low water absorption of Penoplex will only work to its advantage. In frame buildings, preference is also given to EPS if it is necessary to ensure a sufficient level of sound insulation.

The reason is that ordinary polystyrene foam not only does not block noise, but also amplifies it. That is why for loggias, where every centimeter of space counts, it is better to choose extruded polystyrene foam. Even the standard 50 mm are too flimsy, and it is sometimes scary to attach them to a vertical.

At my dacha I glued Penoplex thermal insulation only to the base, so that no problems would arise from soil movements and constant dampness. And the rest of the facade was simply covered with foam plastic. Out of desperation I had to insulate myself from the inside. After reading the reviews, I settled on Penoplex in order to somehow preserve the usable area. The third year everything is fine - no dampness or problems with the walls. That is, the difference will no longer be so significant. How many cans of foam do you need to pour out to collect a layer of ever-crumbling PSB?

It is good to use it for its intended purpose: under a concrete or floating screed, underground or somewhere closer to the foundation. We did everything together: the walls were aerated concrete, with PSB-Sf on top.

Penoplex and polystyrene foam actually differ slightly from each other, although some features of EPS make it necessary to choose it for certain types of work: insulating structures subject to mechanical loads, in the ground or in conditions of high humidity.

In all other cases, everything is decided only by the price - even the desired thermal conductivity can be selected based on the density and thickness of the sheets. So if there are no special requirements for the insulation of surfaces, it is best to stick with ordinary foam plastic, and it is better to purchase Penoplex for serious work.

The first places among building materials for insulating houses and apartments are occupied by polystyrene foam and penoplex. These types of building materials have many similarities, but due to some differences, these insulation materials differ not only in cost, but also in quality, which affects their choice for insulation work. Today, the question of insulating your living quarters is quite relevant, so every homeowner is faced with the question: what is better to choose for insulating a balcony - penoplex or polystyrene foam?

Comparison of characteristics

The differences between these building materials lie in production technology. Polystyrene foam is produced using polystyrene foam technology, without the use of pressure. The production technology provides for an increase in pentane and polystyrene granules by 50 times. Thanks to this production technology, the building material has high thermal insulation properties.

Penoplex is a derivative of polystyrene foam, only the principle of its manufacture is slightly different. Penoplex is obtained as a result of the extrusion method. This method involves exposing polystyrene granules to pressure and high temperature. The result is a durable and solid material with a uniform consistency.

It is also called expanded polystyrene. Compared to polystyrene foam, expanded polystyrene has a higher density and therefore has worse vapor permeability. But due to its high strength, such insulation can be subjected to various types of mechanical loads.

An important indicator for building materials is their ability to ignite. Polystyrene foam belongs to the category of normally flammable materials, while penoplex is a highly flammable material. To reduce its flammability, at the production stage, the material is treated with fire retardants. The result was achieved, but only the penoplex began to release dangerous toxic gases into the atmosphere. Manufacturers of both types of materials claim an unlimited service life.

But such a statement is appropriate if there is no ultraviolet radiation on the surface of the materials. Therefore, we can talk about durability after covering the penoplex and polystyrene foam with protective materials.

Thermal conductivity of mineral wool in comparison with other insulation materials

Types of mineral wool

Mineral insulation is insulation made from raw materials of mineral origin. The most popular and widely used insulation is mineral wool. The thermal conductivity of mineral wool is an important indicator of the feasibility of use as insulation.

There are stone and slag mineral wool. Stone wool is made from various rocks, for example, basalt, limestone, dolomite. It is durable, high quality, has high performance characteristics and is often used in the construction of buildings and structures.

The raw material for slag wool is a mixture of ferrous and non-ferrous metallurgy slags. It is less durable and is not intended for long-term use buildings. Do not use it in conditions of temperature changes and high humidity.

Thermal conductivity of mineral wool

If we compare the thermal conductivity of mineral wool with the thermal conductivity of other thermal insulation materials, we get the following indicators:

Thermal conductivity, W/m °C / required thickness of insulation layer, mm:

Basalt wool – 0.039/167 mm Expanded polystyrene – 0.037/159 mm Glass wool – 0.044/189 mm Expanded clay – 0.170/869 mm Brickwork – 0.520/1460 mm

Comparative thermal conductivity coefficients of building materials:

Concrete – 1.5 Mortared masonry – 1.2 Working brick – 0.6 Facing brick – 0.4 Plaster – 0.3 Cellular concrete – 0.2 Glass wool – 0.05 Cork coverings – 0.039 Mineral wool – 0.035 Foam plastic - 0.034

As can be seen from the indicators, the thermal conductivity of mineral wool is second only to expanded polystyrene materials. Although if you compare polystyrene foam and stone wool in terms of fire resistance, then stone wool is definitely the winner. All types of stone wool are classified as non-combustible materials.

Characteristics of different materials

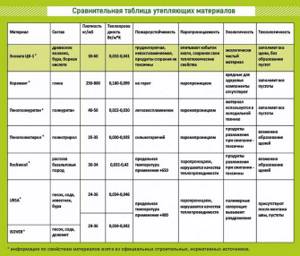

Before considering the table of thermal conductivity of insulation, it makes sense to read a brief overview. The information will help developers understand the specifics of the material and its purpose.

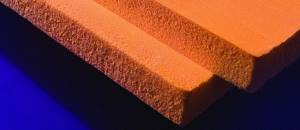

Styrofoam

. Board material made by foaming polystyrene. It is distinguished by ease of cutting and installation, low thermal conductivity - compared to other insulators, foam plastic is lighter. The advantages of the product are low cost, resistance to humid environments. Disadvantages of polystyrene foam: fragility, rapid flammability. For this reason, slabs with a thickness of 20-150 mm are used for thermal insulation of light external structures - facades for plastering, walls of plinths and basements.

When polystyrene foam burns, toxic substances are released.

Extruded polystyrene foam

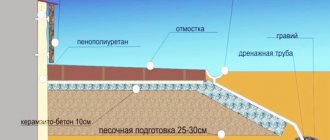

Extruded polystyrene foam is resistant to moisture. The material is easy to cut, does not burn, and is easy to install and transport. In addition to low thermal conductivity, the slabs have high density and compressive strength. Extruded polystyrene foam of the Technoplex and Penoplex brands is popular among Russian developers. It is used for thermal insulation of blind areas and strip foundations.

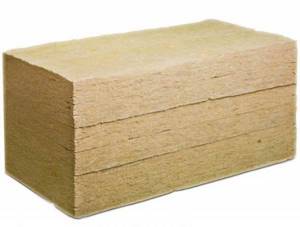

Mineral wool

The thermal conductivity coefficient of mineral wool is 0.048 W/(m*C), which is higher than polystyrene foam. The material is made on the basis of rocks, slag or dolomite in the form of slabs and rolls, which have different stiffness indexes. To insulate vertical surfaces, it is allowed to use rigid and semi-rigid products. It is better to insulate horizontal structures using lightweight mini-plates.

Despite the optimal thermal conductivity index, mineral wool has little resistance to a humid environment. The slabs are not suitable for insulating basements, steam rooms, and dressing rooms.

The use of mineral wool with low thermal conductivity is allowed only if there is a vapor barrier and waterproofing layers.

Basalt wool

The basis for insulation is a type of basalt rock that swells when heated into fibers. Non-toxic binding components are also added during manufacturing. Rockwool brand products are on the Russian market, using the example of which you can consider the features of insulation:

- not subject to fire;

- has good thermal and sound insulation;

- absence of caking and compaction during operation;

- environmentally friendly building material.

Thermal conductivity parameters allow the use of stone wool for external and internal work.

Glass wool

Glass wool insulation is made from borax, limestone, soda, sifted dolomite and sand. To save on production, glass cullet is used, which does not affect the properties of the material. The advantages of glass wool include high heat and sound insulation, environmental friendliness and low cost. More cons:

- Hygroscopicity - absorbs water, as a result of which it loses its insulating characteristics. To prevent rotting and destruction, structures are laid between vapor barrier layers.

- Inconvenient installation - fibers with increased fragility disintegrate and can cause burning and itching of the skin.

- Short-term use - shrinkage occurs after 10 years.

- Impossibility of use for insulation of wet rooms.

When working with glass wool, you need to protect your hands with gloves and your face with goggles or a mask.

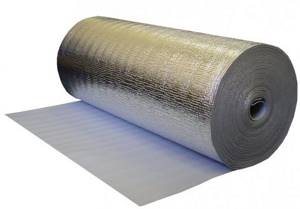

Foamed polyethylene

polyethylene rolls with a porous structure and has an additional reflective layer of foil. Advantages of isolon and penofol:

- small thickness - from 2 to 10 mm, which is 10 times less than conventional insulators;

- the ability to retain up to 97% of useful heat;

- resistance to moisture;

- minimal thermal conductivity due to pores;

- environmental cleanliness;

- reflective effect due to which thermal energy is accumulated.

Rolled thermal insulation is suitable for installation in damp rooms, on balconies and loggias.

Spray insulation

If you look at the table, you can see that sprayed types replace 10 cm of mineral wool. They are produced in cylinders, resemble polyurethane foam and are applied using a special tool. Sprayed insulation comes in different hardnesses; the container also contains foaming agents - polyisocyanate and polyol. According to the type of main component, insulation is:

- PPU. Polyurethane foam with an open cell structure is durable and thermally efficient. If there are closed voids in the composition, steam can pass through.

- Foam insulation. Liquid polystyrene foam based on urea-formaldehyde is characterized by vapor permeability and fire resistance. Apply by pouring. The optimal hardening temperature is from +15 degrees.

- Liquid ceramics. Ceramic components are melted to a liquid state, then mixed with polymer substances and pigments. The result is evacuated cavities. External insulation provides protection for the building for 10 years, internal insulation for 25 years.

- Ecowool. Cellulose is crushed to dust and becomes sticky when exposed to water. The material is suitable for use on damp wall surfaces, but is not used near fireplace pipes, chimneys and stoves.

Sprayed insulation is characterized by good adhesion to surfaces for which wood, brick or aerated concrete were used.

Properties of mineral wool

The thermal conductivity coefficient shows the ability to conduct heat. However, in order to decide on the right material for insulation, it is important to take into account not only its thermal conductivity, but also other equally important characteristics.

In addition to good thermal conductivity, mineral wool:

- Fireproof - the material resists high temperatures

- Resistant to aggressive chemical environments

- Eco-friendly - the material is harmless to humans

- Vapor permeable - allows water vapor to pass through

- Plastic - under the influence of external force is able to take the desired shape

- Easy to install - soft is easy to cut with a knife, durable - with a hacksaw

- Moisture resistant - when fully immersed, the water absorption level is 0.5%

- Resistant to bacteria and fungi

- Does not shrink over time, thereby preventing the appearance of cold bridges

- Durable - with proper use, the service life is about 70 years.

Another important advantage of mineral wool is its cost. It is thanks to all of the above characteristics that mineral wool has become one of the most popular insulation materials on the building materials market.

The correct choice of insulation will allow you to have comfortable conditions in your home for many years.

Source

What should you buy?

The building materials market offers a huge selection of polystyrene foam boards. The high thermal conductivity of insulation boards depends on their type. For example: a sheet of polystyrene foam PSB-S 15 has a density of up to 15 kg/m3 and is 2 cm thick. For a sheet from 2 to 50 cm, the density is no more than 35 kg/m3. When comparing polystyrene foam with other similar materials, you can easily trace the dependence of the thermal conductivity of polystyrene foam boards on its thickness.

So, for example: the thermal conductivity of polystyrene foam is 50 mm, twice that of mineral wool of the same volume; in this case, the thermal conductivity of polystyrene foam with a thickness of 150 mm will generally be 6 times higher than these indicators. Basalt wool is also very inferior to polystyrene foam.

In order to apply one of the insulation methods, it is necessary to select the correct dimensions of the material. The following algorithm can be used to calculate:

- It is necessary to clarify the overall thermal resistance. This value depends on the region in which the calculation needs to be performed, namely on its climate.

- To calculate the thermal resistance of a wall, you can use the formula R=p/k, where its thickness is equal to the p value, and k is the thermal conductivity coefficient of the foam.

- From constant indicators we can conclude what resistance the insulation should have.

- The required value can be calculated using the formula p=R*k; the value of R can be found based on the previous step and the thermal conductivity coefficient.

Main characteristics of insulation

Let us first provide the characteristics of the most popular thermal insulation materials, which you should first pay attention to when choosing. Comparison of thermal conductivity insulation should be made only on the basis of the purpose of the materials and room conditions (humidity, presence of open fire, etc.). We have further arranged in order of importance the main characteristics of insulation.

Comparison of building materials

Thermal conductivity . The lower this indicator, the less thermal insulation layer is required, which means that insulation costs will also be reduced.

Moisture permeability . The lower permeability of the material to moisture vapor reduces the negative impact on the insulation during operation.

Fire safety . Thermal insulation should not burn or emit toxic gases, especially when insulating a boiler room or chimney.

Durability . The longer the service life, the cheaper it will cost you during operation, since it will not require frequent replacement.

Environmental friendliness . The material must be safe for humans and the environment.

Comparison of insulation materials by thermal conductivity

Economical . The material must be accessible to a wide range of consumers and have an optimal price/quality ratio.

Easy to install . This property for a thermal insulation material is very important for those who want to make repairs themselves.

Thickness and weight of the material . The thinner and lighter the insulation, the less heavy the structure will be when installing thermal insulation.

Soundproofing . The higher the sound insulation value of the material, the better the protection in the living room from extraneous noise from the street.

Practical application of thermal conductivity coefficient

After a theoretical comparison of materials, it is necessary to take into account their division into thermal insulation and structural groups. Structural raw materials have the highest heat transfer indices, so they are suitable for the construction of ceilings, fences or walls.

Without using raw materials with insulation properties, you will need to lay a thick layer of thermal insulation. Referring to the thermal conductivity table, you can determine that low heat transfer of reinforced concrete structures will only occur if their thickness is 6 m. The finished house will be bulky, may sink under the soil, and construction costs will not pay off even after 50 years.

Sufficient thickness of the thermal insulation layer is 50 cm.

The use of thermal insulation materials reduces construction costs and reduces overpayments for energy in winter. When purchasing insulation, you need to take into account thermal conductivity parameters, main characteristics, cost and ease of self-installation.

Comparison of insulation materials. Thermal conductivity table

Comparison of foam block, mineral wool and polystyrene foam by thermal conductivity

The table above comparing thermal insulation by thermal conductivity gives a complete picture of which material is best to use. All that remains is to compare the data from the thermal conductivity table with the cost of thermal insulation from suppliers. In this case, it is necessary to accurately calculate the required thickness of insulation when using various materials in order to select the required amount of material.