Differences between a hood and a ventilation system

At first glance, it is difficult to say how a kitchen hood differs from ventilation. To find the answer, you need to understand the terminology in detail.

Sanitary requirements today require the installation of special units in residential premises that ensure the proper level of air exchange. To meet these standards, a ventilation system is installed in multi-story buildings. The latter is presented in the form of a pre-designed chain of channels, which are located in the walls and facilitate the discharge of air masses to the roof.

The ventilation ducts themselves are needed to remove waste air flows outside the residential building. In turn, fresh air naturally enters the room through joints and cracks in window and door openings. However, one must take into account the fact that such a system is not able to quickly eliminate various unpleasant odors that often appear during cooking in the kitchen.

To get rid of such troubles, a special ventilation system is installed, which functions forcibly. In common parlance it is called a “hood”. The principle of operation of such devices is slightly different - they absorb vapors emanating from the cooking surfaces, and then, using an air duct, discharge them into a special channel of the ventilation system.

Installing a hood in the kitchen: is it possible to do without it?

It is not always possible to install a hood in the kitchen. There are cases when its installation is prohibited according to the rules for operating gas appliances. For example, if a gas water heater, the so-called gas water heater, or a gas heating boiler with an open combustion chamber is installed in the room, it is contraindicated to install a circulation hood.

In most cases, it is impossible to do without a hood

Helpful advice! Removal of decomposition products from the boiler occurs without force, and when the fan on the hood is turned on, the draft may overturn, which will lead to the release of toxic combustion products into the apartment. Therefore, installation of a flow-through exhaust device is allowed only if the boiler is installed with a closed firebox, that is, with a coaxial type chimney and combustion air intake from the street. It is possible to install a circulation hood with filters that clean the air from grease and fumes.

Therefore, before making a hood in the kitchen, you need to figure out whether it is possible to do without an air duct. If you still need it, then you should decide on the type of device. Hoods can be flow-through or circulating. Flow-type devices extract exhaust air from the kitchen, while circulation devices simply purify the air without eliminating it.

Circulation devices are installed above the stove, the air passes through special carbon filters, and grease is removed there. Such designs do not require air ducts; they are compact and easy to install. The main disadvantages of a hood without an air duct are the need to frequently change filters, incomplete air purification, and the lack of removal of humidity and carbon dioxide.

Flexible and rigid products

There are many different types of kitchen hood ducts. For example, all products can be classified according to the materials from which they are made. The final cost of the product, as well as its performance characteristics, directly depends on this quality. However, this is far from the only factor by which air ducts are divided.

All types of construction are divided into 2 types:

- Flexible - can be placed at different angles. If necessary, they can be compressed or stretched (of course, within reason). However, it should be borne in mind that a slightly elongated air duct resists air flows much better. This contributes to a decrease in the efficiency of the ventilation system as a whole. Such structures are often made from aluminum. The main disadvantage is that experts do not recommend making a corrugated box longer than 3 m. This is due to the fact that every extra meter will reduce the system’s performance by 10%.

- Rigid structures are characterized by ease of assembly. In addition, the inner surface of such products is smooth and even. The price of these models is much higher, but their positive properties justify the cost.

We recommend that you read: Ventilation in the bathhouse - features of the device

Types by shape

Air ducts can be classified by shape. Today there are several product options:

- Rounded ones are less versatile than square ones. They can be installed in rooms with high ceilings. This requirement is explained by the large dimensions of the structures. If the outlet hole is made in the shape of a rectangle, you will need to use special adapters of the required cross-section.

- Square and rectangular ducts for kitchen hoods are most often used. Many owners prefer this particular form due to the fact that such structures can be placed directly behind the cabinets in the kitchen. Because of this property, it is possible to lay the system from the ventilation shaft to the hood along any trajectory. Rectangular structures will fit perfectly into a room of any height. In addition, the models are characterized by a presentable appearance. Such units often have lower productivity compared to other types.

- Oval products are characterized by the advantages and disadvantages of rounded designs.

- Flat air ducts are one of the types of rectangular products. Due to their small size, they are practically invisible.

Rectangular structures should be highlighted as a separate item. Manufacturers produce the following products in different sizes:

- 110x55 mm - used for exhaust systems with a capacity of no more than 300 m3/h;

- 120x60 mm - used for hoods with a capacity of up to 350 m3/h;

- 240x60 mm is an ideal option for working in conjunction with high-performance devices that can withstand a power of no more than 1000 m3/h.

Hiding exhaust pipes

In addition to the simplest method - drawing a contour over the kitchen cabinets - there are several more simple solutions:

- If a suspended ceiling is planned or is already being installed in the kitchen (made of plasterboard, two-level, suspended), you can hide the pipes between the layers of the structure or on top of the new ceiling level (read: “How to hide a pipe from a hood - tricks for disguising a ventilation pipe”) .

- If repairs are not expected in the near future, you can buy a decorative plastic box. the range of such products is quite wide; auxiliary elements, for example, lamps, can be additionally installed in them. Such a solution can be not only beautiful, but also useful.

- It is possible to choose a built-in hood installed in the kitchen furniture. This design can be either completely hidden or retractable during operation of the electric oven.

- The simplest option, which requires the least additional costs, is to paint the hood pipes in a color that harmonizes with the shade of the kitchen walls. In addition, if you want to show your imagination and experiment, you can decorate the pipe in various ways, making it an attractive piece of furniture. The only limitation is that the integrity of the product should not be damaged.

In most cases, air exhaust pipes are purchased together with the hood; you can also find ready-made kits of these products.

Be that as it may, with careful selection and careful installation, the exhaust circuit will serve for a long time and without failure.

Classification by materials

Air ducts for exhaust system equipment are made from various materials. To determine which one is best to choose for a particular case, you need to study the characteristics of all units on the market.

Plastic structures

Today, plastic air ducts for kitchen hoods are considered the most popular. They come in round and rectangular shapes. The latter look quite aesthetically pleasing and neat. In turn, the installation of round products is easier and faster (in such situations it is not necessary to use adapters to connect the air duct to the hood). The main advantages of plastic products:

- rust resistance;

- ease of assembly;

- low cost;

- smooth inner surface minimizes the risk of accumulation of fat and other contaminants;

- light weight, which makes installation much easier;

- absence of noise during operation of the hood.

One of the disadvantages of plastic air ducts for kitchen hoods is that installation often requires the use of adapters and other switching elements. In addition, it is not recommended to expose products to very high temperatures, because under such circumstances harmful substances will begin to be released from the plastic.

Steel and aluminum units

Aluminum products take second place in the popularity ranking. This material is also used to make structures for ventilation system equipment. Main advantages:

We recommend reading: Choosing an air purifier for an apartment

- aluminum is a simple and versatile material;

- products are cheap;

- quick and easy installation;

- designs are resistant to high temperatures.

However, aluminum air ducts, like any other product, have a number of disadvantages. Some of them:

- The material has high thermal conductivity. In a room where an aluminum air duct is installed, condensation often accumulates.

- Unpresentable appearance. Often, such units are hidden in kitchen cabinets or disguised using special boxes.

- Aluminum is not very durable and can be subject to deformation due to mechanical stress.

It is not uncommon to see steel air ducts. In most cases, galvanization or stainless steel is used for the manufacture of such structures. If we talk about home use, galvanized products have performed well here. However, it is important to note that such units are no longer as popular as they used to be. Every year, steel air ducts become less in demand. The main advantages of such models:

- Relatively cheap.

- A flat base that does not interfere with the passage of air flow. In addition, dust deposits and soot do not accumulate in smooth products.

- Steel products are not subject to deformation under high temperature exposure. In addition, no harmful substances are released into the environment.

Despite a number of obvious advantages, steel units also have some disadvantages. The latter are the reason for the decrease in demand for products.

Some cons:

- for mounting on walls, the most stable and reliable fixing elements are required;

- to assemble a non-standard air duct, you will need to additionally cut metal pipes;

- heavy weight (especially compared to plastic structures), so it will not be possible to carry out installation yourself;

- To seal the channels, the use of special means will be required;

- During operation there is a lot of noise.

How to hide a kitchen hood duct: decorating methods

An air duct running from the hood to the ventilation hole is unlikely to look beautiful in the interior (especially if it is corrugated). Therefore, they often decide to hide it.

Ways to do this are:

- Plasterboard sheathing . In this case, a sheathing is installed around the air duct, onto which plasterboard is then attached, and then finished like the rest of the room. This option can be beautifully implemented, but it will be difficult to reach the air duct if necessary.

- Plastic box . There are special plastic boxes on sale that are designed specifically for decorating corrugations in the interior. A simpler and cheaper analogue of plasterboard sheathing.

- Installation above a suspended/stretch ceiling . In this case, the air duct rises upward from the hood and is hidden under the ceiling structure. The section running from the hood to the ceiling is either covered or left without decoration. The downside is that this option is only suitable at the stage of renovation of the premises (that is, if you buy a hood after the finishing is completed, this will no longer be possible). And if you need to get to the air duct, you can do this only by disassembling the ceiling.

- Embedding hoods and air ducts into furniture (wall cabinets). In this case, a cabinet is hung on the wall (under the ceiling), and the air duct runs inside it. The downside is that the free space for various kitchen utensils is reduced.

- Hinged “visor” for the cabinet . A budget version of the previous method. The cabinet is not built to the ceiling, the air duct is taken out of it to the top and leads to the ventilation shaft. A canopy protruding upward is installed on the cabinet, which will hide the air duct.

- Air duct installation over kitchen cabinets close to the wall . If the cabinets are tall and deep (protrude far), then the air duct will either not be visible at all, or it will not be so striking.

- Painting . The cheapest and easiest way is to paint the pipe to match the interior so that it does not catch the eye.

Review of fire retardant coating Isovent for air ducts: what is good about the material?

Review of fire retardant Fibergain for air ducts

Related Posts

Recommendations for selection

Experienced specialists give a number of tips to make it easier for owners to choose products for arranging a ventilation system. Some of them:

- It is best to buy products in branded stores or specialized retail outlets.

- In addition to the product, the kit should contain instructions for use, as well as a warranty card. If such documentation is missing, it is better to refuse the purchase.

- It is necessary to take into account the design of the products so that they fit organically into the interior of the room.

- The manufacturer is of no small importance. It is advisable to choose high-quality branded models.

- No need to focus on low prices. Of course, a high-quality and reliable ventilation system will be quite expensive, especially if good materials are used. However, you need to understand that high-quality models will serve for many years without complaints.

- Products must have sufficient performance. If the ventilation system is weak, the hood will not be able to cope well with its main task, so the exhaust air masses will remain in the room.

We recommend that you read: Types and design of ventilation ducts

In addition, when choosing the components of the ventilation system, you need to take into account the main functions of the kitchen hood. The latter must meet the following characteristics:

- An attractive appearance is important so that the device fits organically into the interior, complementing it.

- Low noise level during operation.

- The ability to quickly and to the required extent remove foreign odors.

Installation Features

You can easily install the air duct yourself. In this regard, the simplest solution is to use corrugated products. The latter should be cut into pieces of the required length, and then connected to the elements of the hood and ventilation shaft in the kitchen. It is recommended to replace a simple grille with one that has a built-in connecting pipe. In such cases, special clamps are used for fixation. To achieve maximum strength, the joints are treated with sealant.

The installation of PVC air ducts is carried out in a similar way. Using a hacksaw, you need to cut the pipe into separate parts of the required sizes, then, using special adapters, connect them with the hood elements. The pipe must enter the pipe no less than 5 cm. The joints must be coated with a sealing compound.

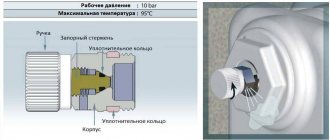

If you install an overly powerful hood in the kitchen, a reverse draft may occur: odors from the ventilation shaft will enter the room. A similar effect can occur when using particularly powerful units, the productivity of which is 600-700 m3 of air per hour. To combat this problem, you need to install a check valve. The latter is produced in several variations:

- in the form of a plastic disk on an axis;

- filmy.

The product must be installed vertically, otherwise it will begin to regularly operate under its own weight.

To ensure that all ventilation parts in the kitchen are in the same color scheme, it is advisable to buy ready-made kits. Today, most manufacturers produce kits that consist of a hood, an air duct and an additional element. The quality of materials plays an important role. Excessive savings may result in the system operating for no more than five years. At the same time, high-quality PVC products are designed for an operational period of at least 30 years.