0

5522

14.12.2015

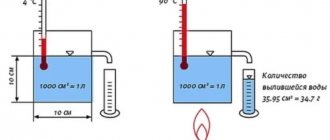

The problem of lack of hot water supply is quite widespread in most of our cities. Even where it exists in principle, there are periods when there is simply no hot water in the tap. A storage water heater is an acceptable solution to this problem. There are other types of water heating equipment, but in this article we will look at storage water heaters: the operating principle of these devices, features of operation, maintenance and repair. These devices can be powered by burning gas, electricity and even solar energy, the main thing is that they meet the requirements for this type of household appliance.

Connection

Let's look at the wiring diagrams for different types of boilers

Connecting a boiler to a double-circuit gas boiler

The piping, in most cases, is done in such a way that the tank is in direct contact with the heating circuit.

The technical solution works well in systems that lack the power of the heating source, in addition, it is the only effective method of connecting the BKN to a double-circuit boiler.

The supply pipe to the BKN is included in the pipeline going to the in-house heating system, immediately after leaving the boiler. Using electronic control, the boiler is set to heat the coolant above +70C, which enters the water heater, where the process of heat transfer from the heating coolant occurs, through the internal heating surface - the coils to the water for the DHW system.

The operating temperature is adjusted by a thermostat, which commands the electrical shut-off valves to turn on/off.

Piping diagram for a boiler and a single-circuit boiler

Single-circuit boilers can simultaneously perform only one of the options declared by the manufacturer, either they organize water heating for DHW needs, or they heat the room, while the other option is used in homes more often.

A combined heat supply scheme, which consists of a single-circuit heating boiler and an indirect heating unit, is the most effective for cottages up to 200 m2.

Heating of the coolant for heating and hot water occurs simultaneously, after which it is divided into 2 lines - to the heating devices and the storage tank.

Approximate diagram. Photo source: remontik.org

The technological heating process proceeds according to the following scheme:

- cold water from the water supply network goes to the heating source - the boiler unit, where it is heated to the required temperature, for example, 80 C, thanks to the process of burning fuel in the combustion device;

- the hot coolant enters the heating circuit - to the batteries and into the internal heater BKN;

- the temperature of the water in the container will increase to the set parameter, usually 40-55 C;

- the water in the boiler is heated and when the mixer is turned on, it flows to the consumer;

- When the maximum temperature of the water in the tank is reached, the regulator sensor will operate when the parameter is exceeded, and a signal will be sent to the solenoid valve, which shuts off the coolant supply from the boiler.

Nuances of the strapping device

It is easier to do the wiring and piping if the KN boiler is installed together with a boiler, pumps and other equipment involved in the assembly of the hot water supply system. It is much more difficult to insert an additional device into an existing network.

In any case, for normal operation of the devices you will have to follow a number of rules:

- choose the right installation location - as close to the boiler as possible;

- provide a flat surface for mounting the boiler;

- to protect against thermal expansion, install a membrane hydraulic accumulator (at the heated water outlet), the volume of which is at least 1/10 of the volume of the BKN;

- equip each circuit with a ball valve - for convenient and safe maintenance of devices (for example, a three-way valve, pump or the boiler itself);

- to protect against backflow, install check valves on the water supply pipes;

- improve water quality by installing filters;

- correctly position the pump (or several pumps) - the motor axis must be in a horizontal position.

For safety reasons, do not attempt to secure heavy devices to plasterboard or thin wood partitions. Walls made of concrete and brick are suitable. Brackets or other types of holders are secured with brackets, anchors, and dowels.

When installing, the pipes are directed towards the boiler (even if they are masked in the back or behind a false wall). Do not use unreliable equipment, such as corrugated hoses that cannot withstand pressure and water pressure.

For normal operation of an indirect heating storage water heater, the following functional devices must be included in the piping:

Two options for connecting the boiler to the boiler

The electric boiler is connected to the heating boiler through a three-way valve. With this connection, one pump works - the one installed inside the boiler or the one connected outside. The boiler can also be connected to the boiler via an auxiliary pump. Pump switching works with this connection option. If the boiler works for the boiler, then the boiler pump turns on, if the boiler works for the heating system, then the external or internal pump of the heating boiler works.

Connection to a single-circuit boiler

A boiler in combination with a single-circuit boiler works more efficiently, and connecting it is quite simple:

- First, the plumbing is connected and water is distributed throughout the premises.

- The electrical network is connected, the boiler sensor and the electric drive of the three-way valve are switched.

- The software control of the boiler is configured and tested.

When connecting a single-circuit boiler to an external boiler, a special installation kit is used. It includes:

- three way valve drive

- cable with connector

- several copper pipes with fittings for connecting the drain.

How to use the kit correctly?

To install the kit correctly, follow these guidelines:

- Turn off the power to the boiler using a two-pole circuit breaker.

- Disconnect the boiler from heating and hot water supply.

- Using the drain plug, drain the water from the boiler circuit.

- Remove the plugs on the pump group.

- Insert the sealing gasket into the hydraulic group.

- Seal the supply pipe on the boiler.

- Place the gasket on the return water supply pipe of the boiler and connect this pipe to the hydraulic group.

- Install connectors on the return water supply and boiler supply pipes.

- Connect two pipes to the boiler, secure them with locknuts, install seals and flat gaskets.

- Install the three-way valve actuator.

- Connect the three-way valve drive in the boiler using a connector.

- Check that the kit is installed correctly and that all connections are tight.

- Open the cover of the boiler control panel.

- Remove the safety resistor, which is installed to prevent the consequences of incorrect connection. You can find it using the diagram.

- Connect the boiler temperature sensor with a cable with a cross section of 2x0.35 mm2.

- Connect power to the three-way valve actuator.

- Secure all cables and connection points.

Connecting the electrical part of the boiler

- Open the cover of the boiler control panel.

- Remove the safety resistor, which is installed to prevent the consequences of incorrect connection. You can find it using the diagram.

- Connect the boiler temperature sensor with a cable with a cross section of 2x0.35 mm2.

- Connect power to the three-way valve actuator.

- Secure all cables and connection points.

How to connect a boiler to a double-circuit boiler

To connect a boiler to a double-circuit boiler, you need to mount it next to the boiler, and use pipes to combine them into one system. This method of combining two devices is called an indirect heating boiler. The water is heated in a heat exchanger through which water heated in the boiler circulates.

Hot water supply systems (boilers) usually have built-in automation, which, in connection with the automation of the boiler, maintains the required temperature. Modern boilers are designed to work with double-circuit heating boilers, and are connected using a special installation kit.

Connecting a boiler to a double-circuit boiler is not difficult, but it is still better to entrust this operation to a specialist, because there are some small connection features.

It makes no sense to connect a boiler to an electric boiler - this is what many professionals think. An indispensable condition for the operation of the boiler is a small consumption of heating energy from the boiler. The boiler should not overload the heating system with its connection.

If the boiler consumes more than half of the thermal energy generated by the boiler, then problems with heating a house or apartment cannot be avoided.

If you use a boiler and a gas double-circuit boiler, then with a small flow of hot water, a wall-mounted thermoblock with 2 circuits is enough, and if the house has a large bathtub or spa pool, then a boiler with a boiler is needed. To improve the operation of the heat exchanger, you should use another circulation pump, always with an automation system and the ability to control the temperature of the water (or other coolant).

In summer, it is best to use a combined heating scheme - from a savings point of view. This circuit consists of a boiler, heating element and heat exchanger. In winter, the boiler operates from a heating boiler, and in summer – from a heating element.

What is an indirect heating boiler

What is it for?, the typical average person asks first of all. Owners of country houses rightly believe that it is much easier to buy a double-circuit boiler. One circuit will be used to heat the household using a heating system. The second circuit will prepare hot water for DHW, thus immediately solving two issues with one purchase.

Yes, such reasoning is fair, but up to a certain point. Firstly, the double-circuit boiler instantly switches to hot water preparation mode as soon as you open the tap. At this time, the boiler completely stops taking care of your heating system, leaving it to the mercy of fate. Simply, the boiler directs all its power to heating the hot water supply, blocking the heating of the heating heat exchanger.

Secondly, as a rule, a double-circuit boiler does not have the full functionality of a gas water heater; its power is hardly enough for one water collection point. It turns out that if a family returned from a ski trip and the household decided to take a shower, then the heating system will be turned off for at least a couple of hours.

In addition, the rest of the family will have to wait patiently for all participants and not open the tap in the kitchen if they do not want to hear flattering words addressed to them. Thus, only at first glance an indirect heating boiler looks like a waste of money. In fact, it is a necessity to ensure a comfortable stay. An acceptable compromise would be to buy an indirect heating boiler with a capacity of 200 liters.

Schematic diagram of an indirect heating boiler

The heat exchanger installed inside is the heart of the structure, most often made of brass or carbon steel; coolant circulates through it from the heating boiler. The heat exchanger has the shape of a spiral, which allows you to quickly and efficiently heat the liquid in the tank.

Through the hot water outlet and cold water inlet, the device is connected to the main water supply system. It turns out that the design of an indirect heating boiler is more than simple, and it is not even clear why the simplest invention was not used by humanity for so long.

By spending just three and a half minutes watching the video review, you will understand the principle of operation of an indirect heating boiler, especially since the video series is easier to understand:

Indirect heating has the following advantages in use:

- The main advantage is that an indirect heating boiler does not require financial costs for operation. It does not at all burden the electrical wiring with additional load during the peak heating period, because the described system does not consume electricity;

- Due to the closed circuit, the water constantly circulates through the boiler and is in a hot state; after opening the tap, the consumer immediately receives a hot stream without draining the cold sludge;

- The recirculation process not only keeps the water hot, but also protects the hot water system from infection by pathogenic microorganisms - Legionella. Maintained high temperature prevents their development.

- Running water is excluded from interaction with the inner surface of the heat exchanger tubes, scale and salts are not deposited in it, which ensures the possibility of long-term operation of the boiler system;

- Large reserves of hot water and the increased power of modern designs allow the liquid to heat up much faster than traditional storage tanks. The volume of reserves easily makes it possible to connect an indirect heating boiler to two or more points consuming hot water.

- The coolant coil and the auxiliary heating element are protected from corrosion by a special anode. In fact, the anode takes on the entire corrosion load, extending the service life of the heating elements.

This device also has some disadvantages:

- depending on connected heat sources;

- in the summer, in the absence of heating, the boiler must be connected to electricity, which is why it is equipped with electric heaters.

Essentially, an indirect water heating system uses thermal energy generated by a solid fuel or gas boiler. The combination of a heat-generating device and an indirect heating boiler forces the boiler to do double work. The advantage is especially felt in winter - it turns out that the water is heated for free, due to the fact that the heating system is working one way or another.

Read also What fresh dates look like photo

In winter, the cost of heating water can account for up to one third of all energy bills. Connecting an indirect boiler system to a gas or pellet boiler effectively helps save our finances.

Advantages and disadvantages of an indirect heating boiler

The positive factors of using such a boiler include:

- Indirect water heating does not create additional load on electrical wiring, especially during the heating season, since it is connected to centralized heating and has practically nothing to do with electricity;

- with proper connection and configuration, the boiler is able to show a high performance coefficient with an acceptable cost comparison;

- the heater located inside as well as the coolant do not come into contact with the inlet water, thereby ensuring the duration of operation and safety of the unit;

- It is always possible to connect an indirect heating boiler to other heat sources, as well as simultaneously use several devices, creating a cascade.

The tank and emergency heating element are protected from corrosion by an anode made of magnesium alloy. To avoid the maximum permissible pressure, a thermostat and a safety valve are installed in the boiler. The tank body can be of any design to suit a variety of interiors.

Along with the undeniable advantages of this system, there are also disadvantages:

- if it is necessary to re-equip an existing system, you need to be prepared for the costs;

- The price of an indirect heating boiler is very high; the initial costs of purchase and installation will require significant financial resources. Thus, the price will always be higher than the cost of instantaneous electric or gas water heaters;

- after installation and first start-up, heating the first 100 or more liters of water will last up to two hours, which may negatively affect the heating of the house during this period;

- buying a boiler is only half the battle, a capacity of 100 - 200 liters has large dimensions that will have to be taken into account, your boiler room must provide free space.

How to choose an indirect heating boiler

The main difference between a boiler and a traditional water heater is the tank capacity. To make the right choice and avoid excessive costs when purchasing a boiler, you need to know how much water will be required to meet the demand of the family unit. The average indicators are presented by the following calculations: personal hygiene, per day - up to 15 liters; washing kitchen utensils - up to 25 liters per day; shower - up to 100 liters per day; bathroom - up to 200 liters.

It is generally accepted that one person consumes about one hundred liters of hot water, but this, of course, is a convention; actual consumption depends on the person himself and his habits. Some people visit the shower twice a day, others spend one day a week taking a bath. We can certainly say that a larger heater volume will have a higher cost.

The second important factor influencing the cost of the boiler is the materials from which it is made, in particular its internal parts. It is recommended to choose a unit with a brass coil, which provides more efficient heating compared to steel. Brass is also convenient because it is much easier to remove scale from it than from steel.

The level of corrosion protection should also be taken into account. In inexpensive models, the surface of the tanks is covered with an enamel layer or glass ceramics. In higher quality devices, instead of an internal coating, stainless steel is used in the production of the tank.

A good boiler must be provided with a thermal insulation layer. This material is either basalt wool or gas-filled plastic - polyurethane foam. If the thermal insulation of the boiler is foam rubber, it is better to ignore this model.

Correct connection of an indirect heating boiler

The first step is to correctly select the location of the device. It is necessary to take into account, at the place where the boiler is installed, quick and easy accessibility to important connecting links of the system - this will allow routine repair work of the equipment and maintenance.

Mounted models of an indirect heating boiler will require a strong brick load-bearing wall at the mounting location. Plasterboard walls or light interior partitions cannot provide the required rigidity and cannot be fully used in installation work

The distance from the tank fastenings to the ceiling should be 15-20 cm. The fasteners are anchor-type spacer bolts, and their length and diameter are selected based on the wall material and the volume of the boiler.

The approximate load for tearing out a container of up to 100 liters is from 25 to 25 kilograms; when mounted on a concrete wall, a bolt 10 mm thick in diameter and 100 mm long will be sufficient. For the same parameters, but taking into account the brick-cinder block wall, a bolt with a diameter of 12 mm and a length of 120 mm is needed.

After installing the heater to the wall, it must be connected, for this:

- two separate shut-off valves are installed on it;

- a fum tape is wound and a discharge valve is attached to the cold water inlet line;

- connection to the water supply system is made using a flexible hose;

- After all connection operations, you can supply cold water to the water heating and at the same time turn off the hot water tap - this will allow any possible air to bleed out.

Connecting an indirect heating boiler

It can be carried out using both a hydraulic system and an electric one. The most effective is considered to be a scheme in which the connection occurs on 2 pumps, i.e. a hydraulic scheme, where one of the pumps functions as a room heater, and the second is used for indirect heating of the boiler itself. The electrical connection is made via a relay switching system.

When an indirect heating boiler is connected through two pumps, the heat-carrying flows move in different directions due to the operation of recirculation (recirculation) pumps.

The hot water supply line coming from the coolant and the water heater is simultaneously connected to the circulation pumps, and the operating mode of the pumps is controlled by the heater temperature sensor.

Direct-acting fittings in the form of a check valve must be installed behind the pumps in sequence, for autonomy and independent operation of the pumps from each other.

Connection to pipes made of various materials

The insertion of the boiler may differ slightly, depending on what material the water pipe is made of.

Polypropylene pipe

Pipes not sewn into the wall will not create connection problems. The work will consist of cutting the water supply pipe in the required location and soldering tees into the holes, from which tubes will go to the boiler. The taps are connected using ordinary couplings. If the pipes are walled up, the algorithm of actions will change slightly:

- pipes should be opened;

- a cut-in occurs;

- pipes are diverted;

- pipes are sewn into the wall.

Metal-plastic pipes

Since there is no technology to install such pipes using a hidden method, insertion will not be a problem. The pipes are cut, tees are attached to them, and water supply pipes are connected to the heater.

Steel pipes

Connecting to steel pipes is a complex matter. In this case, it is rational to use the mixer pipes through which the tank will be connected. Tees are put on the pipes, by connecting them, the water heater and mixer are connected to one pipe.

Frequent mistakes when connecting an indirect heating boiler

A common mistake is the wrong location for the boiler. It should be installed as close as possible to the heating boiler or central heating outlet - this will help save on laying additional pipes and other accompanying infrastructure.

The bathroom is almost ideal for this; the only catch is its small dimensions:

Another “popular” mistake is incorrect connection of the cold water inlet. Connecting the thermal energy substance (thermal body) in a sequential order of input and output must ensure correct and efficient operation of the boiler.

Read also Coastal plant which is often called reed

The optimal and effective option for heating and heat supply would be to enter the coolant into the water heater from above, and exit, accordingly, from below.

Incorrect connection of the circulation pump can lead to a lot of adverse consequences, namely:

- a motor axis other than horizontal can lead to rapid wear of the bearings;

- An important factor is keeping the pump clean and free from debris. Mesh filters should be checked regularly.

Cost of equipment

Potential buyers, faced with the choice of an indirect heating boiler, solve the problem of finding an acceptable price for equipment with optimal functions. The cost of equipment presented in stores varies greatly depending on the model. Here are just a few factors influencing pricing:

- Manufacturing company. European analogues, due to the influence of the high cost of EURO, will cost more than the same Korean ones. However, the quality level of the leading brands in the Eurozone: BOSCH, ACV, Viessmann, Buderus, Vaillant, Baxi, Protherm, Drazice, Gorenje, always remains at the highest level, which makes the products in demand in the domestic market.

- The materials present in the product and the quality indicator of the tank.

- The components are high quality and not very good. Expensive models are equipped with tanks made of brass or stainless alloy. Hull cladding made of such material also leads to an increase in price.

- Constructive solution. The “tank in tank” module leads to higher costs compared to the traditional design of an indirect heating boiler.

- Dimensional parameters of the device . Of course, a more spacious tank is offered at an increased cost.

- Functionality. Equipping an inlet for a recirculation system requires additional costs in the production process. As you might guess, the seller will include everything in the final price.

At the beginning of 2021, the price for a foreign-made indirect heating boiler design with a volume of 100 liters or more is around 50-90 thousand rubles. The cost of a similar boiler with a volume of 300 liters increases to 100 thousand rubles, and for a device with a capacity of 1000 liters, you will have to pay 350-450 thousand rubles.

Conclusion

Based on the numerous positive reviews from owners of indirect heating boilers, you can see that the system is quite popular and in demand. When purchasing a particular model, almost all the information can be found on the Internet, where you can also consult online stores specializing in such equipment.

For private homes, such designs will be an indispensable help in saving money, and you can forget about the lack of hot water.

To provide the home with the required amount of hot water, an additional device is used - an indirect heating boiler (IBC). Its use can be considered one of the most rational and economically justified.

We will try to find out which piping scheme for an indirect heating boiler is most effective and how to connect the equipment to avoid common mistakes.

Optimal operating mode of an electric boiler

Setting the temperature to the minimum permissible is highly not recommended for the following reasons:

- Reduced efficiency of water heating equipment;

- Liquid temperature 30-40⁰ C is an ideal environment for the formation and proliferation of bacteria and mold, which inevitably end up in the water;

- The rate of scale formation increases.

These devices are often equipped with an economy mode option, designated by the letter E. This operating mode means heating the liquid inside the capacitive tank to a temperature of +55⁰ C, which allows you to extend the period of use before maintenance. That is, at a given temperature regime, scale forms the slowest, and accordingly it is necessary to clean the heating element less often. This does not apply to energy savings.

Principle of operation

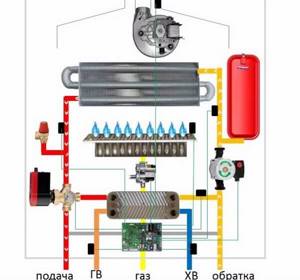

The operating principle of a gas heating boiler is quite simple. Through the return pipeline from the heating network inside the house, cooled water is supplied by a circulation pump to the input of the heating circuit heat exchanger.

At low coolant temperatures, an electromechanical valve opens, supplying fuel to the injector. The igniter ignites the gas and the combustion process begins. The boiler constantly operates on the heating circuit.

The DHW circuit begins to function when the tap on the mixer is opened. This thermal scheme of the boiler operation in the summer makes it similar to the operation of a conventional gas water heater.

How does a condensing boiler work?

The name “condensing” boiler units was acquired due to the fact that they implement a technology for obtaining additional thermal energy by modifying the aggregate state of condensate from steam located in the flue gases.

Operating principle of a condensing boiler

During the combustion of natural gas in a condensing gas boiler, water vapor is created, which in traditional units evaporates and is released into the atmosphere through a chimney.

The temperature at which the condensate is converted is called the dew point of +55 C, and the technological process is called condensation. This temperature corresponds to the parameters of the return network water entering the boiler from the heating system. If it is more than +60 C, then the condensing boiler will work like a traditional device with low efficiency.

In addition, condensate creates a very aggressive environment containing acids. Therefore, its collection and disposal will require a special neutralization system, which the liquid must undergo before it can be discharged into the city sewer.

Condensing boiler. Photo source: allbuildingtips.com

In general, a convection gas boiler is an expensive device, however, fuel savings of up to 20% allow it to pay for itself within five years.

The principle of operation of a double-circuit gas boiler

The operating principle of a double-circuit boiler unit is designed for 2 thermal modes:

- heating;

- DHW.

In heating mode, the operation of the boiler is practically no different from a single-boiler boiler. Starting the burner involves a fairly long start-up period in order to increase the temperature in the heating circuit to operating levels. When the main mode is reached, the flow of fuel to the burner stops.

The internal air temperature sensor allows you to automatically regulate the temperature and sends a signal to open the gas when the permissible level decreases.

Modern double-circuit Baksi boilers, in addition to an internal temperature sensor, are equipped with a special weather-dependent automatic system that regulates the operation of the boiler based on the outside air temperature outside the building window. The burner increases the temperature of the heating water, the circulation of which through the pipelines of the heating system is ensured by a circulation pump. A three-way valve built into the system switches the movement of coolant through the heating circuit or into the DHW system.

Today's double-circuit heating boilers are equipped with automatic control and safety systems. In emergency situations, flame and draft sensors are capable of shutting off the gas supply to the boiler through an electromagnetic valve, thereby preventing the creation of an increased concentration of gas in the boiler room.

This mechanism not only shuts off the gas supply, but also informs others about the danger using sound and light alarms, and also starts exhaust ventilation to reduce the content of methane and carbon monoxide in the air.

Installation method

Depending on the installation method, gas boilers can be floor-mounted or wall-mounted. Wall-mounted - compact installations, the size of a small kitchen cabinet. They do not require equipment in a separate room and can be installed in the kitchen or other suitable room. The maximum power of a wall-mounted gas boiler is 30-35 kW. This is usually enough to heat rooms with a total area of 250-350 square meters. m.

Floor-standing gas boilers are more powerful and, accordingly, have larger sizes and weight. There are models that can be installed in a living space, while others require a dedicated room - a boiler room. Installation requirements are prescribed by each manufacturer separately, but usually the distance from the top of the boiler to the ceiling, the volume of the room and the presence of ventilation are specified.

Wall-mounted gas boilers are larger in size and weight, but this is due to their higher power

Regardless of the type, a certified project is required to install gas boilers. The diagram must include a gas meter, so if it is not there, you will need to purchase one. Connection work must be carried out by a company that has a license for this type of activity. Only in this case will the boiler be put into operation.

Selecting a double-circuit gas boiler based on installation method is simple. If there is enough power, they usually take a wall-mounted version, if not, a floor-mounted one.

Important Buyer Tips

The experience of specialists involved in the development of heating systems powered by natural gas and conducting tests, including in our climatic conditions, will allow you to make the right choice. Just follow the tips below:

- When purchasing a small-sized boiler, be sure to look at the lower power value. If it slightly exceeds the calculated value, then it is worth purchasing a thermostat in addition. It will save money on equipment operation in the long term, and will also significantly increase the service life by reducing the number of equipment starts.

- The heat exchanger is known to suffer from one serious ailment, the deposition of salts and lime. To avoid this, in conditions of “hard” water, you should take equipment with bithermic heat exchangers. If the water undergoes pre-treatment, the so-called “softening”, then it is better that the heat exchanger is separate; in the first case you will reduce the formation of lime, and in the second you will save money.

- In the case of spruce, the house area is large, and the consumption of hot water is also high due to the large number of points of its consumption, it would be more advisable to purchase such a wonderful thing as a boiler. In some double-circuit boilers it is already present, but if not, then it must be added. The boiler will allow you to increase the consumption of hot water several times, so you will not experience a shortage of it.

Information!

It is important to remember that gas boilers are mostly designed to work with a central gas pipeline, but if there is no such thing, and it is necessary for the equipment to operate on liquefied gas, then be sure to notify the seller during setup and installation, use only the services of a qualified specialist, not expose yourself and your loved ones to unnecessary risk

Also, if there is a need to connect such things as heated floors, ventilation and other third-party circuits to the boiler, it is important to entrust the calculations and selection of components to a specialist. When purchasing a boiler, you should take care of purchasing and installing an automated control system in your home. Automatic controls will not only more than pay for themselves in the long run, but will also significantly reduce the cost of heating premises

They work on the principle of adjusting and regulating the boiler power during daily operation. By purchasing an automated control system once, you can save about 20% on fuel, which will definitely affect your wallet.

The issue of heating a living space and providing hot water requires maximum responsibility and care. It is necessary to buy a wall-mounted gas double-circuit boiler with a boiler in specialized stores and centers with mandatory preliminary consultation. Otherwise, inattention and frivolity can lead to accidents and disastrous consequences. Only qualified specialists and consultants can guarantee the correct operation of such delicate equipment throughout its entire service life.

TOP 5 storage electric water heaters

| Photo | Name | Rating | |

| #1 |

| Zanussi ZWH/S 50 Splendore XP 2.0 | ⭐ 99 / 100 1 — vote |

| #2 |

| Ariston LYDOS R ABS 50 V | ⭐ 97 / 100 |

| #3 |

| Gorenje FTG 50 SM B6 | ⭐ 96 / 100 |

| #4 |

| Electrolux EWH 50 Quantum Pro | ⭐ 93 / 100 |

| #5 |

| Thermex Flat Plus Pro IF 50V (pro) | ⭐ 93 / 100 |

What would you choose or recommend?

Take the survey

To a certain extent, continuing the conversation about selecting the optimal model, we move on to the last section of the publication. Here is a short review of boilers, those that, according to the cumulative assessment of users, can be classified as the best options, which have practically no disadvantages from a technical point of view. The selection was made solely based on reviews from consumers who had already tried this technique in practice for at least a year.

Just for comparison, all models belong to the “primary class”, for a young small family. Tank volume is 50 liters or so. But in all these model lines there are boilers of a larger volume. And this is while maintaining all the indicated advantages and comments.

#5 Water heater “Thermex Flat Plus Pro IF 50V (pro)”

- Russian, with an admixture of “Italian roots”, specializes in the production of electric water heaters. The assortment includes models of different volumes, power equipment, and external design. Boiler tanks are made of stainless steel or glass porcelain.

Water heater “Thermex Flat Plus Pro IF 50V (pro)”

“Thermex Flat Plus Pro IF 50V (pro)” has an ergonomic shape and neat appearance. An electronic display with large numbers adds convenience to operation.

Technical characteristics of “Thermex Flat Plus Pro IF 50V (pro)”:

| Parameter names | Indicators |

| Manufacturer country | Brand – Russia, assembly – China |

| Tank volume, l | 50 |

| Power consumption, kW | 2,0 (220) |

| Maximum heating temperature, ˚С | 75 |

| Outlet water pressure, atm. | 0,5÷7,0 |

| Device control | electronic |

| Indication | switching on and heating |

| Thermometer (availability) | There is |

| Display | There is |

| Water heating limitation | There is |

| Protection system | RCD, protection against overheating and switching on without water |

| Anti-freeze function | There is |

| Safety valve | yes, included in delivery |

| Protective anode (qty.) | magnesium - one |

| Tank manufacturing material (internal coating) | Stainless steel tank |

| Heating time to max. temperature, min | 96 |

| Heating element (qty.) | Electric copper heating element - two |

| Installation methods | Vertical |

| Eyeliner | Lower |

| Mounting method | Wall |

| Dimensions (w×h×d), mm | 452×865×239 |

| Device weight, kg | 12.06 |

| Connection diameter, inch | ½ |

| Additional functions | Self-diagnostics, accelerated heating |

| Warranty period, years | 7 |

pros

- affordable price;

- fast heating;

- excellent design;

- convenient pipe for draining water;

- possibility of remote control via Wi-Fi

- presence of RCD;

- economical operating mode.

Minuses

- The self-diagnosis system is not informative enough for the user.

Thermex Flat Plus Pro IF 50V (pro)

#4 Water heater “Electrolux EWH 50 Quantum Pro”

Electrolux is a Swedish brand that is well known to Russian consumers. However, a large number of products from this company are produced in different countries of the world, including China. The Electrolux EWH 50 Quantum Pro water heater was manufactured in this country, but, judging by the reviews, it retains excellent workmanship.

Water heater "Electrolux EWH 50 Quantum Pro"

The device is compact in size and easy to operate. There will be no problems with it even for those who are not very comfortable with various equipment. The boiler has a neat appearance and therefore fits perfectly into a small kitchen or bathroom.

Technical characteristics of "Electrolux EWH 50 Quantum Pro":

| Parameter names | Indicators |

| Manufacturer country | Brand – Sweden, assembly – China |

| Tank volume, l | 50 |

| Power consumption, kW | 1.5 |

| Maximum heating temperature, ˚С | 75 |

| Outlet water pressure, atm. | 0,8÷7,50 |

| Device control | electromechanical |

| Indication | inclusion |

| Thermometer (availability) | There is |

| Display | No |

| Water heating limitation | There is |

| Protection system | From overheating and turning on without water |

| Anti-freeze function | There is |

| Safety valve | yes, included in delivery |

| Protective anode (quantity) | magnesium - one |

| Tank manufacturing material (internal coating) | Enameled steel |

| Heating time to maximum temperature, min | 96 |

| Installation methods | Vertical |

| Eyeliner | Lower |

| Mounting method | Wall |

| Dimensions (w×h×d), mm | 385×703×385 |

| Device weight, kg | 18.01 |

| Connection diameter, inch | ½ |

| Additional functions | Water disinfection, economy mode and scale protection |

| Warranty period, years | 5 |

pros

- affordable price;

- fast heating;

- the tank keeps warm for a long time, up to two days;

- economical;

- presence of RCD;

Minuses

- I had to connect an additional hose to the valve, since it constantly drips (the high pressure protection system in the tank is triggered). Perhaps the cause is simply a defective valve, and replacing it will solve the problem. By the way, it is better to let the valve drip than to risk an explosion due to a non-working or jammed valve.

- There is no display - but electronics are usually not installed on devices in this price category.

Boiler Electrolux EWH 50 Quantum Pro

#3 Water heater “Gorenje FTG 50 SM B6”

known to consumers for the high quality of its products. The manufacturer supplies the market with boilers and geysers. Gorenje boilers are produced in round and rectangular shapes; they have compact dimensions and stylish design. Water heaters can have different volumes, so you can choose the right option from them.

Water heater “Gorenje FTG 50 SM B6”

"Gorenje FTG 50 SM B6" has a semicircular front wall of the case, which gives the device elegance. The model is highly reliable, and according to user reviews it deserves a five-star rating.

Technical characteristics of “Gorenje FTG 50 SM B6”:

| Name of parameters | Indicators |

| Manufacturer country | Slovenia |

| Tank volume, l | 48.7 |

| Power consumption, kW | 2 |

| Maximum heating temperature, ˚С | 75 |

| Outlet water pressure, atm. | 6 |

| Device control | electronic |

| Indication | Switching on and heating |

| Thermometer (availability) | There is |

| Display | There is |

| Water heating limitation | There is |

| Protection system | There is |

| Anti-freeze function | There is |

| Safety valve | yes, included in delivery |

| Protective anode - presence and quantity | There is. magnesium, one |

| Number of internal tanks, pcs. | 2 |

| Tank manufacturing material (internal coating) | enameled steel |

| Heating time to max. temperature, min | 122 |

| Installation methods | Vertical or horizontal |

| Eyeliner | Lower |

| Mounting method | Wall |

| Dimensions (w×h×d), mm | 490×920×297 |

| Device weight, kg | 31 |

| Connection diameter, inch | ½ |

| Additional functions | Self-diagnosis, Anti-Legionella function, EcoSmart |

| Warranty period, years | 2 |

pros

- aesthetic appearance;

- easy connection and setup;

- “EcoSmart” function, designed to configure the device depending on the amount of water consumed;

- ease of use;

- excellent reliability.

Minuses

- no significant comments were made.

Boiler Gorenje FTG 50 SM B6

#2 Water heater “Ariston LYDOS R ABS 50 V”

"Ariston LYDOS R ABS 50 V" is another Italian-made model. is one of the leaders among manufacturers of water heating and heating equipment, and other household appliances.

Tanks can be made of stainless steel or have an internal coating of the tank with a layer of enamel with the addition of silver ions, due to which the water undergoes antibacterial treatment. Water heaters are equipped with highly effective thermal insulation, so the devices are very economical to operate.

Water heater "Ariston LYDOS R ABS 50 V"

The Ariston LYDOS R ABS 50 V model has compact dimensions, so it does not require much space and fits perfectly on the back wall of the toilet of a typical apartment.

Technical characteristics of "Ariston LYDOS R ABS 50 V":

| Name of parameters | Indicators |

| Manufacturer country | Italy |

| Tank volume, l | 50 |

| Power consumption, kW | 1.5 |

| Maximum heating temperature, ˚С | 75 |

| Outlet water pressure, atm. | 0,20÷8,0 |

| Device control | electromechanical |

| Indication | inclusion |

| Thermometer (availability) | There is |

| Display | There is |

| Water heating limitation | There is |

| Protection system | RCD |

| Anti-freeze function | No |

| Safety valve | yes, included in delivery |

| Tank manufacturing material (internal coating) | Titanium enamel coated steel |

| Installation methods | Vertical |

| Eyeliner | Lower |

| Mounting method | Wall |

| Dimensions (w×h×d), mm | 450×553×480 |

| Device weight, kg | 14 |

| Connection diameter, inch | ½ |

| Additional functions | No |

| Warranty period, years | 5 |

pros

- aesthetic appearance;

- convenient location of the water heating regulator;

- presence of RCD;

- titanium coating of the internal walls of the tank;

- boiler efficiency

- ease of use.

Minuses

- the kit does not include anchors for hanging the boiler;

- Not everyone likes the appearance of the thermometer.

Boiler Ariston LYDOS R ABS 50 V

#1 Water heater “Zanussi ZWH/S 50 Splendore XP 2.0”

The storage electric water heater “Zanussi ZWH/S 50 Splendore XP 2.0” is the leader in this rating. The presented device is distinguished by ergonomics and a laconic design solution, which allows it to fit into any kitchen or bathroom interior. The boiler is equipped with various functions that facilitate its operation, and has only positive customer reviews.

Water heater “Zanussi ZWH/S 50 Splendore XP 2.0”

Technical characteristics of "Zanussi ZWH/S 50 Splendore XP 2.0":

| Name of parameters | Indicators |

| Manufacturer country | Italy |

| Tank volume, l | 50 |

| Power consumption, W | three modes: 700/1300/2000 |

| Maximum heating temperature, ˚С | 75 |

| Outlet water pressure, atm. | 0,78÷5,92 |

| Device control | electronic |

| Indication | inclusion |

| Thermometer | There is |

| Display | There is |

| Water heating limitation | There is |

| Protection system | RCD |

| Anti-freeze function | There is |

| Safety valve | included |

| Tank manufacturing material (internal coating) | Stainless steel |

| Heating time to maximum temperature, minutes | 90 |

| Heating element power, kW | 2 |

| Installation methods | vertical, horizontal |

| Eyeliner | lower |

| Mounting method | universal |

| Dimensions (w×h×d), mm | 435×970×260 |

| Device weight, kg | 15.5 |

| Connection diameter, inch | ½ |

| Additional functions | Timer, antibacterial system for water disinfection, USB port for Wi-Fi adapter - for remote control. |

| Warranty period, days | 2 years |

pros

- boiler efficiency

- availability of additional control functions;

- reasonable cost;

- high quality;

- ease of use.

Minuses

- did not speak out

Boiler Zanussi ZWH/S 50 Splendore XP 2.0

* * * * * * *

We hope that the information obtained in the article will make it easier for the reader to select the optimal model of a storage water heater - an electric boiler.

Additional help in this matter can be obtained by watching the video below:

How gas boilers work

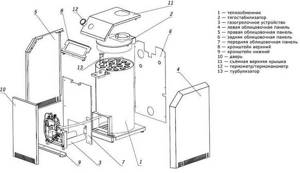

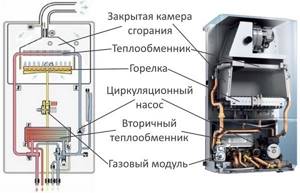

The schematic diagram of a gas heating boiler is practically identical for most modifications. This means that the main blocks from which the boilers are assembled and the operating principle of a gas heating boiler are the same:

- The gas burner device is made in the form of a perforated rectangular structure. Inside which the nozzle is located. Gas fuel is supplied through it for combustion in the combustion chamber. Combustion efficiency is ensured by uniform distribution of fuel over the entire combustion surface.

- The heat exchanger is a steel box with a developed tubular heating surface. When gas burns, the heat released heats the walls of the heat exchanger, along the internal circuit of which the heating coolant flows. From contact with hot surfaces, the boiler heats the water, which later gives off its heat in the heating system. Single-circuit boilers have one heat exchanger for the heating circuit. In a dual-circuit system there are two, including a DHW heat exchanger.

- The circulation pump serves to force the movement of heating water in the heating circuit. The device is present only in boiler models with forced circulation.

- The expansion tank is a protective device that discharges excess coolant that is formed during heating of the heating circuit.

- Chimneys and components. Requirements for chimneys for gas boilers are determined by SNIP rules. In open-type atmospheric boilers, they are connected to chimneys operating with natural draft.

The presence of auxiliary components in the boiler distinguishes it from a gas water heater. The design of a floor-standing gas boiler differs from a wall-mounted one, with more powerful dimensions and weight, due to the fact that their design usually includes a storage tank for hot water.

The automatic control and protection unit is designed to regulate boiler modes depending on the internal/external air temperature and unit protection in case of emergency situations.

For example, high gas or coolant pressure, separation of a gas torch, water leakage, high temperature of the heating circuit or hot water supply. Its operation is based on the use of primary sensors - a gas boiler thermocouple and the operation of a three-way valve.

Double-circuit boiler

A double-circuit gas unit differs from a single-circuit boiler in that its design contains not one heat exchanger for heating, but two - primary and secondary.

Operating principle of a double-circuit boiler

The first is located directly in the gas combustion zone. Its purpose is to heat the heating fluid. The secondary one does the job of heating hot water.

It must be noted that a double-circuit gas boiler cannot operate synchronously in 2 modes. This explains the presence in its system of a three-way valve, which, when the hot water tap on the mixer is opened, sends the coolant into the DHW circuit.

Gas burner device for a boiler

The burner device of a gas boiler unit is classified into the following types:

- Single-level, capable of operating only in two options - Stop/Start. Despite their low profitability and reduced service life, they are popular due to their simple design and low price.

- Two-level, ensures the boiler operates in two modes - 50/100%. Its advantages are felt during the transitional heating period, since there is no need to use the device at full power to heat the home.

- Modulated - a smart system for adjusting the boiler unit modes, which is capable of independently adjusting the operation in the range of 20-100%. This system ensures efficient and long-lasting operation of the boiler. Moreover, its price is an order of magnitude higher than conventional heating analogues with one and two-level burner devices.

In addition, burners are divided into open and closed type installations. In the first option, the air needed for the gas combustion process comes directly from the room in which the boiler unit is located. Air for a closed firebox is supplied through a coaxial chimney using a fan to draw it from the atmosphere.

Schemes and rules for connecting BKN

The connection diagram and installation features of an indirect heating boiler depend on the class of the device and the heating system in the house. It is necessary to choose the right installation location, focusing on the location of the boiler, pump insertion and existing wiring. Let's try to figure out what needs to be taken into account when installing heating equipment.

Option #1 – piping with a three-way valve

This is one of the most popular schemes, since when it is used, there is a parallel connection of the heating system and the BKN, equipped with shut-off valves. The boiler must be installed near the boiler, a circulation pump must be installed in the supply, then a three-way valve.

This scheme is successfully used if several heating devices are used, for example, two different boilers.

Essentially, this is a priority system that ensures rapid heating of water in the boiler when the radiators are completely turned off for a while. As soon as the temperature rises to the set value, the three-way valve is activated again and returns the coolant to its previous direction - to the heating system. This piping method is useful for those who use the boiler constantly.

Option #2 – scheme with two circulation pumps

If the boiler is rarely used (for example, seasonally or on weekends) or there is a need for water whose temperature is lower than in the heating system, use a scheme with two circulation pumps. The first is installed on the supply pipe, directly in front of the BKN, the second - on the heating circuit.

There is no three-way valve in this scheme; the piping is equipped using simple connecting tees.

Option #3 – piping with a hydraulic arrow

This connection is used for volumetric boilers (200 liters or more) and branched heating systems with many additional circuits. An example is the heating system in a two-story house, where, in addition to a multi-circuit radiator network, heated floors are used.

The water gun equipment allows you to avoid thermal shock, since the water pressure in each circuit will be the same. It is quite difficult to make the piping according to this scheme yourself, so it is better to turn to professional installers.

Option #4 - using coolant recirculation

Recirculation is useful when there is a circuit that requires a constant supply of hot water - for example, a heated towel rail. If it is connected to the heating system, the coolant will constantly circulate, and the dryer will function and at the same time serve as a heating device.

But this scheme also has disadvantages. The main one is an increase in fuel costs, because constant heating of the water cooled in the circuit is required. The second disadvantage is mixing water in the boiler. Typically, hot water is located in the upper part, and from there it flows to the water supply points, where it is mixed with cold water, as a result of which the outlet temperature is slightly lower.

There are models of boilers with built-in recirculation, that is, with ready-made connections for connecting a heated towel rail. But it’s cheaper to buy a regular tank using tees for connection.

Option #5 – system with a non-volatile boiler

A distinctive feature of this scheme is the installation of the boiler at a higher level than the boiler and heating appliances. Preference is given to wall-mounted models that can be hung at a height of 1 m above the floor.

The non-volatile type of heating is based on the application of the laws of gravity, therefore, the coolant will circulate even when the electricity is turned off. In normal mode, you can connect circulation pumps.

Materials and tools

Materials:

- Pipes, shut-off valves, check valves - there are no special requirements for them: use the same materials as for working with hot water supply or heating systems.

- Expansion tank - a separate one is required for the domestic water supply system; it serves to prevent sudden pressure changes when opening/closing taps.

Attention! The tank must be designed for use with hot water; usually such devices are marked with special markings. Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater. Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater

Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater.

In addition, in DHW systems with recirculation, a separate pump is required to circulate water in the DHW circuit.

This will eliminate the need to wait for hot water to arrive through long pipes from the installation site of the water heater: the water will immediately be hot.

- Wires and small electrical wiring - if you plan to connect the water heater thermostat to the boiler automation.

- Fasteners - especially in case of wall installation, also for securing pipes and pumps.

- Standard plumbing set of sealants, seals, gaskets.

Tool:

- gas key;

- wrenches of various diameters;

- Adjustable wrench;

- building level;

- hammer drill, screwdrivers, screwdriver;

- Minimum electrician's kit: knife, wire cutters, electrical tape, phase tester.

Installation process: how to connect

Ideally, the boiler should be located as close as possible to the heating boiler to minimize heat loss.

Cold water is always supplied to the bottom pipe of the boiler, and hot water is drawn from the top.

- Choose a location for the water heater so that it is not in the way and is easy to maintain. Mount brackets, stands, and secure it to them.

- Connect to the cold water network: make a tap, install a shut-off valve and a coarse filter.

- Through a tee, take the cold water line to consumers, connect the second output to the boiler through a safety valve.

- Connect the domestic hot water line to the boiler, not forgetting about the expansion tank on it. In addition, install bypass taps so that you can disconnect it from the circuit during maintenance.

- Now connect the boiler to the gas boiler according to one of the given diagrams. Don't forget to turn off the boiler and shut off the system before connecting!

- Connect electronics, sensors, pumps according to the instructions.

Startup and testing

After installation, the first thing you need to do is connect and fill the boiler with cold water. Make sure that all air pockets are removed from the system and that the boiler is completely filled to avoid overheating.

When the boiler is full, set the desired temperature using automation. Start the boiler, open the coolant supply from the heating system to the boiler.

When the system reaches operating mode, make sure that the safety valve (usually set to 8 bar) is not leaking, i.e. there is no excess pressure in the system. You should also check all connections, seals and taps for leaks.

Selecting an indirect heating boiler

Before purchasing and connecting a buffer tank-accumulator (as BKN is also called), you should understand the design features of the most popular types. The fact is that there are many types of equipment, including combined models that operate from heating systems and alternative energy sources simultaneously.

We will look at traditional coil boilers that use hot water as a heater.

Design features and operating principle

What does indirect heating mean? Directly heated devices operate by connecting to electricity or a gas burner; BKN has a different heat source. The water is heated by connecting to the hot water supply, that is, it turns out that the source is the coolant - hot water (or its substitute).

If we look at new models of well-known brands, we will notice that gas boilers and KN boilers often have the same design. They are mounted side by side or one under the other - this way you can save on the placement area.

The main element that performs the heating function is a steel or brass heat exchanger (coil) with a large surface area, which is located inside a metal tank coated with a protective layer of enamel. To prevent the water from cooling too quickly, the outer side of the housing is surrounded by a layer of thermal insulation, and some models are surrounded by a casing.

An important part that most heating devices are now equipped with is a magnesium anode. A rod fixed to the top of the device protects metal parts from corrosion, as a result the water heater lasts much longer.

Barriers against high pressure are a safety valve and a built-in thermostat. If the tank is not equipped with a safety group, it is installed separately when installing the piping.

Often the water circulating in the heating system does not exceed 65-70 °C. Many people doubt its effectiveness when it acts as a heat source for heating in a BKN. In fact, the indicated temperature is sufficient, because the speed and magnitude of heat transfer largely depends on the area (quite large) of contact of the coil with water.

How does the heating process occur? Cold water intended for heating enters through a separate hole and fills the entire container. Water also flows from the boiler into the heat exchanger, but already heated. The hot walls of the coil transfer heat to cold water, which at the outlet already has a temperature suitable for taking a shower or washing dishes.

Advantages of controlled equipment

Controllability is a characteristic that affects the assembly of the entire water heating system. There are two types of BKN: simple (cheaper) and with a built-in control function.

A distinctive feature of controlled models is the additional equipment with a temperature sensor and the ability to supply/stop the supply of water to the heat exchanger. Such equipment operates automatically.

To start you need to connect:

- inlet/outlet for hot water from DHW;

- supply of cold water to the tank;

- manifold for distributing heated liquid at the outlet.

After this, you can start the boiler - the water will begin to heat up.

The process of connecting and piping an indirect heating boiler occurs in one of the following ways (described below).

How can control affect water temperature? Almost nothing. The maximum value that the outlet temperature can reach does not exceed the parameters of the coolant in the DHW system. Most likely, it will be 1-2 °C lower.

If more intense heating is required (this can happen if the boiler usually operates in low temperature mode), then it is better to choose a model with a built-in heating element.

It is advisable to purchase such equipment together with boilers operating on solid fuel (the water remains hot even after the boiler has cooled).

Types of devices with additional functions

Tanks with a simple design are only part of the range presented on the water heating equipment market. There are many models of boilers, the functions of which are very useful for integration into a DHW system.

For example, one of the purposes of more expensive models is heat accumulation. If power outages are possible or daily consumer tariffs are too high, the accumulation mode will be very useful. The design features of such models are enhanced thermal insulation and increased tank volume (300 liters or more).

Another option that provides the fastest supply of hot water to water collection points is a recirculation boiler. Unlike the usual design, this one is equipped with three pipes for communication with the hot water supply system. Two supply hot water, one supply cold water. Water is supplied using a pump.

When using a model with recirculation, you can install an additional useful circuit, for example, for installing a heated towel rail.

The water in such a tank heats up faster than in units with a heat exchanger, but its cost is higher.

Tank size and its meaning

Cylindrical and cubic tanks differ in their sizes. Their volume is indicated in liters: there are small models with a capacity of 80-100 liters, but there are also bulky ones that can hold up to 1400-1500 liters. The size is selected based on the family’s need for hot water.

Dimensions are important during installation. Only light models are suitable for wall installation - up to 200 liters; all others are floor-mounted. Both horizontal and vertical wall-mounted devices have special fastenings, while floor-mounted ones are equipped with legs or a small stand.

Read also Herring Ambassador at home in its entirety

Rectangular units take up slightly less space than cylindrical units due to their tight fit to the pipes.

How does a double-circuit boiler with a biothermal heat exchanger work?

A bithermal heat exchanger is a coil made of a coaxial pipe. To simplify somewhat, these are two pipelines inserted into one another.

The coolant moves through the external volume, and water for the hot water circuit moves through the internal volume. This heating method significantly changes the quality of the boiler’s operation - efficiency increases, the amount of hot water increases and allows you to satisfy the needs of a large family.

However, a bithermal heat exchanger has a significant drawback - the complexity of organizing the internal space of the tube makes washing much more difficult.

All lime deposits, which quickly appear on the inner surface of the pipe, must be periodically removed, otherwise it will completely block the cross-section of the heat exchanger.

In addition, as the thickness of the lime layer increases, the heating efficiency decreases - the deposits begin to act as a heat insulator. The user has to increase the gas supply to adjust the boiler operating mode.

CAREFULLY! As a result, the heat exchanger quickly fails due to excessive heating outside and a large amount of scale inside.

Not all service centers perform flushing of such a heat exchanger, and the design of some boilers is such that it is easier to change than to dismantle and reinstall the same unit.

The disadvantage of bithermic heat exchangers relates entirely to operational issues. From an efficiency point of view, this design is very successful and allows you to increase the volume of hot water available for simultaneous delivery without loss of temperature in the heating circuit or the DHW itself.

Priority connection principle

Before installing an indirect heating boiler in the DHW system, you must choose the principle of its connection: with or without priority. In the first case, when there is a need to quickly obtain a large amount of hot water, the entire volume of coolant is pumped through the BKN coil, as a result of which the water heats up much faster.

Once the water temperature has reached the required level (measured by a thermostat), there is a way to redirect the flow to the radiators.

A connection without priority does not allow the entire volume of coolant to pass through, and the boiler serves only part of the total flow. When equipped with such a circuit, the water takes longer to heat up.

The priority scheme is more effective, as it makes it possible to quickly heat the required amount of water without compromising heating. If the heating appliances are turned off for 30-50 minutes, the temperature in the rooms is unlikely to drop in such a short period of time, but there will be enough heated water.

The only condition for equipping a priority circuit is a powerful boiler.

Boiler installation

It is recommended to place the boiler in a place where it will not interfere, for example, above the toilet in the corner.

- Having determined the installation location of the boiler, you need to drill 2 holes in the wall, hammer 2 dowel nails into them and screw in the mounting brackets.

- The next thing that remains is the story of the boiler on the brackets.

- Crash into a plumbing system.

- Install a ball-type shut-off valve.

- Install a water purification filter with a cartridge.

Then a tee is installed, and a pipe is led from it to the cold water tap. Another pipe is led to the boiler simultaneously with the installation of the second shut-off valve. This pipe is connected to the overpressure valve, which is pre-installed on the boiler.

Two more taps, built into the boiler itself, are intended for preventive maintenance and draining water. The faucet for complete drainage began to be installed quite recently, and if you do not open it, then you will always have 80-100 liters of water in stock. But for the drain to work, both taps are needed to eliminate hydraulic plugs in the pipes.

The collet, which is connected to the hot water outlet pipe, serves to start distribution throughout the apartment. During pipe laying, holes are drilled for special mounting clips for pipes. The power cable is supplied in a separate line; grounding must be done. An electric boiler must be connected to voltage through a paired circuit breaker.