Modern heating devices using natural gas are high-tech and safe thanks to the introduction of automatic control and monitoring systems.

Automatic tracking systems improve equipment efficiency while providing ease of use without the need for constant human supervision.

Control system

Boiler automation is conventionally divided into volatile (electronic) and non-volatile (mechanical).

Automation algorithm and functions

The operating principle of a gas boiler is simple. When gas enters, the electronic ignition device is activated. The wick lights up, which then burns constantly - the automation will not supply gas if it is not lit.

It ignites the burner - the heating device. The burner heats the coolant (water) to the required temperature. As soon as the water heats up, the automation turns off the burner. When the water temperature drops, the thermostat will send a signal to the valve and gas will begin to flow. The burner will start again and so on.

Today, heaters receive systems whose list of functions includes automatic provision of:

- Security.

- Continuity - automatic switching on and off.

- Controls based on various criteria - time, temperature throughout the day and other parameters.

Tips for organizing remote heating control

Diagram for connecting modules to the heating control unit

In most cases, you can make a cottage heating control system yourself. This is only possible with the correct selection of system components. Those. First you need to analyze the condition and capabilities of the already installed equipment.

The classic heating system control unit diagram has one control unit, which is connected to all heat supply elements. The programmer must meet the following requirements:

- The number of connected terminals and their configuration must coincide with similar communication nodes of the boiler and thermostats. Otherwise, heat supply control via SMS will be impossible. If necessary, adapters are purchased;

- Maximum distance of the user from the control unit. If this distance does not exceed 300 m, you can purchase models with mine control. To increase the communication area, it is recommended to use heating control via a mobile phone or the Internet;

- The ability to independently (or with the help of specialists) set additional operating parameters. This is done with a controller based on heating control boards;

- Connecting an autonomous power supply unit. To do this, you need a sufficiently large heating control box. This parameter is taken into account when choosing the installation location of the control unit in the house.

Don't forget about the ability to control heating radiators. This can be done using local devices - mechanical thermostats. They are low cost, but cannot be connected to a common electronic control system.

If the heating also performs the function of hot heat supply, it is necessary that the programmer has a control function for this area.

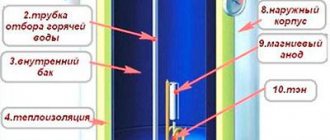

Automation diagram for a gas boiler

The components, automation device and set of boiler sensors are different, but in any case they meet the basic requirements of reliability and safety. They are divided into several element groups that perform various functions and are present in one form or another as part of control systems for gas heaters for various purposes:

- Gas fittings.

- Valves.

- Gas and water pressure switch.

- Thermostat. A room thermostat can be included in the circuit.

- Controller.

- Water presence sensor.

- Traction sensor.

- Programmers (daily and weekly, including wireless)

Armature

Where to order a board with delivery

Sometimes, for older models of boiler units, it is impossible to repair the board and purchase a new one, if the factories no longer produce spare parts because the unit is no longer in production.

Then the service center will need to make a new board to interchange the old one, using tracing, writing its own program code for the controller and modeling the electronic unit on a modified base. In this case, you can get a more modern product with increased characteristics.

For those users who live in another area, such a board can be ordered online with delivery.

In Moscow and the Moscow region, this can be done through the online service “Spare parts for boilers”. Average prices for such advanced boards in Russia:

- Domina E/Pie, RUB 4,786.

- Ferroli, RUB 6,974.

- Ferroli with display, RUB 6,864.

- Vaillant, RUB 12,314.

- Buderus, RUB 15,171.

- Logamax U042-24K, RUB 15,171.

- LED Buderus, RUB 6,068.

- Proterm Skat 9-12 kW, 10,430 rub.

Gas fittings

With the help of gas fittings or devices that process commands from the control circuit for execution, processes are regulated - starting and stopping the boiler, changing the flow rate and direction of gas flow, and heater power. But the main purpose is job security.

Types of fittings:

- Constipated. The composition includes dampers, various valves and taps. Connection is made using flanges, couplings and fittings.

- Regulatory. To adjust the flow rate by changing the flow area. This includes mechanical and electronic valves.

- Safety. This equipment includes shut-off and safety valves.

- Emergency. This includes shut-off valves that stop the flow of fuel.

The main function of a gas heater is to open or close the flow of fuel to the burner.

Operating rules

During operation of an open-type gas boiler, it is necessary to ensure a sufficient air supply in order to ensure complete combustion of gas.

Otherwise, the efficiency of the unit will be low, and the volume of unburned gas will be large, with possible release into the room. In closed fireboxes, it is also important to monitor the sufficiency of air and the functionality of the blower fan.

Basic rules for the safe operation of a heating boiler operating on gas fuel if there is a gas smell:

- immediately turn off the gas valve to the burner device;

- open windows for ventilation;

- in closed-type boilers, forced ventilation is turned on in the chimney system of the gas boiler;

- do not use electrical switches and matches;

- immediately turn off the open flame;

- report an emergency to the gas service.

Autonomous heating is gaining popularity; for many homeowners it has become as necessary in the cold season as an air conditioning system in the summer - an affordable level of comfort in residential premises that ensures normal life activities.

The main function in this is performed by modern boiler installations - technologically advanced, innovative units capable of solving multi-level thermal problems.

Relays and sensors in a gas boiler circuit

Any heater is designed for a certain operating gas pressure. Deviation from the norm will lead to a drop in performance or burnout of the housing.

If there is a drop, the minimum gas pressure switch comes into operation, turning off the boiler.

The limit value is adjusted during commissioning. It is mounted on the inlet line before the control unit or in front of the gas supply valve.

Minimum pressure switch

When the pressure increases, the maximum pressure switch comes into operation. The device prevents possible overheating and destruction of the burner. The connection is made in series in the same circuit with the previous relay.

The thermostat is considered one of the most complex devices in the automation circuit of a gas boiler. The main purpose is to maintain the desired water temperature. Threshold values are adjustable.

The draft sensor performs an important function - it monitors the process of exhausting combustion products.

If something goes wrong, for example, for some reason a backdraft appears, it will cut off the gas supply to the burner. This is a vital element because carbon monoxide poisoning occurs unnoticed. Installed in the smoke eliminator above the boiler.

In case of problems with water supply, minimum and maximum pressure switches are provided. Low blood pressure is dangerous. It causes water to boil and, as a result, leads to air entering the system and overheating of the boiler with the ensuing consequences. To set the relay, use the minimum temperature values at which the functionality of the boiler is ensured. The minimum pressure switch will turn off the burner. An increase in pressure above the nominal value occurs less frequently, but is also dangerous. In this case, the corresponding relay will stop the boiler.

Operation will resume only after the factor that caused the triggering has been eliminated. After shutdown, manual restart is required due to increased pressure. For this purpose, a special button is provided to disable the gas heater protection.

In rare cases, a water presence sensor is included in the automation circuit. It is placed in the boiler itself. If the water level is below the required level, it will not allow the automation to start the boiler.

Controller

Repair of electronic boards by specialists

When choosing a service organization to repair circuit boards, you need to make sure that it is certified to perform work specifically for a specific boiler model.

Next, you will need to find out the company’s operating forms, it is better if there is an opportunity to work from home. Then, before changing the board, the company will carefully analyze the operation of the unit and the possibility of failures of auxiliary equipment.

Working from home, a service specialist must have a gas analyzer, a diaphanometer and a set of research and repair equipment. Carrying out diagnostics of the operation of the pump, fan and power supply circuits, based on the results of the examination, he identifies a failure.

The specialist’s repair kit should contain a backup boiler board for this model, which he replaces while repairing the faulty one. Such repairs last no more than 2 hours, which is especially important in the cold season, so as not to cool the premises.

In the workshop, a complete diagnosis of the board is carried out on a specialized stand, which simulates the operating modes of a specific boiler unit and records failures with special software.

In addition, a thermal imager, oscilloscope and logic analyzer are used. This repair technology allows you to identify “floating” defects, identify minor defects, software failures, and power surges.

Long-term testing makes it possible to notice and record absolutely all the details of the functioning of the electronics. 70% of board breakdowns in a good workshop are repaired within the first 24 hours; if spare parts are needed, delivery time will take 2-3 days; if components are needed from abroad, repairs can last up to 2 weeks. As practice shows, 90% of boards can be restored.

- Primary diagnostics are carried out - up to 500 rubles.

- Based on the results, the full cost of repair work is determined. The average price for units up to 16 kW is from 3,000 rubles, more than 20 kW - from 4,000 rubles.

- Installation of Ariston boiler board - from 1,500 rubles.

- Payment is made upon completion of the repair, upon confirmation of the functionality of the board.

- Additional costs for transport services within the Moscow Ring Road - 1000 rubles, additional payment for 1 km from the Moscow Ring Road - 30 rubles.

- A 6 month warranty is provided.

Despite the fact that the service center gives a guarantee for six months, in fact, a repaired boiler control board can last much longer.

Since 2014, most manufacturers of Western-made heating boilers, especially if they are assembled in other countries, have used inexpensive parts in boards.

Service centers are certified by factories and brand owners who require the use of original spare parts, so quite often after repair the board is superior in quality to the original one.

Installation features

The direction of the water must coincide with the direction of the arrow on the device body

The valve is placed on the pipe so that the direction of the liquid coincides with the direction of the arrow. The filter plug is directed downward, and the adjustment screw must be accessible for use. The pressure gauge dial rotates to make it easy to read the values.

The winding material is used rationally so that excess does not fall into the lumen of the gearbox. Boiler feed in the form of a valve should not depend on main loads (compression, torsion, bending, vibration). For this purpose, additional supports or compensators are installed.

The mismatch between the axes of the pipelines should not be more than 3 mm for a length of 1 m. For longer lengths, 1 mm is added for each linear meter. The make-up circuit is connected to the pipeline near the expansion tank.