Which design is better?

Systems, depending on the design and material of the expansion tank, differ in the list of pros and cons. But, according to experts and experienced users, the advantages in functionality are on the side of closed options.

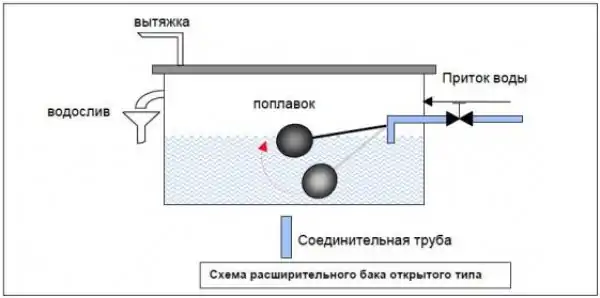

Pros and cons of an open tank

A self-flowing system requires larger diameter pipes, which in turn directly increases costs. The budget for installing an open heating system with a leaky expander increases slightly, although it remains relatively small.

The main advantages of this option are simplicity, plus the low cost of components and installation work. Another positive feature is that there is no need to control the pressure level.

An open-type expander for small systems can be assembled from available materials, and its installation will not be difficult

However, there are much more disadvantages:

- the use of anti-freeze is dangerous due to toxic fumes;

- installation possibilities are limited only by the top point of the system;

- constant contact with the atmosphere increases the risk of air locks and corrosion;

- slow warm-up;

- temperature changes accompanying convection circulation accelerate equipment wear;

- used in heating low-rise buildings, maximum two floors;

- large heat losses and energy consumption for heating.

Another disadvantage of an open system is losses from evaporation and overflows. Therefore, when installing the tank, care should be taken to ensure that the filler hole is accessible.

Pros and cons of a closed tank

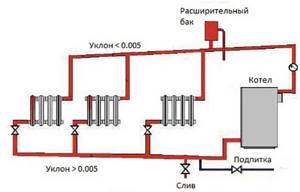

If open expanders win in terms of prices and ease of installation work, then functionality is the strong point of a closed tank, which is also called an expansion tank. They are used in the construction of closed heating systems that do not have direct contact with the atmosphere.

Expanzomats have the following advantages:

- complete tightness allows the use of antifreeze;

- The location of the expander does not affect the performance of the system;

- insulation of the internal space of the tank minimizes the likelihood of air locks and corrosion;

- after startup, the system warms up faster and is more sensitive to temperature control;

- smaller difference between the operating conditions of the supply and return lines, which as a result increases the service life;

- does not require the installation of large diameter pipes, which allows saving on construction;

- does not require constant attention to the level and condition of the liquid;

- possibility of use in systems designed for several floors;

- small heat losses, reducing costs during equipment operation.

When choosing expanders of this type, you may encounter sealed cylinders with a non-separable design. If the diaphragm malfunctions, the cylinder will have to be replaced with a new one.

To monitor the level of working pressure, a pressure gauge is mounted on the cylinder; an automatic or mechanical air vent is installed to remove excess air.

Among the disadvantages, it is important to note the complexity of the design, special requirements for materials, which increase the cost of the equipment. To this we can add the need to constantly monitor pressure and restore it if necessary.

Calculation of unit volume

The required tank volume will be the sum of several components:

- 5% of the total system volume;

- 2% taking into account coolant evaporation;

- 1% is a margin to avoid water overflowing over the edge of the tank.

To find out the amount of coolant in the system, you need to sum up the volume of the boiler, radiator and heating pipes, and 5% is a theoretical calculation for water.

If the system uses a different coolant, then an adjustment is necessary based on the corresponding rate of thermal expansion of the liquid.

Reference. Indirect determination of the system volume is carried out thanks to the boiler power - 1 kW is designed for 15 liters of coolant.

Selection of device according to calculation

Before you start calculating the membrane, you need to know that the larger the volume of the heating system and the higher the maximum temperature index of the coolant, the larger the volume of the tank itself should be.

There are several ways to carry out the calculation: contacting specialists at a design office, performing the calculations yourself using a special formula, or calculating using an online calculator.

We recommend: Hydrogen heating boilers: why you should not choose a hydrogen fuel boiler for heating a private home, review and comparison of efficiency and cost-effectiveness, the best models and their prices

Formula

The calculation formula looks like this: V = (VL x E) / D, where:

- VL – volume of all main parts, including the boiler and other heating devices;

- E – coefficient of expansion of the coolant (in percent);

- D – membrane efficiency indicator.

Determination of volume

The easiest way to determine the average volume of a heating system is by the power of the heating boiler at the rate of 15 l/kW. That is, with a boiler power of 44 kW, the volume of all system lines will be equal to 660 l (15x44).

The expansion coefficient for a water system is approximately 4% (at a coolant temperature of 95 °C).

If antifreeze is poured into the pipes, then they resort to the following calculation:

- 10% - 4% x 1.1 = 4.4%;

- 20% - 4% x 1.1 = 4.8%, etc.

The efficiency rating (D) is based on the initial and maximum pressure in the system, as well as the starting air pressure in the chamber. The safety valve is always set to maximum pressure. To find the value of the efficiency indicator, you need to carry out the following calculation: D = (PV - PS)/(PV+1), where:

- PV is the maximum pressure mark in the system, for individual heating the indicator is 2.5 bar;

- PS – the charging pressure of the membrane is usually 0.5 bar.

Now it remains to collect all the indicators into the formula and get the final calculation:

- VL = 15x44=660 l;

- D = (2.5 – 0.5) / (2.5+1) = 0.58;

- E = 4% = 0.04;

- V = (660×0.04) / 0.58 = 45.5 l.

You can round up the resulting number and choose an expansion tank model starting from 46 liters. If water is used as a coolant, the volume of the tank will be at least 15% of the capacity of the entire system. For antifreeze this figure is 20%. It is worth noting that the volume of the device may be slightly larger than the calculated number, but in no case less.

Popular tank manufacturers

1. Wester heating tanks are recognized as one of the best in Russia for home use. The domestic manufacturer produces vertical and horizontal models with a volume ranging from 8 to 500 liters. Their rubber is made of especially durable heat-resistant material that can withstand heating up to 100 °C. Plus, the expansion tank is equipped with a replaceable membrane, which increases its service life.

The body is made of durable steel. The heaviest barrels are equipped with supports. The warranty covers 3 years. The price of the Wester WRV 80, the most popular model, is about 2,500 rubles.

2. The next interesting brand is Reflex from a German manufacturer. It is characterized by high strength and long service life - up to 12 years. The Reflex expansion tank for heating of any model is made using the famous technology of the Krupp dynasty, famous for its high-quality steel.

Volumes are very different: from 8 to 1,000 liters. The tank is equipped with a replaceable membrane designed for temperatures up to 70 °C. The cost of this line starts from 1,520 rubles.

3. A series of Chinese manufacturer Zilmet CAL-PRO is very often found on sale. Tanks with capacities from 4 to 900 liters are offered on the market. Their body, made of carbon steel, is either ringed or welded. The membrane is made of synthetic rubber. The device can operate at temperatures from – 10 to 100 °C.

The cost of a membrane expansion tank of the CAL-PRO series for heating starts from 1,170.

How to choose for your home

When heated to 70-90 °C, all water increases in volume by 4-5%. Without a buffer, it creates high pressure in the pipes, which can cause them to burst. Therefore, the correct choice of a membrane tank for a heating system is very important. It should be done on the basis that the expander must take on all the excess volume of liquid. Therefore, before purchasing, it is necessary to correctly calculate this amount, and even better, consult with the designers.

It is also advisable to ensure that the tank is made of high-quality materials, otherwise it simply will not withstand the loads.

Very often, inexperienced or unscrupulous sales consultants try to sell clients devices intended for water supply instead of the required ones, believing that there is practically no difference between them, except perhaps in color (blue and red). In fact, hydraulic accumulators are used in heating systems only due to oversight. In this case, since their rubber is not designed to withstand heat, they quickly fail.

Brief DIY installation instructions

- First you need to decide on the location of the device. According to the instructions, the expansion tank can be installed anywhere in the heating system, but in order to avoid sudden pressure surges, it is better to place it immediately behind the circulation pump.

- The device must be installed so that there is access to the air valve, drain valve, shut-off valves and other important parts.

- During installation, the room must not be below 0 °C. The safety valve must be installed along the flow direction.

- There is nothing complicated in the installation itself, you just need to follow the instructions and use the proper tools, in particular a wrench for metal-plastic pipes and connectors. The pipe must match the pipeline.

- Tanks with a large capacity must be mounted on additional brackets. To do this, first mark the location, then drill a hole and attach the hangers with anchor bolts.

- After the equipment is secured, a pipe is connected to it so that it does not interfere or put pressure on the tank.

- Then a pressure reducer is installed; it must be installed after the meter.

- If everything is done correctly, you can start setting up - pump in air and water, observing the pressure. When it is balanced, you can start turning on the heating.

- It is better to entrust the installation of a tank in a multi-boiler system to specialists who have been tested and received the appropriate license.

Prices in Moscow

You can buy a membrane expansion tank at the estimated cost indicated in the table.

| Brand | Cost, rubles | |||||||||||

| Volume, l | 8 | 12 | 18 | 24 | 35 | 50 | 80 | 100 | 150 | 200 | 300 | 500 |

| Wester | 790 | 860 | 900 | 1 000 | 1 650 | 1 900 | 2 500 | 3 500 | 5 200 | 9 500 | 11 500 | 18 100 |

| Volume, l | 8 | 12 | 18 | 25 | 33 | 60 | 80 | 100 | 140 | 200 | 300 | 500 |

| Reflex | 1 520 | 1 600 | 1 980 | 2 300 | 3 070 | 4 900 | 5 900 | 6 700 | 9 060 | 10 860 | 15 000 | 23 000 |

| Volume, l | 8 | 12 | 18 | 25 | 35 | 50 | 80 | 105 | 150 | 200 | 250 | 500 |

| Zilmet CAL-PRO | 1 170 | 1 230 | 1 300 | 1 630 | 2 100 | 3 100 | 4 200 | 6 100 | 7 600 | 9 480 | 12 200 | 22 200 |

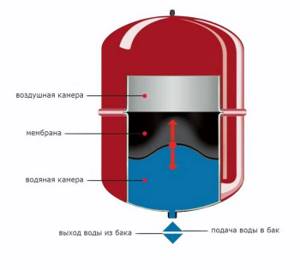

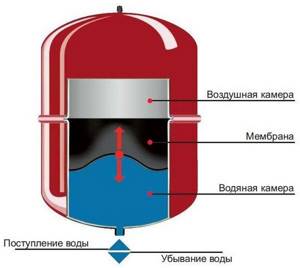

Equipment and principle of operation

The expansion tank, in addition to the housing, includes a membrane (cylinder or diaphragm), the upper part of which is filled with inert gas or air. The lower compartment of the sealed container is intended for coolant.

Along with an increase in temperature, the water expands, and the excess mass of the coolant enters the membrane. The volume of the chamber with air decreases, and the pressure in this part of the closed system increases, compensating for the pressure in the line. When the coolant temperature decreases, the reverse process is observed.

The expansion tank can be equipped with a replaceable (flange) or permanent membrane. The second type of product is cheaper.

The membrane in the tank is pressed tightly against the inner wall, since its entire volume is filled with gas.

When water gets inside, the pressure increases. At the moment the heating starts, there is a risk of damage to the diaphragm from a pressure surge, and then the pressure gauge gradually changes the readings and the integrity of the part is out of danger.

To avoid damage to the membrane, it is necessary to install a pressure gauge safety valve that reacts to increased pressure (for private houses the norm is from 3.5 to 4 bar).

Advantages of the flange model

The advantages of flanged devices include the following characteristics:

- withstands greater pressure inside the system than a device with a constant diaphragm;

- it is possible to replace the membrane if it is damaged;

- horizontal and vertical installation of the device.

Calculation of the expansion tank using the formula

If you do not want to go into details, you can install a tank with a capacity of 10% of the total coolant volume. But sometimes it’s better to calculate everything exactly. By equipping a large heating system, you can save a lot.

To calculate the required volume of the expansion tank, you need to know the following:

- Minimum coolant temperature;

- Maximum coolant temperature;

- Heating system volume;

- The percentage of ethylene glycol or propylene glycol in the coolant.

Important! If you are going to heat a house or cottage where you do not live permanently, be careful when selecting the type of coolant. They have different freezing temperatures and expansion coefficients

To calculate the volume of the expansion tank you need to use the formula:

V = V1 x (Q – Q1)

In this formula:

- Q1 – expansion coefficient at minimum temperature (see tables below);

- Q – expansion coefficient at minimum temperature (see tables below);

- V1 – volume of coolant in the heating system in liters;

- V – volume of the expansion tank in liters.

If an expansion tank is already installed in the heat source, then it must be taken into account. To do this, subtract the built-in capacity from the obtained “V” value. The resulting number is the required volume of your expansion tank.

Important! If you have a heating system with forced circulation, the minimum total capacity of the expansion tank is 15 liters

Thermal expansion coefficient of ethylene glycol solution

| t, °С | 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% | 100% |

| 0.00013 | 0.0032 | 0.0064 | 0.0096 | 0.0128 | 0.016 | 0.0192 | 0.0224 | 0.0256 | 0.0288 | |

| 10 | 0.00027 | 0.0034 | 0.0066 | 0.0098 | 0.013 | 0.0162 | 0.0194 | 0.0226 | 0.0258 | 0.029 |

| 20 | 0.00177 | 0.0048 | 0.008 | 0.0112 | 0.0144 | 0.0176 | 0.0208 | 0.024 | 0.0272 | 0.0304 |

| 30 | 0.00435 | 0.0074 | 0.0106 | 0.0138 | 0.017 | 0.0202 | 0.0234 | 0.0266 | 0.0298 | 0.033 |

| 40 | 0.0078 | 0.0109 | 0.0141 | 0.0173 | 0.0205 | 0.0237 | 0.0269 | 0.0301 | 0.0333 | 0.0365 |

| 50 | 0.0121 | 0.0151 | 0.0183 | 0.0215 | 0.0247 | 0.0279 | 0.0311 | 0.0343 | 0.0375 | 0.0407 |

| 60 | 0.0171 | 0.0201 | 0.0232 | 0.0263 | 0.0294 | 0.0325 | 0.0356 | 0.0387 | 0.0418 | 0.0449 |

| 70 | 0.0227 | 0.0258 | 0.0288 | 0.0318 | 0.0348 | 0.0378 | 0.0408 | 0.0438 | 0.0468 | 0.0498 |

| 80 | 0.029 | 0.032 | 0.0349 | 0.0378 | 0.0407 | 0.0436 | 0.0465 | 0.0494 | 0.0533 | 0.0552 |

| 90 | 0.0359 | 0.0389 | 0.0417 | 0.0445 | 0.0473 | 0.0501 | 0.053 | 0.0557 | 0.0584 | 0.0613 |

| 100 | 0.0434 | 0.0465 | 0.0491 | 0.0517 | 0.0543 | 0.0569 | 0.0595 | 0.0621 | 0.0647 | 0.0673 |

Volume expansion coefficient of propylene glycol

| t, °С | 0% | 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% | 100% |

| 0.00013 | 0.00014 | 0.00015 | 0.00015 | 0.00017 | 0.000175 | 0.000185 | 0.00019 | 0.0002 | 0.00021 | 0.00023 | |

| 10 | 0.00027 | 0.00029 | 0.00031 | 0.00032 | 0.00035 | 0.00036 | 0.00038 | 0.0004 | 0.00042 | 0.00044 | 0.00047 |

| 20 | 0.00177 | 0.0019 | 0.00203 | 0.00208 | 0.0023 | 0.00239 | 0.00252 | 0.00262 | 0.00275 | 0.00288 | 0.0031 |

| 30 | 0.00435 | 0.00467 | 0.005 | 0.00511 | 0.00565 | 0.00587 | 0.0062 | 0.00644 | 0.00676 | 0.00707 | 0.00761 |

| 40 | 0.00782 | 0.0084 | 0.00899 | 0.00919 | 0.01017 | 0.01056 | 0.01114 | 0.01157 | 0.01216 | 0.0127 | 0.01368 |

| 50 | 0.0121 | 0.013 | 0.01391 | 0.01421 | 0.01573 | 0.01633 | 0.01724 | 0.0179 | 0.01881 | 0.01966 | 0.02117 |

| 60 | 0.0171 | 0.01838 | 0.01966 | 0.02009 | 0.02223 | 0.02308 | 0.02437 | 0.0253 | 0.02659 | 0.02779 | 0.02992 |

| 70 | 0.0227 | 0.0244 | 0.0261 | 0.02667 | 0.02951 | 0.03064 | 0.03235 | 0.0336 | 0.0353 | 0.03689 | 0.03972 |

| 80 | 0.029 | 0.03117 | 0.03335 | 0.03407 | 0.0377 | 0.03915 | 0.04132 | 0.04292 | 0.04509 | 0.04712 | 0.05075 |

| 90 | 0.0359 | 0.03859 | 0.04128 | 0.04218 | 0.04667 | 0.04846 | 0.05116 | 0.05313 | 0.05582 | 0.05834 | 0.06282 |

| 100 | 0.0434 | 0.04665 | 0.04991 | 0.05099 | 0.05642 | 0.05859 | 0.06184 | 0.06423 | 0.06749 | 0.07052 | 0.07595 |

In order to determine the amount of coolant in the heating system, you need to take into account the volume:

- Connected devices (radiators, underfloor heating, etc.);

- Pipes;

- Collector (comb);

- Heat source (for example, how much coolant is in the boiler or boiler coil).

The volume of pipes can be calculated using the formula:

V = L x 0.0785 x D x D

In this formula:

- L – heating pipe length;

- D – diameter in cm;

- V is the volume of coolant in the pipe in liters.

You can see the volume of coolant in the batteries in the specifications or instructions for them. If there are none, you can find out the amount of coolant in the publication “The volume of water in a heating radiator - aluminum, cast iron, bimetallic.”

Boiler - which one to choose

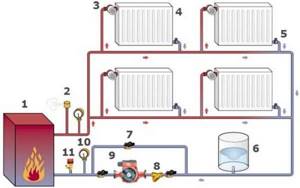

Since the closed heating system of a private house can operate autonomously, it makes sense to install a heating boiler with automation. In this case, having configured the parameters, you do not need to return to this. All modes are supported without human intervention.

The most convenient gas boilers in this regard. They have the ability to connect a room thermostat. The temperature set on it is maintained with an accuracy of one degree. It dropped by a degree, the boiler turned on, heating the house. As soon as the thermostat is activated (the temperature is reached), the operation stops. Comfortable, convenient, economical.

Some models have the ability to connect weather-dependent automation - these are external sensors. Based on their readings, the boiler adjusts the power of the burners. Gas boilers in closed heating systems are good equipment that can provide comfort. The only pity is that gas is not available everywhere.

Two-pipe closed heating system in a house on two floors (diagram)

Electric boilers can provide a no less degree of automation. In addition to traditional units, induction and electrode units have recently appeared on heating elements. They are distinguished by their compact size and low inertia. Many believe that they are more economical than boilers using heating elements. But even this type of heating unit cannot be used everywhere, since power outages in winter are a common occurrence in many regions of our country. And provide the boiler with electricity. 8-12 kW from the generator is a very difficult matter.

Solid or liquid fuel boilers are more versatile and independent in this regard. An important point: to install a liquid fuel boiler, a separate room is required - this is a requirement of the fire service. Solid fuel boilers can be installed in the house, but this is inconvenient, since a lot of debris falls from the fuel during combustion.

Modern solid fuel boilers, although they remain periodic equipment (they warm up during combustion and cool down when the fuel burns out), but they also have automation that allows you to maintain a given temperature in the system, regulating the intensity of combustion. Although the degree of automation is not as high as that of gas or electric boilers, it is there.

Example of a closed heating system with an induction boiler

Pellet boilers are not very common in our country. In fact, this is also solid fuel, but boilers of this type operate in continuous mode. Pellets are automatically fed into the firebox (until the stock in the burner is finished). If the fuel quality is good, ash cleaning is required once every few weeks, and all operating parameters are controlled automatically. The only thing holding back the spread of this equipment is its high price: the manufacturers are mainly European, and their prices are corresponding.

A little about calculating boiler power for closed-type heating systems. It is determined according to the general principle: per 10 sq. meters of area with normal insulation take 1 kW of boiler power. It’s just not recommended to take it “back to back”. First, there are unusually cold periods during which you may not have enough rated power. Secondly, working at the power limit leads to rapid wear of the equipment. Therefore, it is advisable to take the boiler power for the system with a margin of 30-50%.

Diaphragm expansion tanks for Wester heating systems

| View from above | Bottom view | |

| All volumes | ||

| ||

| Increase |

membrannye-rasshiritel'nye-baki-dlja-otoplenija-wester-wrv_, General rear view, enlarge

membrannye-rasshiritel'nye-baki-dlja-otoplenija-wester-wrv_, Top view, enlarge

membrannye-rasshiritel'nye-baki-dlja-otoplenija-wester-wrv_, Bottom view, enlarge

membrannye-rasshiritel'nye-baki-dlja-otoplenija-wester-wrv_, All volumes, enlarge

Manufacturer: Wester Heating Settlement: 8, 12, 24, 35, 50, 80, 100, 120, 150, 200, 300, 500, 750, 1000, 1500, 2000, 2500, 3000, 5000, 10,000 liter -object in the air cavity: 1.5 barMax. pressure: 5.0 bar Operating temperature: -10°C…+100°C— Designed to compensate for thermal expansion of the coolant in closed heating systems. — The main elements of the tank are a body made of high-quality steel, an elastic membrane made of rubber. — The pressure in the air cavity for tanks from 8 to 150 liters is 1.5 bar, from 200 to 10,000 liters — bar. — The coolant in the heating system is water with a glycol content of no more than 50%. — Expansion tanks are equipped with a replaceable membrane. — Operating temperature — from -10 °C to +100 °C — Service life — 100,000 cycles. — Body color is red.

| Specifications and prices >>> |

| Name | Cost with VAT, rub. | Available in warehouse |

| Membrane tank for heating Wester WRV8 | 991,00 | Buy membrane tank for heating Wester WRV8 |

| Membrane tank for heating Wester WRV12 | 1 073,00 | Buy membrane tank for heating Wester WRV12 |

| Membrane tank for heating Wester WRV18 | 1 173,00 | Buy membrane tank for heating Wester WRV18 |

| Membrane tank for heating Wester WRV24 | 1 343,00 | Buy membrane tank for heating Wester WRV24 |

| Membrane tank for heating Wester WRV35 | 2 199,00 | Buy membrane tank for heating Wester WRV35 |

| Membrane tank for heating Wester WRV50 | 2 624,00 | Buy membrane tank for heating Wester WRV50 |

| Membrane tank for heating Wester WRV80 | 3 832,00 | Buy membrane tank for heating Wester WRV80 |

| Membrane tank for heating Wester WRV100 | 5 508,00 | Buy membrane tank for heating Wester WRV100 |

| Membrane tank for heating Wester WRV150 | 8 325,00 | Buy membrane tank for heating Wester WRV150 |

| Membrane tank for heating Wester WRV200 (top) | 12 367,00 | Buy membrane tank for heating Wester WRV200 (top) |

| Membrane tank for heating Wester WRV300 (top) | 15 114,00 | Buy membrane tank for heating Wester WRV300 (top) |

| Diaphragm tank for heating Wester WRV500 (top) | 29 572,00 | Buy membrane tank for heating Wester WRV500 (top) |

| Membrane tank for heating Wester WRV750 | 67 580,00 | Buy membrane tank for heating Wester WRV750 |

| Membrane tank for heating Wester WRV1000 | 90 664,00 | Buy membrane tank for heating Wester WRV1000 |

Features of open and closed tanks

Let's first consider all the advantages and features of open-type expansion tanks. If we take into account the design, all the characteristics and other data of such tanks, we can conclude that the main advantages of such equipment are the following:

- Fairly standard forms

- Relatively simple design

- Lack of many controls

All of the above parameters provide open-type expansion tanks with an affordable price, as well as high reliability and durability. And that is why most buyers opt for such equipment.

Closed expansion tanks. How will they please the buyer during purchase and will they bring further ease of use?

Such tanks have a fairly high cost compared to the previous type. Such equipment has a more complex design and small dimensions. But thanks to all this, the following advantages belong to this type of expansion tank:

- These tanks never come into contact with air. This ensures the absence of fumes and corrosion processes in further use. Also, when using closed expansion tanks, there will be no need to periodically refuel the heating system;

- Also, such equipment can be installed anywhere in the heating system. Be it an attic or a room inside the house. Thanks to its placement near the heating system, users will not have to run a long pipe to the tank;

- Such tanks will ensure a long service life of your boiler and radiators;

Perhaps some users will prefer the lower cost of open-type expansion tanks, but taking into account all the advantages and advantages of closed-type tanks, you need to think about it and choose the appropriate option.

Recommendations from experts

The main advantage of membrane expansion joints lies precisely in the possibility of placing it in the place most convenient for installation and operation.

Small tanks with a volume of 20-25 liters are usually installed in systems with a circulation pump whose power is 1.2 kW. Increasing the capacity to 20-60 liters will lead to an increase in pump power to 2.0 kW.

There are compensating devices with a volume of 100-200 liters on sale. In addition to their direct purpose, they can play the role of a storage tank for warm water. True, they can be used in this way only if the main source of hot water is turned off for a short period of time.

The standard sizes of expansion tanks cover a fairly wide range. Among them there are models with dimensions so large that standard doorways do not allow them to be brought inside the room. In such a situation, it is better to replace one huge container with several small ones. The main thing is that their total volume is equal to the calculated one.

Expansion tank maintenance

To ensure a long service life of the expansion tank, it is necessary to ensure the correct maintenance conditions:

- The tank should be regularly inspected for external damage (cracks, dents, corrosion, leaks);

- every six months the pressure of the gas space is checked, for which the equipment is disconnected from the system and water is pumped out of it;

- the integrity of the membrane is checked twice a year (for membrane expansion tanks);

- If the heating system will not be used for a long time, it is necessary to drain the water from it and from the tank.

Types of expansion tanks and their features

Tanks for heating systems are open and closed

This is a fundamental difference to note

Open tanks are installed only at the highest point of the system, usually under the ceiling or in the attic of the house.

These tanks are most often rectangular in shape. They are made of steel. Another requirement for open tanks is their impressive dimensions, which is why many people don’t like them because they are conspicuous. The design of such containers is quite primitive. This is just a reservoir with a tube lowered into it to drain liquid from the circuit. To prevent water from overflowing over the edge of the tank during significant expansion, it is equipped with a drain mechanism into the sewer. In such a tank you can visually monitor the amount of coolant in the system and add it if necessary.

The fundamental difference between a closed tank is that it is completely sealed.

This circumstance eliminates the possibility of air leaking into the circuit. Essentially, it is a capsule with a membrane mechanism that separates the reservoir into air and liquid parts. When excess fluid enters, the valve reduces the pressure by releasing air. The whole structure is quite compact, looks neat and can be placed in any place convenient for you. Unlike an open tank, in this option you will not feel any foreign odors, nor will you encounter rust or overflow. Using sealed devices will protect your radiators and boiler from corrosion. But the cost of these tanks is much higher.

How to install the tank correctly

When installing an open tank in the attic, a number of rules must be followed:

- The container should stand directly above the boiler and be connected to it by a vertical riser of the supply line.

- The body of the product must be carefully insulated so as not to waste heat heating a cold attic.

- It is imperative to organize an emergency overflow so that in an emergency situation hot water does not flood the ceiling.

- To simplify level control and make-up, it is recommended to install 2 additional pipelines into the boiler room, as shown in the tank connection diagram:

Note. It is customary to direct the emergency overflow pipe to the sewer network. But some homeowners, in order to simplify the task, bring it through the roof straight to the street.

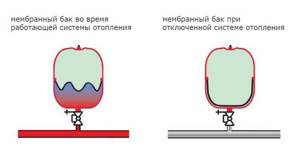

Installing a membrane-type expansion tank also has its own characteristics. Considering how this product works, it can be placed vertically or horizontally in any position. Small containers are usually attached to the wall with a clamp or suspended from a special bracket, large containers are simply placed on the floor. There is one point here: the performance of a membrane tank does not depend on its orientation in space, which cannot be said about its service life.

A closed-type vessel will last longer if it is mounted vertically with the air chamber upward. The fact is that sooner or later the membrane will exhaust its resource, causing cracks to appear in it. The internal structure of the tank is such that when positioned horizontally, air from its half will quickly penetrate through the cracks into the coolant, which will take its place. We will have to urgently install a new expansion tank for heating. The same result will quickly appear when the container is hanging upside down on the bracket.

In a normal vertical position, air from the upper part will not rush to penetrate through the cracks into the lower part, just as the coolant will reluctantly go up. As long as the size and number of cracks do not increase to a critical level, the heating will work properly. This process sometimes takes a long time, and you will not notice the problem right away. But no matter how you place the vessel, you should adhere to the following recommendations:

- The product must be located in the boiler room in such a way that it is convenient to service. Do not install floor-standing units close to a wall.

- When wall-mounting the expansion tank of the heating system, do not place it too high so that during maintenance you do not have to reach the shut-off valve or air valve.

- The load from the supply pipelines and shut-off valves should not fall on the tank pipe. Attach the pipes and taps separately, this will make it easier to replace the tank in the event of a breakdown.

- It is not allowed to lay the supply pipe along the floor through a passage or hang it at head height.

How to beautifully place equipment in a boiler room

Open type expansion tank for heating systems

Large heating structures use expensive closed tanks.

They are characterized by a sealed housing with an internal rubber partition (membrane), thanks to which the pressure is adjusted when the coolant expands.

For full operation of home systems, an open type expansion tank is a suitable alternative that does not require special knowledge or professional training for operation and further repair of equipment.

An open tank performs several functions for the smooth operation of the heating mechanism:

- “takes away” excess heated coolant and “returns” cooled liquid back to the system to regulate pressure;

- removes air, which, thanks to the inclination of the pipes by a couple of degrees, itself rises to the open expansion tank located at the top point of the heating system;

- The open design feature allows you to add the evaporated volume of liquid directly through the top cap of the tank.

Operating principle

The workflow is divided into four simple steps:

- the tank is two-thirds full in normal condition;

- an increase in the flow of liquid into the tank and an increase in the filling level when the coolant is heated;

- liquid leaving the tank when the temperature drops;

- stabilization of the coolant level in the tank to its original position.

Design

The shape of the expansion tank exists in three versions: cylindrical, round or rectangular. There is an inspection cover on the top of the housing.

Photo 1. Open type expansion tank design for heating systems. The components are indicated.

The case itself is made of sheet steel, but with a homemade version, other materials are also possible, for example, plastic or stainless steel.

Reference.

The tank is coated with an anti-corrosion layer to prevent premature destruction (primarily this applies to iron containers).

The open tank system includes several different pipes:

- to connect the expansion pipe through which water fills the tank;

- at the junction of the overflow, for pouring out excess;

- when connecting a circulation pipe through which the coolant enters the heating system;

- for connecting a control pipe designed to eliminate air and adjust the fullness of pipes;

- spare, necessary during repairs to discharge coolant (water).

Volume

The correctly calculated volume of the tank affects the duration of operation of the joint system and the uninterrupted functioning of individual elements.

A small tank will lead to breakdown of the safety valve due to frequent operation, and a tank that is too large will require additional finances when purchasing and heating an excess volume of water.

The availability of free space will also be an influential factor.

Appearance

An open tank is a metal tank, the upper part of which is simply closed with a lid, with an additional hole for adding water. The tank body can be round or rectangular. The latter option is more practical and reliable during installation and fastening, but the round one has the advantage of sealed seamless walls.

Important! A rectangular tank requires additional reinforcement of the walls with an impressive volume of water (homemade version). This makes the entire expansion mechanism heavier, which needs to be lifted to the highest point of the heating system, for example, to the attic.

Advantages:

- Standard form. In most cases, it is a rectangle that can be installed and connected to the general mechanism yourself.

- A simple design without an excessive number of control elements, which makes it easy to control the smooth operation of the tank.

- The minimum number of connecting elements, which gives the body strength and reliability during operation.

- Average market price, thanks to the above facts.

Flaws:

- Unattractive appearance, without the ability to hide thick-walled bulky pipes behind decorative panels.

- Low efficiency.

- Using water as a coolant. With other antifreezes, evaporation occurs faster.

- The reservoir is not sealed.

- The need to constantly add water (once a week or once a month) due to evaporation, which, in turn, affects airing and the normal functioning of the heating system.

- The presence of air bubbles leads to internal corrosion of system elements and a decrease in service life and heat transfer, and the appearance of noise.

Varieties

Depending on the design, they are divided into open and closed.

Open

These are cylindrical or rectangular tanks that are mounted at the highest point of the heating system (often in the attic) . The container is connected to the water supply to replenish the water supply and to the sewer system to remove excess coolant.

Photo 1. Open type expansion tank. The unit is rectangular in shape, installed at the top point of the heating system.

The disadvantage of this type of equipment is that there is no automatic adjustment of the water level. You will have to control the amount of liquid in it visually, and to add water, open the valve in front of the inlet pipe. Another inconvenience is the difficult installation, because the tank has considerable weight, and it will have to be lifted into the attic. Due to the described nuances, this type of equipment was almost replaced by closed tanks.

Open type containers

These tanks are used for an open heating system (otherwise known as gravity, gravity) and are a metal tank with an open top of any shape. A pipe for connecting a hose or overflow pipe is welded to the upper part of the side wall; the coolant is supplied to the tank from below. The element is installed above the entire system on the supply pipeline, usually in the attic of the house.

We recommend: Thermocouple for a gas boiler: detailed instructions on the design and principle of operation, checking the serviceability of the thermoelectric sensor with a multimeter, restoration and replacement

Note. In correct technical language, an open system is one from which water is directly taken for the needs of hot water supply. It is not used in private homes, only in centralized networks. A scheme with natural coolant circulation is mistakenly called open.

Any expansion tank for open type heating performs 2 functions:

- serves to compensate for the expansion of the coolant;

- removes air from the system, since its top communicates with the atmosphere.

This is its advantage, but it is not the only one. An open container can also successfully and durablely serve in systems with forced circulation, since the design of the tank is very simple, there is nothing to break. However, it also has many disadvantages:

- a tank installed in the attic requires good insulation;

- During the season, it is necessary to constantly monitor the water level in the tank and replenish it in a timely manner;

- the coolant is constantly saturated with oxygen from the atmosphere, which is why the metal parts of the boiler corrode faster;

- additional consumption of materials and difficulties during installation.

Closed

design with two chambers inside: one for air and the other for water coming from the heating system. They are separated from each other by a membrane, which is a rubber bag-like reservoir that can expand and contract.

When water enters the first chamber, the membrane stretches and air from the second chamber exits through a special valve. When the liquid cools, the membrane begins to return to its original position and squeezes water back into the heating system.

Photo 2. A fairly simple device for a closed expansion tank. The arrows indicate the components.

Depending on the type of membrane, there are two types of closed expansion tanks:

- Equipped with a non-removable diaphragm membrane

The design is highly durable due to its production by cold stamping. In addition, tanks of this type have anti-corrosion surface protection on the outside and inside. The cavity of the tank is divided into two chambers by an elastic membrane. The coolant flows from the system into the lower chamber. When the membrane takes the desired position, on the surface of the liquid, the device is ready for use.

- With flange mounting

The membrane is connected to the inlet pipe using flange fasteners, which allows you to replace a worn membrane with a new one . The coolant is located inside the membrane and does not come into contact with the walls of the tank, which makes it possible not to resort to anti-corrosion measures.

Closed expansion tanks are often installed next to heating boilers. The second option is installation near the boiler , if you plan to install a double-circuit heating system that provides hot water supply.