Gas heating equipment is deservedly famous for its high performance characteristics, reliability, fairly high power with a relatively low consumption of “blue fuel”. But in order for the heating installation to work effectively and not create danger for the owner and others, it is necessary to strictly follow the rules of its use and carry out maintenance of gas boilers. Why, how and by whom these procedures are carried out will be discussed in this publication.

[contents]

Why does a heat generator need maintenance?

When purchasing a boiler for operation in closed heating systems, we all most often think exclusively about its rational use and the advantages of the chosen model.

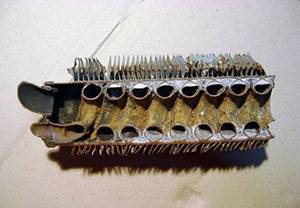

Most homeowners continue to use this equipment for ten years, until suddenly, in the middle of the heating season, the boiler unit became unable to properly heat the room. And the reason for this may be ordinary corrosion of the heat exchanger: for many years without maintenance, scale has formed in the heat exchanger coil, which has led to a gradual decrease in efficiency. The boiler power at normal settings became insufficient, which resulted in an increase in the coolant temperature and, as a consequence, gas consumption. A simple procedure for flushing the heat exchanger of a gas boiler during maintenance solves this problem even at the stage of scale formation. And this is not the worst scenario of what can happen to a boiler without maintenance.

Let us remember that a gas boiler is a set of equipment that uses gas and electricity to operate. In the event of a malfunction of the electrical system or gas pipeline, not only the property and inhabitants of the apartment in which the equipment is installed are in danger, but also the residents of the entire apartment building. Regular inspection and maintenance will allow a specialist to identify only emerging problems at an early stage, without bringing them to the point where the operation of the equipment poses a threat to life and health.

The quality of operation of the heat generator determines gas consumption, as well as the comfort and safety of your household.

Cleaning the gas burner chamber and heat exchanger

gas boiler burner

After removing the cover, clean the outer fins of the heat exchanger from combustion products with a coarse brush. A well-cleaned heat exchanger ensures uniform heating of water or other coolant and prevents local overheating.

Using a soft copper brush, you need to remove any remaining soot from the ignition electrodes and ionization sensor, which are located in the chamber, and wipe them with isopropyl alcohol. Finally, you need to check the gap from the electrode to the burner, which should be about 4 mm.

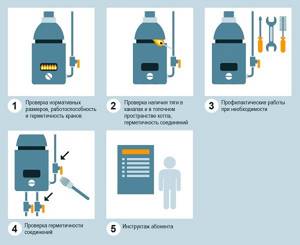

What is included in the list of services

The list of work carried out by the service depends on the type of boiler room and is regulated by the boiler manufacturer’s instructions.

The list includes:

- equipment inspection;

- installation of the input panel;

- checking the expansion tank;

- identifying the operability of safety devices;

- control of power supply, exhaust and supply ventilation, as well as the chimney;

- replacing filter cartridges and injectors;

- cleaning of mud filtration elements;

- study of the functioning of servos, valves and circulation pumps.

The technician checks the external and internal state of the device, the automation settings and the burner operation algorithm.

Goals of servicing gas boiler houses by a service company

Everyone wants their gas boiler to last for many years. But its performance depends on many factors. Poor performance provokes rapid wear of parts or their breakdown.

The problem can be prevented by regular checks, which are possible under warranty and post-warranty service.

After the end of the warranty period, six months must pass before the first inspection. The regularity of such inspections and repairs is specified in the contract between the client and the organization’s representative. If problems arise between checks, you should contact the organization, which will carry out repairs upon request.

Read about what you should pay attention to when choosing reliable gas boilers here:.

Service goals:

- Control of automation parts;

- Determining the correct functioning of the burner;

- Checking the functionality of all parts.

Each goal affects the maintenance of high-quality operation of the device. In addition, special attention should be paid to gas supply and exhaust pipes. The condition of the ventilation and chimney should be assessed. Certain tests will also need to be performed to adjust the burners. The tightness of the joints is checked using a gas trap and a soap solution. Any problems should be corrected here. When an element cannot be repaired, it is replaced.

Process Execution

In order not to harm the device, you need to know about the repair of its various parts. Routine maintenance includes several stages, which include inspection, cleaning and adjustment. Before starting work, it is necessary to turn off the system and the source of gas supply. Then wait for the disconnected system to cool down.

Maintenance Efficiency

Regular and timely maintenance of the boiler room and gas equipment brings undeniable benefits: • Increases operational safety. Eliminating potential breakdowns in advance reduces the risk of emergency situations. • Extends equipment life. Timely repair or replacement of critical parts prevents damage to associated elements and assemblies. • Increases system efficiency. The heat transfer of fuel increases and its consumption decreases.

Equipment used Professional maintenance is impossible without the use of special instrumentation. To measure concentration levels of hazardous gases, stationary or portable gas analyzers are used. Differential pressure gauges are used to check pressure reducing valves and safety automatics of heating circuits. Enterprises that have state licenses and certificates for the relevant types of work can competently perform work on technical support of boilers and boiler equipment.

Elimination of emergency situations, repair of boiler rooms

Our company has its own warehouse with all the necessary equipment for prompt elimination of emergency situations and repair of the boiler room. From the moment a signal is received about the failure of a system until the arrival of our employees, it takes from 1 to 3 hours, even if the facility is located not in Moscow, but in the Moscow region. There are situations when the issue can be resolved without going to the site, by telephone, because in the operation of gas-using equipment (especially during the heating season), every minute is important.

Discontent aside, is the maintenance justified?

If the customer and the contractor treat the need for service not as a mere formality, then it definitely makes sense.

First of all, this is a diagnosis of possible problems. Before the heating season, you can assess the condition of the boiler and other components so that in an unexpected moment you do not find yourself without heat.

Over time, the performance of the heating system may deteriorate:

- The boiler turns on and off frequently.

- Everything works, but the batteries are cold.

- The pressure in the system jumps.

- The hood doesn't work.

During maintenance, the operation of all boiler components is checked and scheduled work is carried out:

- Testing the wiring.

- Clean the internal parts and filter.

- Set up the burner.

- Check the pump.

Regular maintenance helps to be on the safe side and identify possible problems in advance.

If something happens to the boiler, then quickly replacing it during the heating season will be problematic.

If problems arise in winter, you will have to urgently seek specialists. Winter is a “hot” season for companies; queues for orders are long and prices are high. The heating operation will stop until the boiler is repaired or replaced. If you have carried out maintenance, you have peace of mind for the entire heating season.

The question is rather what is more comfortable for you: play it safe and feel calm or hope that the boiler will work as long as possible without intervention, and the gas services will not remember about you.

What problems do owners of gas boiler houses usually face?

If an enterprise or household has a gas boiler room, then by law it is necessary:

- Registration of the boiler house in Rostechnadzor as a hazardous production facility with the inclusion of the facility in the Rostekhnadzor register.

- Selecting an insurance company and concluding an accident insurance agreement with it.

- Development of an action plan and conclusion of an agreement for: – emergency response with the Ministry of Emergency Situations; – localization of emergency situations with AVR GRO.

- . Creation of our own gas and dispatch services.

- Employee training.

- Maintaining operational documentation.

What does the law say?

Today, all owners who have entered into a gas supply agreement are required to carry out annual maintenance of gas equipment. The consumer must provide the gas service with documents confirming the conclusion of a maintenance agreement with the relevant company.

It is noteworthy that in Europe there is no practice of boiler maintenance - this is an exclusively Russian norm.

On May 14, 2013, the Decree of the Government of the Russian Federation was adopted

№ 410.

Who can carry out maintenance?

Both legal entities and individual entrepreneurs can provide services. The list of approved organizations is published in the register of the State Housing Inspectorate for your region. Specialists from authorized companies and firms undergo training at special plants, in our case, “UKK Mosoblgaz”.

What happens if you don't carry out maintenance?

Everything that is in the apartment (house) is the responsibility of the consumer. That is, it is the consumer who is obliged to find an organization to carry out maintenance, conclude an agreement with it and send the necessary documents to Mosoblgaz or Mosgaz.

If the regulatory authorities do not receive the necessary papers, then you may face a fine, and in the future, the gas supply will be turned off. They will cut the pipe and put a plug on it.

How do you solve the whole range of problems associated with operating your own boiler room?

The best way to solve all the problems associated with the operation of a boiler room is to entrust this matter to a specialized organization. An example of such an organization is -. After concluding an operating agreement, all responsibility for what is happening in your boiler room passes to us.

- We will register your boiler house with Rostechnadzor, conclude an insurance agreement, and an agreement with the Ministry of Emergency Situations.

- Our specialists will completely take care of all the setup and maintenance of the boiler room.

- You will be sure that all necessary logs and documents are carefully and correctly maintained at the facility.

- We will take on all the work with inspection and control organizations.

How do you solve the whole range of problems associated with operating your own boiler room?

The best way to solve all the problems associated with the operation of a boiler room is to entrust this matter to a specialized organization. An example of such an organization is -. After concluding an operating agreement, all responsibility for what is happening in your boiler room passes to us.

- We will register your boiler house with Rostechnadzor, conclude an insurance agreement, and an agreement with the Ministry of Emergency Situations.

- Our specialists will completely take care of all the setup and maintenance of the boiler room.

- You will be sure that all necessary logs and documents are carefully and correctly maintained at the facility.

- We will take on all the work with inspection and control organizations.

How to save on maintenance?

It's best to wait until the special offer period. From April to June, service companies are at their lowest workload, so prices may be lower at this time.

Once again the most important thing:

- By law, you are required to enter into an agreement for the maintenance of in-house gas equipment and provide it to the supplying organization. Otherwise, your gas supply may be cut off.

- You choose the organization for concluding a service contract yourself.

- Boiler manufacturers have nothing against maintenance, and in some cases they increase the warranty period.

- Regular gas boiler maintenance has enough benefits to justify the expense.

- Carry out maintenance immediately after the end of the heating period - this way you will solve the problem in advance and can save money.

Proper operation and care of gas boiler rooms

The operation of gas boiler houses, subject to compliance with the rules, instructions and requirements, will extend the service life of the equipment. Careless handling of this type of equipment can cause not only problems related to the performance of the equipment, but is dangerous for others. Therefore, the operation of stationary gas boiler houses should be based on knowledge of the design and the principle of operation of the mechanism.

Safety requirements

Actions such as installation and installation, as well as putting a gas boiler room into operation, are carried out in accordance with building codes, as well as the Rules for the design and operation of steam and hot water boilers. Persons over 18 years of age who are specially trained and have a certificate of admission and maintenance of hot water boilers are allowed to operate the equipment. Moreover, the employee’s knowledge level should be checked regularly.

To monitor the operation of the equipment, in addition to the accompanying technical documentation (passport), a log must be kept, where the time of reception and delivery of shifts by personnel is noted, emergency situations are recorded with a description of the causes and ways to eliminate them. In addition to this, a water treatment log is kept, where the characteristics of steam and water are recorded. There should also be an operational log based on the results of the inspection of the equipment, as well as a book of orders, where instructions on the need to perform various types of work are recorded.

To ensure the safety of the boiler room, there must be open access to pipeline layout diagrams and operating instructions for such equipment. As a rule, it is recommended to post this information directly at the operator’s workplace.

Regularity of work

Preventative work should be carried out before the heating season to check the performance of the boiler and its components. If necessary, clean and adjust the unit to optimal mode.

Often the instructions indicate the rules for preserving the device for the summer and the step-by-step process of returning the unit to working condition.

Thanks to proper conservation, the owner will protect the unit from corrosion and extend the service life of the device components.

Maintenance and repair of gas boilers

Find out the common reasons why a gas boiler is noisy

Why does a gas boiler smoke - reasons and solutions

Scope of boiler room maintenance work:

Routine boiler room maintenance work includes checking and adjusting all heating and hot water supply circuits and systems.

While a well-trained building employee can monitor the daily water consumption of systems by checking the water meter, chemical water treatment for boilers that require them should only be carried out by a company specializing in this line of work and on a schedule specified by the boiler manufacturer or other qualified specialist. If a boiler is having problems, the nature of those problems may be related to how the boiler was installed and how it has been maintained since then.

But if installed incorrectly, a new boiler may begin to leak two or three years after installation. Unlike steel boilers, cast iron boilers usually do not require chemical water treatment; in fact, water can actually damage the gaskets on some models of these boilers. And when it comes to caring for leaky boiler pipes, Stewart eschews a step-by-step approach. “We recommend that if you notice a few pipe leaks, you replace them,” he says.

- Comprehensive inspection of boiler operation and maintenance of boiler equipment:

Cleaning and adjusting the operation of burners to ensure maximum heat transfer and efficient fuel consumption; – checking the quality of gas combustion, the composition of combustion products, adjusting the fuel and air supply; – diagnostics and cleaning (if necessary) of heating heat exchangers and hot water supply systems.

Other potential problems have arisen with New York's Clean Heat Initiative and its efforts to reduce heat-related pollution. Mandatory transitions of buildings to cleaner burning fuels, including No. 2 oil, No. 4 oil and natural gas, have helped make natural gas a more attractive option for running some buildings. Not only does natural gas satisfy the need for cleaner heating, but it is also now cheaper and more efficient to heat a building with gas.

Device, types and principle of operation

When choosing a heating system for their home, many owners prefer to install a gas boiler, which makes almost no noise and can heat a large area of the house. Its components are:

- burner;

- heat exchanger;

- thermostat;

- control device;

- one or two circulation pumps;

- expansion tank;

- pressure gauge;

- thermometer.

Read more: types and operating principles of a gas boiler.

Operating principle of gas boilers:

The thermostat is designed to measure the temperature in a room. As soon as the need arises, the heating mode is switched on using the valve, after which the circular pump begins to operate, under the influence of which water flows through the heating circuit. Then the valve opens and the burner lights.

In the heat exchanger, energy is generated from the combustion of gas, which begins to heat the water. As soon as the air temperature in the room becomes optimal, the pump automatically turns off. After some time, the process repeats.

Depending on the current capabilities, two types of boilers can be distinguished: double- and single-circuit. The latter are used only for heating, so their design is much simpler than that of double-circuit ones: there are no heating elements for the production of hot water.

A double-circuit gas boiler is used to heat the home and supply hot water. This is an ideal option if there is no space to install a boiler. Its device provides two circuits. The first is a closed system with heated water passing through it, which heats the room. When the tap in the kitchen or bathroom is opened, the supply of hot water to the heating circuit is stopped, after which it enters the water supply system.

Comparison of wall-mounted and floor-standing gas boilers: Boilers in this category are divided into condensing and convection. In condensing units, the steam produced from gas combustion is released into the street through ventilation. In the second option, the heated steam also passes through a heat exchanger, additionally heating the water. Convection boilers last a long time and do not corrode, since there is no condensation inside the body. But condensing ones are distinguished by high efficiency, which is achieved by using energy not only from gas combustion, but also from the liquid released during combustion.

Maintenance of gas boilers:

This is interesting: How to sheathe the outside of a wooden house: a review of the best materials and technologies for exterior finishing

Why is it necessary to maintain boiler rooms and all heating equipment?

During operation, boiler equipment, under the influence of various factors, gradually reduces its productivity, parameters and quality of work. Regular maintenance of boiler rooms ensures the good condition of the main and auxiliary equipment and is the main condition for the safe operation of the boiler room.

Professional maintenance of boiler rooms stabilizes and optimizes the operation of the boiler system. Carrying out scheduled inspections allows you to obtain the most complete information about the technical condition of the equipment and check whether the devices are being operated correctly and which elements require repair or replacement. By entrusting the maintenance of boiler rooms to specialized organizations, you receive timely implementation of preventive, repair and adjustment work in compliance with the requirements of the equipment manufacturer and Federal Norms and Regulations. After boiler room maintenance, your equipment will be ready for efficient and uninterrupted operation throughout the heating season.

Choosing a boiler servicing organization: main rules

Not all boiler manufacturers have service centers. Special organizations receive a license for this, having the necessary equipment and specialists. Such a company receives a certificate to perform a certain type of work.

Service center technicians must undergo training at the boiler manufacturer's plant. This way they receive the necessary knowledge for work.

To find out the qualifications of specialists, you should read all the company’s documentation. However, there are a number of recommendations that should be followed when choosing an organization. These rules will protect you from scammers.

Recommendations for choosing a service organization:

- The location of the company should be as close as possible. Ideally, this is the same city or at least region. This will reduce the time it takes for specialists to arrive.

- The organization must provide a certificate from the manufacturer.

- It is required to draw up an agreement with a detailed description of all services and responsibilities of the parties.

You can find out about service centers on the website of the gas boiler manufacturer. There should be a list of all organizations. This allows you to obtain a certain guarantee about the certification of organizations.

What work is included in boiler room maintenance?

Maintenance and adjustment of boiler room equipment is carried out to increase the service life of the units, extend the operating time of heating devices and hot water supply. Boiler room repairs and maintenance are carried out by employees of organizations responsible for the safety of operating personnel during the heating season.

Boiler room maintenance consists of the following stages:

- planned care;

- maintenance once a month;

- emergency service.

Scheduled maintenance includes the following types of maintenance: service of boilers and gas equipment, filters included with the boiler. The technician sets up the gas burners and examines the condition of the internal gas pipeline.

Maintenance of boiler equipment includes studying the technical condition of pressure gauges, temperature metering devices (emergency and working regulators). The equipment that monitors the management of boiler room loads is checked.

Scheduled service includes maintenance of hydraulic equipment.

The master needs to check:

- water filters;

- membrane tank>;

- taps;

- valves;

- chemical reagents.

The tests necessary to check the operating condition of the boiler room equipment are carried out; if necessary, minor repairs are carried out that do not require a complete reconstruction of the equipment. The technician inspects the gas pipeline, water tanks, fuel ignition systems, pumps, sensors, thermometers and pressure gauges.

If deviations from standard parameters are found during the inspection, they are corrected. The results are recorded in a special journal, describing the operation process, and maintenance is carried out no later than 24 hours from the moment the equipment is turned off.

The boiler room has technological documentation, which indicates the procedure for servicing boilers and burners. It records the results of operational activities and data on the condition of instruments and sensors.

Service options

Boiler room service is subject to the following rules:

- draw up an action plan to monitor the performance of equipment;

- Maintenance of equipment is carried out during the operation of the boiler room;

- perform technical inspections, eliminate defects, check technical standards;

- check or replace faulty mechanisms;

- adjust oil seals, take care of equipment that is in a mothballed state.

Maintenance of boiler room safety automation is carried out in accordance with regulatory documents.

. The following activities are included in the inspection plan:

- performing automation diagnostics;

- adjustment of instrumentation and automation;

- studying and adjusting sensors;

- checking housings and covers, insulation;

- fan motor inspection;

- repair of safety devices.

Maintenance of gas boiler houses includes inspection of equipment for the purpose of proper operation of boiler room equipment.

Pump groups and heat exchangers

During the inspection of a gas boiler, technical errors in the operation of boilers are identified. The automatic equipment is checked and the heating elements are examined.

The foreman checks taps and main pipelines. He repairs smoke lines and studies the tightness of connections.

During diagnostics, the burners are adjusted using a soap composition. The examination is carried out by a qualified master or representative of an organization who has permission to carry out this activity.

Technical service includes:

- inspection of the unit;

- cleaning mechanisms: electrodes, sensors;

- filter replacement;

- gas burner testing;

- boiler adjustment;

- security system control.

Maintenance of boiler room safety automation includes:

- cleaning of technical structures;

- lubrication of bolts and their connections.

A minor update is necessary to improve the performance of the mechanisms or their components. Maintenance of instrumentation and automation of a gas-fired boiler room includes the following types of control:

- adjustment of measuring equipment (once every 30 days);

- inspection of instrumentation and instrumentation;

- testing devices once a month;

- setting up an emergency backup power system (ESP);

- inspection of electric motors, load check once every 3 months.

Periodicity

Rules for repairing the unit are necessary to completely restore the equipment, improve test results, and extend the service life of the equipment.

A qualified master must:

- create a hardware upgrade plan;

- use modern technology;

- provide testing work with the necessary equipment and spare parts.

Operation of the boiler unit is impossible without the following types of maintenance:

- current;

- capital;

- restorative.

Regular inspection of measuring sensors is carried out every 4 months, but at least once a year . Small defects are eliminated without stopping the unit.

If checking instruments on a running unit is not permitted, stop its operation for a routine inspection. The recovery stage of studying thermal boilers is carried out to eliminate malfunctions associated with an explosion or fire. Major correction of defects is carried out in order to establish device performance at the level of calculated values.

During the year, the steam boiler drums are adjusted, the collectors are adjusted, and the amount of wear on the lining, frame, and components is determined.

A major inspection is carried out once every 2 years . Current repairs of individual thermal stations are carried out every month. The goal of the work is to prevent wear and tear on equipment at points and eliminate disruptions in the operation of automatic systems.

The efficiency of the heat station depends on the labor intensity and cost of the inspection performed. A qualified technician repairs equipment, heat pipes, eliminates insulation defects, adjusts electrical devices, and checks the automation system.

Repair of heating equipment from the Viessmann system manufacturer is carried out by specialists with extensive experience. They carry out installation and service maintenance of gas heating units.

Wissmann boilers are tested in the event of ignition failure, leakage, low temperature in the room after turning on the unit, the appearance of scale, or breakdown of the automatic unit. Repairs and professional diagnostics of the unit are performed once a year.

Sequence of maintenance of gas boilers

Routine maintenance consists of cleaning, inspection and adjustment. Before work, turn off the gas supply. After which the system is given time to cool down. Next, the condition of the system is assessed by the appearance of the parts. The documentation and warranty seal are checked. Then attention is paid to all elements of the system. Next, they begin cleaning, having first cleaned the boiler.

Elements that need to be removed and cleaned:

- Support washer. Determines the location of the burner relative to the heat exchanger.

- Air sensor. Mixes air and gas.

- Flame detector. Lets you know when cravings are getting worse.

- Ignition electrodes. The mixture of oxygen and gas is ignited.

Any metal deteriorates when exposed to burning and soot. During normal burner operation, the flame is blue. A yellow tint indicates the need to clean the equipment.

The burner is cleaned using a special brush. In this case, the event should be carried out regularly.

Checking the automation is considered the most important part of the work, since life depends on the performance of the automation. The safety system includes a thermostat, gas valves and fittings, a controller, and a pressure switch. The main thing is to identify problems in time.

Maintenance of central heating boilers and auxiliary boiler room systems:

- External inspection of boilers and burners;

- Checking gas input parameters;

- Checking the tightness of gas communications from the gas distribution point to the boiler;

- Checking the operation of the gas shut-off valve and the automated gas control and alarm system type VARTA-1-03

- Checking the operation of safety valves;

- Checking that there is no water leakage from the boiler;

- Checking the operation of boiler safety automatics;

- Checking the gas combustion process;

- Checking the operation of boiler automation, reviewing the condition of cables, terminal blocks, automatic devices, sensors, limit switches and actuators;

When is maintenance carried out and how long does it last?

By law, gas boiler maintenance is carried out at least once a year. The contract with the contractor specifies a list of services, and after maintenance, a certificate is issued. The procedure lasts from 2 to 4 hours - everything is done within one working day. The work can be carried out at any time of the year, but it is better to do it in advance, before the start of the heating season.

During maintenance, the boiler is disassembled. If it is in operation, then it is advisable to turn it off a few hours before the technician arrives - so that the system has time to cool down.

inspection of heating circuits

At this stage, a general idea of the current state of the operating system is formed.

First of all, the technician checks the documents and the warranty seal, determining whether the installation of the gas appliance meets the requirements of two main regulatory documents:

- SNiP - sanitary building codes and regulations.

- “Rules of technical operation and safety requirements in the gas industry of the Russian Federation.”

Since a gas boiler is a set of equipment that uses both gas and electricity, electrical elements are also subject to visual testing.

For an external inspection of a gas boiler, the protective casing is removed from the unit and all visible elements are sequentially inspected, identifying the degree of wear of parts

Checking the condition of the boiler unit is intended to clarify the following points:

- integrity of the device structure;

- gas valve pressure;

- ignition electrodes, if available;

- condition of gas supply connections;

- electronics performance;

- serviceability of emergency machines.

At this stage, the expansion tank is monitored and pumped, which is designed to protect the system elements and compensate for the pressure that is created during the expansion of the coolant.

During the technical inspection, the condition of the unit itself, protection devices and gas communications is visually and using instruments.

The pressure level in cold water, depending on the type of boiler, is 1.1-1.3 bar. It is important to ensure that after heating the pressure does not exceed the recommended standard specified in the passport for the unit.

checking control automation

Modern boilers are equipped with automatic control systems, the main purpose of which is to ensure the operation of the unit without constant human supervision. The degree of complexity of automation can be very different.

But regardless of the model, its main elements are:

- Thermostat is a regulating device responsible for maintaining the set temperature parameters of the coolant in the boiler.

- Gas valves are designed to open and shut off the gas supply.

- Gas fittings are an actuator designed to execute commands from the boiler control circuit.

- The controller is an electronic device designed to implement a complex algorithm for controlling the unit depending on changing environmental conditions.

- Minimum and maximum pressure switches are membranes that act on groups of contacts, turning off the unit if the pressure drops/increases below/above the setting value.

This technique “painfully” endures a regular drop in tension. The technician’s task is to promptly detect problems in the electronic system, possible problems with parts, and correctly adjust the automation.

The boiler connected to the gas boiler, which is designed to supply the DHW system, must also be checked annually and regularly adjusted.

To check the functionality of the boiler safety system and identify vulnerable areas of the equipment, the technician simulates the occurrence of an emergency situation. After starting the system, he monitors the speed of operation of the alarms, the tightness of the shut-off valve and other devices.

If the automation does not work correctly, the unit is disassembled and the failed membranes are replaced with new ones.

The inlet part of the gas pipe is also subject to inspection. It is examined for corrosion and other damage.

The master must ensure the integrity of the gas supply pipeline throughout the entire section laid in the house, paying special attention to the outer surface of the pipes and their connections

All connections of the gas path, including flanged, threaded and prefabricated, are tested for leaks. Measure the pressure in the gas pipeline. If necessary, adjust the gas fittings. Places where paint has peeled off from the surface of the pipe are repainted.

Having adjusted all components of the boiler unit, the technician sets the parameters recommended by the manufacturer.

At the final stage, it carries out a final inspection of the boiler. The master fills out certification documents, confirming with his signature personal responsibility for the quality of the inspection performed. Finally, he makes a note indicating the period for the next service.

cleaning system elements

Before starting work, empty the boiler. After this, they begin to inspect the gas burner, determine the quality and direction of the flame.

To do this, remove and clean sequentially:

- retaining washer - a device that regulates the position of the burner torch relative to the installed heat exchanger;

- air sensor - it is designed to regulate the ratio of the mixture of air and gas;

- flame detector sensor - it generates a signal when traction indicators deteriorate;

- ignition device electrode – responsible for igniting gas-air mixtures;

All metal structures can become deformed over time under the influence of high temperatures and carbon deposits.

To prevent scale from clogging the burner, which is a key working element of the boiler, it must be cleaned in a timely manner using special brushes.

During normal operation of the burner, the flame has the shape of a cone, colored blue. A yellowish color indicates contamination.

Measuring and analyzing the boiler exhaust gases will help check the operation of the key operating element of the boiler and assess the compliance of the burner settings with the composition of the supplied gas, as well as the completeness of its combustion.

The fire area on the fuel combustion chamber and all parts of the boiler that are in direct contact with the torch must be cleaned. This task can be easily accomplished using a soft brush and a vacuum cleaner.

When cleaning injectors, do not use a metal brush, the bristles of which can damage the surface.

Separately, unscrew and blow air through the gas channels of the boiler. The gas supply pipe to the burner is removed, disassembled and purged under pressure.

The heating system is equipped with two filter elements. The first is located in the hydraulic unit, and the second is located on the cold water tap. These filters also require periodic cleaning of salt deposits by washing.

As maintenance is carried out, all faults discovered by the technician must be eliminated, replacing failed parts and assemblies with new elements.

Sources

- https://ventilationpro.ru/sistemy-otopleniya/gazovoe-otoplenie/tekhnicheskoe-obsluzhivanie-gazovykh-kotlov-chto-ob-ehtom-nuzhno-znat.html

- https://kotle.ru/sovety/obsluzhivanie-nastennyh-kotlov

- https://www.kip-energ.ru/tehnicheskoe-obsluzhivanie

- https://www.bertex.ru/ekspluatacija-gazovoj-kotelnoj/

- https://progazosnabgenie.ru/gazifikatsiya-chastnyh-domov/ekspluatatsiya-gazovoj-kotelnoj.html

- https://heatinng.ru/how-to-service-a-gas-boiler-maintenance-of-gas-boiler-house/

- https://rsenergo.com/obsluzhivanie-kotelnyh/

- https://kotle.ru/kotelnye/obsluzhivanie-kotelnyh

- https://homeli.ru/stroitelstvo-doma/inzhenernye-sistemy/otoplenie/obsluzhivanie-gazovykh-kotlov

- https://enbsv.ru/journal/article/to-gazovogo-kotla-deistvitelno-nuzhno

- https://sovet-ingenera.com/otoplenie/kotly/texnicheskoe-obsluzhivanie-gazovyx-kotlov.html

Causes and types of malfunctions

As heating equipment becomes more complex, the list of possible defects is constantly expanding.

But we can highlight a number of malfunctions that are typical for all models, including not the newest ones, and which users have to deal with most often.

Heat exchanger damage

A serious problem that can be caused by a number of reasons.

Cast iron heat exchanger

In the case of a cast iron heat exchanger, cracks appear in the wall due to a sharp temperature change. This usually happens when, as a result of a power outage, the circulation pump stops for some time. During its downtime, the coolant in the circuit manages to cool down greatly, and in the boiler heat exchanger, on the contrary, it becomes very hot.

When the power supply is restored, the pump begins to pump cold media into the overheated heat exchanger, causing the wall of the latter to burst.

Cast iron heat exchanger for boiler

To prevent such accidents, a mixing unit is made in the boiler piping, which is a bypass between the “supply” and “return” with a valve installed on it.

The valve is equipped with an electric drive and opens automatically upon a signal from a temperature sensor installed on the return line, while the hot coolant is mixed with the cold one.

If you are looking for a powerful heater, floor-mounted gas boilers for heating your home are the best option. Read useful recommendations for choosing a model.

Why does a gas boiler go out? You can find an overview of the main types of faults here.

Are you looking for a heating boiler? In this topic you can read reviews about Conord heating boilers.

Steel

In the case of a steel heat exchanger, failure may occur due to the intensive development of corrosion.

The intensive development of heat exchanger rust is caused by operating the boiler in low-temperature mode, when the temperature of the coolant entering the boiler tank drops below 55 degrees.

Under such conditions, the water vapor present in the flue gases condenses on the walls of the heat exchanger, turning into water.

Regular maintenance allows you to identify rusted areas before they cause an accident.

Increase in pressure in the system above permissible values

The heat exchanger of a domestic heating boiler is usually designed for an operating pressure of up to 3 atm. The main cause of pressure surges is water hammer, but it can also rise due to a decrease in the flow area of the pipeline somewhere at the beginning of the circuit. The pipes could have become coated with scale inside, or the thermostat may have tightly closed the automatic valves in front of the radiators due to the sudden warming.

Under such conditions, a backpressure forms in front of the circuit, and if the circulation pump is powerful enough (such are installed in front of particularly long circuits), the pressure in this zone may well exceed the permissible one. But even if it does not go beyond 3 atm, this phenomenon is still undesirable - the circulation pump wears out faster.

Circulation pump for gas boiler

There are two ways to prevent it:

- use a pump with the ability to smoothly or step change the engine rotation speed (set automatically);

- install a jumper (bypass) with a bypass valve installed on it between the “supply” and “return”: when backwater is formed, the coolant will be discharged through this valve and the bypass into the “return”, which will lead to pressure stabilization.

Coolant boiling

At low pressure in the system, the coolant in the heat exchanger may boil, as a result of which the pressure in it will begin to rise sharply. In this case, the boiler is equipped with a safety group consisting of an air vent, a pressure gauge and a safety valve. In everyday life, spring valves are usually installed, which tend to stick.

During regular maintenance (possibly more often), the functionality of such a valve must be checked by manually pressing the spring using a special lever.

Scale fouling of the heat exchanger

In closed heating circuits, desalted water is usually used as a coolant, in which scale does not form.

But in open systems, the coolant constantly evaporates, so they have to be recharged with ordinary tap water.

It contains a lot of calcium and magnesium salts, which are deposited inside the heat exchanger in the form of scale.

During scheduled or major maintenance it is removed using special reagents.

Failure of the electronic board

The main reason is power surges, which sensitive imported equipment is not designed for. Therefore, many manufacturers, under pain of removing the boiler from warranty repairs, require that it be connected to the electrical network through a stabilizer.