A fireplace is not so much a heater as an elegant accessory for a wealthy home. Its dimensions are relatively small, the device is much simpler than that of a heating stove, and it is not used often. And, since its functions are mainly aesthetic, in urban dwellings they prefer to equip a decorative hearth.

In a country house, a real working fireplace is, of course, more impressive.

Installation features

The design of a fireplace on the second floor of a house or country house requires special consideration. The fact is that you first need to make a solid foundation, but not every interfloor ceiling is designed for the installation of heavy structures, so it’s worth thinking about how to strengthen it.

The second problem is the chimney. It ensures the removal of combustion products outside the house and draft to maintain pressure. The minimum length of the chimney is 4.5-4.6 m. The floor of the second floor is located quite close to the ridge of the roof, which makes it difficult to ensure the required size. According to the rules, the outlet pipe should be located as close as possible to the ridge. The most important requirement is fire safety. The fireplace can even be installed on a wooden floor, but appropriate measures are taken for this. In the fireplace area, it is necessary to remove part of the casing and install a fire-resistant base.

When choosing a project, you should also take into account the design features of the house. Wooden walls shrink over time. The fireplace is made of brick, i.e. not subject to shrinkage. To combine such different materials, a compensation gap is required between the ceiling and the upper boundary of the structure. Special conditions must be taken into account when constructing a fireplace on the second floor in a bathhouse. It is best to place the fireplace directly above the sauna stove.

Types of fireplaces

Fireplaces of various types can be installed in a living room. The table shows the main options.

Table 1

Types of fireplaces for residential buildings

| № | Name | Peculiarities | |

| Design | Advantages | ||

| 1 | Classic fireplace with open hearth | Brick construction with open firebox, chimney, external cladding and solid foundation. Often a metal frame is mounted. | Can be used to heat the room and provide comfort. Has an attractive appearance. The structure weighs a lot and requires a strong foundation. A full calculation of the strength and structure of the chimney is required. An open firebox increases fire safety requirements |

| 2 | Light version | A firebox is used in the form of a metal chamber with an outlet (chimney). Only a brick facing box is erected at the installation site. | The weight of such a structure starts from 150 kg, which reduces the requirements for the foundation. Installation is greatly simplified and accelerated. Increased fire safety requirements remain. |

| 3 ____ 4 | Cassette fireplace _______________ Closed stove-fireplace | The basis of the design is a finished steel or cast iron firebox, covered with fire-resistant glass. It is equipped with a standard chimney. The firebox is finished on top with decorative bricks or tiles. ______________ The firebox can be brick or metal, but is closed with a door. Heating is provided by installing coolant circuits and air duct routing | The lockable firebox makes it possible to leave the fireplace unattended. Installation is simple and quick. ________________________________________ The main purpose of the design is to heat the room. Installation is complicated, but fire safety is increased. |

Recently, decorative fireplaces have become popular. They are not intended for heating, but only imitate a hearth. The finished design fits harmoniously into any interior. Electric fireplaces are widespread. Do-it-yourself decorative structures are made from plasterboard and covered with tiles, tiles, and carved decorations.

Selection of materials

To build a fireplace you will need the following basic materials:

- refractory brick for lining (furnace);

- red brick for the portal;

- facing material for the portal:

– natural or artificial stone;

– ceramic, porcelain stoneware or clinker tiles, etc.

- sand, clay, cement, fine crushed stone, etc.

The brick must be special, with regular angles and a smooth surface. Experienced stove makers check each brick for sound - the brick should not have caverns and when struck with a hammer, it emits a clear, uniform sound.

The material for cladding is selected taking into account the interior style of the room. Here you just need to remember that the facing material, like all materials that take part in the construction of the fireplace, must have high resistance to open fire. You can even make a fireplace out of plasterboard, but such a fireplace will be fake and carry an exclusively aesthetic load.

Crushed stone is needed to build a foundation for a fireplace in a house. In total, you will need about 1/5 of a cube with a fraction of no more than 50 mm.

Preparing the base

When planning the installation of a fireplace on the second floor, first of all, the weight of the structure is calculated and the ability of the interfloor ceiling to withstand additional load is determined. It is generally accepted that when a fireplace weighs more than 700 kg, a capital foundation of increased strength is required. Weighing less than 250 kg, even wooden beams can withstand the load, so the base for the fireplace performs a protective function. In other options, the necessary strengthening of the floor is provided.

When building a fairly heavy fireplace on the top floor, it is necessary to build a columnar foundation. To do this, you can use a wooden beam measuring 20x20 cm. Such a pole is designed for a load of approximately 300-320 kg. To evenly distribute the mass of the structure, the supports are connected from above by a frame (grillage).

Metal pillars made of a steel pipe with a diameter of at least 10 cm or a profile of 15x15 cm look more convincing. One of the most reliable structures is made of channel bars. Depending on the massiveness of the fireplace, 2 or 4 supports are mounted. The grillage can be welded from a steel corner measuring 10x10 cm. When installing, it is important to securely connect the supports to the main foundation of the house.

The basis of the structure on the 2nd floor can be a large stove or fireplace on the first floor. In this case, the lower structure becomes a reliable foundation, and fire safety measures have already been taken when removing the chimney. Another option is to use a supporting frame under the stairs. Here the supports are sufficiently strengthened, and they can be loaded additionally.

A strong foundation can be built in the form of brick walls or columns erected between the foundation of the house and the ceiling. This is the most expensive option, but it is quite justified if the new isolated space that has appeared on the ground floor is usefully used, for example, as a closet or storage room.

Fireplace in a wooden house

A fireplace also differs from a stove in that it has an open firebox and is considered a more fire hazardous design. In fact, compliance with fire safety measures reduces this threat to an ordinary household one. Much more restrictions in its arrangement are caused by the weight of the structure.

Even the smallest brick fireplace weighs at least 300–400 kg. The structure requires its own foundation, which is not connected with the foundation of the building, since their load is different. The hearth is planned in advance, the foundation for it is laid along with the foundation of the house.

In cases where the foundation of a country house is monolithic, it is possible to build a fireplace in a finished wooden building. Although, of course, such work will be much more difficult, since you will have to remove part of the finish yourself in order to lay fire-resistant insulation. The use of a ready-made fireplace insert makes the situation much easier: the base for it consists of 3 zero rows, and brick laying around the firebox is done in the simplest way.

Fireplace on the second floor

If the fireplace is supposed to be installed on the second floor, much more difficulties arise. Several situations are considered.

- If the floors between the floors are wooden, and the hearth is supposed to be brick, then nothing will come of this idea: the wooden beams simply cannot withstand such weight.

In some cases, the following solution is proposed: instead of timber, channels or pipes with a diameter of 150 mm are installed and further reinforced. On the second floor, in this area, a metal sheet 5–8 mm thick is laid on the floor: this way the load will be distributed more evenly. It is difficult to call the method universal, since here the load will fall on the wooden wall. Whether the wall of a country house can withstand such weight is determined in each specific case.

Chimney installation

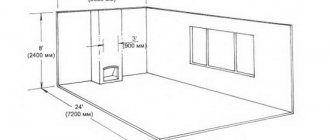

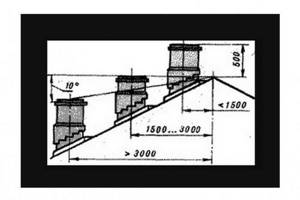

The chimney plays an important role in the reliable and safe operation of the fireplace. When installing it on the second floor, a problem may arise with the length of the channel, which impairs traction. The photo shows a diagram and standards for installing a chimney on the roof of a house. Compliance with the standards limits the possibility of simply increasing the length of the channel due to the height of the roof outlet.

Reliable draft is ensured when the chimney length is at least 450 cm from the ash pan to the edge of the pipe. If it cannot be ensured by increasing the height, then safety is increased by additional measures. The main methods are to install a deflector at the outlet and place spark arrestors inside the channel.

Heating distribution systems

When organizing a heating distribution system, it is worth considering that they come in two varieties: open and closed.

In the first case, water circulation occurs due to the inclination of the pipeline. Heated water is supplied to the highest point. After this, it passes through the entire pipeline by gravity. The level gradually decreases. Water returns to the boiler through a pipe called return. An expansion tank is installed in the attic to allow for expansion as temperatures increase. The heated water is forced into the expansion tank; with gradual cooling, the reverse process is observed.

The main advantage of an open system is its simplicity. Installation can be done independently. However, it is not suitable for heating a large area.

The closed type circulation system is forced using a special pump. In this case, the pipeline is most often installed from plastic pipes. Since their design includes several layers, they have increased thermal insulation compared to metal pipes. This allows you to reduce heat loss during water transportation.

Water in a closed system heats up to 90 degrees or even lower. It enters the storage boiler, after which it enters the pipeline system. Its movement is carried out due to the functioning of the circulation pump. The cessation or disruption of heat transfer may cause water to boil. This will lead to a shutdown of the pumping equipment and an increase in pressure inside. This, in turn, will cause the system to fail.

To prevent this, an additional coil is installed in the fireplace. If necessary, cold water is supplied through it, lowering the temperature of the system. Another protection option is to install a temperature sensor. As soon as the water temperature reaches critical values, the automatic system discharges it into the sewer system.

A fireplace with a water circuit is an economical option for organizing additional heat supply or heating a small cottage or country house.

How to install a fireplace

After choosing a project and strengthening the interfloor ceiling, you can begin work on the construction of a fireplace on the second floor. All wooden floor beams are impregnated with a non-flammable composition. To protect the wooden parts and redistribute the load, a metal sheet with a thickness of at least 7-8 mm is installed and securely fastened to the load-bearing elements.

The masonry of a brick fireplace is no different from the masonry on the first floor. It is necessary to use only high-quality bricks, and in the area of the firebox - increased heat resistance. The internal lining of the combustion chamber is provided with refractory fireclay bricks.

When installing a fireplace, the following requirements must be met:

- The distance to the wooden wall is at least 100 cm. If this cannot be ensured, then an intermediate protective wall made of brick is erected or metal and asbestos sheets are installed.

- The distance to a concrete or brick wall is at least 70 cm.

- The floor in front of the fireplace must have a fireproof coating. You can use metal, porcelain stoneware, marble, ceramic tiles.

Particular attention is paid to the chimney. The gases generated during combustion have a high temperature, so the passages in the roof must be reliably protected. The chimneys themselves are equipped with dampers to regulate draft.

Thermally efficient stove with one firebox

This two-story model has a high heat capacity - one firebox per day for 2-2.5 hours is enough to heat a house. Fuel consumption is about 60 kg of dry firewood. Average heat transfer is 5500 kcal/hour.

Description of design and materials

The channel single-turn furnace has one firebox on the ground floor. Dimensions of the building: 89*115 cm. Height – 715 cm. Dimensions of the heating panel on the lower floor are 77*102 cm, on the second floor – 77*95 cm. Heat exchange outlets are provided in the lowering channels of the smoke circulation panels, increasing the heating rate and heat transfer.

For masonry you will need the following materials and stove equipment:

- 1900 pieces of red ceramic bricks;

- 170 pieces of fireclay bricks;

- 2.1 m3 of red oven clay;

- 0.2 m3 of refractory clay;

- 2.3 m3 of mountain sand;

- grate (40*40 cm);

- steel sheet (50*70 cm);

- firebox door (35*35 cm);

- blower door (13*12 cm);

- 5 cleaning doors (13.5*12 cm);

- 2 valves (13*26 cm).

Fireplace projects

The fireplace on the second floor is built according to a project that can be chosen from standard options or developed individually. It is important to take into account the load-bearing capacity of the support, the size of the room and the design style. The structure can be installed in a corner, along a wall or in the middle of a room. The project is selected accordingly.

For small rooms, a corner option is suitable, as well as a lightweight fireplace. If the wall is of significant size, then a classic design with an arrangement along the wall will do. In large rooms on the second floor, the fireplace can be placed in the center. In this case, the approach will be free, or the fireplace will be surrounded by a fenced area.

You can build any fireplace on the second floor of the house, but to do this you need to take into account the design and installation features. With a large mass of the structure, strengthening of the interfloor ceiling is required. Construction is not much different from installing a fireplace on the first floor. It is important to correctly calculate and install the chimney and follow all fire safety rules.

What do you think about it?

Leave a comment, your opinion is important to us