Wood belongs to the group of porous building materials that can allow air vapor to pass through and also absorb moisture.

These characteristics have a very negative impact on the structure of the walls, and, consequently, on the strength of the entire wooden house.

The condition of the tree is negatively affected not only by external atmospheric moisture, but also by internal moisture generated as a result of human activity.

According to calculations, during the residence of one average family of 4 people, up to 200 liters of water vapor are generated in the house per year. Wood walls absorb this moisture, which leads to changes in structure, shape and volume, causing cracks to form on them.

These changes also have a negative impact on the condition of the interior and exterior of the house, ceilings, windows and doors. In order to protect a wooden building and all its structures from deformation and subsequent destruction caused by the accumulation of moisture in the internal structure of the material, hydro- and vapor barrier films of the walls are installed. This process occurs in conjunction with the thermal protection of wooden walls.

Why is vapor barrier necessary?

For the walls of a wooden house, a layer of vapor barrier (also called waterproofing) is necessary in almost all cases. The reason is in the characteristics of wood as a building material: it allows air to pass through well, but at the same time absorbs a lot of moisture, which is why it swells. If timely measures are not taken, this can lead to negative consequences:

- the walls will begin to curve or heave;

- the structure of the house will inevitably begin to sag due to increased wood density;

- finishing materials (lining, drywall and others), as well as wall coverings (wallpaper, MDF, PVC) can be damaged due to wall movement;

- mold may grow in the thickness of the walls and corners, which will create an unpleasant odor in the house;

- if water freezes during the winter cold, it will increase in volume, which will cause cracks and microcracks in the wood to increase, and the material will wear out faster;

- an increase in cracks also has another negative effect - over the years, the walls will freeze much faster, which is why you have to spend more resources on heating the room;

- finally, when moisture is absorbed into the insulation material, this quickly leads to its softening and deterioration - eventually you will have to dismantle the wall and install a new layer.

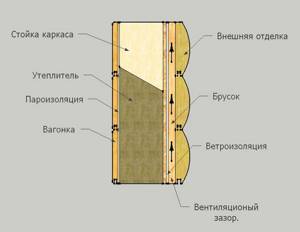

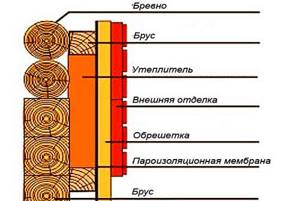

All these consequences can be easily avoided if, after completion of construction, a vapor barrier layer is laid, which follows immediately after the finishing material (for example, lining) and is tightly adjacent to the insulation, as shown in the diagram.

NOTE. Sometimes a vapor barrier layer is understood as a material that does not allow moisture to pass through, but allows air to pass through, and waterproofing is a material that does not allow either water or air to pass through. In a practical sense, the words are often used as two synonyms.

The need for vapor barrier

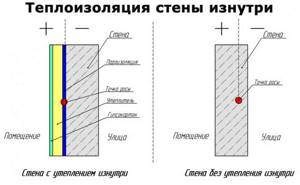

Let's figure out whether a vapor barrier is needed for insulation? When a room is warm, water vapor always forms in it, and the warmer the air, the more vapor it contains. At a certain temperature regime, called the “dew point,” water vapor is converted into condensate. If there is a large temperature difference between the inside and outside of the house, the “dew point” moves to the wall of the house.

Internal vapor barrier

When air exchange occurs naturally in the house, steam freely leaves the room and goes outside. Now imagine that a multilayer barrier has arisen in the path of the steam. Condensation gets into the insulation and lingers there.

This happens day after day, and as a result, moisture accumulates in the heat insulator. The insulation is deformed, its heat-insulating ability decreases, moisture contributes to the formation of mold, fungi, rotting and destruction in the wood.

A vapor barrier allows you to avoid such unpleasant consequences, which becomes a protective barrier on the path of steam, preventing moisture from entering the insulation.

Is it possible to do without vapor barrier walls?

This option is, in principle, possible if the walls of the house are made of rounded or laminated veneer lumber, which is thoroughly dried during production. In addition, all the dimensions of the grooves where the logs will fall are calculated to the nearest millimeters, which ensures their tightest contact with each other.

But even in such cases, it is impossible to give a firm guarantee that moisture will not penetrate the tree, since the following risks remain:

- Wood as a material has its own specifics - it is porous, fibrous, and serves as a breeding ground for the development of microorganisms.

- Protective varnish treatment works well during the first 5-10 years, but over time it tends to disappear - accordingly, after this period, moisture can gradually begin to penetrate into the wood.

- Finally, if you plan to live permanently in a wooden house, it is best to take care of a vapor barrier to protect its walls - the constant action of moisture coming from the kitchen, bath, aquarium and other household sources will make itself felt over several years.

- To house a bathhouse, a layer of vapor barrier is, for obvious reasons, necessary in any case.

If the house is located in a humid coastal climate, then waterproofing is an absolutely necessary measure: it is done both inside and outside.

Approximate calculations show that in 1 year an ordinary family consisting of 3 people (two adults and a child) releases 150 liters of moisture into the air.

Vapor barrier in external insulation of wooden houses

When insulating wooden walls from the outside, a vapor barrier membrane is fixed to the base surface of the wall, after which the sheathing and heat insulator are installed, and then the finishing material is installed.

When using multifunctional protective membranes that combine the properties of steam, wind and water protection as a vapor barrier, the film is installed between the insulation layer and the façade cladding with a mandatory ventilation gap.

Membranes with improved windproof parameters are recommended as a vapor barrier for external insulation of wooden walls using the curtain-facade principle: Ondutis A100, A120, A120 Smart.

For detailed information, read the article “How to properly install a vapor barrier film.”

Vapor barrier materials: types, selection rules and prices

Modern industry offers many types of materials for waterproofing. Almost all of them are artificial polymers, because natural fibers always absorb moisture well and allow it to pass in both directions.

The main indicator of the quality of such products is vapor permeability, which is defined as the amount of water (in grams) that a unit of material area (1 square meter) will let through in one day: g/m2. Normal vapor permeability does not exceed 15-20 g/m2.

From the point of view of advantages and disadvantages, the material is judged on the basis of the following consumer qualities:

- life time;

- mechanical strength;

- ability to pass air, i.e. “breathe” while retaining moisture.

Many waterproofing materials have low air permeability, which creates a greenhouse effect in the house - you have to constantly ventilate the room, including in the cold winter.

A comparison of the pros and cons of the most common materials is presented in the table (price - in rubles for 1 roll, the total area of which is standard 70 m2). In the case of a vapor barrier membrane, the average cost is given for a roll with dimensions of 75 by 1 meter (area 75 m2).

| material | pros | minuses | price |

| single-layer polyethylene films | affordable price, easy installation | low mechanical strength, insufficient vapor barrier | 1000 |

| reinforced (double-layer) polyethylene film | affordable price, high strength | create a greenhouse effect | 1400 |

| polypropylene film | high strength and long service life | 1300 | |

| vapor barrier membranes | long service life, good vapor barrier, high strength and good ventilation properties | high price | 6500 |

| isospan (reinforced polypropylene film) | high strength and long service life, good protective qualities | Greenhouse effect | 1200 |

If you make small holes in a polyethylene or propylene film, this will not provide enough air - the walls must “breathe” the entire surface. In addition, warm air currents will penetrate into these cracks along with the moisture evaporated into them. Therefore, such a vapor barrier will not give the desired effect.

Types of vapor barrier membranes

From the point of view of consumer properties, materials for waterproofing the walls of a wooden house can be divided into membranes and all others. The reason is that membranes are a new generation material, different from traditional artificial polymers (polyethylene and polypropylene).

Their key advantages are as follows:

- allow moisture to pass through in an amount of no more than 10 g/m2 per day (they are especially often used in baths, saunas, and swimming pools);

- thanks to the porous structure, they retain condensation well, preventing it from penetrating into the insulation;

- withstand temperature changes from –40°C to +80°C;

- thanks to the reinforced structure, the fibers are able to work without wear for decades;

- the porous structure of the material ensures sufficient gas exchange between the room and the environment;

- Some membranes are reinforced with foil, which reflects heat coming from the house - thanks to this, it helps the insulation maintain the internal temperature in the room in winter.

Thus, from the point of view of their functions, all membranes are divided into:

- anti-condensation – i.e. preventing moisture penetration;

- foil - which, along with a vapor barrier for the walls of a wooden house, retain its heat.

They are much more expensive on the market and are mainly sold in rolls of 75 m2. Comparative prices in rubles indicating the roll dimensions are presented in the table.

| product brand | price, rub |

| Tyvek Soft

| 5200 |

| Delta Vent N

| 8900 |

| Delta Maxx

| 12100 |

| EUROTOP T150

| 8000 |

The main manufacturers of high-quality membrane films are German brands. High prices pay off if a major renovation of the house is planned, since if you make a calculation, then frequent replacement of insulation and laying a new vapor barrier layer will become more expensive than the initial selection and installation of high-quality material.

Why do you need a water vapor barrier?

The owners of such houses put up with its shortcomings: rapid wear of the walls due to high humidity and low-quality heating.

But today everything is different - buildings made of wood have turned into technologically complex structures , the wall structures of which are multi-layered, containing heat, steam and waterproofing, covered with a wide variety of decorative coatings.

The wood itself, in order to become more bio- and fire-safe, began to be impregnated with special solutions - antiseptics and fire retardants, which change the natural structure of the wood. After this treatment, the impregnation interferes with the natural path of vapor through the walls. Because of this, the level of humidity inside the rooms will begin to increase, which leads to the formation of a harmful environment.

In addition, vapor-permeable heat insulators began to be used for thermal protection of wooden walls, but they are hygroscopic , for example, like mineral and basalt wool. Plates of such insulation are able to quickly absorb moisture, and when wet, they lose up to 65% of their heat-protective properties. Therefore, it is very important to prevent water vapor or water from entering the thickness of such insulation.

Note ! Increased humidity and the formation of condensation on wooden walls at subzero air temperatures will lead to the fact that it will begin to freeze in the thickness of the wood, causing additional ruptures in the walls. A similar process begins to occur when drying the material, after the end of the heating season, when the moisture accumulated over the winter begins to leave it en masse.

The reverse deformation will begin, the formation of new cracks and the violation of the tightness of the inter-crown and corner joints. If you do not protect the walls from steam, they will “expand/contract” for many years until deformation processes completely destroy the wall structures.

Consequences of absence

At a certain “temperature limit” or “dew point”, conditions arise under which the temperature of the air and the percentage of humidity become sufficient for this process to begin on the walls.

It occurs when there is a difference in “partial pressure”.

Water vapor contained in the air will rush to a colder source of air outside , through the enclosing walls. In the case when there is no vapor barrier layer, they penetrate inside the walls and turn into condensation at the “cold front” line, and at a lower temperature - into ice. At a stable above-zero temperature, the ice will melt, then new breaks and cracks will become noticeable.

“Aggravating” circumstances of wood destruction in the absence of layers of hydro- and vapor barrier of wooden walls include:

- Seasonal temperature fluctuations. The higher the moisture level of the wood, the more serious the deformations will be.

- Atmospheric precipitation, both direct, in the form of rain and snow, and indirect, in the form of fog, leads to the absorption of moisture by wooden elements and their serious deformation.

- Negative outside temperatures. In the process of freezing water inside the tree, the compressive, tensile and bending loads increase than the strength of the wood can withstand, and therefore additional cracks appear.

- The formation of mold fungi on the surface in the form of a greenish or white coating, during their life activity, organic acids arise that damage the tree.

- The emergence of wood-staining fungi that produce a bluish-gray color. It can be superficial up to 2.0 mm, deep over 2.0 mm, sublayer or hidden. Such formations increase water absorption by wood, due to the destruction of cell walls and resinous passages, which reduces the mechanical strength of wooden walls.

- The emergence of wood-destroying fungi, leading to massive rotting of walls, cracking and their final mineralization.

Types of vapor barrier materials for a wooden house

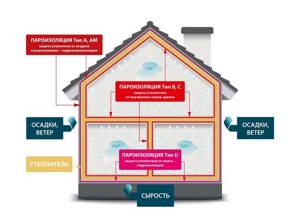

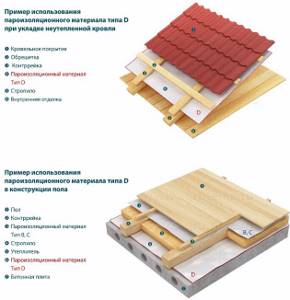

Depending on the location of the material in one or another part of the house, the following are distinguished:

- type A and AM - protection of insulation in walls and roofs from external influences;

- type B and C – protection of insulation in walls and roofs from internal moisture;

- type D – protection of the floor from dampness coming from the ground.

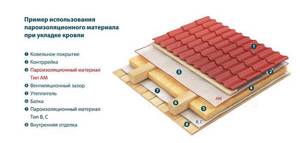

Type A

The materials of this group are intended for external insulation of the walls and ceiling (roof) of the house from the action of wind and air moisture. Installed:

- for external wall finishing on insulation;

- under the roof of the roof;

- into ventilation shafts.

In order for the membrane to work correctly, allowing moisture to pass through from the inside and blocking it from the outside, you need to carefully lay the layers - with the marked side (with the brand inscription and towards the street.

The material is installed on the counter-lattice so that excess moisture can drain off. It is important to create an appropriate angle on the roof (at least 30-35o).

Type AM

At the place of installation, this material is mounted in the same way as type A. It has a more complex multi-layer structure:

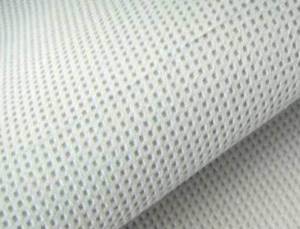

- layers of spunbond (1-2);

- diffuse film.

It is thanks to the diffuse film that steam escapes from the inside, but liquid does not pass through from the outside. An important feature of this material is that it does not require a ventilation gap, so it is mounted close to the surface of the insulation.

Spunbond refers to a special technology for the production of polymer moisture-proof film, as well as the product itself of this production. In this case, the fiber consists of artificial threads that are stitched together under the influence of chemicals, heat or water jets.

The result is a very durable porous fiber that allows air and moisture to pass through well, but at the same time reliably protects not only from precipitation, but also from the effects of wind. All these valuable properties are explained by the structural features of the multilayer material.

Type B

This vapor barrier is used to protect the walls of a wooden house from internal moisture. It is also used for finishing the roof from the inside, especially in cases where it is intended to create a living space in the attic with the possibility of year-round living (like an attic).

And another use option is internal insulation of the floor, as well as the interfloor ceiling.

Multilayer materials additionally protect from wind, and foil materials retain heat inside by reflecting it from its surface.

Type C

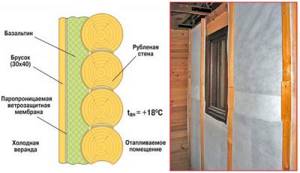

It is a particularly durable membrane consisting of 2 layers. It is used in the same cases as B. It is also used for insulation in unheated rooms adjacent directly to the house:

- attics;

- basements;

- plinths;

- verandas, canopy.

Type D

Such materials are made of polypropylene and reinforced with an additional laminating layer, due to which they are used in floor and roof insulation - i.e. in cases where heavy mechanical load is expected (pressure from furniture, movement and wind exposure).

Description of technology and installation process

The contractor must not make dangerous mistakes when installing steam and waterproofing, so he will need to know exactly how steam and condensate will behave during operation of any type of protection . The thermal insulation wall pie, which includes hydro-vapor barrier membranes, is installed depending on the type of installation: internal or external.

External wall protection is usually carried out in old housing construction in order to change its appearance to a more attractive one. Internal thermal protection is carried out on newly constructed objects after completion of all shrinkage processes and completion of a full range of finishing works.

When installing vapor barrier membranes, the contractor must adhere to the basic installation rules:

Carefully study the membrane manufacturer's instructions for installing the film on external/external wooden walls.- Correctly align the side of the film in relation to the insulation.

Typically, the smooth surface of the membrane is placed on the insulation, and the rough surface is placed on the outside. Foil membranes are placed indoors with the sparkling work surface facing the room. - Maintain overlaps of material when connecting at least 100 mm.

- The joint seams of the film are sealed using 2-sided tape with a width of at least 100 mm.

- A reserve of film is left near the technological openings of windows and doors to prevent the deformation of the building material.

Important ! For external thermal protection, you will need to install an additional layer of wind protection after the insulation. In this case, a ventilation gap should be left in the cake from the windbreak to the outer finishing layer.

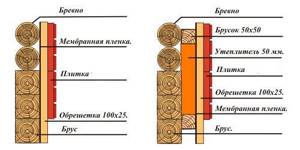

Outside

The technology for installing vapor barriers on external walls will depend on the type of timber.

If logs were used as wall material, then the membrane can be laid directly on them, since the configuration of such a surface assumes the presence of air gaps, if a rectangular beam was used, in this case a ventilation gap is created, first a 25x25 mm lath is filled in increments of at least 1 m, and only then the membrane is fixed on them with a stapler.

Standard external installation technology will look like this :

- Install ventilation gap slats 25x25 mm in increments of up to 1 m.

- Install a vapor barrier, glue it with tape, with a joint overlap of at least 100 mm, attach the membrane to the slats with a stapler

- Install a sheathing with cells corresponding to the size of the insulation so that it does not wrinkle.

- Thermal protection boards are laid.

- Install wind protection with a counter-lattice.

- Perform decorative finishing.

When using multifunctional safety universal films as a vapor barrier, combining the characteristics of wind, hydro, and vapor protection, the film is placed between the insulation and the facing material with the obligatory installation of a ventilation gap.

Inside

Before starting work, they carry out preparatory work , thoroughly clean the walls from dust, seal the crown joints and cracks with special sealants or modern sealants and perform antiseptic treatment of the wood.

Technology for internal installation of vapor and waterproofing as part of a multi-layer wooden wall structure of a house:

- A waterproof membrane is installed through the ventilation gap to prevent moisture from the walls from getting onto the insulation.

- Wooden sheathing is installed on the inside of the walls. First, vertical posts are placed on both sides of the wall, and after completion, intermediate posts are placed.

- The size of the lathing cells will depend on the size of the insulation boards and external finishing sheets.

- Insulation is tightly packed into the cells.

- A vapor barrier membrane is reinforced on top of the insulation with an overlap of at least 100 mm.

- Tape the joints with double-sided tape.

- Fix the membrane with a stapler to the sheathing posts.

- Install a counter-lattice to secure the final finish and create a ventilation gap.

- The final covering is carried out with finishing material.

Methods for fixing vapor barrier film

Materials are fixed using two methods:

- construction stapler;

- special tape (adhesive tape).

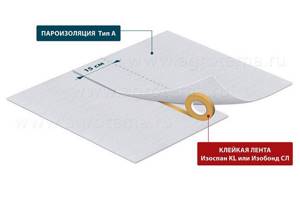

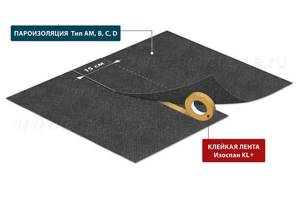

Often both methods are combined together. At the same time, the adhesive tapes themselves are made from approximately the same materials as the vapor barrier. They are reinforced using spunbond technology, since it is assumed that they will be subject to constant load. There are several types of adhesive tapes that correspond to the types of waterproofing membranes discussed:

- Izospan KL is used to fix type A fabric. It has great strength, can withstand temperature changes, and is also resistant to moisture. Serves without complaints for several decades. The canvases should be glued with an allowance of at least 15-20 cm.

- Izospan KL+ has increased mechanical strength due to the two-layer structure of the polymer with reinforcement. It is intended for use in Siberian winters, as it can withstand temperatures down to –50°C. Another advantage is the versatility of this tape: it can be used to fix membranes of all types.

- Izospan ML professional is an excellent option for finishing complex surfaces (with junctions of pipes, bends in the ceiling and walls, protrusions of corners and communications), since it not only fixes the membranes well, but also creates a good vapor barrier itself.

Basic rules for vapor barrier of roof, floor and walls ↑

The vapor barrier material must be clean and dry. It must fit tightly to the roof surface, ventilation units and pipes. It makes no sense to lay a vapor barrier layer on an old, dilapidated roof. This will only speed up the process of its destruction.

The material is laid to the insulation on the rafter legs with the smooth side. Fixed with staples (step 30-50 cm). The overlap when laying the bottom sheet on the top sheet is 10-15 cm. Of particular importance is the tightness of the connection of individual sheets of material with each other and in the places adjacent to the elements of communications conducted through the roof.

It is better to glue the sheets together with foil adhesive tape 10 cm wide. This method ensures the reliability and strength of the connection. It is better not to stretch the film during installation; 1-2 cm is considered acceptable sagging. So at low temperatures it will not crack.

To glue vapor barrier to a brick wall, unplaned wood or other rough surfaces, it is recommended to use special glue made from synthetic rubber, polyurethane or acrylic mixtures.

Having figured out why a vapor barrier is needed, it is also important to know that regardless of the type of surface being protected, be it a ceiling, a wall or a roof, the principle of operation will be the same. The film preserves the structure with the heat-insulating layer from the penetration of steam, therefore it is always laid only on the warm (residential) side, between the room and the insulation

The main condition for high-quality vapor barrier is that the film must be laid in a continuous layer, without breaks or cracks. To secure, they often use a construction stapler, fixing the material with thin slats. This way it is better to press the film, it is more convenient to regulate its tension and it is easier to avoid tears with iron staples.

Particular attention is paid to the corners. It is better if the material in these sections of the walls is laid in one solid piece rather than consisting of pieces

This recommendation applies to both internal and external corners of the house.

When laying a vapor barrier on the floor, it is permissible to lay it both perpendicularly and parallel to the joists. Secure with wooden slats or staples in increments of 30-50 cm. Overlap of 10 cm or more.

This method of protection as vapor barrier is very effective. By protecting the building structure from condensing moisture, the insulating layer ensures a long service life for the house, which will be cozy and warm in any weather.

Do-it-yourself vapor barrier installation: step-by-step instructions

The technology for laying a vapor barrier layer into the walls of a wooden house depends on its design:

- frame house;

- house made of timber.

In addition, there are features of laying the material indoors and outdoors. Since in the latter case it makes sense to protect the house from cold winds, a layer is almost always installed that protects against them. And waterproofing is installed in cases where the house is quite old and the walls need to be protected from the destructive effects of moisture.

Vapor barrier from inside

When laying a layer of waterproofing inside the walls, you must take into account that water, evaporating on the surface of the material, must drain somewhere. Thus, the layer should not be in too tight contact with the insulation - a small gap is necessary.

The sequence of actions is as follows:

- If the house is built from a cylindrical beam, then due to its natural rounding it creates a sufficient gap for moisture removal - in this case, the membrane is attached directly to the logs using a stapler.

- Next comes the sheathing and internal finishing material (lining, drywall, etc.).

- In the case of houses made of rectangular timber, as well as when installing insulation (in cold winter conditions), the membrane is attached to a counter-lattice, which is mounted to the main beam through small wooden beams of the same size. They are located at a certain interval and hold the insulation, on top of which a vapor barrier is placed. The same technology is proposed for a frame wooden house.

A visual representation of the installation method for internal vapor barrier can be seen here.

Possible errors that are important to take into account immediately when laying the layer are presented in the video.

NOTE. The layers of material are overlapped by at least 15-20 cm and securely fastened with joints.

Vapor barrier outside

In this case, the film or membrane should lie immediately under the sheathing layer (for example, siding) and fit tightly to the insulation.

Space for the accumulation and natural removal of condensate must also be present.

The technology is as follows:

- On a round log, the vapor barrier is also attached using a construction stapler.

- All joint surfaces are fixed using construction tape (if a foil membrane is used, using metallized tape).

- In the case of a frame house or a house made of rectangular timber, the membrane is mounted on the counter-lattice in the same way as it is done from the inside.

- Next, the film is fixed with wooden slats at the same intervals as the counter-lattice posts.

Features of the technology are shown in the video.

The external vapor barrier membrane must allow air to pass through well. The use of polyethylene, polypropylene and other films in this case is unacceptable, since the moisture leaving the house will encounter a barrier and will not be able to go outside - it will settle on the walls and insulation, which is why they will begin to rot.

Vapor barrier of a frame house

Frame structures do not have a rigid base for attaching the material, so the technology for laying vapor barriers is somewhat different.

Vapor barrier of a frame house

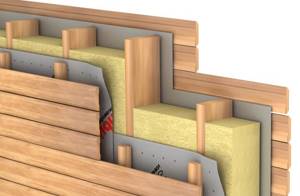

The frame house must have the following structure:

- External cladding (lining, siding, etc.)

- Water and wind insulation, which is installed with an air gap in relation to the exterior finish.

- Frame with insulation.

- Vapor barrier membrane.

- Wooden sheathing.

- Internal lining.

This wall pie is an ideal solution for a frame house.

You can do the vapor barrier of log house walls yourself, but if done ineptly, this will lead to numerous errors and problems. The subtleties of this work are known only to professionals.

is ready to provide its services to residents of Moscow and the region. We guarantee high-quality and fast work on insulation and vapor barrier of your home. To ensure that your home is always warm and cozy, contact the professional craftsmen of our company.

You can leave a request and contact us using the coordinates on the “Contacts” page.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

Vapor barrier and insulation: what is the ratio

Since vapor barrier of walls in a wooden house is carried out mainly to protect the insulation, you should figure out in which cases this is especially necessary, and in which cases it is enough to simply cover the walls, for example, with plastic film. In this sense, there are 2 options:

- If polystyrene foam, polyurethane foam and similar materials are used as insulation, then a film or membrane is not needed directly to protect them, since they do not absorb moisture.

- If the house is insulated with mineral or ecowool, as well as sawdust, the membrane is extremely necessary - damp cotton wool will turn into dust in literally 1-2 years.

If the house is old and made of wood frame or infill construction, a moisture retention layer will be needed anyway to protect the wood itself.

By correctly choosing and installing a vapor barrier layer, you can not only improve the microclimate in the house, but also significantly extend the service life of the insulation and wood.

Installation of vapor barrier for internal insulation of a wooden house

Quite often, in order to preserve the appearance of the house, a vapor barrier is made for the walls of a wooden house from the inside. A layer of material is placed between the insulation and the material used for finishing

During the work, the film is fixed in place using a construction stapler on the sheathing. After fixing, the film joints are sealed. To do this, you need to use mounting tape.

There are several brands of films that are used to create a barrier to steam. There are brands of film on the surface of which a strip is applied with an adhesive composition pre-applied to its surface. It significantly facilitates installation, while reducing the time required to complete the work, without loss of quality.

Common brands of membrane materials

Currently, vapor barrier materials are presented in a wide range. Moreover, each of them is intended for a specific area of use.

Vapor-proof materials installed outside

This group of materials includes “Izospan A”, “Izospan B” .

One of their features is that the materials contain fire retardant additives, which increases their fire safety. This also includes “Megaizol A”, “Megaizol SD”. All of the listed materials are used to protect structures made of timber, as well as houses built using frame technology, and panel buildings. These insulators provide protection from precipitation, snow and wind. They are used for all types of external insulation. When using them, it is extremely important to ensure a tight fit of the membrane to the insulation. Therefore, these materials should be securely secured during work. There should be no sagging or loose areas. Otherwise, in case of strong winds, rare gusts will occur.

Materials for installation indoors

When the task is to perform a vapor barrier on walls and ceilings from the inside of a wooden house, “Megaizol V” is used. It is a polypropylene film, which consists of two layers. On the outside of this material there is an anti-condensation surface. The use of this material in winter ensures its protection from phenomena such as condensation and fungus. In addition, its use eliminates the destruction of wall structure elements. This material also protects the room from insulation particles. The same function is inherent in Izospan V.

Materials for hydro- and vapor barrier with a reflective layer

This group includes the following materials: “IzospanFD”, “IzospanFS”, “IzospanFX” . They are used in cases where it is necessary to install a vapor barrier in rooms where special requirements are imposed on this procedure. For example, these could be saunas or baths.

Vapor barrier for the walls of a wooden house - why is it needed and installation technology

We all know that wood is a porous material that allows air to pass through it very well and also absorbs water well. This property has a very negative effect on both the tree itself and the wooden structure as a whole.

What can constant moisture inside a tree lead to?

How to protect a wooden structure from destruction and deformation due to the accumulation of water in it?

First of all, it is worth noting that vapor barrier is mainly used in conjunction with insulating the walls of a wooden house.

Where does moisture come from and how does it affect the walls of a wooden house?

With average calculations, when one full-fledged family lives in a house, up to 150 liters of water vapor can be produced per year.

What can serve as a source of moisture inside the walls of a wooden house? First of all - the kitchen and bathroom, then everyday life. We breathe - we release steam, we sweat - we release steam, etc. It’s impossible to list all the sources, but if you also have insufficient ventilation, the walls will start to sweat.

Any changes in the amount of moisture in the wood lead, first of all, to a change in shape and size, as a result of which cracks appear on it.

Changing the shape and size also has a very negative impact on the interior and exterior decoration of the building itself, on windows and doors. Gaps may also form between the logs, which will become an additional source of cold in the house. And these changes, as a rule, can occur within 5 years after the construction of the house.

Why do you need vapor barrier on walls?

Proper vapor barrier of a wooden house will protect the walls from moisture generated in the room. The construction market offers us a bunch of different vapor barrier materials, the main and highest quality of which is the vapor barrier membrane, which allows moisture to pass through to the wood and the thermal insulation of the walls at the same time, and at the same time allows the wall to “breathe.”

First of all, the comfort in the room and the service life of the walls of a wooden house depend on the correct application of the technology for installing vapor barriers for the walls of a wooden house.

Technology for installing vapor barriers with wall insulation from the outside and inside

First, you need to check all the seams between the wooden structural elements; if necessary, they need to be sealed. Only after you are sure that all the cracks are sealed can you begin the process of insulation and vapor barrier.

The vapor barrier film should not be installed outside the house close to a wooden wall (not to be confused with a frame wooden house); ventilation gaps must be created. The outer wall must be blown to constantly remove moisture from the wood.

Ideally, the vapor barrier is installed only from the inside; the outside should have hydro or wind protection with wall ventilation.

Also, wooden structures should not be tightly covered with film on both sides, thereby preventing the natural drying of the wood.

From the inside, a vapor barrier is usually attached over the insulation, thereby protecting not only the wooden walls, but also the insulation itself from vapors inside the house. You can read about this in one of the previous articles about insulating the walls of a wooden house.

Tips for installing a vapor barrier from the inside of a wooden house

- The installation of a vapor barrier should be carried out for the entire interior of the wall, but the installation of a vapor barrier in rooms with high humidity, such as a bathroom, bathhouse or kitchen, must be approached with particular rigor and caution, I think, for obvious reasons.

- It is advisable to provide a ventilation gap between the vapor barrier and the facing part from the inside to naturally remove condensate from the vapor barrier film.

- It is necessary to take into account that the wood in the wall will dry out a little over time and shrink, and after construction in a couple of years, cracks may appear that will need to be corrected.

- Do not insulate wooden walls on both sides without access to air and ventilation, because it will not be possible to completely dry the wood, and the remaining moisture inside will have a detrimental effect on the wall as a whole.

Source: https://postroj-sam.ru/derevyannye-doma/paroizolyatsiya-sten-derevyannogo-doma-zachem-nuzhna-i-tekhnologiya-montazha.html

Vapor barrier of house walls: how to insulate the walls of a log house with vapor barrier

Wood is a special building material, an important quality of which is the ability to breathe, that is, to allow air and water vapor to pass through. This allows you to create a special light atmosphere and natural microclimate in the house, but excess steam can be destructive for both wood and insulation. When creating multi-layer insulated walls, it is imperative to equip a vapor barrier, otherwise the resulting condensation will lead to deterioration of the properties of the insulation and rotting of the logs.

Why do you need a vapor barrier membrane?

Water vapor is one of the essential components of the atmosphere of the house: a large amount of steam, for obvious reasons, is formed in the kitchen and bathroom, but there can be quite a lot of it in other parts of the house. Vapor barrier of the walls of a log house is designed to prevent the accumulation of steam inside the “wall pie”; membranes made of special materials are used for this.

Do-it-yourself vapor barrier of house walls can be done using several types of materials:

- The simplest solution is ordinary polyethylene or polypropylene film: these materials do not allow air or moisture to pass through. They will protect the walls from dampness, but the house will not breathe, so one of the advantages of wood for construction will be lost.

- A more modern and reliable solution is a special diffusion membrane. It is more expensive, but thanks to its special properties it allows you to preserve the benefits of wood. The multilayer material allows air to pass through, and the atmosphere remains light and pleasant.

- Another option is a vapor barrier layer combined with insulation. For this purpose, thin foil polymers are used: including penofol, foamed polyprofen. If you install the foil side towards the inside of the house, it will reflect heat, this will make it possible to reduce heating costs.

- Roofing felt can also be used for external vapor barrier work. It is inexpensive and quite effective.

Any insulating material must be overlapped so that there are no gaps between the sheets. Otherwise, water vapor will penetrate into the insulation, and the vapor barrier will be useless.

How to make your own vapor barrier membrane

You can insulate the wall of a log house with a vapor barrier from the outside and from the inside: experts consider external insulation to be a good solution: this will prevent freezing of the walls and the formation of condensation inside the wall “pie”. However, in some cases, you can only insulate a house from the inside, and it is important to do it correctly.

In both cases, there must be a gap for ventilation between the vapor barrier membrane and the wooden wall: it is needed so that the condensate can evaporate freely. The insulating layer for a house made of timber is installed on a sheathing several centimeters thick, and if you need to insulate a log house, it is not necessary. The special shape of the logs will already provide sufficient air voids for ventilation.

When performing external insulation work, it is necessary to create several layers:

- A vapor barrier membrane is installed on the log walls using a construction stapler. If you are using not ordinary polyethylene, but a special film, you need to figure out which side it should be facing the wall. The manufacturer usually indicates this instruction on the packaging. One side is impervious to water and the other to steam, so it is important to position it correctly. The sheets are overlapped so that one edge overlaps the other by at least 2 cm.

- A sheathing is installed into which insulating material is inserted. Most often, layers of mineral wool are used for this, as it allows air to pass through well.

- Then the counter-lattice and finishing material are attached to the wall. The insulation for the walls of a log house is completely hidden by a layer of lining, siding or other materials.

At the same time, a ventilation gap will remain between the insulation and the finishing layer: the insulation will be protected from street moisture, while it will dry freely and will not become damp. Ventilated facade technology allows you to keep mineral wool and other materials in working order for a long time.

Internal insulation with vapor barrier

Internal insulation work is carried out in a slightly modified order: a waterproofing membrane is attached to the sheathing on the walls or directly to the log wall, and it is covered with a frame with insulation. After this, a layer of vapor barrier is installed, and all cracks are sealed with construction tape.

Materials for protecting walls from steam

There are several types of materials for equipping a home with a vapor barrier. All of them have good vapor barrier characteristics, but differ in their composition and properties:

- Polyethylene film. It is recommended to use reinforced film. The most budget option, affordable and widely distributed in the retail chain. Significant disadvantages include the complete lack of penetration of air and moisture. This leads to condensation accumulating on the surface, which reduces the vapor barrier characteristics. In addition, it has low strength, which leads to a relatively short period of operation.

- Laminated polyethylene film with aluminum coating. It has another name - aluminum foil. Its thickness is only 0.02 cm, but it has excellent vapor barrier characteristics. Installation of such a vapor barrier is carried out with an aluminum coating inside the room. As a result of this installation, heat is reflected from the film and remains inside the building. The disadvantages include the cost of the material.

- Diffusion membrane. This vapor insulator is made of several layers. The number of layers is determined based on the degree of humidity in the building. The membrane can be single-sided or double-sided. In addition to vapor insulation, it additionally performs the functions of waterproofing and thermal insulation. The disadvantage of this material is its high cost and the impossibility of installation from the outside of the building.

Before installing the film, you must study its markings. The film should be installed with the logo inside the room.

- Polypropylene film. The characteristics are similar to polyethylene film. But, unlike it, it is more durable. Cellulose fillers in polypropylene film prevent condensation from forming on its surface.

- Foil polymer. It includes such vapor barrier materials as kraft paper with a metallized layer, kraft paper with a metallized-lavsan layer, fiberglass with a foil coating.

They can be used in combination, as they have good thermal insulation characteristics. Installation is carried out with the foil side facing the inside of the building. Just like aluminum film, heat is reflected and remains inside the building.

- Rolled vapor barriers. This could be roofing felt - a material saturated with fiberglass with a layer of bitumen. Rolled materials include roofing felt, which is cardboard impregnated with tar. You can use glassine, which is cardboard impregnated with bitumen. Rolled materials are used to equip the exterior of buildings with vapor barriers. The main positive characteristic of roll materials is excellent adhesion. It makes it possible to retain not only steam, but also moisture on the surface of the mastic.

- Izospan. A relatively recent invention that combines films of varying strengths and vapor barrier membranes. Easy to install, but quite expensive.

You can choose any type of steam protection, depending on the age of the building, the content of the walls, and financial capabilities.

What materials to choose for vapor barrier of wooden walls

To increase the durability and heat-saving parameters of wooden houses, frame, timber and log house estates are often insulated: usually on the outside to avoid the greenhouse effect in the interior, but they also practice installing insulation from the inside.

To protect the thermal insulation layer from moisture, a vapor barrier must be placed in the insulating “pie” of wooden walls - a film that removes condensation from the insulation, but at the same time allows air to pass through.

Types of vapor barriers for wooden walls

- Anti-condensation membranes. Films with a layer of non-woven fiber that effectively absorbs moisture. Installation of this type of vapor barrier is simplified - no ventilation gap is required between the insulation layer and the wall cladding.

- Diffuse “breathable” films. They are optimally suited for vapor barrier of wooden walls - they do not interfere with air exchange and promote good ventilation of wooden structures.

- Polymer multilayer films. The best solution for vapor barrier of unheated wooden buildings and cottages.

- Multifunctional hydro, wind and vapor barrier membranes. They are used as part of the insulation of wooden walls from the outside: both when installing ventilated facades and finishing walls using “wet” technology.

Video on the topic of vapor barrier of a wooden house

1. Ceiling vapor barrier

2. Laying vapor barrier Technology, errors

The site uses modern web technologies and your browser (web browser) does not support them. To work with the site, update your browser or install any of the recommended ones:

8

Vapor barrier is one of the key elements of insulating wooden walls - it prevents getting wet, freezing, destruction of the insulating “pie” and wall decoration, protects the wood from deformation and increases the service life of the structure.