Some promising technical developments related to the design of home fireplaces can increase their efficiency. The design has been improved in all influencing aspects, thanks to which the efficiency indicator for a solid fuel fireplace has been raised from 20 to 80%. But even these successes do not contribute to the fireplace becoming a full-fledged device for heating a house or apartment. The heat generated is local in nature. a fireplace, no matter how efficient it may be, is only capable of heating the air in one room in which it is installed.

Air has poor thermal conductivity, so heat transfer will not occur, which means you need to use substance transfer. It is not advisable to use air as such a substance, since as it moves through the rooms it will cool quickly.

The air will already reach the farthest room cold, but water is perfect as a coolant due to its high specific heat capacity. In this article we will talk about how you can build a fireplace with a water circuit for heating with your own hands, and we will study the principle of operation of the entire system and its elements separately.

Self-built brick structure

How to organize heating with a fireplace

To organize water heating with your own hands, where the basis of the system will be a fireplace, you must first select the type of equipment. As mentioned above, there are three of them:

- finished metal unit;

- finished firebox;

- brick fireplace with heat exchanger.

Ready fireplace

The simplest thing is to purchase a ready-made fireplace with a water circuit. Manufacturers today offer a wide range of models, so choosing one that suits the customer’s requirements will not be difficult.

This is an oven with two pipes coming out of it. They must be connected to the circuits of the heating system of the house. The chimney must be connected. And with this, the installation of the fireplace can be considered complete. Among the three options, this is the most expensive. Such a fireplace costs a little less than a boiler, but still decent.

Combustion chamber

This is also a finished metal structure, which has one fundamental feature. There is no heat exchanger in the firebox; the device consists of two boxes inserted into each other. The coolant is located between them, which is why the device is called a fireplace with a water jacket.

It differs from other designs in higher efficiency due to the large heat exchange area. We will consider this option, as the optimal one for many consumers, below.

We will pay special attention to installing it yourself

Brick fireplace

This is the most complex design, because you will have to build a real fireplace using special bricks (refractory and fireclay), as well as a special clay mortar. The design of traditional fireplaces is complex; it is simply impossible to build it yourself if you are not a specialist in this matter. A small mistake or inaccuracy and the fireplace will not work correctly. The least that can happen is that it will smoke.

And yet such a design exists. As mentioned above, during the construction of the fireplace, a heat exchanger is inserted into it. Its location is located next to the rear wall of the firebox. Sometimes, in order to increase the heat exchange area, the heat exchanger is made in the form of the letter “P”, laid on its side. That is, this device covers both the side and rear walls.

Construction of fireplaces with a water circuit

All work can be divided into two stages:

- Construction of the body of the heat source, that is, the fireplace itself;

- Installation of heat exchanger.

Construction of the fireplace body

The construction of the fireplace body should begin with the search for a formal masonry scheme. When choosing materials, give preference to those that allow you to build a fireplace with a water jacket. To ensure tightness, steel sheets are usually used.

The construction of a fireplace begins with the installation of the foundation. To fill it you will need:

- Boards for installation of formwork;

- Ruberoid;

- Crushed stone;

- Sand;

- Cement.

The size of the base should be slightly larger than the dimensions of the future fireplace. To ensure waterproofing of the finished foundation, roofing material is laid on it. After this you can start laying. Fire-resistant bricks are used for the construction of the building; the firebox is assembled from a heat-resistant fireclay grade. A special clay mixture is used as a solution. It is not recommended to make it yourself. Experts use ready-made dosage formulations.

The masonry should be assembled from horizontal main rows. At this stage, it is important to ensure accurate positioning in the horizontal plane. After this, the ash pan is assembled, then the craftsmen lay out the fireplace firebox. The final part of the installation differs significantly from the construction of a classic fireplace. At this stage, installation of the heat exchanger is required.

Heat exchanger organization

The simplest type of heat exchanger is a small tank with two flanges for connecting pipes. Cold water enters through the first pipe, heated water is discharged through the second. Due to the harmful effects of open flames, temperature changes, and the negative effects of combustion products, it will not last long. The material for the heat exchanger must be sheet steel with a thickness of at least 4 mm.

The exact dimensions of the tank are determined by the design of the fireplace. To increase efficiency, it is recommended to use coil-type heat exchangers. Such designs consist of sections and registers, assembled in the form of a labyrinth.

After the heat exchanger is manufactured, it is built into the body of the fireplace. After this, special stands are formed on which the tank will rest. Installation is carried out in such a way that the heat exchanger flows are outside the fireplace. This allows for repairs in the event of a breakdown.

After installing the heat exchanger, the assembly of the fireplace fuel chamber is completed. It is covered with masonry with the obligatory organization of a smoke hole. Finally, a chimney is erected.

After the masonry has completely dried, which will take at least 10 days, the system can be filled with water for the first time. During initial start-up, it is necessary to check for leaks. In an open system, leaks lead to a decrease in the volume of water, but in a closed system they will cause a lack of circulation.

If the fireplace will be used as a backup heat source, a system must be provided for turning on and off the circuits from it. Using a bypass valve allows you to stop the water supply.

Application

Obviously, water-heated fireplace stoves are used in private homes. They are characterized by ease of use and a high level of safety, even though firewood is used as fuel. At the same time, they can have an attractive appearance that improves the impression of such a device.

Attractive looking fireplace stove

Thanks to all these qualities, there is a high demand for designs, especially those with a hob. They are effective in those regions where there are problems with electricity supplies and there is no gas supply.

In summer, such a device can be used to heat water for household needs. And if there is an addition, it can also perform a heating and cooking function. Since fireplace stoves are characterized by high heat output, they significantly reduce energy costs.

Stove with hob and oven

Advantages vs Disadvantages

Based on the above, it can be noted that a fireplace insert with a water circuit is a good solution for providing your home with heat. Yes, such a system is somewhat inferior to gas heaters, but in the absence of the possibility of running a gas line, a pellet fireplace with a water circuit can be an ideal way out of the situation.

To finally decide for yourself whether you need such a system with a Zharko water circuit, we will introduce you to the main strengths and weaknesses of thermal fireplaces.

The advantages of a thermal fireplace include:

- Easy to install into existing heating systems. You can install the equipment yourself if you have a little experience;

- Thermal fireplace can be a complete replacement for the existing heating system;

- Multitasking. Thermal fireplace heats the house, supplies hot water and simply decorates the room due to its appearance;

- Impressive heating capabilities - up to 250 square meters;

- Durability ensured by design features;

- High level of fire safety;

- Energy independence of open systems;

- The presence of cooking surfaces on some models. Reviews say that the taste of food cooked on a thermal fireplace is much more pleasant than a gas stove;

- Attractive price. A good thermal fireplace can cost from 20-25 thousand rubles.

As for the shortcomings, that's what they are.

- Lack of process automation. To light the fireplace and maintain the temperature, firewood or other fuel will have to be added manually.

- Not the highest efficiency. If you live in a region with harsh winters, the power of a thermal fireplace may not be enough to fully heat the entire house.

Thermal fireplaces are an excellent solution for heating the entire house and providing hot water.

Tips for setting up the system

At their core, such designs are the progenitors of modern solid fuel boilers. But unlike them, heat transfer is carried out not only through piping and a radiator system, but also from the stove itself.

Plus, installing brick stoves with water heating yourself is much easier and cheaper than installing a solid fuel boiler.

A few words about the register

Without exaggeration, the metal register can be considered the heart of the entire heating system. This design is installed directly in the firebox itself and is responsible for the heating level of the coolant.

Lateral arrangement of registers.

The simplest and most affordable option is to install a rectangular metal tank directly into the firebox. Such a tank is made of heat-resistant steel, with a thickness of 3 mm or more, most often from stainless steel.

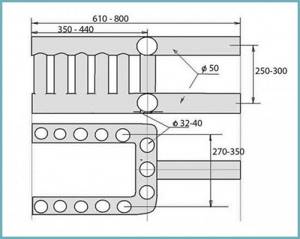

To heat a house of 200 m², a tank 750 mm long, 500 mm wide and 300 mm high is sufficient. The outlet is made from the top of the structure, the return line cuts into the bottom of the tank.

Registers welded from stainless steel pipes with a wall thickness of at least 3 mm are considered more functional. In this case, the heating area increases several times, hence the efficiency of the system is disproportionately higher.

Advice: it is not difficult to find cast iron registers on the market now; according to most experts, they are the best option. Firstly, cast iron is little susceptible to corrosion, practically does not burn out, and most importantly, this material is considered the best heat accumulator.

Stainless steel registers.

During installation, pay attention to the location of the register. The more contact with fire, the higher the productivity

But at the same time, regardless of the configuration of the tank, there must be a compensation gap of at least 5 mm between it and the walls of the furnace. Otherwise, during heating, the metal will begin to expand and the walls of the firebox will crack.

Diaphragm tank

Installing a register into the firebox is only part of the story; it is equally important to properly arrange the piping. Any heating system built on this principle must be equipped with an expansion or membrane tank

As a rule, it is installed on the return pipe, but this is not important; some craftsmen prefer to mount it at the highest point of the system.

Operating principle of a membrane tank.

In a system with natural coolant circulation, its function is performed by an ordinary metal container. But now, in most cases, owners prefer to install circulation pumps. It is advisable to install a real membrane tank in such a system.

The device is a sealed metal container, in the upper part of which there is a valve. Air is forced through the valve, creating excess pressure in the system. As the temperature rises, the coolant expands proportionally, squeezing the excess into the membrane tank. During the cooling process, the air that presses on the membrane compensates for the pressure drop in the system.

Some aspects of laying a furnace

As mentioned earlier, you can build water-heated brick stoves with your own hands, but if you are not confident in your abilities, it is still better to invite a specialist.

Although in any case, there are general rules that it is not advisable to break.

- All brick ovens are made of solid red brick. It is not advisable to use hollow brick even for cladding. The fact is that hollow blocks are a heat insulator, and in this case this can only do harm.

- If you plan to burn with wood, then the firebox can be made of ordinary baked brick. But if there is a possibility of using coke or high-grade coal, such as anthracite, then we would advise making the firebox from special fireclay bricks, which are used in the construction of blast furnaces.

- There is no need to save on wall thickness; in addition to the weight of the oven itself, the load from the registers will also be added here.

- And yet, any stone structure needs a reliable foundation; as for stoves, the foundation should be laid separately and in no case should it come into contact with the general foundation of the house, the minimum distance between them should be 50 - 100 mm.

Circulation pump in the system.

The video shows some of the intricacies of installing the system.

In this case, we were talking about heating a house. But it is worth noting that if a metal water container is inserted into the system in parallel, it will act as a passive boiler, as a result of which hot water will still appear in the house for domestic needs.

Types of fireplaces

Water fireplaces are conventionally divided into two types:

- Designs in finished form. Heat exchangers are provided in order to connect the heating system to such a structure.

- Structures that at the base look like a fireplace insert. There is a water heat exchange circuit.

All these types can be characterized by their individual merits. It is better to learn more about each of them.

Finished structures

This type is purchased ready-to-use. It only needs to be placed in a suitable area and connected to the heating of water resources. The chimney is also installed.

If you put a solid fuel boiler in comparison with such a stove, then the finished design has clear advantages. The hearth not only increases the temperature of the coolant, but also heats up itself. Thanks to this, the building itself warms up.

One of the advantages of this structure is that it can be transferred from one site to another.

A fireplace with water heating can be:

- Of steel.

- Made of cast iron.

Cast iron models boast such qualities as durability and good heat retention. Steel samples are more affordable. There are also models with tile finishing. At the same time, heat is retained longer, and a more attractive appearance will easily decorate the room. However, one of the disadvantages is the high price.

Devices with a base in the form of a fireplace insert

The appearance of such a structure with a water jacket is very similar to the classic version. True, this model is more complex than a standard oven. But the heating efficiency clearly increases. Such a device allows not only to heat the resource coolant, but also to ensure the efficiency of air convection, which is caused by the enclosure equipment.

Such structures are divided into two groups:

- closed form;

- open form.

The design contains a heat exchanger, thanks to which the energy resource is transferred to the heating system during the combustion of fuel materials. The process takes place through radiator pipes located almost everywhere within the room.

The design contains a heat exchanger, thanks to which the energy resource is transferred to the heating system during the combustion of fuel materials

System Features

A conventional brick stove consists of components such as a combustion chamber, an ash pan, grates and chimneys. These components of a simple Russian stove are probably familiar to any village resident. Visually, modern types of stoves are practically no different from traditional village designs.

Main characteristics of water-heated furnaces

Traditional ovens have the following characteristics:

- A simple village stove can produce more than 6500 Kcal of heat in one hour. This amount of heat is quite enough to heat a house with a small area. Such a heating system would be an ideal solution for a small country house. A water-heated furnace, in which the main component is a water boiler, will be approximately 2.5 times more efficient. Using such a heating system, you can heat a house with a much larger area. In order to heat a house, the same amount of fuel will be required, which means that such a system will be more economical.

- A heating system that combines a stove and a boiler will also be effective. If both systems work simultaneously, their productivity increases many times over. A tandem of two such heating systems can release more than 21,000 Kcal of heat in one hour of operation. This amount of heat is enough to heat a house with an area of up to 300 square meters. meters.

Stove connected to water heating

- Most often, such a heating system uses fuel such as coal or wood. The price of such fuel is not high, and its transportation should not cause any particular difficulties. Firewood can be combined with coal at the same time.

- There is no need to constantly heat water-heated stoves. Fuel can be added to the stove several times a day. You can create comfortable conditions indoors, no matter what the weather or temperature is outside.

- If we compare the efficiency of traditional stove heating with a combined system, this figure will increase from 50% to 85%. For heating with wood, this figure can be called ideal.

- The materials that are necessary to organize such a heating system are quite affordable and are not included in the expensive price category.

Disadvantages of water-heated stoves

Stove heating also has its disadvantages, and it would be unfair not to list them.

A brick stove with water heating can be installed not only in a rural or country house, but also in luxury cottages. Typically, owners of luxury homes strive to ensure that such a water heating stove, in addition to its usual functions, also plays a decorative role. During operation of such a combined system, it is necessary to follow some safety and system care rules:

A stove for water heating at home must be under human control at all times.

This applies not only to the issue of loading fuel, but also to cleaning the ash chamber. Smoke ducts also require attention. Before starting a fire in the lever, you must make sure that the smoke channel valves are in the open position. Such systems can only be used in the cold season

During the warm season, using such a heating stove with a water circuit for cooking will be impractical. If you need to cook food, it is better to use another alternative heat source for this purpose.

If you want to make custom-made stoves for water heating at home, it is better to turn to professionals for help. If your stove is manufactured by an unqualified person, there is no guarantee that the stove will function properly or be completely safe. Overheating of the oven can cause some problems that will eventually lead to complete breakdown of the oven.

A conventional stove is usually designed to heat a small room

Since the flame has high temperatures, it will eventually damage the integrity of the boiler walls. This means that the time will come when the heat exchanger will need to be replaced. This is not so easy to do, since you need to remove a good part of the masonry.

Application options

Water fireplaces are used as a backup or main source of heat. If the fireplace is planned as the main source of heating, it is connected according to a special scheme, which takes into account not only the heating of the home, but also the heating of water and “warm floors”.

A water fireplace can be connected to the existing system as a backup heating option. If a water fireplace is used, the electronics automatically turns off the main heating system, since the temperature of the water in the pipes is controlled by special devices.

Partitions

The interior of the kitchen and living room begins to be thought out from the junction of the two zones.

- Here are some of the ways and objects that delimit space:

- installation of a bar counter;

- kitchen island;

- big table;

- installation of a low partition.

Designers advise installing a wide counter, since you can sit at it like at a regular table, and high chairs are quite suitable for the whole family.

However, in small rooms (16 sq m), narrow counters are installed. Kitchen islands are convenient to use, but are only suitable for large kitchen-dining rooms (25 sq m or 30 sq m). Capital low partitions are installed only if it has been decided in advance what they will be used for (for example, as a TV stand).

Equipment design

Today, a fireplace heating element can be purchased on the market for similar equipment. However, some people want to make a water heating fireplace with their own hands. To do this, you need to familiarize yourself with its device in more detail.

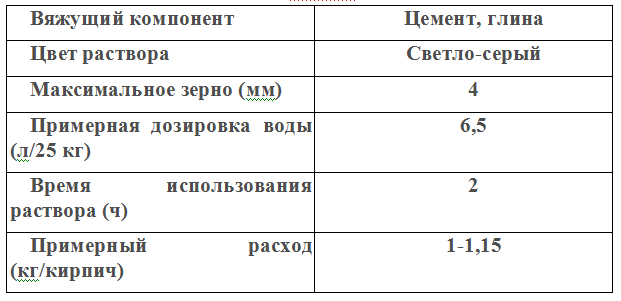

The basis of the fireplace is a steel casing (16). The combustion chamber (1) is mounted in it. The cast iron door (2) prevents heat from escaping from the combustion chamber. For this purpose, it is equipped with tempered glass (3) and a deadbolt (4). The combustion chamber casing (5) is connected to the frame using cast iron axles. The bottom of the firebox is made of thick cast iron (6). Grate bars (10) are laid on top of it.

They also have an impressive thickness, since a direct oxidation reaction of the energy carrier occurs here. Gas fireplaces for heating do not have a grate, since ash is not formed here, which should accumulate in the ash pan. The combustion chamber has a cast iron fence (11). It also performs a decorative function and acts as additional protection against loss of burning fuel. The ash pan (7) at the bottom of the device is necessary to collect solid combustion products. It must be retractable.

Fireplace components with water heating circuit.

The combustion intensity of the energy carrier is adjusted through the supply of primary air. The regulating function is performed by a window (8) in the ash pan and a manually controlled throttle (9). Secondary air, necessary for afterburning of gaseous combustion products of wood and solid particles that rise along with gas flows, enters through a hole in the tempered glass of the door.

A do-it-yourself fireplace with a water heating circuit is equipped with smoke pipes through which the smoke passes into the chimney (12). A mandatory attribute of the chimney is a regulating damper (13). The angle of its inclination is determined by a special mechanism (14). The supply of cold coolant from the heating circuit occurs through the lower pipes (18). The heated coolant leaves the fireplace through the upper pipes (19). Pipes 20-22 are intended for installation of a coil and a thermostat.

If you decide to install autonomous gas heating for a country house, the cost of registration will be no less than the cost of the work.

Everything about autonomous heating of a private house (photos and video instructions) is here.

Main types

When constructing stove water heating, you can go one of two ways:

- If the house already has a stove, then it is necessary to make a coil for installation inside the structure. This technique is used infrequently due to its complexity. In this case, it is quite difficult to make a firebox to fit the existing dimensions of the structure.

- Construction of a heating plant on your own, taking into account the size of the register. If everything is done correctly, the reliability and longevity of the furnace service is guaranteed. The internal dimensions of the shirt deserve special attention. Its thickness should start from 4-5 cm, in order to avoid the threat of boiling water. To protect yourself from problems with coolant circulation, you usually install a suitable pump.

- When choosing wall thickness, the calorific value of the selected fuel is taken as a guide. If it is intended to use exclusively firewood as energy carriers, then 3 mm will be sufficient. If you plan to use coal, the thickness should be increased to 5 mm. The distance from the furnace register to its walls is recommended within 10-20 mm. This will completely neutralize the thermal expansion of metal elements, preserving them from premature destruction.

Fireplace connection diagrams

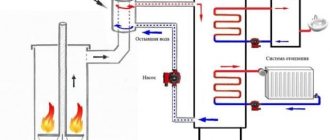

- Open. In this case, there must be a special expansion vessel, which must be located above the furnace and work as communicating containers. Then the water that is heated in the furnace is transferred from the heating system, passing through a heat exchanger.

- Closed. The hearth is connected immediately to the heating system, without passing through the expansion tank and heat exchanger.

The scheme is selected depending on certain situations. Experts believe that the open form of the system has increased security, but it is not always possible to connect it technically.

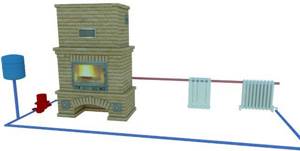

Autonomous fireplace heating scheme

A little about heating systems

In order to deliver heat to every room of the house, a pipeline is required through which water will circulate. Plastic or metal pipes are used as such a pipeline. Water gives off heat in special radiators installed in the lower part of the rooms. The cooled water returns to the heat source.

According to the method of organization, heating systems are divided into open and closed.

- Open systems. In an open system, water circulates by tilting the pipes. It reaches the top point thanks to convection, and then goes around all the rooms without outside intervention, gradually lowering the level. It returns to the boiler through a pipe called return. The possibility of expansion with increasing temperature is ensured by the presence of an expansion tank installed in the attic. It is hidden from view and occupies the highest possible position. When heated, the volume of water increases and it is forced into the expander. After cooling, the reverse process occurs.

- Closed systems. A closed expander helps increase the pressure in the system when the water is heated. This additionally protects the system from overheating, since boiling occurs later at elevated pressure. A closed type system is characterized by forced circulation, which is provided by a special pump. Most often, the pipeline for a closed system is made of plastic pipes. They consist of several layers that provide heat insulation. In this way, water is delivered to the desired room without wasting energy. In metal pipes, heat leaves through the metal as it is transported. On the other hand, this heat does not go outside, but into the room, heating it. The debate between supporters of metal and plastic remains relevant at any time.

Heating system operation diagram

Fireplace - advantages, features, installation

A fireplace as the main heating helps save money on energy, since wood and wood-based products are the most inexpensive fuel today. Fireplaces are used to heat one- and two-story buildings, for cooking food and hot water. The modern market offers customers fireplaces of various types, designs and operating principles.

However, energy-efficient installations are popular among consumers - these are pellet fireplaces and long-burning heating elements. Connecting the fireplace to heating will increase the efficiency of the equipment. This can be an open or closed heating system. Today it is possible to connect a fireplace and a boiler in parallel.

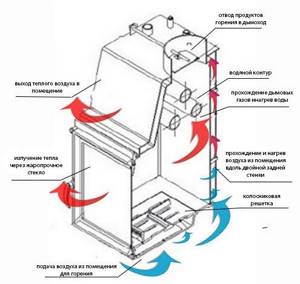

Stove mixture

The reinforcement of the concrete slab under the fireplace portal is a pedestal made of stove mixture. Concrete is less resistant to constant increases and decreases in temperature than clay. The concrete mixture is unsuitable for lining stoves and fireplaces.

The concrete solution will quickly crack, and the body of the fireplace stove will cool quickly. The composition of the kiln mixture is sand and clay in a certain proportion. To independently prepare a solution, you will have to carry out simple experiments on the ratio of sand and clay.

Stove mixture

Hangar fireplace stove

Solutions with different proportions of sand, clay and water are diluted in small containers. Roll into balls and leave at room temperature until completely dry. Completely dried clay balls are thrown onto a stone or concrete slab. The proportion of the one that didn't crumble is perfect. Clay blanks that cracked during the drying process are not included in the experiment.

In order not to forget what proportion of the mixture corresponds to a particular ball, you need to attach a note with the composition to it. There is no universal recipe for making a solution, because the clay in each region is different. One type of sand requires more, another requires less. Ready-made dry oven sand-clay mixture is available in any hardware store.

Working principle and functions of the heat exchanger

The coolant in the heat exchanger can be water or antifreeze.

A liquid heat exchange device is a container, part of the furnace structure, equipped for connection to a pipeline. The tank heats up in contact with the products of fuel combustion and transfers this energy to water. Water, moving through the system, gives off heat to heating devices - radiators, from which the air is heated by convection. Heating of the container can be direct or indirect, and the circulation of the coolant can be natural or forced.

Coolant

Instead of water, antifreezes based on ethylene glycol, propylene glycol, alcohol or oil are often used. Their main advantage is their low freezing point, ranging from -30 to -70°C. The exact numbers depend on the chemical composition and concentration of the liquid. The use of such chemistry provides a number of advantages:

- protection of system elements from damage due to defrosting;

- anti-corrosion protection due to appropriate additives;

- absence of abrasives, salts and other impurities that destroy (clog) the pipeline or fittings.

Some heat exchangers, for example for a bath, serve not only heating devices, but also a shower or a separate tank. That's why water is used here. To avoid defrosting, the device is designed so that filling water does not take much time. If the bathhouse or sauna is heated frequently, and the enclosing structures are well insulated, the problem is eliminated.

The function of the heat exchange tank, as part of the furnace structure, is to receive and transfer heat to the coolant from combustion products. But as an element of a wider system (heating, water supply), it solves several problems.

- Distribute heat evenly and economically throughout heated rooms.

- Provide your home (cottage, cottage, bathhouse, apartment, etc.) with hot water.

- Accumulate thermal energy for use when the stove is not working.

A heat accumulator connected to a heat exchanger for a wood stove stores energy thanks to the thermal capacity of the storage agent. Therefore, it can be made by insulating any container. A barrel covered with polyurethane foam and partially filled with crushed stone or sand is already a heat accumulator. If you equip it with four pipes and connect it correctly, the unit will become a functional element of the system.

It works on a fairly simple principle.

Heat exchanger option

Water enters the heat exchanger, which is located in the fuel part of the stove. There it is heated from the combustion of wood or other fuel. Then, the already heated water enters the radiator batteries, where the heat from it is distributed throughout the room. When the water cools, it returns to the coil, where it is heated again, etc.

Characteristics of the Angara 12 Aqua fireplace stove

It differs not only in its dimensions and performance, but also in the new design of the 10-liter heat exchanger and afterburner, which allows increasing combustion efficiency, reducing the amount of soot deposits on the glass door and chimney and heating the room up to 360 m³.

The main advantages of the Angara 12 Aqua fireplace stove include rapid heating of the coolant surface and a long burning time

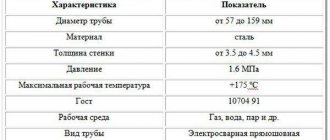

The table below presents for comparison the main characteristics of Aqua fireplace stoves from the Russian Meta group of companies:

| Name | power, kWt | Width, mm | Depth, mm | Height, mm | Weight, kg |

| Angara | 9 | 550 | 510 | 1020 | 140 |

| Angara 12 | 12 | 700 | 535 | 1040 | 175 |

| Hangar 12 with stove | 12 | 700 | 545 | 950 | 195 |

| Angara Aqua | 13 | 550 | 490 | 1020 | 150 |

| Angara 12 Aqua | 16 | 700 | 545 | 1040 | 205 |

Common features for all Hangar models are a wall arrangement, the use of firewood or fuel briquettes (the manufacturer strictly prohibits burning with coal), a chimney outlet with a diameter of 150 mm (top or rear) and a “clean glass” system, that is, self-cleaning of glass. Lining the stove with decorative ceramics makes Hangar models attractive for use in various rooms.

How to make it yourself

If you intend to independently equip your country house with a stove - a fireplace with a water circuit, then carefully evaluate your capabilities and abilities.

There are quite a lot of ready-made devices of this type that can be purchased assembled, installed in a convenient place, connected to a chimney and connected to a water heating system. To install such a structure, it is necessary to prepare a special foundation: a foundation and a tiled area near the fireplace area. The latter is especially necessary if the floor in the house is wooden, since small coals falling from the fireplace insert can cause a fire.

Typically, such ovens have a transparent door made of heat-resistant glass, through which you can admire the burning flames. If necessary, such a device can be relocated to a new location without losing its performance qualities.

You can also build your own outdoor fireplace with a brick water circuit that will last you a lifetime.

First, you need to decide on the size of the fireplace and its permanent location, because it will be impossible to move a brick fireplace with a heat exchanger to a new location. The size of the fireplace should be commensurate with the height of the ceilings and the surrounding interior. There should be enough space around the fireplace to accommodate all guests in the house.

If you are an experienced builder, you don't need to limit yourself in design choices.

The main elements of an open fireplace with a water circuit:

- A solid foundation, which is poured from concrete mortar or laid out of brick;

- Firebox with water heating circuit;

- A portal with a recess for the firebox (which is then covered with stone or tile cladding);

- Chimney;

- Portal lining elements;

- Heating connection system.

Most designs use brick, which is the most economical material for creating both the foundation and skeleton of the fireplace.

The firebox for the fireplace is selected based on its approximate performance and based on the size of the room. It is advisable to purchase a more powerful device, with a margin of approximately 25-30% of the required consumption.

The design of the firebox and its type are important. There are corner and built-in fireboxes - inserts, but they all require proper installation and subsequent cladding.

All fireplace inserts with a water circuit provide heating not only of the coolant, but also of the surrounding space. This fact must be taken into account during installation and a portal must be built under the fireplace stove in strict accordance with the drawings specified in the documentation.

When creating a brick portal, it is necessary to use refractory ceramic bricks. Another option is to use foam blocks, which are laid on fire-resistant glue and strengthened with reinforcement.

The installation of the chimney must comply with fire safety standards, for which it is necessary to invite a specialist and obtain the necessary permits from the fire inspection service.

To give the fireplace an attractive appearance and create a romantic atmosphere, the surface of the portal is lined with natural or artificial stone, tiles or tiles.

You need to connect a homemade fireplace with a built-in water circuit very competently, since the efficiency of its operation will largely depend on this.

Important conditions due to which the water circuit will be protected from overheating:

- Creating a so-called “safety group” when connecting, which is necessary so that in the event of an emergency increase in pressure in the system, it can be urgently lowered;

- Installation of a “mixing unit” with an adjustment valve to redirect part of the hot water to another circuit, for example, to a “warm floor” system;

- Installation of expansion tank. In the case when a closed heating system is installed, a membrane tank is installed to prevent oxygen from entering the pipes. For open heating systems, an option is provided in the form of a container built into the highest point of the system;

- The use of metal pipes when connecting elements of the heating system. Since heating water can reach its boiling point, pipes made of metal-plastic or PVC may become unusable. The best choice is metal pipes. Copper pipes are an excellent choice, as they are durable and do not develop internal deposits (rust). However, in this case, it is necessary to use brass adapters and copper radiators, since it is unacceptable to mix copper and aluminum products when installing one system, as this can cause an accident.

What is the difference between a water fireplace and a regular one?

After lighting a fireplace with an open firebox, it immediately begins to release heat into the room, but due to the openness of the combustion space, the heat transfer of such a fireplace is very small. Therefore, such fireplaces are installed not as the main means of heating, but rather for the purpose of aesthetic interior decoration. Fireplaces with a closed firebox are more efficient - their efficiency can reach 85%. The combustion space is closed using flaps made of glass ceramics or fire-resistant quartz glass.

The firebox of a fireplace with a water circuit is also of the closed type, however, unlike conventional fireplaces, it has double metal walls, inside of which coil heat exchangers are installed. These heat exchangers are connected to the water heating system of the entire house, which allows the thermal fireplace to become both an additional and completely independent means of heating the house, as well as a water heating device in the house.

The fuel for fireplaces with a water circuit is the same logs of deciduous and coniferous trees that are used for other fireplaces, as well as the most efficient type of fuel - sawdust briquettes, which leave behind a very small amount of ash.

Pellet stoves

Pellets are conquering the energy market today. Somewhere they are available due to the fact that they are produced from waste. In some places it is becoming more and more difficult to get classic fuel (wood and coal), while others like the fact that pellets are suitable for supply automation.

An additional bunker is installed to the boiler, into which a large volume of pellets is loaded at once and, as they are consumed, the fuel is supplied by an auger into the chamber. The main element of any such boiler is a special pellet burner, which is almost impossible to replicate at home, and the price of which makes up a large part of the total cost of the boiler.

Pellet boiler Valdai 15M2

Examples of models with a water circuit:

- Valdai 15M2 – 15 kW. In emergency cases, it will be able to “digest” both coal and firewood. Efficiency with wood is 76%, with pellets up to 90%. 120 – 125 thousand rubles.

- Cooper OVK 10 (from Teplodar, Russia). This is not strictly a pellet boiler. It can be a compact solid fuel stove with a hob. But by adding a tank and burner it turns into a pellet one. Another special feature is that the tank is built on top and takes up less space in the boiler room than other similar devices. Open chamber, single-circuit, efficiency 75%, price: 75 - 90 thousand rubles.

- Peresvet 10MA (from Obshchemmash, Russia). Backup fuel – briquettes and firewood. The bunker is installed next to the boiler, single-circuit. Price – about 150 thousand rubles.

You can convert many simple solid fuel boilers to pellets by purchasing a burner and a bunker (or even building the latter yourself - it turns out to be somewhat cheaper).

Design of water-heated furnaces

A distinctive feature of any home heating stove equipped with a water circuit is the heat exchanger, otherwise called a coil, radiator or boiler. This device is capable of heating an unlimited amount of water. The dimensions and shape of the tank depend on the volume of the combustion chamber and can vary within a wide range.

Heat exchanger

In some modifications of stoves for heating a home, the heat exchanger is installed directly in the firebox, but with this method there is a danger of coolant leakage (that is, water) or even an explosion when it overheats and boils. In addition, in this case, the capacity of the combustion chamber inevitably decreases. A safer option is to install a heat exchanger in the chimney cap. In this case, most of the hot air rising from the firebox will heat the coolant rather than escaping through the pipe to the street.

Classification of fireplaces

Fireplace placement options.

For an ordinary person who does not have the education of a builder-designer, the variety can be confusing. Without having the necessary information regarding the classification and species diversity of a given heating element, it is very difficult to make a choice.

A fireplace for heating a country house can be of the following types:

- by installation method: wall-mounted, built-in, island;

- by type of fuel used: wood, gas, electric, bio fireplaces, fireplace stoves;

- by type of fuel combustion chamber: open and closed type.

In addition to the devices described above, in modern houses you can find a fireplace for heating two floors. Similar designs are used to create two circuits for heating a room and servicing hot water supply. They are characterized by efficiency and at the same time high cost. Not everyone can build such a structure with high quality on their own, without the proper education and skills, since they are complex in execution.

Realities make it possible to modernize stove heating in a wooden house and insert water circuit heat exchangers into them.

How can an electric stove for heating a home replace a classic one? The answer is here.

Usage and operational capabilities

Fireplaces and stoves with a water circuit are intended for installation both in country houses and in private multi-storey buildings. Due to their high efficiency, such fireplaces can serve as the main source of heating. Also, the presence of a water jacket allows you to make a connection in such a way that the house has hot water and a boiler for its regular heating.

A fireplace stove with a water circuit does not depend on the availability of gas and electricity, and thus can be installed even in towns and villages, where interruptions and shutdowns of these resources often occur.

The main features and positive qualities of such installations include:

- Possibility of connection to almost any type of heating system;

- Wide range of prices, brands, models and manufacturers;

- To kindle and operate the structure, you need dried and prepared logs or purchased briquettes;

- The working process is fully streamlined, and the furnace itself can operate in an autonomous and economical mode;

- Each model has its own unique and inimitable style;

- For small rooms, you can choose a corner heating unit;

- Due to the presence of a heat exchanger and a water jacket, heating of the premises occurs very quickly and evenly.

This article presents a large number of photos of various models and installation schemes that will help you make a melting choice and determine the visual qualities of the hearth you need.

Criterias of choice

A fireplace stove with a water circuit can have different characteristics and operational capabilities

Before purchasing, pay special attention to the following criteria:

- Determine the required power of the heating unit. You can visually recognize it based on the size, shape, and location of the hearth. The most powerful are massive cast iron structures that have a wall or island arrangement. You can learn more about this parameter by studying the instructions included with the model. Keep in mind that to heat 10 square meters, you will need about 1 kilowatt;

Steel model, with sidewalls finished with fire-resistant materials

Steel model, with sidewalls trimmed with fire-resistant materials, a hob and firebox equipped with transparent fire-resistant glass

The principle of heating using the example of a two-story house

The principle of heating using the example of a two-story house

- Fireplace stoves with a water circuit can be of both domestic and foreign origin. When choosing, give preference to a proven, well-known brand, the quality of which has been tested by time;

- The installation must be of high quality and durability. As a base material, give preference to cast iron or sheet steel, which is additionally painted with a special protective paint. Such fireplaces are suitable for both regular heating and periodic heating; they can be located in rooms that do not have other heat sources;

- Long-burning fireplace stoves with a water circuit are more suitable for installation in rooms where you live permanently, as well as for houses with a large area and several floors.

Diagram showing the passage of air masses and heated air

Diagram showing the passage of air masses and heated air

Some steel models with a water circuit have average efficiency

Some steel models with a water circuit have average efficiency with small dimensions

Device and principle of operation

From a technical point of view, a water fireplace is a metal firebox, the thickness of the walls (from 4 to 8 mm) depends on the type of fireplace - open or closed, as well as the material of the firebox. The body is made of boiler steel or cast iron and coated with fire-resistant paint. The inside of the firebox is lined with heat-resistant tiles.

The heat exchanger tubes are located between the walls of the firebox. In normal condition, the coolant system (also called the “water jacket”) contains about 40 liters of water, which circulates through the heat exchanger and is heated by energy from the burned fuel. Between the walls of the firebox there are air channels for access to oxygen necessary to support the combustion process, and heat exchangers are also installed here. Air heated in the channels enters the room through special openings, and water heated in the coils enters the heating and hot water supply system of the house.

To drain hot water in the heating system and heated floors, temperature sensors and elements of the pipeline system that control the water supply are connected to the coolant. The heating device is complemented by a fireplace portal. Its appearance can be coordinated with any interior.

The power of a fireplace with a circuit can be adjusted manually by adjusting the air flow in the firebox; there are also automatic fireplaces, where the control is from a remote control and parameters are set.

How to build a water stove at home?

- There are three ways to do stove heating with a water circuit with your own hands:

- buy a steel stove from a manufacturer whose services include system installation;

- hire a craftsman - a specialist will select the material, make the device, lay out the stove and install the boiler;

- do it yourself.

How to make such a stove yourself

The principle of a boiler for water heating

Can you make such a system yourself? Quite, just experience in welding and bricklaying when building a furnace is enough. First you need to prepare the boiler (register, coil, heat exchanger).

You can buy such a device or make it yourself using sheet iron and pipes. Since the full process of manufacturing and installing a water circuit cannot be summarized in a short review, the main recommendations are presented below.

Manufacturing options and recommendations

Water heating from a wood-burning stove - diagram

For the boiler, a sheet of metal with a thickness of at least 5 mm is used, and its design is made in such a way that there is maximum heating of the water for further circulation. The boiler, welded from sheet steel, is easy to manufacture and operate – it is easy to clean.

But such a heat exchanger has a smaller heating area, unlike a pipe register. It is difficult to make a pipe register at home yourself - you need an accurate calculation and suitable working conditions; usually such boilers are made to order by specialists who themselves install the system on site.

The simplest method of a solid fuel heat exchanger is a regular potbelly stove with a built-in water system. Here you can take a thick pipe as a basis, then there will be much less welding work.

Attention! All welding seams must be made double, since the temperature in the firebox is not lower than 1000 degrees. If you weld ordinary seams, there is a chance that this place will quickly burn out

Complete the register drawings in accordance with the dimensions of the stove at home. The layout of the rooms of the house and the arrangement of furniture also need to be taken into account.

Here you need to pay attention that it is better to choose a scheme with sheet-metal boilers - they do not have pipe bends connected into one continuous circuit. It is not so troublesome to build such a structure

It is also convenient because after installation you can use the hob without any problems, which is not the case with some tube boilers.

Register made of smooth pipes - drawing

When the coolant moves by gravity, you need to raise the expansion tank higher and use larger diameter pipes. If the pipes are of insufficient size, then you cannot do without a pump, since there will not be good circulation.

Boilers equipped with pumps have their pros and cons: you can save money by installing pipes of a smaller diameter and not raising the system so high, but there is one significant disadvantage - when the electricity is turned off or the circulation pump burns out, the heated boiler may simply explode.

It is better to assemble the structure at home, on site, since the device, like individual parts, has a very large weight and dimensions.

System installation

Heat exchanger made of cast iron battery

- Before installation, a solid foundation is poured, on top of which it is better to lay a layer of brick.

- The grate can be laid at different stages: before the boiler, if there is a double structure, the lower part of which can be equal to or higher than the upper part of the grate, when the stove is low and the system is placed a little higher, then the grate, doors, corner on the stove are usually installed after installing the boiler .

- The housing is installed - usually it consists of two containers connected to each other by pipes.

- The entire heat exchange system is welded to the boiler: the exhaust pipe goes to the expander, goes in a circle, through the radiators, and on the other side the return pipe is welded to the boiler from below.

Stove heating with a water circuit allows, firstly, to use firewood much more rationally, and secondly, to evenly distribute warm air throughout the heated room.

If you decide to make your own heating system at home with a water circuit using wood, think through all the stages of the work, and if you have doubts about the successful outcome, it is better to contact specialists.

How to heat a two-story house?

The owner of a private two-story cottage wants to heat the entire building using a fireplace or stove. There are two possible scenarios here:

- with one firebox, while the second floor is heated by circulating thermal air from the chimney;

- with two fireboxes independent of each other.

Fireplaces with two fireboxes and one chimney are lighter in weight, have a simplified design, and therefore are increasingly being built in houses with their own hands. However, this option for heating a house has a significant drawback: two fireboxes cannot function simultaneously, since the draft will be present at one source, while combustion products from the other will enter the room. The optimal fireplace for heating two floors should have two fireboxes and two independent chimneys, allowing each fireplace to be used separately.

How to make a fireplace for heating a house on two floors with your own hands? In this case, you need to familiarize yourself with the diagram-drawing of brick laying for the fireplace from professionals.

Construction of a fireplace for a two-story house.

This design is a two-tier stove with two independent fireplaces, separated from each other by a lintel. On the ground floor, the firebox is surrounded by two air ducts. They improve heat exchange between the heating element and the room. On the second floor there is only one such air duct, while the second is the chimney from the first firebox.

Fireplaces for two-story buildings are heavy, which requires the construction of a separate foundation for the structure. This must be a reinforced, reinforced concrete structure, which is laid below the freezing level of the soil. The following video will help you properly organize stove heating in a two-story house:

We assemble and install equipment

Is it possible to build such a heating system yourself? If you have experience in building stoves and brickwork, then you can. Initially, prepare the most important part of the stove - the coil, which can be bought ready-made or welded using pipes or sheet iron. If you build the stove yourself, then using your imagination, you can build a structure that will be individual for your home and layout.

There are two options for creating this heating system:

- The coil is installed in the stove during the construction stage of the latter.

- The heat exchanger is built into an already erected furnace structure.

Using a radiator as a heat exchanger

The latter method is more labor-intensive because it involves dismantling the brickwork of the stove. In addition, the fuel part will be reduced after installing the coil.

The heating system is connected to the coil through sockets. They are inserted into one of the walls of the stove. The water circuit in such heating has a two-pipe system. The wiring can go top or bottom.

Complete the heating circuit. The highest point of the line must be equipped with a storage tank, it is mandatory to install a safety and air valve, as well as a safety unit with a pressure gauge. Where the radiators enter and exit the furnace, connect the valves.

- To prevent the water in the coil from boiling, its thickness must be at least 40 millimeters.

- The walls of the heat exchanger must be at least 5 millimeters. If the stove is heated with coal, then this figure increases. Otherwise, the walls of the coil may burn out.

- The exchanger should not fit tightly to the wall of the fuel part of the stove. There should be a space of at least 2 centimeters between them. This is necessary due to thermal expansion of the heat exchanger.

- Pay great attention to the fire safety of the system. If the stove has wooden partitions, then there must be an air space between them, because if the wooden structures overheat, a fire may occur. This is why wood is not the best facing material for a stove. To do this, it is better to choose materials with fire-resistant qualities.

Pipe coils

Coil option for heating and cooking stoves

The photo above shows a diagram of one of the coil options. This is what stoves designed for both heating and cooking are equipped with, because it is easy to build a cooking surface over it.

A profile pipe used instead of the upper and lower U-shaped pipes in such a coil will greatly simplify the process of creating it. Rectangular profiles can replace vertical pipes if necessary.

If the oven where the coil will be installed is not equipped with a hob, then to increase the efficiency of the heat exchanger, add a certain number of horizontal pipes to it. Processing and removal of liquid can be done from different sides. It all depends on the design of the stove and the design of the coil.

To make a steel heat exchanger, the thickness of the steel must be at least 5 millimeters. The use of a 6x4 centimeter profile and 5 centimeter pipes is necessary for the inlet and outlet of liquid. Depending on the length of the fuel part of your stove, the size of the heat exchanger is selected.

If you are going to insert a steel heat exchanger into a stove that is equipped with a hob, then experts advise making the design so that the gas flows around the top shelf of the coil. This gas then escaped into the smoke circuit, which is located in front of the coil.

Sheet steel heat exchanger

Using sheet steel, you can build an exchanger in the form of a book.

To do this, the walls of the heat exchanger are connected using pipes or a profile. Here in the register there is no top shelf. To improve circulation, connecting pipes are added at the top of the register. The inlet and outlet are made at the back or side of the heat exchanger. The hob is installed above the register.

Installation options for heat exchange structure

Installing a heat exchange device of any kind involves a considerable amount of work, especially if its efficiency is of serious importance. For example, the simplest spiral on a chimney may heat up poorly, and there will be no circulation at all without a pump. Then you have to take measures, including abandoning such a design.

- cast iron or steel U-shaped register in the firebox;

- water jacket around the firebox or at any of its surfaces;

- U-shaped diplomat in the firebox;

- diplomat directly above or behind the firebox, with maximum contact;

- water jacket around the heater;

- register, diplomat or coil in the heater;

- diplomat or coil behind the heater;

- water jacket on the chimney.

A coil on a chimney is conventionally the least effective option. However, the simplicity of the device often offsets the disadvantages. In addition, efficiency is increased in various ways. Among them are lining the coil with a thermally insulated casing and filling the voids with sand, or installing the structure directly into the heater.

A wood stove or fireplace with any heat exchanger is only part of the system. For its energy-efficient operation, coolant circulation remains a key factor. Even when the use of a pump is clearly necessary (for example, in a large two- or three-story house), natural circulation is important. Thanks to it, the pipes will not burst due to defrosting too quickly, and the water will not boil so easily if the electricity goes out. To improve circulation, it is advisable to adhere to the following rules:

- the higher the height of the heat exchanger pipes, the better;

- the expansion tank is placed as high as possible, next to the stove;

- a pipe goes to the tank from the top pipe;

- the pipe from the expansion tank goes to the lower inlet of the radiator;

- all horizontal sections are made at an angle (at least 3 mm per 1 m);

- The outlet from the radiator is only on the opposite side or diagonally.

We invite you to read: Cleaned up the firewood: how to properly stack a woodpile

Another important point is the permeability of the pipeline. The higher it is, the better. Therefore, you should not narrow the diameter, build in extra elbows, fittings, or use rusty or plastic pipes from the inside.

Design elements

In order to create complete heating of a building, it is necessary to use a complete system. Which includes a metal container and pipes connected to it that are not in direct contact with an open flame. Furnace equipment heats water, which moves through a coil throughout the house, heating it.

Here the quality and correct connection of the device to the oven is extremely important.

There are several types of coil connection:

- Outside. Here the coil is represented by a separate container containing water. The container contains part of the exhaust pipe for combustion products. Installation of this device is difficult and it is better to use the help of specialists. But it is quite easy to use. If plaque forms on the walls or in case of leakage, it can be easily dismantled.

- Inside. This option will require special equipment, which is installed directly inside the stove and connected to a coil laid around the entire perimeter of the house. It is better to do this at the stage of construction of the stove, because after completion of construction it will not be easy to get it.