that the dangerous technology of insulating loggias with isolon has been promoted online.

10 mm thick. A video review from Instagram about the sad consequences of this technology was the last straw that pushed us to figure it out. We studied the theory and standards, performed thermal calculations, studied the recommendations of thermal insulation manufacturers and specialists in building thermal physics. Doctor of Technical Sciences Anatoly Vitalievich Zhuchkov helped us find out the causes of problems with the insulation of balconies and loggias. We express our special gratitude to him for his informative consultations.

The purpose of this article: to give good advice and protect you from mistakes that lead not only to loss of money, but also to loss of health

.

Argument No. 1. Insulating a loggia with isolon: review from Instagram

You can get into a lot of problems if you ignore the laws of heating engineering and the instructions of building materials manufacturers. See for yourself:

This thermal protection is similar to walking in the cold in light clothing. Will it keep you warm? Same with walls. If they have too thin insulation, the room will be cold. In addition, condensation will accumulate on and under the finish. Due to constant dampness, rot and mold will appear over time, which can cause dangerous diseases. We’ll talk about them a little later, but for now let’s look at where the insulation technology shown on Instagram came from.

Use of polystyrene foam

Polystyrene foam is a plastic material with a cellular structure. All internal voids are filled with gas, which ensures low thermal conductivity of the foam. Polystyrene foam is produced in the form of square sheets with a side size of 1 m and a thickness of 2, 3, 4, 5 and 10 cm. The material can have different densities, but the greatest demand is for foam with a density of 15-25 kg/sq.cm.

Foam plastic will certainly be of interest to those who are looking for ideas for quick, effective, and most importantly, not too expensive insulation of a balcony. What is the attractiveness of this thermal insulation material?

- Insulating a balcony with polystyrene foam will cost you little, since the prices for the material are quite affordable;

- Polystyrene foam is characterized by a low level of thermal conductivity;

- Foam plastic is non-toxic, therefore it does not require mandatory insulation during installation and operation;

- Polystyrene foam is easy to transport and install;

- Foam plastic is suitable for both external and internal insulation work;

- The polystyrene foam is practically not inhabited by pathogenic microorganisms.

What should you pay attention to when using polystyrene foam?

- Foam is loved by rodents, so you should protect the loggia from mouse attacks;

- It is not recommended to insulate with foam plastic in windy weather due to its high windage;

- Caution should be exercised when working with paints and solvents;

- Installing polystyrene foam inside the balcony will reduce the free space by 2-10 cm.

Menu

RULES FOR LAYING LAMINATE

Laying a new floor is an integral part of the renovation work. If you want to achieve the desired result, you should not forget about the rules for laying laminate flooring. We counted 5 common mistakes that can affect the result

INSULATION OF UNDER ROOF SPACE WITH ISOLON-BLOCK STROY

The presence of snow cover in winter on roofs, in houses for year-round use, indicates excellent thermal insulation of the under-roof space and roof. The appearance of ice on the roof, the accumulation of ice build-up and the presence of parts of the roof free from snow indicate that the thermal insulation of the roof and attic space is compromised. At the same time, clearing the roof of ice in winter is difficult, since the use of a crowbar and a shovel can damage it.

Cross-linked polyethylene foam, production technology

ISOLON® (Isolon) is a well-known brand. Depending on the production method, they distinguish between physically cross-linked ISOLON 500 and chemically cross-linked ISOLON 300. Cross-linked polyethylene foam - the molecular structure of which is modified as a result of cross-linking.

Izhevsk plastics plant. New in road construction

Truly high-quality, smooth and durable roads are built in almost the same way as airfields. Their durability and ability to withstand heavy loads is ensured by a rigid cement concrete base. This technology, with all its advantages, also has its own characteristics, for example, the risk of overstress and cracks due to daily and seasonal temperature changes.

Innovative solutions in road construction

The compensator produced by Izhevsk Plastics Plant JSC is used as a filler for expansion joints at airfields and on roads.

Reflective insulation - foil Isolon

One of the main tasks in construction is the organization of high-quality thermal insulation of residential buildings. The requirements for thermal insulation materials today are quite high. High-quality insulation of the house allows you to maintain an optimal level of humidity and temperature in the room.

Types of Isolon materials and their key differences.

ISOLON (Isolon) is a well-known brand under which polyethylene foam is produced. Depending on the production method, there are: physically cross-linked (Isolon 500), chemically cross-linked (Isolon 300) and non-cross-linked gas-filled (Isolon 100) polyethylene foams

Izolon - new generation sound insulation

Today it is difficult to do without soundproofing and soundproofing of various rooms. Modern materials that protect premises from various influences are used by both large construction companies and private developers. In our store you can buy isolon of any thickness.

Sound and noise insulation materials

In modern construction, sound and noise insulation materials are of great importance. In a noisy metropolis it is difficult to protect yourself from excessive noise. Modern materials come to the rescue, absorbing excess noise and providing people with comfortable living conditions. All noise is divided into three types: airborne, impact and structural.

Foam based adhesive tapes

OJSC Izhevsk Plastic Plant is one of the largest manufacturers of physically and chemically cross-linked polyethylene foam under the ISOLON trademark, as well as single-sided and double-sided adhesive tapes ISOLONTAPE. ISOLONTAPE adhesive tapes are ISOLON with an adhesive layer applied to it, which is protected by an anti-adhesive material: paper or film. The adhesive layer serves as an ideal installation method and is a replacement for existing means of fastening to the surface.

Warm walls

Among the newest materials that can solve the problem of cold walls without serious financial costs and extensive installation work, as well as provide additional sound insulation of the room, is the EcoHeat wallpaper backing. It is used when covering internal walls with wallpaper, primarily in residential premises, as well as cold (northern) walls of country houses and concrete walls with low heat-insulating properties.

Ideal underlay for floor coverings

Laminate flooring, due to its undeniable advantages, has gained enormous popularity and distribution in modern construction. They are durable, wear-resistant, easy to install and do not require special care. However, most of the benefits of flooring depend on the underlay used.

Izolon

Isolon is a universal insulating material based on elastic polyethylene foam with a uniform closed cell structure. Izolon has rightfully earned the title of universal insulation due to its properties: with equal success it can be used as thermal insulation, waterproofing, vapor barrier, sound insulation and fire resistance.

Soundproofing

Soundproofing of premises is an extremely relevant and pressing problem. This is especially true for large cities, which have a lot of noise sources. We can say that it was thanks to this problem that the production of sound insulation was born and began to develop.

Construction Materials

Izolon has excellent waterproofing, vapor barrier, sound insulation and thermal insulation properties. Izolon is a universal insulator and can replace many insulating materials for construction, without compromising the quality of the insulation. As a building material, isolon is used for:

Reflective insulation

OJSC Izhevsk Plastics Plant produces and wholesales reflective insulation of the Isolon type. Our company produces only high-quality reflective insulation that meets the international quality standard ISO 9001:2008.

Isolon or polystyrene foam - which is better?

Currently, expanded polystyrene is the most popular insulation material used in construction. Expanded polystyrene insulation is very light and has a porous structure, which allows it not only to effectively retain heat in the room but also act as sound insulation.

Thermal insulation

Thermal insulation serves to reduce the level of thermal conductivity of various structures or protect them from thermal influences. Depending on the scope of application, thermal insulation is divided into three types:

Car noise insulation

OJSC Izhevsk Plastics Plant offers to buy materials for car sound insulation in bulk. Our company is the only one in Russia and the CIS that produces universal material for car sound insulation - ISOLONTAPE.

Soundproofing the apartment

In the modern world, soundproofing an apartment is a pressing problem for every resident of a large city.

News 1 - 20 of 31 Home | Prev. | 1 | Track. | End | All

Using isolon

Another material with very attractive characteristics is isolon. Such a heat insulator will be an effective solution to the problem for those who are planning to insulate a loggia and at the same time want to save as much usable space as possible. Izolon is called foamed polyethylene. During its production, foaming of polymer raw materials is carried out in the presence of a special catalyst and under high pressure conditions. As a result, isolon takes the form of a rolled material consisting of thousands of sealed bubbles filled with air. Thanks to this structure, the thermal conductivity of isolon is very low, and sound absorption, on the contrary, is very high.

Another remarkable feature that insulating a balcony with this material has is that the heat is not only not released into the environment, but is reflected back into the room. This is possible due to the fact that the walls are finished with isolon, covered with foil on the outside.

Other characteristics of isolon include complete moisture resistance, resistance to gasoline and other petroleum products, and complete safety for human health.

Very often, isolon is used not as an independent insulation, but as one of the layers of the “thermal insulation cake”. Thus, insulation with polystyrene foam with an additional top layer of isolon shows good results.

Izolon is supplied in rolls, so before installation it must be cut into pieces of suitable sizes. The joints between the pieces are glued with ordinary stationery or special construction tape.

Izolon foil: application

Covering the product with foil gives it a number of additional useful properties. The combination of polyethylene foam with a thin aluminum layer turns isolon into a kind of thermos. Moreover, the material can not only perfectly retain heat inside, but also not let it pass outside. The shiny outer coating successfully reflects over 96% of solar heat, making the material ideal for exterior coatings.

Thanks to the above advantages, isolon is widely used in various sectors of the national economy:

- Insulation of car interiors;

- In construction: both for above-ground and underground buildings;

- River and sea fleet (life jackets, floating barriers to prevent the spread of oil);

- Healthcare (insoles, products for the treatment of the musculoskeletal system, containers for medical devices);

- Packaging material in warehousing and logistics (wrapping expensive household appliances or fragile goods);

- The outdoor and sports industry (both clothing items and various sports equipment).

How's it going with penoplex?

Penoplex is a more modern analogue of polystyrene foam. Accordingly, the insulation of the loggia using it is carried out using a similar technology. Penoplex is called extruded polystyrene foam. If you come across the abbreviations XPS or EPS, then know: we are talking specifically about penoplex. Its main difference from polystyrene foam is its higher density, which means greater rigidity and resistance to damage due to mechanical stress. For comparison: if foam plastic for thermal insulation work is chosen with a density of 10-25 kg/sq. cm, then penoplex – 35-45 kg/sq.cm. The increased rigidity of this material makes it an ideal heat insulator not only for walls, but also for balcony floors. Coverings made from OSB panels can be laid directly on polystyrene foam, without installing joists.

Other attractive characteristics of penoplex

- Ease of installation due to the presence of special grooves along the edges of the plates;

- Long service life - up to 40 years;

- Moderate level of combustion toxicity (T2).

Which is better: penoplex or isolon?

Having compared all the properties of penoplex and isolon, the question arises: which is better? Both insulation materials have their pros and cons, so they can be used to insulate various surfaces . Having a cellular type structure, isolon excels in thermal insulation of floors and roofs, increasing the thermal insulation and sound insulation properties of rooms. For insulating the foundation and walls, the best choice would be penoplex; it is very convenient during installation.

In addition to construction, isolon is widely used at various industrial facilities, while penoplex is useful only for repairs. Penoplex has a service life several times lower than what manufacturers claim. In fact, it will last approximately 15 years .

Despite the fact that the thickness of isolon is only a few millimeters, which is 10 times thinner than penoplex, it reflects up to 97% of heat . The only thing where cross-linked isolon loses is its high price . Otherwise, it is an excellent material for insulating rooms.

Mineral wool - a proven option

Mineral wool based on glass, slag or stone is one of the best sellers in the modern market of thermal insulation materials. Insulating a loggia with such material will also be relatively inexpensive, which, however, will not affect the quality in any way.

Mineral wool is supplied both in the form of rolls and in sheets packed in bales. Its internal structure can be layered (horizontally and vertically), as well as spatial or corrugated. It depends on the raw materials used in the manufacture of mineral wool.

The thickness of the mineral wool layers varies from 20 mm to 20 cm. For maximum effective insulation, wool is used, covered on one side with foil. This, firstly, facilitates installation, and secondly, helps to reflect heat back into the room.

In addition, mineral wool

- is resistant to temperature changes;

- does not collapse under the influence of chemical reagents;

- provides excellent sound insulation;

- does not require preliminary leveling of the walls.

However, please note that when working with mineral wool, you should be careful, namely, use special clothing and personal protective equipment (gloves, goggles, respirator). This is necessary to prevent the negative effects of dust and formaldehyde resins on your health.

Amateurish technology

The origins of balcony disasters originate in the following statements:

- «for normal high-quality insulation of a loggia, in order for it to be as warm as in an apartment, ordinary insulation with a thickness of 10 millimeters is enough

«; - using expanded polystyrene is “ the height of stupidity and inefficiency

,” since isolon “

has higher thermophysical characteristics

.”

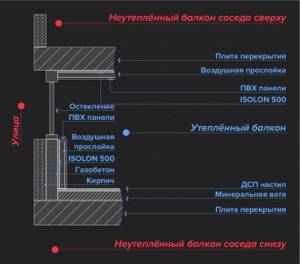

Based on these stupid tips, people are sold a miracle technology for insulating balconies and loggias, which is built according to the following scheme:

The author of the above statements and thermal insulation technology is a person who can speak confidently on camera, but does not understand construction and repairs.

Amateurish

. After all, any competent builder knows that 1 cm of isolon is extremely insufficient for insulating balconies and loggias. Further in the text we will confirm our words.

REMINDER. Expanded polystyrene (foam) or mineral wool are often used for thermal insulation of building structures. Both of these materials retain heat approximately equally, but the main thing is that they are laid in layers not 1 cm thick, but on average 10 cm thick. Perhaps this is because they are really much worse than the super insulation isolon and are not capable of protecting the balcony from frost with the thickness of a finger? But is this really so?

Argument No. 2. Super insulation is a myth

The first indicator of thermal efficiency - the ability of a material to retain heat - is the thermal conductivity coefficient, which is denoted by the letter "?" – lambda.

? (W/m°C) is the amount of heat in watts (W) passing through a layer of material 1 m (meter) thick if the temperature difference between its opposing surfaces is 1 °C (degree Celsius).

- How ? The smaller the better the insulator.

- ? depends on the nature of the material and does not depend on its thickness. Coefficient of thermal conductivity ? is a laboratory value that is measured on samples of the same size.

Place two frying pans on the fire - one with cast iron and one with plastic handles. Soon the handle of the first frying pan will become scalding hot, and the handle of the second will remain cold. This is a result of the fact that metal has a much higher thermal conductivity coefficient than plastic.

Let's compare the lambdas of several popular insulation materials. Data about them can be found on the websites of thermal insulation manufacturers, as well as in regulatory documents (we took higher values from SP 50.13330.2012):

- Izolon (foamed polyethylene) – 0.036-0.05;

- EPPS – extruded polystyrene foam (TechnoNIKOL) – 0.030-0.034;

- EPS – expanded polystyrene, polystyrene foam (GOST 15588.2014) – 0.035-0.059;

- Stone wool (Rockwool) – 0.035-0.048.

CONCLUSION: Coefficients? all materials are from approximately the same range. Statement that isolon “ has higher thermophysical characteristics

- illiterate.

Foiled polystyrene foam is the best solution

What is insulation of a balcony with such material? Expanded polystyrene is also called gas-filled polystyrene. To minimize heat loss, it is equipped with a backing made of aluminum foil.

Although the moisture absorption of polystyrene foam does not exceed 0.25 mm per year, it is not recommended to install it on a floor or wall that is subject to dampness, since the foil will not allow them to dry out properly. As a result, mold or mildew may develop under the polystyrene foam.

Expanded polystyrene is resistant to temperature changes in the range of 80°: from minus 40°C to plus 40°C. This heat insulator exhibits the same stability when interacting with alcohols. The integrity of expanded polystyrene can be damaged only by the action of solvents, but when insulating a balcony it is quite possible to do without the use of such means.

Expanded polystyrene is considered a very flammable material. Its ignition occurs already at 210-310 °C, so the most serious manufacturers add fire retardants to the raw materials, which significantly reduce the flammability of polystyrene foam. The presence of such components in the heat insulator can be recognized by the letter “C” in the material marking, for example, PSB-S.

As a rule, expanded polystyrene is supplied in the form of rolls 1 m wide. The thickness of the insulation is 10-50 mm.

Polystyrene foam, polystyrene foam and penoplex

Foam plastic has been used for insulation of balconies and other premises for a long time, about 50 years. It consists of polystyrene foam balls glued together. The material is produced in the form of slabs of different sizes, thicknesses and densities. The higher the density, the more durable the insulation will be. Let us list the main advantages of polystyrene foam.

- Polyfoam is very light and has low thermal conductivity, which makes it suitable for insulating balconies. It is better to use sheets 3 cm thick.

- It is easy to insulate a balcony with polystyrene foam, since it is affordable and easy to find in any city.

- The material is moisture resistant and does not grow mold.

- Working with polystyrene foam is not difficult. The slabs are cut with a knife and laid effortlessly.

- High-quality foam plastic will last 50 years or more without loss of properties.

Expanded clay

Expanded clay is produced by thermal transformation of low-melting clay. As a result, expanded clay takes the form of granules with a porous structure. During thermal insulation work, expanded clay is used only as backfill at the stage of floor insulation. Expanded clay is especially suitable for arranging wooden floors.

Expanded clay absorbs water well, but releases it slowly, so it is recommended to cover the backfill with plastic film before pouring the concrete screed. Please note that the thickness of the screed must be at least 5 cm, otherwise cracks may appear.

Penofol

Insulation of loggias, interfloor, basement and attic floors, foundations, roofs - all this work can be carried out with penofol. This material is suitable for both external and internal thermal insulation.

The most commonly used types of penofol:

type A – foil-coated on one side; type B – foil coated on both sides; type C – foiled on one side and covered with a self-adhesive backing on the other; types R and M – embossed (foiled on one side); ALP type – foil-coated on one side, laminated with polyethylene film on the other.