Owners of apartments or houses with gas heating will not be interested in the topic of this article, but those who use any solid fuel for heating are well aware that sooner or later, soot accumulates in the chimney, and what consequences this can entail. In this article we will talk about the causes and how to remove soot from the chimney.

Reasons for its appearance and what it means

The reasons for the formation of soot in the chimney can be very different, and often this is a consequence of improper operation of the stove device. Let's list the most common causes:

- Using raw firewood or fuel briquettes.

- Incorrect chimney configuration, preventing the normal passage of smoke.

- A large number of irregularities on the inside of the pipe.

- Pollution and littering of the chimney during the time when it is not in use.

- Burning various household waste and especially plastic in a furnace.

- Frequent change of wood species burned in the firebox.

In fact, these are not all the causes of soot, but they are the most common.

Advice! To fire a stove or fireplace, you need to use only well-dried firewood, aged for at least one and a half years.

Causes of insufficient and reverse draft in the chimney

A smoky room, difficult ignition and slow combustion are the main consequences of poor draft in the chimney.

The reverse draft can “knock” fire out of the firebox into the room or, in the minimum version, extinguish the boiler burner. With poor air flow, soot is retained in the pipe and condensation accumulates more. Traction disorders have four main causes:

Reason No. 1 - Incorrect chimney design

- low height relative to the roof (less than 0.5 meters or 1 meter above a flat form);

- the channel cross-section does not correspond to the characteristics of the boiler or furnace;

- the chimney consists of sections of different diameters;

- incorrect turns, slopes and angles of the channel (the norm is a bend of 45, a turn of 90 degrees);

- horizontal pipe sections longer than 1 meter.

For a chimney, it is better to focus on a cylindrical cross-section - in rectangular-shaped channels, vortices are formed at the corners. Soot settles there first, limiting traction.

Important! You cannot independently combine several exhaust chimneys into one network. Only professional calculations will help you do this. This is the case when savings at the beginning are reflected in wasted time and nerves in the end.

Reason No. 2 - Insufficient tightness

When the damper in the chimney (usually in stoves and fireplaces) does not close tightly, warm air from the room enters the chimney. Uninsulated metal chimneys are especially susceptible to cold. As a result, at sub-zero temperatures the channel can be completely blocked by frost. Changing the valve to a denser damper and insulating the chimney itself helps.

Unsealed joints in a metal pipe disrupt the flow of air during the fire and often extinguish the flame of a gas burner. Each joint seam must be tightly treated with a heat-resistant sealing compound.

Reason #3 - Ventilation

For good traction, uniform access of oxygen is necessary - properly functioning ventilation. Its violation or absence guarantees questions. Too strong drafts interrupt the draft and return it to the house. Lack of oxygen affects combustion. Thus, gas boilers often draw air back from the chimney, compensating for the lack of air with reverse draft. This is why the burner goes out.

By opening the access of fresh air to the room, you can properly organize the flow from bottom to top.

Reason #4 - External factors

The draft often worsens under the pressure of cold street air (when the stove has not been heated for a long time and the cold has accumulated in the chimney). With strong air currents or pressure differences - when the house is colder than outside. The weather is changing, and to restore draft, you can warm up the chimney in front of the main firebox, burning paper (preferably closer to the duct). The draft is also severely limited by fallen bricks, debris in the chimney, in the form of bird's nests, or banal soot.

How can you improve chimney draft:

- resolve issues regarding chimney design;

- insulate the outlet channel;

- organize a constant flow of air;

- Clean the chimney from soot in a timely manner.

Regular inspection of the chimney for leaks and damage helps resolve many issues already at the start.

Consequences of soot accumulation

Often, homeowners neglect cleaning the chimney, and in vain, since in addition to the basic deterioration of draft, this can lead to a number of sad consequences, some of which can not only cause harm to health, but can also lead to death.

We are now talking about the absence of draft and penetration of carbon monoxide into the room. Its danger lies in the fact that, unlike smoke, which has a characteristic odor, carbon monoxide has no odor at all, but at the same time it is deadly to health and life. But that’s not all, here are just a few possible scenarios for the development of events with a clogged chimney.

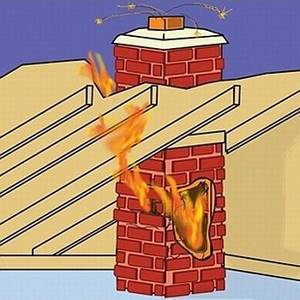

- The soot that accumulates in the chimney can sooner or later flare up and with poor brickwork, high temperatures can lead to a fire in the roof, as shown in the photo above.

- The narrower the chimney passage, the more sparks escape from the tip. In strong winds, both the roof itself and the surrounding buildings may catch fire.

- ignition of soot in the chimney can lead to strong backdraft, as a result of which the fire will go inside the room and it will be very difficult to stop it.

- A thick layer of soot will accelerate the wear of the brickwork.

- Carbon deposits prevent uniform heating of the fireplace and chimney, resulting in a significant reduction in the efficiency of the device.

These and many other factors sooner or later make every homeowner wonder how to deal with soot in the chimney, and this is what will be discussed below.

Important to remember! Experts advise carrying out preventive cleaning of the chimney at least twice a year; this will not only extend the life of the stove or fireplace, but will also allow you to clean it yourself quickly and without much difficulty.

Formation of condensation in the chimney

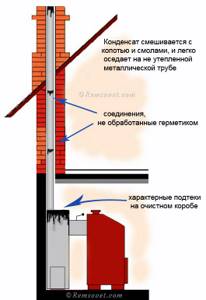

Moisture in the chimney impairs draft; this is easy to notice with constant use. Sticky soot blocks the pipe. In the masonry of brick chimneys, smudges appear at the seams, the bricks are saturated and destroyed.

At the bottom of the channel the temperature of the exhaust gases is maximum. Moving upward, the flow cools, lingering at the bends, and settles in drops on the cold surface of the chimney. Metal pipes that are not insulated cool down in a few minutes (when switching to a smoldering combustion mode), brick and ceramics give off heat more slowly. Hence the ability of the metal to collect drops of moisture on itself.

Insulating the pipe helps keep the temperature of the exhaust gases above the “dew point”. With a “lined” chimney, the space between the masonry and the pipe is filled or filled with non-flammable insulation (expanded clay, stone or glass wool). The top and bottom of the gap are sealed with a plug.

If the diameter allows, it is reasonable to assemble an analogue of the sandwich system. Having insulated the outside of the existing metal pipe with a layer of 5-10 cm of mineral wool, it is necessary to protect the entire structure on top with metal sheets or a pipe of a suitable diameter. On the outside, the channel experiences less stress, so a more aesthetic material can be chosen.

Correct installation of the chimney is important. The joints of the insulation and pipes should be staggered. The metal is connected with heat-resistant sealant and fasteners, and the entire structure is tightly fixed with clamps. If the joints in a homemade or purchased sandwich system are not sealed, condensation will seep in and destroy the insulation. In response, the temperature and fire danger will increase. The chimney will more often than not be damp and clogged.

Conditions under which excess condensation forms:

- burning with raw wood;

- cold chimney (not insulated or not used for a long time);

- weak combustion of fuel (with a lack of air, too weak draft or too strong), for example, in boilers in smoldering mode.

In a poorly calculated chimney design, the escaping gases also cool quickly. Channels with high heights, complex bends or narrowing diameters slow down and cool the smoke. If the cross-section is larger than optimal, then the draft weakens and condensation also forms.

Wood-burning stoves with 5-7 channels are difficult to warm up with a small load. The smoke will go into the chimney cold. To warm the smoke and reduce the amount of moisture, the design makes a thin direct connection between the firebox and the upper last channel. Also, previously, firewood was sprinkled with rock salt before the firebox - it removed some of the condensation. An ancient method of prevention.

Chimney cleaning

Today, with the growing popularity of fireplaces in private homes, the profession of a chimney sweep is becoming increasingly in demand. Of course, the price for their work is often very high, so many people decide to clean the chimney themselves.

Below we will provide detailed instructions and describe several methods, the choice of which depends on personal capabilities and the degree of contamination of the chimney. For example, traditional methods or chemical cleaning methods are most often possible only at the very beginning of the build-up of soot, but if a lot of soot has accumulated, then you will have to resort to mechanical cleaning, and this is the most complex and time-consuming method, but first things first.

Traditional methods

Most traditional methods are based on burning soot in the chimney, and therefore, it is necessary to increase the combustion temperature to such an extent that the soot ignites without starting a fire in the ceilings. That is why, before using one of the listed methods, you need to make sure the quality of the pipe laying.

- Rock salt. One of the most popular methods by which soot is burned out of a chimney. Salt is poured onto the burning wood and the firebox is closed. The temperature in the vent will rise and the soot will flare up, while some of it will burn without a trace, and some will fall down.

- Potato peelings . At first glance, the method may seem strange, but in fact, everything is simple - the starch in potatoes softens the hard soot and it ignites. The main difficulty of this method is that it is very difficult to calculate the required number of cleanings, but on average they take one full bucket per ignition, after which they check the condition of the chimney and, if necessary, repeat the procedure.

- Aspen logs . The fact is that this tree has the highest combustion temperature, so if you fill the firebox with aspen logs, soot will burn out from the chimneys, but this must be done very carefully, since the temperature in the solid fuel stove and chimney will be very high.

- Turpentine . Another method was very popular in the past; firewood is generously watered and set on fire, which creates intense heat, which removes soot from chimneys.

- PHC. A domestic product produced in the form of a powder, packaged in 50 gram bags. The contents of one package must be poured onto the firewood and lit. The active substances in the product will react with carbon deposits and decompose it into its constituent components, which will burn out without a trace.

Important! Burning soot in chimneys is a very dangerous method, so it can only be done on a slightly smoked chimney and as a preventive measure or preparation for the main cleaning.

Chemical method

Today, products for chemical removal of soot in the chimney are presented in a huge assortment, so it’s easy to get confused when choosing the one that actually works. We will present an overview of several popular products that have proven themselves over the years.

- Log chimney sweep . This is a solid composite material, the convenience of which lies in the fact that it is simply added to the firebox with ordinary firewood and burns with it. Stove specialists advise using it as an aid before removing soot from the chimney. You need to add a chimney sweeper to the stove twice a year for prevention, and this significantly extends the service life of the chimney and prevents the formation of soot.

- Kominichek , a Polish-made chimney soot remover. The main component of this product is copper oxide, which dissolves accumulated soot.

Important! Chemical cleaning methods, as well as traditional ones, cannot be used when there is a large accumulation of soot, as this is fraught with consequences. Most often they are used only as a preventive measure or as an adjuvant before mechanical cleaning.

Is it just soot?

Cleaning a chimney from black soot, as the ignorant imagine it, is quite simple, and if the chimney is brick, then you cannot expect serious negative consequences from manual cleaning with improvised means. But, firstly, not only black soot is deposited in chimneys, and in different ways. Secondly, modern chimneys, in terms of their properties, are by no means brick.

In brick and, when fired with high-quality fuel (deciduous or pine firewood, properly seasoned in a woodshed), in simple steel chimneys, the so-called. plump soot (item 1 in the figure), which is almost pure amorphous carbon. As a rule, plump soot completely covers the lumen of the pipe before it cokes (sinters; cemented with bituminous substances, mainly creosote). Puffy soot ignites most easily, but external signs of its influence on traction (see below) appear early and clear. Cleaning a chimney from plump soot or preventing its deposition using any of the methods described below does not present any technical difficulties.

Main types of deposits in chimneys

Gray soot (item 2) is typical for conventional steel chimneys of stoves/boilers operating on coal or random wood fuel. Coking of gray soot begins when its layer reaches approx. 2 mm and then spreads to the entire plaque. External signs of a chimney being overgrown with gray soot are weakly expressed and develop slowly. The combustion of gray soot is a rare phenomenon, but it necessarily entails the most severe consequences: part of the amorphous carbon is modified to graphite during the bituminization process, and the burning gray soot develops a temperature of over 1600 degrees. Manually cleaning a chimney from gray soot is not always possible or is very labor-intensive, so in this case preventive measures against soot deposition are of paramount importance.

Note : pure graphite burns at 2500 degrees. According to the recollections of the helicopter pilots who extinguished the Chernobyl reactor, its interior shone dazzlingly, like the Sun.

Light gray soot in sandwich chimneys (item 3) cokes instantly at the moment of deposition. A modular sandwich chimney, at the moment of starting the device that is connected to it, experiences a thermal shock: the cold inner surface of a thin-walled steel pipe in thermal insulation very quickly warms up to the temperature of the flue gases. From the point of view of the energy efficiency of the device, this is good: almost no fuel is wasted to accelerate the stove/boiler to its rated thermal power. But the first to settle on the pipe wall is a creosote film, which immediately grabs unburned fuel particles. Further, if the chimney is not prevented from soot falling out, its clearance quickly becomes overgrown with ordinary gray soot. Only an experienced professional chimney sweep can remove a coating of light gray soot without damaging the chimney, alternately using installations for hydraulic and mechanized rotary (rotary) cleaning.

Oily (white) soot, pos. 4, is formed in the chimneys of devices intended for cooking over an open fire: barbecues, barbecues, etc. In addition, in sandwich chimneys of household fireplaces, a real coal-wood fireplace, thanks to the always open firebox, perfectly cleans the room of dust. Where does the fat come from? From dust drawn into the firebox. A significant proportion of house dust consists of dried grease from the inhabitants of the home, kitchen fumes and splashes. Oily soot manifests itself just as clearly and quickly as plump soot, and can be easily cleaned off with a brush or ruff both from above and below. Preventive measures against greasy soot are quite effective and, if applied correctly, urgent chimney cleaning will never be necessary. But, if there is greasy soot in the chimney, you should not hesitate to remove it under any circumstances - greasy soot catches fire very easily; True, it burns weakly and the chimney can always be extinguished in time. But a complete replacement of the expensive modular system is inevitable after this.

About sandwich systems...

The advantages of sandwich chimneys do not end with their efficiency, but it is almost never possible to clean a clogged sandwich without compromising its service life. The fact is that customers, tempted by the ease of installation of sandwich pipes, for the sake of cheapness, ask to make a chimney (or make it themselves) with inclined sections and blind corners (kinks). Even with manual cleaning (see below), the brush gets through them, but it scratches the smooth stainless steel so much that the deposition of soot on the fractures becomes chronic, to the point that the chimney elbows have to be replaced at the height of the season.

A properly modular sandwich chimney is assembled from horizontal (hogs) and vertical (otters) bends connected by tees with cleaning and inspection hatches, see figure:

Correct construction of a modular sandwich chimney

In this case, even if solid light gray soot is detected in the chimney, after hydrotreatment it is cleaned with a gentle rotary brush (see below) and its service life is practically not reduced. If chemical prevention and inspection of the chimney is carried out in a timely manner, then “impact” chemical cleaning (see below) will work. Then the remaining soot can be raked out into the tees and removed by the owner himself without calling a specialist. In general, additional the costs of “extra” elbows and tees during operation are paid off by savings on cleaning and peace of mind.

Note: what is in fig. designated as otters, according to the rules of technical terminology - risers. The otter in the stove industry is the widening of the part of the chimney protruding above the roof, which improves the wind flow around it, the draft of the chimney and partly prevents the joint between the pipe and the roofing pie from getting wet. But there are already plenty of risers in everyday life - water supply, sewerage, gas - so it would not be a great sin to call the vertical modules of a sandwich chimney otters.

When to call a pro

It is recommended to clean the sandwich chimney yourself only using chemical (non-contact) methods, but they are effective if the soot layer is no thicker than 2 mm. Otherwise, you need to call a chimney sweep, but first show them a photo of the soot in the chimney and ask: how will you clean it?

Puffy soot and gray in a not too thick layer, i.e. not completely coked, the so-called with a gentle brush of rapid rotation, on the left in the figure:

Brushes for mechanized rotary cleaning of chimneys

Its flexible shaft (see below) can be driven by a drill or hammer drill with the blow turned off. Next, if the gentle brush fails, use a hydraulic unit to remove soot and repeat the passage with the gentle brush; this is already extra. payment. There is soot left - more. payment, and the master prepares the unit for mechanized rotary cleaning with hard brushes (the rest are in the figure). A “handy” drive is not suitable for them, because The rotation speed must be kept stable regardless of the load on the brush. The brush frequency and type are chosen by the master depending on the type, structure of the chimney and the nature of its contamination. A hard rotary brush will remove everything, but if the sandwich was cleaned with this, a conscientious specialist warns: “Don’t forget to replace the chimney in the summer. I can’t guarantee whether this next season will last.”

...and about ceramic chimneys

Glass chimneys and solid ceramic chimneys made by slip casting are very expensive, but in terms of efficiency and overall performance they surpass the best sandwich. If regular chemical prophylaxis is carried out, the soot in them either does not fall out at all, and if it does fall out, it holds on very weakly. But such chimneys are fragile, and damaged ones quickly become overgrown with plump soot. Therefore, if it comes to mechanical cleaning of a ceramic/glass chimney, you need to use only and only a special tool, see below.

Mechanical methods

Conventionally, mechanical cleaning methods can be divided into two:

- From below, when cleaning is done with a special brush through the firebox.

- From above, using a weighted brush or metal ball.

To learn more about these methods, you can watch the video in this article, and we will present several important nuances that you need to know when cleaning yourself.

Of course, mechanical cleaning is the most difficult and time-consuming, but only it can give an appropriate result if the chimney is completely clogged. Well, the key to a long service life of a stove is regular preventative maintenance and compliance with all the rules and regulations for the use of stoves and marble fireplaces.

When should you clean?

The chimney is cleaned next. cases:

- Planned annually - before the start and after the end of the heating season with the furnace/boiler stopped;

- Scheduled preventive maintenance - during the use of the heating and cooking device without stopping it;

- Unscheduled without shutdown - if there are initial signs of soot deposition and if, based on the results of the chimney inspection, the thickness of its layer is established to be up to 2 mm;

- Urgent with shutdown - based on signs of heavy soot deposits and the thickness of its layer is more than 2 mm.

Annual scheduled cleanings must be carried out mechanically (see below). During the autumn, the readiness of the device for the heating season is checked, even if it was not used in the summer: a bird's nest, a tangle of wintering snakes, or just random debris may be found in the pipe. In no case should you skip the spring one: over the summer, the winter soot in it from the heat and precipitation will become so coked that the autumn cleaning will turn from a simple inspection into a complex, expensive procedure.

Smoke or flame?

It is usually advised to determine the need to clean the chimney while the stove/boiler is moving by looking at the smoke from the chimney: if, they say, it is white, curly, everything is OK. It has turned grey, thickened, pulled down - it needs to be cleaned. This is an unreliable sign: the type of smoke from the chimney is highly dependent on weather conditions; You know that they use it to predict the weather, right?

The more reliable condition of the chimney is determined by the type of flame in the firebox. Fuel must be loaded into it according to the norm; the wood should flare up, i.e. be completely engulfed in flames and charred on the outside. If the stove/boiler is new, correctly designed, built and heated correctly, then after they are accelerated (brought up to design power by test fireboxes), the cores of the flames will become light yellow, and the tongues themselves will stretch straight up (on the left in the figure). This means that the device has become stable: a layer of soot with a high content of graphite up to 0.5 mm thick has been deposited in its chimney. Such plaque is harmless, and in a brick chimney it is useful, because... makes its walls smoother and increases traction.

Type of flame in the furnace firebox depending on the condition of the chimney

Over time, the cores of the tongues will turn straw-yellow and the flames will begin to dance (center in the picture). This is a sign that it’s time to start chemical prevention (see below) and carry it out until the flame stretches straight up, remaining straw-yellow at the core. If this does not happen after 2-4 fires, you need to burn the aspen or log for impact dry cleaning. It didn’t help, the flame died down, turned red at the top and beats in the firebox; especially if it splashes onto the forehead of the stove, on the right in Fig. – urgent mechanical cleaning of the chimney is required and the appliance should be stopped.

Note: smoke can be used to determine the condition of the chimney if the flame does not give a definite answer; e.g. when changing the type of fuel. Provided that you remember (or take a good quality photograph) what the smoke was like from the chimney of a new or thoroughly cleaned stove in different weather conditions. If during the same period it darkens and thickens, you need to trim the chimney and, if necessary, clean it.

Cleaning if the pipe lumen is completely blocked

To do this, pour water (about three liters) into the chimney from above. After this, steam is released, which cleans the hole in the pipe. Soot flies out of the chimney in a compacted cloud of thick consistency. To prevent a chimney made of steel from rusting, they immediately begin to heat it and warm it up until the last moisture evaporates.

There are special cleaning logs or pellets , which are placed in the stove without opening the packaging, and the combustion lasts for about two hours. After this, the accumulation of soot and soot in the channel becomes loose, the separated light particles rise, and the heavy ones fall down into the firebox.

If special inspection holes are provided along the chimney, it is recommended to carry out preventive cleaning after using cleaning logs. There are special powders for cleaning the furnace outlet channel, for example, a Czech product called Kominichek, Smoke-Glas and others.

For their use instructions have been developed that will tell you how to use them correctly and what dosage to use. But all of them are used in the furnace to produce a chemical reaction, which results in substances that destroy the soot layer in the pipe.

In conclusion, it should be said that the smoke duct should be cleaned in any case, so that the misfortune of poor combustion of the stove is not added to the grief of sudden smoke in the room or a fire in the attic, where a pipe clogged with soot passes through.

Folk remedies for cleaning the chimney

There are methods for cleaning a chimney that were used by more than one generation of our ancestors, and therefore there is no need to doubt their effectiveness.

Effective options:

- We clean the pipe from soot with regular boiling water , pouring several liters into it before heating the stove. All contaminants will instantly fly away. Boiling water will cope with even the heaviest raid.

- Alder or aspen are “special” firewood for combating soot. When burned, wood produces a special evaporation that peels off soot from the walls of the chimney pipe. Alder and pine logs themselves practically do not provide heat, but you should have them in reserve in raspberries to complete the firebox. It is important to strictly monitor combustion or, if possible, protect the top of the pipe with a deflector. Caution is necessary to prevent fire caused by sparks flying from the pipe.

- One or two tablets of Naphthalene in the fire will help get rid of soot, which will either fall off and burn, or fly out into the chimney. The only disadvantage of this method is the specific smell, which is not easy to get rid of.

- The next old-fashioned method is a combination of copper sulfate (5 servings), coal (2 servings) and saltpeter (7 servings). It is only suitable for stoves that are tightly closed with a door; it is not used for fireplaces due to toxic fumes that will be released into the open space.

- Another method is more suitable as a preventive measure - add regular table salt (several handfuls) to the firewood when burning. In this case, less deposits are formed, but it will not be possible to deal with old deposits.

- To prevent the formation of soot and burning growths, potato peelings (or finely chopped potatoes) are also used. Root waste is burned in a well-heated oven. The starch, evaporating, cleans the pipe well and does not allow a new portion of soot to settle.

From the editor . There are many traditional methods for getting rid of soot, and not all of them work. But practice shows that potato peelings are really effective. The author of the video conducted an experiment and proved from personal experience that potato peels help.

Do-it-yourself chimney pipe insulation technology

How can you clean a chimney from soot?

There are three ways to clean a chimney:

Chimney cleaning with a chimney sweep

- Mechanical. A brush is inserted into the chimney, with the help of which the soot is knocked off the walls. The disadvantage of this method is that you need to have access to the pipe, which is not always easy. Not everyone is able to climb onto the roof, and cleaning from below requires flexible rods and access. Another unpleasant moment: all the contents fall down, you will have to collect it and take it out, and then spend a long time cleaning the soot from the stove or fireplace. Therefore, before starting cleaning, place some kind of container into which everything will be poured.

- Chemical chimney cleaning - powders and briquettes (logs). When the system warms up, the powders are poured into the fire, and logs are placed under the firebox. The substances they contain soften the soot, it gradually flies into the pipe, but can fall down and block the passage altogether. So it is better to use these products for prevention when there is still a little soot.

- Traditional methods. The problem of chimneys becoming overgrown with soot is not new, and our ancestors knew how to deal with it without chemicals. There were, of course, chimney sweeps, but they worked in cities, and their services cost a lot. Nevertheless, the problem was dealt with using very simple means - salt or potato peelings.

There is another drastic solution - go to the fire department and call specialists. They are no longer called chimney sweeps, but perform the same functions, albeit by different means. The solution is not bad, they know their job, since soot is explosive, as long as they don’t give permission to anyone. The only negative is the cost of such services.